Abstract

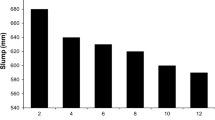

One of the most widespread techniques in concrete pavement construction is roller-compacted concrete (RCC) in which Portland cement is used. Recently, an inclination has been seen toward alternative cementitious materials due to environmental concerns expressed over the production of Portland cement. Alkali-activated slag concrete (AASC) has been proposed as a solution to this problem. However, the application of this type of concrete in RCC has been rarely investigated. This study was to fill this gap in the existing literature experimentally. A solution of sodium hydroxide and sodium silicate helped to activate the slag content of AASC. The mechanical and rheological properties of roller-compacted alkali-activated slag concrete (RC-AASC) were assessed by measuring compressive and flexural strengths, optimum compaction moisture, setting time, and strength development of concrete samples. In mix design of RCC, determination of its optimum compaction moisture is a crucial step; therefore, the optimum moisture required for ultimate compaction was estimated, while the variation in combination of alkali activator affected this optimum moisture. The results indicated that the compressive and flexural strengths of RC-AASC with minimum cementitious content were comparable to those of conventional RCC which is mentioned in ACI 327R-14.

Similar content being viewed by others

References

T. R. Naik, Y. M. Chun, R. N. Kraus, S. S. Singh, L. L. C. Pennock, B. W. Ramme, Strength and durability of roller-compacted HVFA concrete pavements, Pract. Period. Struct. Des. Constr. 6 (4) (2001) 154–165.

F. Vahedifard, M. Nili, C.L. Meehan, Assessing the effects of supplementary cementitious materials on the performance of low-cement roller compacted concrete pavement, Constr. Build. Mater. 24 (2010) 2528–2535.

Z. Wu, M. Mahdi, T.D. Rupnow, Accelerated pavement testing of thin RCC over soil cement pavements, Inter. J. Pavement Res. Technol. 9 (3) (2016) 159–168.

C. Hazaree, H. Ceylan, K. Wang, Influences of mixture composition on properties and freeze-thaw resistance of RCC, Constr. Build. Mater. 25 (2011) 313–319.

N. Delatte, N. Amer, C. Storey, Improved Management of RCC Pavement Technology, Department of Civil and Environmental Engineering. Report Number FHWA/CA/OR. University Transportation Center for Alabama, The University of Alabama, Tuscaloosa, Alabama, USA, 2003.

C.D. Atiş, Strength properties of high-volume fly ash roller compacted and workable concrete, and influence of curing condition, Cem. Concr. Res. 35 (6) (2005) 1112–1121.

J.-M. Lessard, A. Omran, A. Tagnit-Hamou, R. Gagne, Feasibility of using biomass fly and bottom ashes to produce RCC and PCC, J. Mater. Civ. Eng. 29 (4) (2017) https://doi.org/10.1061/(ASCE)MT.1943-5533.0001796.

A.A. Ramezanianpour, A. Mohammadi, E.R. Dehkordi, Q.B. Chenar, Mechanical properties and durability of roller compacted concrete pavements in cold regions, Constr. Build. Mater 146 (2017) 260–266.

M.N. Lam, S. Jaritngam, D. Le, Roller-compacted concrete pavement made of Electric Arc Furnace slag aggregate: Mx design and mechanical properties, Constr. Build. Mater. 154 (2017) 482–495. https://doi.org/10.1016/j.conbuildmat.2017.07.240

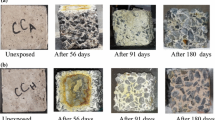

A. Aghaeipour, M. Madhkhan, Effect of ground granulated blast furnace slag (GGBFS) on RCCP durability, Constr. Build. Mater. 141 (2017) 533–541. https://doi.org/10.1016/j.conbuildmat.2017.03.019

A. Karimpour, Effect of time span between mixing and compacting on roller compacted concrete (RCC) containing ground granulated blast furnace slag (GGBFS), Constr. Build. Mater. 24 (2010) 2079–2083.

C. Meyer, Concrete for the New Century, Association of New York City Concrete Producers. Columbia University, Springer, Heidelberg, New York, USA, 2002.

H.F.W. Taylor, Cement chemistry, Cem. Concr. Compos. 20 (4) (1998) 335. https://doi.org/10.1016/S0958-9465(98)00023-7.

Á. Palomo, A. Fernández-jiménez, C. López-hombrados, J.L. Lleyda, I. Eduardo, T. Csic, volante activadas con álcalis railway sleepers made of alkali activated fly ash concrete, Rev. Ing. construcción. 22 (2) (2007) 75–80. https://doi.org/10.4067/S0718-50732007000200001.

