Abstract

This experimental study examines the impacts of two macro synthetic fiber additives (i.e., polypropylene and polyolefin) on laboratory characteristics of roller compacted concrete pavement (RCCP). The mixtures were made at different dosages of 2.0, 3.0, and 4.0 kg/m3. The compressive, splitting tensile, and flexural strengths of RCCP mixtures were determined at 7, 14, and 28 days. Evidently, the test results disclosed adding 2.0 and 3.0 kg/m3 fiber additives could improve the compressive strength of modified specimens although adding 4.0 kg/m3 lowered the compressive strength. In the meantime, the tensile and flexural strengths of RCCP mixtures were considerably improved due to fiber additives, especially at later ages. It is worth mentioning that specimens with polypropylene fiber could manifest higher tensile and flexural strengths compared to polyolefin fiber and any further increase up to 4.0 kg/m3 fiber additives reduced the strength of mixtures over time. Regardless of the fiber type, the toughness of mixtures containing 3.0 kg/m3 fibers outperformed plain concrete for enduring flexural loads. Noteworthy, the Vebe test outcomes revealed that adding synthetic fibers could increase the Vebe time significantly. Finally, the relationships between the splitting tensile strength, flexural strength, and compressive strength were obtained as \(f_{r} = 0.60\sqrt {f^{\prime}_{c} } ,\) and \(f_{t} = 0.41\sqrt {f^{\prime}_{c} } ,\) respectively.

Similar content being viewed by others

Notes

American Concrete Institute.

Portland Cement Association.

South Carolina Department of Transportation.

References

Modarres, A., Hesami, S., Soltaninejad, M., & Madani, H. (2018). Application of coal waste in sustainable roller compacted concrete pavement-environmental and technical assessment. International Journal of Pavement Engineering, 19, 748–761. https://doi.org/10.1080/10298436.2016.1205747

Hesami, S., Modarres, A., Soltaninejad, M., & Madani, H. (2016). Mechanical properties of roller compacted concrete pavement containing coal waste and limestone powder as partial replacements of cement. Construction and Building Materials, 111, 625–636. https://doi.org/10.1016/j.conbuildmat.2016.02.116

Fakhri, M., & Azami, A. (2017). Evaluation of warm mix asphalt mixtures containing reclaimed asphalt pavement and crumb rubber. Journal of Cleanear Production, 165, 1125–1132. https://doi.org/10.1016/j.jclepro.2017.07.079

Amer, N., Delatte, N., & Storey, C. (1834). Using gyratory compaction to investigate density and mechanical properties of roller-compacted concrete. Journal of the Transportation Research Board, 2003, 77–84.

Williams, S. G. (2014). Construction of roller-compacted concrete pavement in the fayetteville shale play Area, Arkansas. Transportation Research Record, 2408, 47–54. https://doi.org/10.3141/2408-06

Hesami, M., Modarres, S., & Soltaniezhad, A. (2015). Influence of coal waste powder on strength properties of roller compacted concrete pavement. Journal of Transportation Infrastructure Engineering, 1, 1–14.

Muzenski, S., Flores-Vivian, I., Farahi, B., & Sobolev, K. (2020). Towards ultrahigh performance concrete produced with aluminum oxide nanofibers and reduced quantities of silica fume. Nanomaterials. https://doi.org/10.3390/nano10112291

Daniel, J.I., Gopalaratnam, V.S., Galinat, M.A. (2002). State-of-the-art report on fiber reinforced concrete, ACI Committee 544, Report 544, 1R-96, Am. Concr. Institute, Detroit, USA

Pacheco-torgal, F., & Jalali, S. (2011). Cementitious building materials reinforced with vegetable fibres : A review. Construction and Building Materials, 25, 575–581. https://doi.org/10.1016/j.conbuildmat.2010.07.024

Islam, M. M., Siddique, A., Pourhassan, A., Chowdhury, M. A., & Tasnim, J. (2019). Flexural capacity enhancement of timber beams partially confining the principal compression arch using carbon fiber reinforced polymer composites. Transportation Research Record, 2673, 276–285. https://doi.org/10.1177/0361198119851051

Hsie, M., Tu, C., & Song, P. S. (2008). Mechanical properties of polypropylene hybrid fiber-reinforced concrete. Materials Science and Engineering A, 494, 153–157. https://doi.org/10.1016/j.msea.2008.05.037

Sukontasukkul, P., Chaisakulkiet, U., Jamsawang, P., Horpibulsuk, S., Jaturapitakkul, C., & Chindaprasirt, P. (2019). Case investigation on application of steel fibers in roller compacted concrete pavement in Thailand. Case Studies in Constrution Materials, 11, e00271. https://doi.org/10.1016/j.cscm.2019.e00271

Sayyar, M., Soroushian, P., Sadiq, M. M., Balachandra, A., & Lu, J. (2013). Low-cost glass fiber composites with enhanced alkali resistance tailored towards concrete reinforcement. Construction and Building Materials, 44, 458–463.

