Abstract

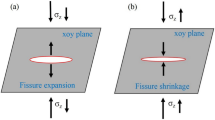

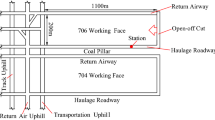

The stability and integrity of protective coal pillars between the longwall working face and development roadways are greatly affected by the mining activities such as the development face advancing or retreat mining. Due to underground strata pressure, the coal pillar cracks could be further developed and then the air leakage passages (mainly cracks) could be produced greatly. The air circulation caused by the atmospheric pressure difference between the two sides of the coal pillar may also provide suitable conditions for the possible spontaneous combustion of the residual coal in the mine gob. In this paper, a typical the protective coal pillar in a Chinese coal mine is studied. The deformation and stress of coal pillars during the mining process of longwall working face are simulated by using FLAC3D. The displacement and strain of coal pillars are analyzed. Two indexes, the linear fracture rate (LFR) and area fracture rate (AFR), are introduced to characterize the development of internal cracks’ development within coal pillars. By using field measurement, the air leakage intensity distribution due to coal pillar cracks is obtained; the equation of air leakage resistance of coal pillar under the influence of mining is derived. Then, the possible location of large air leakage of coal pillar is determined, which can be used as guidelines to study the possibilities of coal spontaneous combustions happening in pillar or mine gob. The research results help to control such potential hazards in advance.

Similar content being viewed by others

References

Wei Lu, Cao Y-J, Tien JC (2017) Method for prevention and control of spontaneous combustion of coal seam and its application in mining field. Int J Min Sci Technol 27(5):839–846

Huang Z, Ma Z, Song S (2018) Study on the influence of periodic weighting on the spontaneous combustion “three-zone” in a gob. J Loss Prev Process Ind 55:480–491

Lei C, Deng J, Cao K (2018) A random forest approach for predicting coal spontaneous combustion. Fuel 223:63–73

Yang Tai, Bin Yu, Binwei Xia (2020) Research on stress release for the gob-side roadway using the roof-cutting technology with a chainsaw arm. Royal Soc Open Sci 7(3)

Wen-Da Wu, Bai J-B, Wang X-Y (2019) Numerical Study of failure mechanisms and control techniques for a gob-side yield pillar in the Sijiazhuang Coal Mine. China Rock Mech Rock Eng 52(4):1231–1245

Han C, Zhang K, Xiaobing Xu (2007) Study on the damage law and reasonable size of small coal pillars in the zone. J Min Saf Eng 03:370–373

Kong D, Wang Z, Li X, Wang Y, WangLi C (2014) Study on the reasonable retention of coal pillars in the section of large mining height comprehensive release face. Geotechnics 35(S2):460–466

Xueyi Yu, Wang Qi, Zhao B (2015) Study on the reasonable width of coal pillar between lanes in large mining height double lane arrangement working face. J Rock Mech Engineering 34(S1):3328–3336

Jaiswal A, Shrivastva BK (2009) Numerical simulation of coal pillar strength. Int J Rock Mech Min Sci 46(4):779–788

Yan S, Bo J, Bian Ka (2012) Study on the reasonable width of coal pillar for reuse back mining roadway protection. Geotech Mech 33(10):3081–3086

Zhang G, Liang S, Tan Y (2018) Numerical modeling for longwall pillar design: a case study from a typical longwall panel in China. J Geophys Eng 15(1):121–134

Zhang GC, Wen ZJ, Liang SJ (2020) Ground response of a gob-side entry in a longwall panel extracting 17 m-thick coal seam: a case study. Rock Mech Rock Eng 53(2):497–516

Li W, Bai J, Peng S (2015) Numerical modeling for yield pillar design: a case study. Rock Mech Rock Eng 48(1):305–318

Li W, Bai J, Cheng J (2015) Determination of coal–rock interface strength by laboratory direct shear tests under constant normal load. Int J Rock Mech Min Sci 77:60–67

Wang J (2017) Study on the division of “three zones” of spontaneous combustion in the mining area of shallow buried deep isolated working face. Coal Sci Technol 45(S1):110–113

Jiang F, Chen Y, Li D (2019) Exploration of the mechanism of initial mining impulsive mechanics in isolated island filled working face. J Coal 44(01):151–159

Guo Weijia, Wang Hailong, Chen Shaojie (2016) Coal pillar safety and surface deformation characteristics of wide strip pillar mining in deep mine. Arab J Geosci 9(2)

