Abstract

A series of naturally occurring diatomaceous earth samples from Ouled Djilali, Mostaganem (Lower Chelif basin, Algeria northwestern), were investigated, which are characterized by the expansion and evolution during the Messinian age. Four varieties of diatomite were distinguished, characterized, and successfully used to adsorb methylene blue dye in aqueous medium. Several properties and characteristics of diatomite have been outlined using analytical methods such as X-ray fluorescence spectrometry, X-ray diffraction (XRD), Fourier transform infrared spectroscopy (FTIR), N2 adsorption–desorption (BET), and scanning electron microscopy (SEM), as well as other complementary analysis tests. Results showed that silica and calcium carbonates were the main constituents of the diatomite samples (ranging between 32.8 and 61.5% for SiO2; and 13.8–25.9% for CaO), with a slight difference in chemical composition between selected samples. Typical for all diatomite samples, the XRD analysis suggests a high mass quantity of amorphous phase (Opal); high content of crystal phase was also registered. FTIR allowed determining the basic characteristic silica bands regarding diatomite samples. While the BET and SEM investigations revealed that the studied diatomite material has a highly porous structure and was very rich in diatoms. The maximum adsorption capacity of methylene blue that was calculated from the Langmuir isotherm model was 116.59 mg/g (for Ouled Djilali: OD05 sample) at 25 °C and pH 7.0. The diatomite from Mostaganemian (Ouled Djilali) deposit may find promising applications as low-cost adsorbent for dyes removal from water.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Nowadays, water pollution has given rise to serious environmental problems [1]. Among the different contaminants affecting the aquatic ecosystems, dyes belong to one of the larger and most important groups generally discharged in wastewaters from industrial and agricultural sectors, which present considerable toxicity to human beings and living organisms [2]. Hence, the depollution of water from dyes has become of high priority concern. In response, several methods have been studied to assess their applicability and removal efficiency. Among these methods, adsorption especially onto activated carbon has been considered as the most effective and widely used one [3,4,5,6,7]. Nevertheless, due to the expensive price and difficult regeneration process of activated carbons, worldwide attention has been focused on finding out alternative adsorbents such as bentonite [8], waste sludge [9], maine algae (Ulva lactuca and Sargassum) [10], bagasse fly ash [11], and almond peel [12].

Diatomite, otherwise known as kieselguhr, diatomaceous earth (DE), or “Tripoli” of Sicily, is provided from the Messinian diatomitic formation [13]. It represents one of the most significant sedimentary events of the Neogene in the Mediterranean [14]. Diatomite is a silica rock consisting essentially of fossilized skeletal remains of single-celled aquatic algae called diatoms. It is characterized by the presence of a rigid skeleton made of hydrated silica (opal), called frustule [15], with a number of impurities such as inorganic and organic matters, and even clay minerals [16]. There are nearly 10,000 species of diatoms forming vast deposits of sedimentation in various parts of the earth. Due to its unique advantages and desirable properties, high porosity and small particle size, that give to the diatomite low density, high permeability, high adsorption capacity and specific surface area, and low thermal conductivity [17], the diatomite provides a wide variety of uses in sustainable development and environment such as purification of drinking water, filtration, insulation, adsorption, manufacture of antibiotics, catalysis, and as an additive in cement [18,19,20].

Algeria is considered to have rich area of natural DE deposits situated in a wide basin called Lower Chelif Basin. These deposits are still little exploited, since the most important exploitation is mainly concentrated on the site of Sig in western Algeria. The present contribution aims to first highlight the physicochemical, mineralogical and textural properties of a natural diatomite from the Mostaganemian deposit (Ouled Djilali) using various methods: X-ray fluorescence spectrometry (XRF), X-ray diffraction (XRD), scanning electron microscopy (SEM), Fourier transform infrared spectroscopy (FTIR), and N2-BET (Brunauer, Emmett, and Teller) adsorption–desorption technique. Adsorption tests were thereafter conducted on the as-studied material to explore on the removal process efficiency of a cationic dye (methylene blue) from aqueous media. Different isotherm models were examined for analyzing the equilibrium data and for a better understanding of the adsorption process.

2 Location and reserves of Lower Chelif Basin diatomite deposits

2.1 Lower Chelif Basin

The current area of interest occurs along the northeastern border of the Lower Chelif Basin; in the northwestern region of Algeria is part of the Lower Chelif Basin (Fig. 1). The basin is regarded as the largest intramountainous basin in the north of Algeria [21], in the same way as the large marginal Neogene basins of the Mediterranean [22]. Geomorphologically, it is a long depression (ENE/WSW direction) over about 350 km and 35 km wide. It is limited to the north by the Oranean coast (Djebel Murdjadjo, Arzew mountains) and Dahra mountains. Tessala, Beni Chougrane, Ouled Ali, and Ouarsenis Mounts represent its borders to the South.

