Abstract

The size of chain pillars in the Indian geo-mining conditions is primarily decided in accordance with the regulatory provisions. These provisions are of little help for deep longwall workings, exceeding the cover depth of 360 m. Furthermore, these provisions are primarily meant to support pillars in bord and pillar workings. They may not be suitable for the chain pillars owing to a significant difference in layouts and functional requirements. Hence, it is imperative to develop a method to evaluate the stability of the chain pillar considering the complex loading and geo-mining conditions. To this end, a machine learning-based model was developed in this study to assess the stability of the chain pillars under high depth of cover considering the field-representative conditions. The data for this work was generated by conducting a parametric study using a field-validated numerical model. The strength and deformability parameters of the caved, fractured, and continuous deformation zones were established by calibrating the numerical model outcomes against the site-specific field observations. The developed ML model was used to evaluate the influence of pillar width, pillar height, cover depth, abutment angle, face length, coal strength, moduli ratio of the roof and floor strata to the coal seam, and the elastic modulus and unit weight of the overburden on the chain pillar stability. An interesting finding of this study showed that the factor of safety of the chain pillar increased with the increasing abutment angle, which may be indicative of the confining effect of the abutment angle on the pillar. Eventually, the ML model was verified by comparing its outcomes with the calibrated numerical model for a typical longwall working from Indian geo-mining conditions.

Similar content being viewed by others

References

Mark C (1990) Pillar design methods for longwall mining. United States Bureau of Mines Information Circular 9247

Colwell MG (1998) Chain pillar design - calibration of ALPS. Australian Coal Association Research Program, final report—ACARP project C6036

Mark C, Chase FE, Molinda GM (1994) Design of Longwall gate entry systems using roof classification. In: Proceedings of the United States Bureau of Mines Technology Transfer Seminar - New Technology for Longwall Ground Control. USBM Special Publication 01–94, pp 5 – 17

Ghosh N, Agrawal H, Singh SK, Banerjee G (2020) Optimum chain pillar design at the deepest multi-seam longwall workings in India. Mining, Metallurgy & Exploration 37:651–664

Seedsman R, Jalalifar H, Aziz N (2005) Chain pillar design – can we? In: Proceedings of the coal 2005: coal operator’s conference. University of Wollongong, Brisbane, pp 59–62

CMR (2017). Coal mines regulations 2017. Retrieved 22 June 2017 from: https://www.dgms.net/Coal%20Mines%20Regulation%202017.pdf

Mark C (1987) Analysis of longwall pillar stability. Ph.D. Dissertation, The Pennsylvania State University

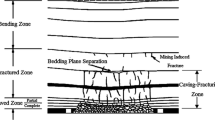

Majdi A, Hassani FP, Nasiri MY (2012) Prediction of the height of destressed zone above the mined panel roof in longwall coal mining. Int J Coal Geol 98:62–72

Singh GSP, Singh UK (2009) A numerical modeling approach for assessment of progressive caving of strata and performance of hydraulic powered support in longwall workings. Comput Geotech 36(7):1142–1156

Peng SS (2006) Longwall mining, 2nd edn. Society for Mining, Metallurgy, and Exploration, Inc. (SME), Englewood

Palchik V (2002) Influence of physical characteristics of weak rock mass on height of caved zone over abandoned subsurface coal mines. Environ Geol 42(1):92–101

Shabanimashcool M, Li CC (2012) Numerical modelling of longwall mining and stability analysis of the gates in a coal mine. Int J Rock Mech Min Sci 51:24–34

Chekan G, Listak J (1993) Design practices for multiple-seam longwall mines. Information Circular 9360, U. S. Bureau of Mines, Pittsburgh, PA

Karmis M, Triplett T, Haycocks C, Goodman G (1983) Mining subsidence and its prediction in an Appalachian coalfield. Rock Mechanics: Theory, Experiment, Practice. In: Proc. 24th US Symp. Rock Mechanics, 20–23 June 1983, Texas A&M University. Balkema, Rotterdam, pp 665–675.

Peng SS, Chiang HS (1984) Longwall mining. Wiley, New York

Styler N (1984) Prediction of inter-strata movements above longwall faces. In: Proceedings of the 25th U.S. symposium on rock mechanics (USRMS), June 25–27, Evanston, IL, Paper No. 84–0651. 8 pages.