Wang D, Yang S, Liu S (2011) Influence of air leakage from mining areas on the risk of coal spontaneous combustion. Coal Mine Saf 42(05):129–132

Cheng J, Qi C, Li S (2019) Modelling mine gas explosive pattern in underground mine gob and overlying strata. Int J Oil, Gas Coal Technol 22(4):554–577

Zhang F, He Z, Huang D (2000) Numerical simulation technique of tectonic stress field for predicting fracture development zone. Pet Geol Exp 02:154–163

Li S, Jingcai Xu (2001) Electro hydraulic servo experimental study of permeability characteristics of soft coal samples. J Geotech Eng 23(1):68–70

Guo X, Xu J, Hui S (2001) Study on the air leakage pattern of coal body in roadway. J Xi’an Jiaotong Univ 03:239–243

Zongxiang Li, Sun Guangyi Sun, Jibo Wang (2001) Numerical simulation of air leakage and oxygen consumption process in coal pillar of header working face. Mech Pract (04): 15–18

Kuai D, Shi B, Zhou D (2011) Study on the spontaneous combustion law of coal along the empty dugway in Wugou mine and numerical simulation. Coal Sci Technol 39(10):65–68

Lu Yi, Qin Botao (2015) Identification and control of spontaneous combustion of coal pillars: a case study in the Qianyingzi Mine, China. Nat Hazards 75(3)

Zhang Xi, Dai G, Nie NS (2016) Application of energy level determination method and SF_6 tracer technology to detect the air leakage status of small coal pillars in isolated working face. Min Saf Environ Prot 43(05):41–44

Sun Z (2019) Experimental study on air leakage channel of fully mechanized caving face in extra-thick coal seam based on tracer gas technology. Mine Saf 50(11):14–17

Chang J (2017) Research on the prevention and control technology of harmful gas in the underground adjacent mining area. Shanxi Coking Coal Sci Technol 41(02):15–18

Wang D (2016) Analysis of the effect of air distribution on air leakage and spontaneous combustion in the mining area at the back mining face. Coal Sci Technol 44(12):96–101

Zhu S, Cheng J, Song W (2020). Using seasonal temperature difference in underground surrounding rocks to cooling ventilation airflow: A conceptual model and simulation study. Energy Science and Engineering.11

Zhu S, Cheng J, Wang Z (2020) Physical simulation experiment of factors affecting temperature field of heat adjustment circle in rock surrounding mine roadway. Energy sources. Part A, Recovery, utilization, and environmental effects 1–18

Zhu S, Wu S, Cheng J (2015) An underground air-route temperature prediction model for ultra-deep coal mines. Minerals-Basel 5:527-545

Cheng J, Wang Z, Li S (2020) Subsurface strata failure and movement based for improving gas emission control: model development and application. Energy Sci Eng 8(9):3285–3302

Qin R, Yang Ke, Liu S (2018) Study on permeability analysis and fire protection effect of zone coal pillar. J Min Saf Eng 35(03):629–634

Liu Y, Wen H, Guo J (2020) Coal spontaneous combustion and N2 suppression in triple gobs: a numerical simulation and experimental study. Fuel 271:117625

Guoguang Wu, Zhang Y, Wang G (2009) Experimental study on air seepage in loose coal. Coal Sci Technol 37(08):42–45

Meng Z, Wang B, Xie X (2012) Mechanical properties of coal rock deformation and its control on permeability. J Coal 37(08):1342–1347

L Chen (2016) Study on deformation damage and permeability evolution of coal body in front of working face and its application. China Univ Min Technol (Beijing)

Cheng J, Luo W, Zhao Z (2021) Controlling coal spontaneous combustion fire in longwall gob using comprehensive methods—a case study. Min Metall Explor 38:1801–16

Cheng J, Zheng X, Lei Y (2021) A compound binder of coal dust wetting and suppression for coal pile. Process Saf Environ 147:92-102

Cheng J, Wu Y, Dong Z (2021) A novel composite inorganic retarding gel for preventing coal spontaneous combustion. Case Stud Therm Eng 28:101648

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Cheng, J., Wu, Y., Wang, Y. et al. Characterizing Coal Pillar Deformation and Air Leakage Pattern During Longwall Face Mining. Mining, Metallurgy & Exploration 39, 1487–1500 (2022). https://doi.org/10.1007/s42461-022-00632-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42461-022-00632-x