A.M. Rashad, A comprehensive overview about the influence of different additives on the properties of alkali-activated slag - A guide for Civil Engineer, Constr. Build. Mater. 47 (2013) 29–55. https://doi.org/10.1016/j.conbuildmat.2013.04.011.

T.R. Naik, Sustainability of Concrete Construction, Pract. Period. Struct. Des. Constr. 13 (2008) 98–103. https://doi.org/10.1061/(ASCE)1084-0680(2008)13:2(98).

J.X. Peng, L. Huang, Y.B. Zhao, P. Chen, L. Zeng, W. Zheng, Modeling of carbon dioxide measurement on cement plants, Adv. Mater. Res. 610–613 (2013) 2120–2128. https://doi.org/10.4028/www.scientific.net/AMR.610-613.2120.

A.M. Rashad, Y. Bai, P.A.M. Basheer, N.B. Mlestone, N.C. Collier, Hydration and properties of sodium sulfate activated slag, Cem. Concr. Compos. 37 (2013) 20–29. https://doi.org/10.1016/j.cemconcomp.2012.12.010.

K. Yang, C. Yang, B. Magee, S. Nanukuttan, J. Ye, Establishment of a preconditioning regime for air permeability and sorptivity of alkali-activated slag concrete, Cem. Concr. Compos. 73 (2016) 19–28. https://doi.org/10.1016/j.cemconcomp.2016.06.019.

J.J. Thomas, A.J. Allen, H.M. Jennings, Density and water content of nanoscale solid C-S-H formed in alkali-activated slag (AAS) paste and implications for chemical shrinkage, Cem. Concr. Res. 42 (2) (2012) 377–383. https://doi.org/10.1016/j.cemconres.2011.11.003.

A. Fernández-Jiménez, J.G. Palomo, F. Puertas, alkali-activated slag mortars: Mechanical strength behaviour, Cem. Concr. Res. 29 (8) (1999) 1313–1321. https://doi.org/10.1016/S0008-8846(99)00154-4.

T. Bakharev, J.G. Sanjayan, Y.B. Cheng, Resistance of alkali-activated slag concrete to acid attack, Cem. Concr. Res. 33 (10) (2003) 1607–1611. https://doi.org/10.1016/S0008-8846(03)00125-X.

J. Provis, J. van Deventer, Alkali Activated Materials, RILEM state-of-the-art Reports, Chapter 10. Report number. TC 224-AAM. Springer, Heidelberg, New York, USA, 2014.

A.R. Brough, A. Atkinson, Sodium silicate-based, alkali-activated slag mortars - Part I. Strength, hydration and microstructure, Cem. Concr. Res. 32 (6) (2002) 865–879. https://doi.org/10.1016/S0008-8846(02)00717-2.

M. Palacios, P.F.G. Banfill, F. Puertas, Rheology and setting of alkali-activated slag pastes and mortars: Effect if organic admixture, ACI Mater. J. 105 (2) (2008) 140–148. https://doi.org/10.14359/19754.

V. Živica, Effects of type and dosage of alkaline activator and temperature on the properties of alkali-activated slag mixtures, Constr. Build. Mater. 21 (2007) 1463–1469. https://doi.org/10.1016/j.conbuildmat.2006.07.002.

J. Chang, A study on the setting characteristics of sodium silicate-activated slag pastes, Cem. Concr. Res. 33 (7) (2003) 1005–1011. https://doi.org/10.1016/S0008-8846(02)01096-7.

D. Krizan, B. Zivanovic, Effects of dosage and modulus of water glass on early hydration of alkali–slag cements, Cem. Concr. Res. 32 (8) (2002) 1181–1188. https://doi.org/10.1016/S0008-8846(01)00717-7.

E. Altan, S.T. Erdoǧan, Alkali activation of a slag at ambient and elevated temperatures, Cem. Concr. Compos. 34 (2) (2012) 131–139. https://doi.org/10.1016/j.cemconcomp.2011.08.003.

S.R. Zedan, M.R. Mohamed, D.A. Ahmed, A.H. Mohammed, Effect of demolition/construction wastes on the properties of alkali activated slag cement, HBRC J. 13 (3) (2017) 331–336. https://doi.org/10.1016/j.hbrcj.2015.12.001.

K. Behfarnia, The effect of alkaline solution-to-slag ratio on permeability of alkali activated slag concrete, Int. J. Civ. Eng. 16 (8) (2018) 897–904. https://doi.org/10.1007/s40999-017-0234-3.

K. Behfarnia, M. Rostami, Mechanical properties and durability of fiber reinforced alkali activated slag concrete, J. Mater. Civ. Eng. 29 (12) (2017). https://doi.org/10.1061/(ASCE)MT.1943-5533.0002073.