Yin, S., Tuladhar, R., Shi, F., Combe, M., Collister, T., & Sivakugan, N. (2015). Use of macro plastic fibres in concrete : A review. Construction and Building Materials, 93, 180–188. https://doi.org/10.1016/j.conbuildmat.2015.05.105

Bayasi, Z., & McIntyre, M. (2002). Application of fibrillated polypropylene fibers for restraint of plastic shrinkage cracking in silica fume concrete. Mater. J., 99, 337–344.

Ros, P. S., & Zerbino, R. (2016). Creep and residual properties of cracked macro-synthetic fibre reinforced concretes. Magazine of Concrete Research, 68, 197–207.

Afroughsabet, V., Biolzi, L., & Ozbakkaloglu, T. (2016). High-performance fiber-reinforced concrete : A review. Journal of Materials Science, 51, 6517–6551. https://doi.org/10.1007/s10853-016-9917-4

Mo, K. H., Yap, K. K. Q., Alengaram, U. J., & Jumaat, M. Z. (2014). The effect of steel fibres on the enhancement of flexural and compressive toughness and fracture characteristics of oil palm shell concrete. Construction and Building Materials, 55, 20–28.

Camille, C., Kahagala Hewage, D., Mirza, O., Mashiri, F., Kirkland, B., & Clarke, T. (2021). Performance behaviour of macro-synthetic fibre reinforced concrete subjected to static and dynamic loadings for sleeper applications. Construction of Building Materials, 270, 121469. https://doi.org/10.1016/j.conbuildmat.2020.121469

Lahucik, J., Dahal, S., Roesler, J., & Amirkhanian, A. N. (2017). Mechanical properties of roller-compacted concrete with macro-fibers. Construction and Building Materials, 135, 440–446. https://doi.org/10.1016/j.conbuildmat.2016.12.212

Saidani, M., Saraireh, D., & Gerges, M. (2016). Behaviour of different types of fibre reinforced concrete without admixture. Engineering Structures, 113, 328–334. https://doi.org/10.1016/j.engstruct.2016.01.041

Yazici, Ş, Mardani-Aghabaglou, A., Tuyan, M., & Üte, A. A. (2015). Mechanical properties and impact resistance of roller-compacted concrete containing polypropylene fibre. Magazine of concrete research, 67(16), 867–875. https://doi.org/10.1680/macr.14.00242

Madhkhan, M., Azizkhani, R., & Torki Harchegani, M. E. (2012). Effects of pozzolans together with steel and polypropylene fibers on mechanical properties of RCC pavements. Construction and Building Materials, 26, 102–112. https://doi.org/10.1016/j.conbuildmat.2011.05.009

Hasan, M. J., Afroz, M., & Mahmud, H. M. I. (2011). An experimental investigation on mechanical behavior of macro synthetic fiber reinforced concrete. International Journal of Civil and Environmental Engineering., 11, 18–23.

Fallah, S., & Nematzadeh, M. (2017). Mechanical properties and durability of high-strength concrete containing macro-polymeric and polypropylene fibers with nano-silica and silica fume. Construction and Building Materials, 132, 170–187. https://doi.org/10.1016/j.conbuildmat.2016.11.100

Hesami, S., Hikouei, I. S., & Emadi, S. A. A. (2016). Mechanical behavior of self-compacting concrete pavements incorporating recycled tire rubber crumb and reinforced with polypropylene fiber. Journal of Cleaner Production, 133, 228–234. https://doi.org/10.1016/j.jclepro.2016.04.079

Yew, M. K., Mahmud, H. B., Ang, B. C., & Yew, M. C. (2015). Influence of different types of polypropylene fibre on the mechanical properties of high-strength oil palm shell lightweight concrete. Construction and Building Materials, 90, 36–43. https://doi.org/10.1016/j.conbuildmat.2015.04.024

Afroughsabet, V., & Ozbakkaloglu, T. (2015). Mechanical and durability properties of high-strength concrete containing steel and polypropylene fibers. Construction and Building Materials, 94, 73–82. https://doi.org/10.1016/j.conbuildmat.2015.06.051

Harrington, D., Abdo, F., Adaska, W., Hazaree, C. V., Ceylan, H., & Bektas, F. (2010). Guide for roller-compacted concrete pavements, National Concrete Pavement Technology Center

Fakhri, M., & Saberi, F. (2016). K, The effect of waste rubber particles and silica fume on the mechanical properties of Roller Compacted Concrete Pavement. Journal of Cleaner Production, 129, 521–530. https://doi.org/10.1016/j.jclepro.2016.04.017

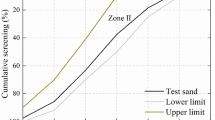

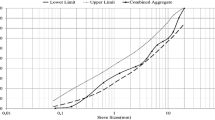

American Society for Testing Materials. (2014). Standard test method for sieve analysis of fine and coarse aggregates. C136. West Conshohocken, PA: ASTM International.

