Abstract

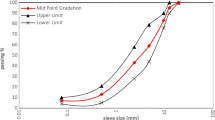

The purpose of this study is to compare the performance of rubber-modified asphalt mixtures prepared with incorporation of latex and crumb rubber. The service characteristics of the rubber-modified asphalt mixtures were evaluated using workability index and compaction energy index to determine the ease of placing, handling, and compacting of the asphalt mixture. The engineering properties of the asphalt mixtures were also evaluated in terms of indirect tensile strength (ITS), resilient modulus, permanent deformation, moisture susceptibility, and the Leutner shear test. Crumb rubber and latex were separately used as modifiers in this study. The percentage of crumb rubber and latex used were 5% and 10%, while organo silane additive was added at a rate of 0.1%, all by the weight of asphalt binder. Through the evaluation, the modified asphalt mixture required comparable energy for compaction through the assessment of compaction energy index (CEI) as compared to the control asphalt mixture. Based on the results of performance test, it can be concluded that the crumb rubber-modified asphalt mixture showed a better performance than the latex-modified asphalt mixture in terms of fracture resistance, permanent deformation, resilient modulus, shear resistance, and moisture resistance. Overall, the rubberised asphalt mixture has better engineering performance properties that can prolong the lifespan of the flexible pavement compared to the conventional asphalt mixture.

Similar content being viewed by others

References

N. Bala, M. Napiah, I. Kamaruddin, Effect of nanosilica particles on polypropylene polymer modified asphalt mixture performance, Case Studies Constr. Mater. 8 (2018) 447–454.

J. S. Chen, T. J. Wang, C. T. Lee, Evaluation of a highly-modified asphalt binder for field performance, Constr. Build. Mater. 171 (2018) 539–545.

Ding, X., T. Ma, W. Zhang, D. Zhang, Experimental study of stable crumb rubber asphalt and asphalt mixture, Constr. Build. Mater. (2017) 157 975–981.

Y. Yildirim, Polymer modified asphalt binders, Constr. Build. Mater. 21 (1) (2007) 66–72.

M. Murphy, M. O’Mahony, C. Lycett, I. Jamieson, Bitumens modified with recycled polymers, Mater. Struct. 33 (7) (2000) 438–444.

X. Yang, Z. You, M.R.M. Hasan, A. Diab, H. Shao, S. Chen, D. Ge, Environmental and mechanical performance of crumb rubber modified warm mix asphalt using Evotherm, J. Clean. Prod. 159 (2017) 346–358.

K. Liu, K. Zhang, X. Shi, Performance evaluation and modification mechanism analysis of asphalt binders modified by graphene oxide, Constr. Build. Mater. 163 (2018) 880–889.

R. Gogoi, K.P. Biligiri, N.C. Das, Performance prediction analyses of styrene-butadiene rubber and crumb rubber materials in asphalt road applications, Mater. Struct. 49 (9) (2016) 3479–3493.

G. Airey, M. Rahman, A.C. Collop, Crumb Rubber and Bitumen Interaction as a Function of Crude Source and Bitumen Viscosity, Road Mater. Pavement Des. 5 (4) (2004) 453–475.

S.A.D. Neto, M.M. Farias, J.C. Pais, P.A.A. Pereira, J.B. Sousa, Influence of crumb rubber and digestion time on the asphalt rubber binders, Road Mater. Pavement Des. 7 (2) (2006) 131–148.

M.A. Abdelrahman, S. H. Carpenter, Mechanism of Interaction of Asphalt Cement with Crumb Rubber Modifier, Transp. Res. Rec. 1661 (1999) 106–113.

F.J. Navarro, P. Partal, F. Martínez-Boza, C. Gallegos, Influence of crumb rubber concentration on the rheological behavior of a crumb rubber modified bitumen, Energy Fuels 19 (5) (2005) 1984–1990.