A. Allahverdi, E. Najafi, K. Babak, Carbonation versus efflorescence in alkali-activated blast- furnace slag in relation with chemical composition of activator, Int. J. Civ. Eng. 15 (4) (2017) 565-573. https://doi.org/10.1007/s40999-017-0225-4.

H. Maghsoodloorad, A. Allahverdi, Efflorescence formation and control in alkali-activated phosphorus slag cement, Int. J. Civ. Eng. 14 (6) (2016) 425–438. https://doi.org/10.1007/s40999-016-0027-0.

M. Shojaei, K. Behfarnia, R. Mohebi, Application of alkali-activated slag concrete in railway sleepers, Mater. Des. 69 (2015) 89–95. https://doi.org/10.1016/j.matdes.2014.12.051.

American Society for Testing and Materials, Standard Specification for Concrete Aggregates, ASTM C33-13, ASTM International, West Conshohocken, Pennsylvania, USA, 2013.

American Concrete Institue, Guide to Roller- Compacted Concrete Pavements, ACI 327R-14, Farmington Hills, Michigan, USA, 2015.

American Society for Testing and Materials, Standard Test Method for Laboratory Compaction Characteristics of Soil Using Modified Effort, ASTM D1557, ASTM International, West Conshohocken, Pennsylvania, USA, 2000.

American Concrete Institue, State of the Art Report on Roller Compacted Concrete Pavements, ACI 325.10R-95, Farmington Hills, Michigan, USA, 2001.

R. Mohebi, K. Behfarnia, M. Shojaei, Abrasion resistance of alkali-activated slag concrete designed by Taguchi method, Constr. Build. Mater. 98 (2015) 792–798. https://doi.org/10.1016/j.conbuildmat.2015.08.128.

M. M. Alonso, S. Gismera, M.T. Blanco, M. Lanzón, F. Puertas, Alkali-activated mortars: Workability and rheological behaviour, Constr. Build. Mater. 145 (2017) 576–587. https://doi.org/10.1016/j.conbuildmat.2017.04.020.

K.-H. Yang, J.-K. Song, Workability loss and compressive strength development of cementless mortars activated by combination of sodium silicate and sodium hydroxide, J. Mater. Civ. Eng. 21 (3) (2009) 119–127. https://doi.org/10.1061/(ASCE)0899-1561(2009)21:3(119).

British Standard, Testing Concete - Method for determination of compresive strength of concrete cubes. BS 1881-116. British Standards Institution, London, United Kingdom, 1983. https://doi.org/Construction Standard, CS1:2010.

S. Aydin, B. Baradan, Mechanical and microstructural properties of heat cured alkali-activated slag mortars, Mater. Des. 35 (2012) 374–383. https://doi.org/10.1016/j.matdes.2011.10.005.

C. Duran Atiş, C. Bilim, Ö. Çelik, O. Karahan, Influence of activator on the strength and drying shrinkage of alkali-activated slag mortar, Constr. Build. Mater. 23 (2009) 548–555. https://doi.org/10.1016/j.conbuildmat.2007.10.011.

T. Bakharev, J.G. Sanjayan, Y.B. Cheng, Alkali activation of Australian slag cements, Cem. Concr. Res. 29 (1) (1999) 113–120. https://doi.org/10.1016/S0008-8846(98)00170-7.

American Society for Testing and Materials, Standard Test Method for Flexural Strength of Concrete (Using Simple Beam Third-point Loading). ASTM C78-02., ASTM International, West Conshohocken, Pennsylvania, USA, 2002.

M. Gharavi, Optimization of compacting time with the effects of different pozzolans (type and dosage) on the mechanical properties of RCC, International Symposium on Roller Compacted Concrete, Madrid, Spain, 2003.

N.K. Lee, H.K. Lee, Setting and mechanical properties of alkali-activated fly ash/slag concrete manufactured at room temperature, Constr. Build. Mater. 47 (2013) 1201–1209. https://doi.org/10.1016/j.conbuildmat.2013.05.107.

A. Wardhono, C. Gunasekara, D.W. Law, S. Setunge, Comparison of long term performance between alkali activated slag and fly ash geopolymer concretes, Constr. Build. Mater. 143 (2017) 272–279. https://doi.org/10.1016/j.conbuildmat.2017.03.153.

Author information

Authors and Affiliations

Corresponding author

Additional information

Peer review under responsibility of Chinese Society of Pavement Engineering.

Rights and permissions

About this article

Cite this article

Bastani, M., Behfarnia, K. Application of alkali-activated slag in roller compacted concrete. Int. J. Pavement Res. Technol. 13, 324–333 (2020). https://doi.org/10.1007/s42947-020-0088-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42947-020-0088-y