Palchik V (1989) Analytical and empirical prognosis of rock foliation in rock masses. J Coal Ukraine 7:45–46

Karacan CO (2010) Prediction of porosity and permeability of caved zone in longwall goafs. Transp Porous Media 82:413–439

Zhou Y (1991) Evaluating the impact of multi-seam mining on recoverable coal reserves in an adjacent seam. Virginia Division of Mineral Resources, Commonwealth of Virginia, Department of Mines, Minerals and Energy, Publication, 104

Zhang D, Fan G, Ma L, Wang X (2011) Aquifer protection during longwall mining of shallow coal seams: a case study in the Shendong Coalfield of China. Int J Coal Geol 86(2–3):190–196

Singh GSP, Singh UK (2011) Assessment of goaf characteristics and compaction in longwall caving. Min Technol-Trans Inst Min Metall Sect A 120(4):222–232

Yadav A, Behera B, Sahoo SK et al (2020) An approach for numerical modeling of gob compaction process in longwall mining. Min Metall Explor 37:631–649. https://doi.org/10.1007/s42461-020-00182-0

Itasca (2015) FLAC-3D Version 5.01 User’s Manual. Itasca Consulting Group Inc., Minneapolis, USA

Pappas DM and Mark C (1993). Behaviour of simulated longwall gob material, RI 9458, United States Department of Interior, Bureau of Mines, Pittsburgh, PA, USA

Salamon MGD (1990) Mechanism of caving in longwall coal mining. In: Hustrulid WA, Johnson G A (ed) Proceedings of 31st US Symposium: rock mechanics contributions and challenges, Rotterdam, Balkema, pp 161–168

Alejano LR, Ramı́rez-Oyanguren P, Taboada J (1999) FDM predictive methodology for subsidence due to flat and inclined coal seam mining. Int J Rock Mech Min Sci 36(4):475–491. https://doi.org/10.1016/S0148-9062(99)00022-4

Tajduś K (2009) New method for determining the elastic parameters of rock mass layers in the region of underground mining influence. Int J Rock Mech Min Sci 46(8):1296–1305. https://doi.org/10.1016/j.ijrmms.2009.04.006

Yao XL, Reddish DJ, Whittaker BN (1993) Non-linear finite element analysis of surface subsidence arising from inclined seam extraction. Int J Rock Mech Min Sci Geomech Abstr 30(4):431–441

Tulu IB, Heasley KA (2012) Investigating abutment load. In: Proceedings of the 31st international conference on ground control in mining, Morgantown, WV, pp 28–37

Hill D, Stone R, Suchowerska A, Trueman R (2015) Pillar abutment loading—new concepts for coal mining industry. In: Proceedings of the 15th coal operators’ conference, University of Wollongong, The Australasian Institute of Mining and Metallurgy and Mine Managers Association of Australia, pp 204–211

Das SK (2000) Observations and classification of roof strata behavior over longwall coal mining panels in India. Int J Rock Mech Min Sci 37:585–597

Tuncay D, Tulu IB, Klemetti T (2021) Re-analysis of abutment angle method for moderate and deep cover retreat room and pillar mines and investigation of loading mechanics using finite volume modeling. Rock Mech Rock Eng 54:3447–3468. https://doi.org/10.1007/s00603-020-02336-4

Yadav A (2022) Design of chain pillars for deep longwall workings in Indian geo-mining conditions. Ph.D. Thesis, Department of Mining Engineering, Indian Institute of Technology (Banaras Hindu University), Varanasi

Obert L, Duvall WI (1967) Rock mechanics and the design of structures in rock. Wiley, New York

Sheorey PR (1994) A theory for in situ stresses in isotropic and transversely isotropic rock. Int J Rock Mech Min Sci Geomech Abstr 31:23–34

Hoek E, Carranza-Torres CT, Corkum B (2002) Hoek-Brown failure criterion-2002 edition. Proceed Fifth North Am Rock Mech Symp Toronto, Canada 1:267–273

Sheorey PR (1997) Empirical rock failure criteria. Balkema, Rotterdam

Mohammad N, Reddish DJ, Stace LR (1997) The relation between in situ and laboratory rock properties used in numerical modelling. Int J Rock Mech Min Sci 34:289–297

Cai MF, He MC, Liu DY (2013) Rock mechanics and engineering, 2nd edn. Science Press, Beijing

Wilson AH (1980) The stability of underground workings in the soft rocks of the coal measures. Ph.D. thesis, University of Nottingham, UK

Singh GSP, Singh UK (2004) Cavability assessment model for longwall workings in India. In: Proceedings of the third Asian rock mechanics symposium, Kyoto, 295–300

Behera B, Yadav A, Singh GSP, Sharma SK (2020) A numerical modeling approach for evaluation of spalling associated face instability in longwall workings under massive sandstone roof. Eng Fail Anal 117:1–29

Behera B, Yadav A, Singh GSP, Sharma SK (2020) Numerical modeling study of the geomechanical response of strata in longwall operations with particular reference to Indian geo-mining conditions. Rock Mech Rock Eng 53:1827–1856

Sahoo SK, Singh GSP, Sharma SK et al (2020) (2020) Numerical modeling study of the influence of softcover on strata and support behavior in a bord and pillar depillaring working. Min Metall Explor 37:1151–1168. https://doi.org/10.1007/s42461-020-00246-1

Yadav A, Behera B, Sahoo SK et al (2020) Numerical analysis of the gob stress distribution using a modified elastic model as the gob constitutive model. J Inst Eng India Ser D 101:127–139. https://doi.org/10.1007/s40033-020-00214-5

Sheorey PR, Mohan GM, Sinha A (2001) Influence of elastic constants on the horizontal in situ stress. Int J Rock Mech Min Sci Geomech Abstr 38:1211–1216

Leroueil S, Tavenas F (1981). Pitfalls of back analysis. XICSMFE, Stockholm, Sweden, p. 185–90.