S.J. Lee, C.K. Akisetty, S.N. Amirkhanian, The effect of crumb rubber modifier (CRM) on the performance properties of rubberized binders in HMA pavements, Constr. Build. Mater. 22 (7) (2008) 1368–1376.

V. Venudharan, K.P. Biligiri, Conceptualization of permanent deformation characteristics of rubber modified asphalt binders: Energy-based algorithm and rheological modeling, Constr. Build. Mater. 126 (2016) 388–397.

A.M. Rodríguez-Alloza, J. Gallego, Mechanical performance of asphalt rubber mixtures with warm mix asphalt additives, Mater. Struct. 50 (2) (2017) 147.

M.F. Azizian, P.O. Nelson, P. Thayumanavan, K.J. Williamson, Environmental impact of highway construction and repair materials on surface and ground waters: Case study. Crumb rubber asphalt concrete, Waste Manage. 23 (8) (2003) 719–728.

J. Shen, S. Amirkhanian, F. Xiao, B. Tang, Influence of surface area and size of crumb rubber on high temperature properties of crumb rubber modified binders, Constr. Build. Mater. 23 (1) (2009) 304–310.

S.E. Paje, M. Bueno, F. Terán, R. Miró, F. Pérez-Jiménez, A.H. Martínez, Acoustic field evaluation of asphalt mixtures with crumb rubber, Appl. Acoustics 71 (6) (2010) 578–582.

G. King, Additives in asphalt. J Assoc Asphalt Paving Technol. A. 68 (1999) 32–69.

P. Mirzababaei, Effect of zycotherm on moisture susceptibility of Warm Mix Asphalt mixtures prepared with different aggregate types and gradations, Constr. Build. Mater. 116 (2016) 403–412.

American Society for Testing and Materials, Standard Test Method for Penetration of Bituminous Materials. ASTM D5 / D5M-20. ASTM International, West Conshohocken, PA, USA, 2020.

American Society for Testing and Materials, Standard Test Method for Softening Point of Bitumen (Ring-and-Ball Apparatus). ASTM D36 / D36M-14(2020). ASTM International, West Conshohocken, PA, USA, 2020.

American Society for Testing and Materials, Standard Test Method for Viscosity Determination of Asphalt at Elevated Temperatures Using a Rotational Viscometer. ASTM D4402 / D4402M-15. ASTM International, West Conshohocken, PA, USA, 2015.

Austroads Test Method, Torsional Recovery of Polymer Modified Binders. AGPT/T122. Austroads, Sydney, Australia, 2006.

H.U. Bahia, T.P. Friemel, P.A. Peterson, J.S. Russell, B. Poehnelt, Optimization of constructibility and resistance to traffic: A new design approach for HMA using the superpave compactor, J. Assoc. Asphalt Paving Technol. 67 (98) (1998) 189–232.

American Association of State Highway and Transportation Officials, Standard Method of Test for Determining the Creep Compliance and Strength of Hot-Mix Asphalt (HMA) Using the Indirect Tensile Test Device. AASHTO T 322-07. AASHTO, Washington DC, USA, 2007.

American Association of State Highway and Transportation Officials, Standard Method of Test for Resistance of Compacted Asphalt Mixtures to Moisture-Induced Damage. AASHTO T 283-14. AASHTO, Washington DC, USA, 2014.

American Society for Testing and Materials, Standard Test Method for Determining the Resilient Modulus of Bituminous Mixtures by Indirect Tension Test. ASTM D7369-11. ASTM International, West Conshohocken, PA, USA, 2011.

British Standards Institution, Method for Determining Resistance to Permanent Deformation of Bituminous Mixtures Subject to Unconfined Dynamic Loading. BS-DD-226. BSI, London, UK, 1996.

S.R. Omranian, M.O. Hamzah, L. Gungat, S.Y. Teh, Evaluation of asphalt mixture behavior incorporating warm mix additives and reclaimed asphalt pavement, J. Traffic Transp. Eng. (English Ed.) 5 (3) (2018) 181–196.