2.2 Ouled Djilali sampling area

The selected diatomite sampling area is deposited in Ouled Djilali location southeastern part of Daira of Sidi Ali, throughout a distance of 11.92 km (N: 36°, 02′, and 36.2″. E: 000°, 31′, 44.4″). It is bounded on the north by Douar Gouassmia, Jebel Chaif Dahmane, and Douar El B'Hara, in the south by Douar Ouled Fellouh, and Douar Ouled Mokhtar, in the east by Douar Haddou, and in the west by Douar Soualmia and Douar Torche (Fig. 2).

3 Materials and methods

3.1 Preparation of samples

Four varieties of natural diatomite samples taken from each layer from the deposit of Ouled Djilali have been distinguished on the basis of the colors variability of the diatomite rocks, their structural and textural features, and their fracturing effects (Table 1; Fig. 3). The samples were denoted with the letters OD (according to the site name: Ouled Djilali), with additional numbers that correspond to the different layers.

The OD samples employed in this study were first dried at a temperature of 110 °C overnight. After being crushed in HERZOG grinder in a tungsten bowl (3 min at 700 rpm), the samples were sieved to obtain a size fraction of 63 μm (no refusal must remain) for characterization with X-ray diffraction and X-ray fluorescence methods, while a size fractions between 100 and 200 μm, served to allow easier analysis.

3.2 Characterization

The chemical compositions of the raw material were determined by X-ray fluorescence spectroscopy (XRF) (S8 TIGER de Bruker). X-ray powder diffraction data (XRD) were acquired with a BrukerD4 ENDEAVOR analyzer operating with a CuKα radiation source filtered with a graphic monochromator λ = 1.5406 Å. The surface morphology of the raw samples was illustrated by scanning electron microscopy (SEM), using « Philips XL 30 model ESEM-FEG» operating at 8 kV. The Fourier transform infrared (FTIR) spectra were obtained from a «Perkin Elmer» spectrometer connected to a computer with the scanning range from 400 to 4000 cm−1.

The characterization of the specific surface area and Brunauer, Emmett and Teller (BET) texture parameters of Ouled Djilali diatomite was carried out by low-temperature adsorption of nitrogen (at 77.3 K) using a Micromeritics ASAP-2420 surface area analyzer. The degassing of the diatomite samples was performed for 12 h at a heating temperature of 140 °C. The nitrogen adsorption–desorption isotherms were analyzed to evaluate the required parameters; the specific surface areas (SBET) were determined on the basis of the BET equation. The total pore volume (Vt) was estimated in accordance with the rule of Gurvich at a relative pressure of 0.977. The volume of the mesopores (Vmes) was evaluated from the difference between the total pore volume (Vt) and that of the micropores (Vmic).

3.3 Physicochemical properties

In this part, the diatomite samples were first crushed and sieved at 200 μm. Several physicochemical parameters were studied. For pH determination, diatomite suspensions (2 g of sample in 100 ml of ultrapure water) were prepared in a beaker of 200 ml volume. The mixtures were stirred for 6 h, and the pH of the aqueous solutions was measured immediately on a pH meter model Hi 208, Hanna instruments. For the chloride ion percentage, diatomite suspensions (1 g of diatomite in 75 ml of ultrapure water) were boiled until a volume of 50 ml. After cooling, the content was filtered, and the chlorides percentage was estimated by MOHR’s method (argentometric method) using silver nitrate as titrant and potassium chromate as indicator solution. The apparent density was expressed by means of the ratio between the mass of diatomite (g) and the occupied volume (cm3). The percentage of humidity was estimated by lyophilization process of the samples for 48 h.

Regarding the water and oil adsorption rate, the determination of their values was obtained by calculation of the ratio between the maximum amount of oil (sunflower oil), or water adsorbed on the diatomite and its mass.