Oreste P (2005) Back-analysis techniques for the improvement of the understanding of rock in underground constructions. Tunn Undergr Space Technol 20:7–21. https://doi.org/10.1016/J.TUST.2004.04.002

Sainsbury BL, Sainsbury DP (2017) Practical use of the ubiquitous-joint constitutive model for the simulation of anisotropic rock masses. Rock Mech Rock Eng 50:1507–1528

Saxena NC (2003) Subsidence management handbook. Scientific publisher (India), Jodhpur, India

Cai M, Kaiser PK, Tasaka Y, Minami M (2007) Determination of residual strength parameters of jointed rock masses using the GSI system. Int J Rock Mech Min Sci 44(2):247–265

Singh B (1973) Continuum characterization of jointed rock masses: part I - the constitutive equations. Int J Rock Mech Min Sci Geomech Abstr 10(4):311–335

Wilson AH (1983) The stability of underground workings in the soft rocks of the coal measures. Int J Min Eng 1:91–187

Smart BGD, Haley SM (1987) Further development of the roof strata tilt concept for pack design and the estimation of stress development in a caved waste. Min Sci Technol 5:121–130

Wilson AH (1981). Stress, stability in coal ribsides and pillars. In: Proceedings of the first conference on ground control in mining, Morgantown, pp l–12

King HJ, Whittaker BN (1971) A review of current knowledge on roadway behaviour, especially the problems on which further information is required. In: Proceedings of the symposium on strata control in roadways. London: Inst. Min. Met., pp 73–87

Choi DS, McCain DL (1980) Design of longwall systems. Trans Soc Min Eng AIME 258:1761–1764

Sheorey PR (1993) Design of coal pillar arrays and chain pillars. In: Hudson JA (ed) Comprehensive rock engineering, vol 2. Pergamon, Oxford, pp 631–670. https://doi.org/10.1016/B978-0-08-040615-2.50030-7

Larson MK, Lawson HE, Tesarik DR (2015) Load transfer distance measurements at two mines in the Western US. In: Proceedings of the 34th international conference on ground control in mining, Morgantown, West Virginia, pp 54–64

Singh AK, Singh R, Maiti J, Kumar R, Mandal PK (2011) Assessment of mining induced stress development over coal pillars during depillaring. Int J Rock Mech Min Sci 48:805–818

Das AJ, Mandal PK, Paul PS et al (2019) Assessment of the strength of inclined coal pillars through numerical modelling based on the ubiquitous joint model. Rock Mech Rock Eng 52:3691–3717

Hsiung SM, Peng SS (1985) Chain pillar design for US longwall panels. Min Sci Technol 2(4):279–305

Rezaei M, Hossaini MF, Majdi A (2015) Development of a time-dependent energy model to calculate the mining-induced stress over gates and pillars. J Rock Mech Geotech Eng 7(3):306–317

Frith R, Reed G (2019) Limitations and potential design risks when applying empirically derived coal pillar strength equations to real-life mine stability problems. Int J Min Sci Technol 29(1):17–25

Niu WJ, Feng ZK, Feng BF et al (2019) Comparison of multiple linear regression, artificial neural network, extreme learning machine, and support vector machine in deriving operation rule of hydropower reservoir. Water 11(1):88. https://doi.org/10.3390/w11010088

Russell S, Norvig P (2016) Artificial intelligence: a modern approach. Prentice Hall, Upper Saddle River, New Jersey

Mercer J (1909) Functions of positive and negative type, and their connection with the theory of integral equations. Philos. Trans. R. Soc A Math Phys Eng Sci 209:415–446. https://doi.org/10.1098/rsta.1909.0016

Gale W.J (1998) Coal pillar design issues in longwall mining. In: Aziz N, editor. Proceedings of coal operators’ conference, Wollongong, Australia, University of Wollongong & the Australasian Institute of Mining and Metallurgy, p. 133–46.

Das MN (1986) Influence of width/height ratio on post-failure behaviour of coal. Int J Min Geol Eng 4:79–87. https://doi.org/10.1007/BF01553759

Acknowledgements

The authors are grateful to the Head, Department of Mining Engineering, Indian Institute of Technology (BHU) Varanasi, for backing with excellent laboratory facilities for the numerical modeling study. The authors would like to express their gratitude to the management of BCCL, ECL, and SCCL mines for their assistance and for allowing for field measurements and observations used in this work. The views and findings expressed in this paper are the opinion of the authors and not necessarily of the organization they serve.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yadav, A., Singh, G.S.P. & Behera, B. A Machine Learning Model for Evaluation of Chain Pillar Stability in Deep Longwall Workings in India. Mining, Metallurgy & Exploration 40, 2119–2137 (2023). https://doi.org/10.1007/s42461-023-00859-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42461-023-00859-2