H.U. Bahia, T.P. Friemel, P.A. Peterson, J.S. Russell, B. Poehnelt, Optimization of constructibility and resistance to traffic: a new design approach for HMA using the superpave compactor, J. Assoc. Asphalt Paving Technol. 67 (1998).

M. Ragab, M. Abdelrahman, A. Ghavibazoo, Performance Enhancement of Crumb Rubber-Modified Asphalts Through Control of the Developed Internal Network Structure, Transp. Res. Rec. 2371 (2013) 96–104.

M. Ragab, M. Abdelrahman, Enhancing the crumb rubber modified asphalt’s storage stability through the control of its internal network structure, Inter. J. Pavement Res. Technol. 11 (1) (2018) 13–27.

B. Huang, Z. Zhang, W. Kingery, G. Zuo, C. Petit, I.L. Al-Qadi, A. Millien, Fatigue crack characteristics of HMA mixtures containing RAP. (2004) 631–638.

S. Tayfur, H. Ozen, A. Aksoy, Investigation of rutting performance of asphalt mixtures containing polymer modifiers, Constr. Build. Mater. 21 (2) (2007) 328–337.

A. Apeagyei, Moisture damage evaluation of asphalt mixtures using AASHTO T283 and DC(T) Fracture Test, in 10th International Conference on Asphalt Pavements. 2006. Quebcec City, Canada, 2006.

J. Ahmad, N.I.M. Yusoff, M.R. Hamm, M.Y.A. Rahman, M. Hossain, Investigation into hot-mix asphalt moisture-induced damage under tropical climatic conditions, Constr. Build. Mater. 50 (2014) 567–576.

M. Ameri, M. Vamegh, S.F. Chavoshian Naeni, M. Molayem, Moisture susceptibility evaluation of asphalt mixtures containing Evonik, Zycotherm and hydrated lime, Constr. Build. Mater. 165 (2018) 958–965.

E.R. Brown, K.Y. Foo, Evaluation of variability in resilient modulus test results (ASTM D 4123), J. Testing Eval. 19 (1) (1991) 1–13.

D.J. Kulash, Toward performance-based specifications for bitumen and asphalt mixtures, Proc. Institution Civ. Eng.: Transp. 105 (3) (1994) 187–194.

P. Tian, M.M. Zaman, J.G. Laguros, Variation of Resilient Modulus of Aggregate Base and Its Influence on Pavement Performance, J. Testing Eval. 26 (4) (1998) 329–335.

M.Y. Shahin, Pavement management for airports, roads, and parking lots: Second edition, Chapman & Hall, New York, USA, 2005.

Acknowledgements

The authors would like to acknowledge Universiti Sains Malaysia (USM) for the funding through Short-Term Research Grant Scheme (304/PAWAM/60313048), and the Malaysian Ministry of Higher Education (MOHE) via the Fundamental Research Grant Scheme (203/PAWAM/6071358). Appreciation also goes to the National Natural Science Foundation of China (NSFC) for providing financial assistance via the Research Fund for the International Young Scientist (Grant No. 51750110491). Thanks are also due to the technical staff of the Highway Engineering Laboratory at Universiti Sains Malaysia for their undivided assistance. Any opinions, findings, and conclusions expressed in this manuscript are those of the authors and do not necessarily reflect the views of USM, MOHE, and NSFC.

Author information

Authors and Affiliations

Corresponding author

Additional information

Peer review under responsibility of Chinese Society of Pavement Engineering.

Rights and permissions

About this article

Cite this article

Poovaneshvaran, S., Zheng, L.W., Hasan, M.R.M. et al. Workability, compactibility and engineering properties of rubber-modified asphalt mixtures prepared via wet process. Int. J. Pavement Res. Technol. 14, 560–569 (2021). https://doi.org/10.1007/s42947-020-1006-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42947-020-1006-z