Abstract

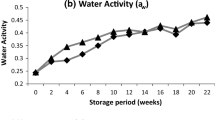

Quinoa is a pseudo-cereal widely acclaimed for its good tolerance to extreme climates. Being suitable for diabetics, while being endowed with superior quality nutrients, quinoa incorporation in diet carries benefits for consumers worldwide. The present study was designed to incorporate quinoa flour at 60% level in extruded snacks made from cereals like rice, corn and oats. The extrudates were investigated for their composition, physico-chemical and sensory properties. Upon varying the barrel temperature from 100 to 170 °C, wide variation in expansion ratios 3.28–3.50, unit density (0.120–0.200 g/cm3), WAI (5.77–6.40 g/g), WSI (12.59–20.93%) and Hunter color parameters were recorded for the extrudates. The optimized extruded snack had protein (15.99%), fat (4.24%), ash (1.94%) and carbohydrates (77.83%). The storage study showed that extrudates were acceptable till 80 days of storage at ambient conditions. The optimized snack could meet the FAO requirements for 6 out of 10 essential amino acids for adults namely lysine, methionine, cystine, threonine and phenylalanine + tyrosine. The fatty acid profile of the developed extrudates showed presence of 58%, 4.4% and 23% of omega-6, omega-3 and oleic fatty acids, respectively. The present study suggests possibility for production of highly acceptable extruded snacks having up to 60% quinoa, which provide good nutrition also.

Similar content being viewed by others

References

Abugoch James LE (2009) Chapter 1 Quinoa (Chenopodium quinoa Willd.): composition, chemistry, nutritional, and functional properties. In: S. Taylor (Ed.) Advances in food and nutrition research. Academic Press, Cambridge, 58: 1–31.

Alajil O, Hymavathi TV, Robert P, Deepika LV (2018) Effect of flour composition and temperature on physico-chemical and sensory properties of quinoa based extrudates. J Pharm Res Int 24(5):1–13

Altan A, McCarthy KL, Maskan M (2008) Evaluation of snack foods from barley—tomato pomace blends by extrusion processing. J Food Eng 84:231–242

Anderson RA (1982) Water absorption and solubility and amylograph characteristics of roll-cooked small grain products. Cereal Chem 59:265–269

AOAC Official Method (2005) Official methods of analysis of AOAC international, 18th edn. AOAC International, Gaithersburg, MD. Methods 935.29, 996.06, 2001.11, 2003.05

Balasubramanian S, Borah A, Mahanta CL (2012) Rheological and nutritional properties of legumes incorporated corn extrudates. Int Food Res J 19(3):971–975

Brady K, Hoa CH, Rosen R et al (2007) Effects of processing on the nutraceutical profile of quinoa. Food Chem 100(3):1209–1216

Brennan C, Brennan M, Derbyshire E, Tiwari B (2011) Effects of extrusion on the polyphenols, vitamins and antioxidant activity of foods. Trends Food Sci Technol 22:570–575

Dehghan-Shoar Z, Mandimika T, Hardacre A et al (2011) Lycopene bioaccessibility and starch digestibility for extruded snacks enriched with tomato derivatives. J Agric Food Chem 59:12047–12053

Diaz JMR (2015) Use of amaranth, quinoa, kañiwa and lupine for the development of gluten-free extruded snacks. PhD thesis submitted to Department of Food and Environmental Sciences, University of Helsinki, Finland. pp. 30–44.

Ding QB, Ainsworth P, Plunkett A et al (2006) The effect of extrusion conditions on the functional and physical properties of wheat-based expanded snacks. J Food Eng 73:142–148

Ding QB, Ainsworth P, Tucker G, Marson H (2005) The effect of extrusion conditions on the physico-chemical properties and sensory characteristics of rice based expanded snacks. J Food Eng 66:283–289. https://doi.org/10.1016/j.jfoodeng

Dini I, Tenore GC, Dini A (2005) Nutritional and antinutritional composition of Kancolla seeds: an interesting and underexploited andiane food plant. Food Chem 92:125–132

Estrada-Girón Y, Martínez-Preciado AH, Michel CR, Soltero JFA (2015) Characterization of extruded blends of corn and beans (Phaseolus vulgaris) cultivars: Peruano and black-querétaro under different extrusion conditions. Int J Food Prop 18(12):2638–2651

Gu L, House S, Rooney L, Prior R (2008) Sorghum extrusion increases bioavailability of catechins in weanling pigs. J Agric Food Chem 56:1283–1288

Guy R (2001) Raw materials for extrusion cooking. In: Guy R (ed) Extrusion cooking: technologies and applications. Woodhead Publishers, Cambridge, pp 5–28

Ijarotimi OS, Keshinro OO (2012) Formulation and nutritional quality of infant formula produced from germinated popcorn, Bambara groundnut and African locust bean flour. J Microbiol Biotechnol Food Sci 1:1358–1388

Kadan RS, Bryant RJ, Pepperman AB (2003) Functional properties of extruded rice flours. J Food Sci 68:1669–1672. https://doi.org/10.1111/j.1365-2621.2003.tb12311.x

Kahlon TS, Avena-Bustillos RJ, Chiu MCM (2016) Sensory evaluation of gluten-free quinoa whole grain snacks. Heliyon 2(12):e00213

Kannadhason S, Muthukumarappan K, Rosentrater KA (2011) Effect of starch sources and protein content on extruded aquaculture feed containing DDGS. Food Bioprocess Technol 4(2):282–294