American Society for Testing Material. (2012). Standard test methods for laboratory compaction characteristics of soil using modified effort. D1557. West Conshohocken, PA: ASTM International.

ASTM C1176-92. (1998). Standard practice for making roller-compacted concrete in cylinder molds using a vibrating table. ASTM C1176-92. West Conshohocken, PA, USA: ASTM International.

American Society for Testing and Materials. (2008). Standard test method for determining consistency and density of roller-compacted concrete using a vibrating table. ASTM C1170/C1170M–08. West Conshohocken, Pennsylvania, USA: ASTM Standards.

American Society for Testing and Materials. (2011). Standard test method for compressive strength of cylindrical concrete specimens. ASTM C39/C39M–11a. West Conshohocken, PA, USA: ASTM Standards.

Hung, C.-H., Chen, W.-T., Sehhat, M. H., & Leu, M. C. (2021). The effect of laser welding modes on mechanical properties and microstructure of 304L stainless steel parts fabricated by laser-foil-printing additive manufacturing. International Journal of Advanced Manufacturing Technology, 112, 867–877. https://doi.org/10.1007/s00170-020-06402-7

ACI 325–10R-95, State-of-the-art report on roller-compacted concrete pavements, (2001) 32 pp.

Vahedifard, F., Nili, M., & Meehan, C. L. (2010). Assessing the effects of supplementary cementitious materials on the performance of low-cement roller compacted concrete pavement. Construction and Building Material., 24, 2528–2535. https://doi.org/10.1016/j.conbuildmat.2010.06.003

Soroushian, P., Plasencia, J., & Ravanbakhsh, S. (2003). Assessment of reinforcing effects of recycled plastic and paper in concrete. ACI Materials Journal, 100, 203–207.

Campione, G. (2006). Influence of FRP wrapping techniques on the compressive behavior of concrete prisms. Cement and Concrete Composites, 28, 497–505. https://doi.org/10.1016/j.cemconcomp.2006.01.002

Aulia, T. B. (2002). Effects of polypropylene fibers on the properties of high-strength concretes. Lacer., 7, 43–59.

Han, C., Hwang, Y., Yang, S., & Gowripalan, N. (2005). Performance of spalling resistance of high performance concrete with polypropylene fiber contents and lateral confinement. Cement and Concrete Research, 35(1747), 1753. https://doi.org/10.1016/j.cemconres.2004.11.013

Kim, B., Boyd, A. J., Kim, H.-S., & Lee, S.-H. (2015). Steel and synthetic types of fibre reinforced concrete exposed to chemical erosion. Construction and Building Material., 93, 720–728. https://doi.org/10.1016/j.conbuildmat.2015.06.023

Shafigh, P., Jumaat, M. Z., Bin Mahmud, H., & Hamid, N. A. A. (2012). Lightweight concrete made from crushed oil palm shell: Tensile strength and effect of initial curing on compressive strength. Construction and Building Material., 27, 252–258. https://doi.org/10.1016/j.conbuildmat.2011.07.051

Kosmatka, S., Kerkhoff, B., Panarese, W. (2002). Design and Control of Concrete Mixtures

Zhang, P., Yang, Y., Wang, J., Hu, S., Jiao, M., & Ling, Y. (2020). Mechanical properties and durability of polypropylene and steel fiber-reinforced recycled aggregates concrete (FRRAC): A review. Sustainability, 12, 1–28. https://doi.org/10.3390/su12229509

Wölfel, E., Brünig, H., Curosu, I., Mechtcherine, V., & Scheffler, C. (2021). Dynamic single-fiber pull-out of polypropylene fibers produced with different mechanical and surface properties for concrete reinforcement. Materials, 14(4), 722. https://doi.org/10.3390/ma14040722

Soltaninejad, M., Soltaninejad, M., Moshizi, M. K., Sadeghi, V., & Jahanbakhsh, P. (2021). Environmental-friendly mortar produced with treated and untreated coal wastes as cement replacement materials. Clean Technologies and Environmental Policy, 23(10), 2843–2860. https://doi.org/10.1007/s10098-021-02204-x

Gauthier, P., Marchand, J. (2005) Design and construction of roller compacted concrete pavements in Quebec, … ), Assoc. Bét. Québec Assoc. http://scholar.google.com/scholar?hl=en&btnG=Search&q=intitle:Design+and+Construction+of+Roller+Compacted+Concrete+Pavements+in+Quebec#0

Beglarigale, A., & Yazıcı, H. (2015). Pull-out behavior of steel fiber embedded in flowable RPC and ordinary mortar. Construction and Building Materials, 75, 255–265. https://doi.org/10.1016/j.conbuildmat.2014.11.037

Luiz, A., & Pereira de Oliveira, J. C. G. P. (2011). Physical and mechanical behaviour of recycled PET fibre reinforced mortar. Construction and Building Materials, 25, 1712–1717. https://doi.org/10.1016/j.conbuildmat.2010.11.044

Mazaheripour, H., Ghanbarpour, S., Mirmoradi, S. H., & Hosseinpour, I. (2011). The effect of polypropylene fibers on the properties of fresh and hardened lightweight self-compacting concrete. Construction and Building Materials, 25(1), 351–358. https://doi.org/10.1016/j.conbuildmat.2009.06.017

Ochi, T., Okubo, S., & Fukui, K. (2007). Development of recycled PET fiber and its application as concrete-reinforcing fiber. Cemente and Concreate. Composites, 29, 448–455. https://doi.org/10.1016/j.cemconcomp.2007.02.002

Wang, J., Dai, Q., Si, R., & Guo, S. (2019). Mechanical, durability, and microstructural properties of macro synthetic polypropylene (PP) fiber-reinforced rubber concrete. Journal of Cleaner Production, 234, 1351–1364. https://doi.org/10.1016/j.jclepro.2019.06.272

Lee, J. H., Cho, B., Choi, E., & Kim, Y. H. (2016). Experimental study of the reinforcement effect of macro-type high strength polypropylene on the flexural capacity of concrete. Construction and Building Materials, 126, 967–975. https://doi.org/10.1016/j.conbuildmat.2016.09.017

Foti, D. (2011). Preliminary analysis of concrete reinforced with waste bottles PET fibers. Construction and building materials, 25(4), 1906–1915. https://doi.org/10.1016/j.conbuildmat.2010.11.066

Taylor, P.C., Voigt, G. F.(2007). Integrated Materials and Construction Practices for Concrete Pavement: A State-of-the-Practice Manual | Local Roads Compendium, 2007. http://localroads.wisc.edu/content/706.

ACI 318–14, Building Code Requirements for Structural Concrete and Commentary, ACI Committee 318, American Concrete Institute, Farmington Hills, MI, USA, pp. 316., 2014.

Zdiri, M., Ben Ouezdou, M., & Neji, J. (2008). Theoretical and experimental study of roller-compacted concrete strength. Magazine of Concrete Research, 60(7), 469–474. https://doi.org/10.1680/macr.2007.00002

Zdiri, M., Abriak, N. E., Ouezdou, M. B., & Neji, J. (2009). The use of fluvial and marine sediments in the formulation of roller compacted concrete for use in pavements. Environmental technology, 30(8), 809–815. https://doi.org/10.1080/09593330902990097

Nikbin, I. M., Beygi, M. H. A., Kazemi, M. T., Amiri, J. V., Rabbanifar, S., Rahmani, E., & Rahimi, S. (2014). A comprehensive investigation into the effect of water to cement ratio and powder content on mechanical properties of self-compacting concrete. Construction and Building Materials, 57, 69–80. https://doi.org/10.1016/j.conbuildmat.2014.01.098

Rahmani, E., Sharbatdar, M. K., & Beygi, M. H. A. (2020). A comprehensive investigation into the effect of water to cement ratios and cement contents on the physical and mechanical properties of Roller Compacted Concrete Pavement (RCCP). Construction and Building Materials, 253, 119177. https://doi.org/10.1016/j.conbuildmat.2020.119177

Yang, J. M., Min, K. H., Shin, H. O., & Yoon, Y. S. (2012). Effect of steel and synthetic fibers on flexural behavior of high-strength concrete beams reinforced with FRP bars. Composites Part B: Engineering, 43(3), 1077–1086. https://doi.org/10.1016/j.compositesb.2012.01.044

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Rights and permissions

About this article

Cite this article

Jahanbakhsh, P., Saberi K, F., Soltaninejad, M. et al. Laboratory Investigation of Modified Roller Compacted Concrete Pavement (RCCP) Containing Macro Synthetic Fibers. Int. J. Pavement Res. Technol. 16, 745–759 (2023). https://doi.org/10.1007/s42947-022-00161-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42947-022-00161-2