Köksel H, Ryu GH, Basman A et al (2004) Effects of extrusion variables on the properties of waxy hulless barley extrudates. Nahrung 48:19–24

Kowalski RJ, Medina-Meza IG, Thapa BB et al (2016) Extrusion processing characteristics of quinoa (Chenopodium quinoa Willd.) var. Cherry Vanilla. J Cereal Sci 70:91–98

León K, Mary D, Pedreschi F, León J (2006) Color measurement in L*a*b* units from RGB digital images. Food Res Int 39:1084–1091

Meilgaard M, Civille GV, Carr BT (1999) Sensory evaluation techniques, 3rd edn. CRC Press, Boca Raton

Navam SH, Tajudini AL, Srinivas JR et al (2014) Physio-chemical and sensory properties of protein-fortified extruded breakfast cereal/snack formulated to combat protein malnutrition in developing countries. J Food Process Technol 5:359. https://doi.org/10.4172/2157-7110.1000359

Ng S, Anderson A, Cokera J, Ondrusa M (2007) Characterization of lipid oxidation products in quinoa (Chenopodisum quinoa). Food Chem 101(1):185–192

Omwamba M, Mahungu SM (2014) Development of protein-rich ready-to-eat extruded snack from a composite blend of rice, sorghum and soybean flour. Food Nutr Sci 5:1309–1317. https://doi.org/10.4236/fns.2014.514142

Paes MCD, Maga J (2004) Effect of extrusion on essential amino acids profile and color of whole-grain flours of quality protein maize (QPM) and normal maize cultivars. Revistabrasileira de Milho e Sorgo 3(1):10–20

Pastor-Cavada E, Drago SR, Gonzalez RJ et al (2011) Effects of the addition of wild legumes (Lathyrus annuus and Lathyrus clymenum) on the physical and nutritional properties of extruded products based on whole corn and brown rice. Food Chem 128(4):961–967

Ranhotra G, Gelroth J, Glaser B (1993) Composition and protein nutritional quality of quinoa. Cereal Chem 70(3):303–305

Repo-Carrasco-Valencia R, de La Cruz AA, Alvarez JCI, Kallio H (2009) Chemical and functional characterization of kaniwa (Chenopodium pallidicaule) grain, extrudate and bran. Plant Foods Hum Nutr 64(2):94–101

Report of a Joint FAO:WHO consultation (1994) Fats and oils in human nutrition. FAO Nutrition Paper No. 57. Rome.

Singh J, Dartois A, Kaur L (2010) Starch digestibility in food matrix: a review. Trends Food Sci Technol 21:168–180

Sonnenberg LM, Quatromoni PA, Gagnon DR et al (1996) Diet and plasma lipids in women. II. Macronutrients and plasma triglycerides, high-density lipoprotein and the ratio of total to high-density lipoprotein cholesterol in women: The Framingham nutrition studies. J Clin Epidemiol 49:665–672

Stojceska V, Ainsworth P, Plunkett A, İbanoğlu Ş (2009) The effect of extrusion cooking using different water feed rates on the quality of ready-to-eat snacks made from food by-products. Food Chem 114(1):226–232

Sumathi A, Ushakumari S, Malleshi N (2007) Physico-chemical characteristics, nutritional quality and shelf-life of pearl millet based extrusion cooked supplementary foods. Int J Food Sci Nutr 58:350–362

Taverna LG, Leonel M, Mischan MM (2012) Changes in physical properties of extruded sour cassava starch and quinoa flour blend snacks. Food Sci Technol 32(4):826–834

United Nations (2011) Draft resolution II, International Year of Quinoa (2013) Agriculture development and food security, Report of the second committee. A/RES/66/446. pp. 21. http://www.un.org/ga/search/view_doc.asp?symbol=A/66/446

Vega-Gálvez A, Miranda M, Vergara J et al (2010) Nutrition facts and functional potential of quinoa (Chenopodium quinoa Willd.), an ancient Andean grain: a review. J Sci Food Agric 90(15):2541–2547. https://doi.org/10.1002/jsfa.4158

WHO/FAO/UNU (2007) Protein and amino acid requirements in human nutrition report of a joint WHO/FAO/UNU expert consultation. World Health Organization, Geneva. https://site.ebrary.com/id/10190691.

Young VR, Pellett PL (1203S) Plant proteins in relation to human protein and amino acid nutrition. Am Soc Clin Nutr 59(suppl):1203S–l2S

Yuliani S, Torley PJ, D’Arcy B et al (2006) Effect of extrusion parameters on flavour retention, functional and physical properties of mixtures of starch and D-limonene encapsulated in milk protein. Int J Food Sci Technol 41:83–94

Žilić S, Mogol BA, Akıllıoğlu G et al (2014) Effects of extrusion, infrared and microwave processing on Maillard reaction products and phenolic compounds in soybean. J Sci Food Agric 94(1):45–51

Acknowledgement

We acknowledge the effort of QC lab. (PJTSAU) especially Dr. Aparna Kuna for assistance with HPLC and GC analysis; Dr. Yassin Al-Qassar for assistance in plagiarism check and the Inner being wellness Pvt. Ltd. for providing of quinoa grains.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no competing interests to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Alajil, O., Hymavathi, T.V., Maheswari, K.U. et al. Nutritional, physico-chemical and sensory attributes of quinoa based extrudates. Vegetos 33, 390–400 (2020). https://doi.org/10.1007/s42535-020-00119-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42535-020-00119-4