3.4 Batch adsorption experiment

The process of methylene blue (MB) dye removal was conducted under common batch adsorption experiments. Approximately, 0.1 g of the natural Ouled Djilali diatomite was put in contact with 50 mL of MB dye solution at different desired concentrations (10, 20, 30, 40, 50, 80, 120, 160, and 200 mg/L). Each adsorbent–adsorbate mixture was mechanically stirred at 125 rpm at ambient temperature (25 °C) until it reached the adsorption equilibrium (according to preliminary results, the contact time was fixed to 60 min). Following this, a 0.45 μm membrane filter was used to separate each dye solution from the corresponding dye–diatomite interaction system. The residual concentration in the MB supernatant was analyzed using a UV–Vis spectrophotometer at the wavelength λmax = 665 nm. All adsorption tests were performed at pH = 7.0. The solutions involved were diluted to proper concentrations before making measurements. The quantity of adsorbed MB at equilibrium (qe, mg/g) was calculated as follows:

where C0 and Ce (mg/L) are the concentration of MB ions at the beginning and the equilibrium concentration, respectively. V(L) is the volume of MB solution, whereas m (g) represents the mass of diatomite adsorbent.

Regarding the modeling of the adsorption isotherm, Langmuir, Freundlich, Sips and Temkin isotherm models are well applied to describe the adsorption process. More detailed information and derivation of such models are summarized in Table 2.

4 Results and discussion

4.1 Macroscopic properties

The whitish raw OD diatomite material has a laminated structure with fine grains, releasing easily in hand. It can be scratched with no significant resistance. Whereas the darker samples are massive, indurate, and highly resistant, this required the use of a big grinding material (HERZOG grinder). They can be also laminated and easily crumbled in hand. The raw material is a lightweight sedimentary rock having strong water absorbability, which emphasizes a high porosity. Because the sampling was done during a rainfall period, the samples contained a large volume of water; significant time was thus required to release absorbed water from samples.

4.2 Geochemical composition by XRF

The geochemical composition of the natural OD diatomite samples was obtained by the X-ray fluorescence spectroscopy, expressed by means of weight percentages, as reported in Table 3. Loss-on-ignition represents the percentage of material removed during the air calcination of a sample at 9500C. As can be seen, the XRF results depict that the main components of the raw OD diatomite consist of silica (SiO2), with significant amounts of calcium (Ca) being mainly in the form of carbonate, whereas other mineral components, existing typically as impurities in minor amounts, contribute to the rest of the diatomite composition. Although the raw diatomite samples are located in the same deposit, the XRF results show significant differences in the SiO2 and CaO percentages between samples, in contrary of the other admixtures contents. The whitish raw materials are composed of 49.5–61.5% SiO2, except for the indurate marl-diatomite (sample OD5) that contains only 32.8% SiO2. The CaO content varies from 13.8 to 25.9% which generally does not depend on the diatomite variety distinguished on the base of the variability of rock colors, and textural features, as it is with the SiO2 content. The two OD04 and OD05 samples have the most elevated value of loss on ignition (LOI). They represent the darker colored diatomite varieties, and both their features (LOI and color) depend probably upon the presence of high amount of organic substances. Indeed, we notice in Table 3 that the rate in LOI is correlated with the rate in CaO (as aforementioned, Ca exists in the natural diatomaceous earth product as calcium carbonate (CaCO3) which decomposes into CaO and CO2 above 800 °C). The presence of high content of SiO2 in both OD03 and OD04 diatomite samples make them interesting materials for adsorption in various.

4.3 XRD analysis

XRD analysis was performed on OD natural diatomite samples for mineralogical and chemical identifications, and the corresponding diagrams are shown in Fig. 4. Additionally, the X-ray detailed diffraction peaks information is listed in Table 4. Typical for all samples and more specifically for OD04 and OD08 materials, the specific shape of the obtained diffractograms and the high intensity of the background suggest a high mass quantity of SiO2 present as amorphous opal A phase whose reflections dominate in the corresponding XRD patterns between 19° and 32° (2 Theta), this finding being in accordance with the XRF results. A high content of crystalline phase and the most important reflections corresponding to calcite, dolomite, illite, and kaolinite phases are also observed (Table 4) revealing raw materials with irregular structures. The difference in impurities contents such as albite, chlorite, and pyrite also points to the different sedimentary environments of the diatomite samples.

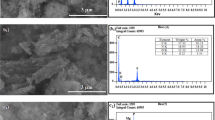

4.4 SEM analysis

An insight was provided about the morphology and microstructure of the obtained OD diatomite samples by means of scanning electron microscopy (SEM) characterization. The microscopic pictures revealed the existence of intact diatomite skeletons whose framework structure is composed of diatomite shells represented by various diatom morphological types. The SEM observation clearly confirmed the presence of a well-defined and mostly preserved porous structure, which is an important parameter and key medium for any adsorption process, the porous shells consisting mainly of SiO2 groups [27, 28]. It can be also inferred that the diatomite samples are rich in two classes of diatoms: centric and pennate, and large void volumes (Fig. 5a–c). Each frustule of diatom contains areolae due to its high porosity, and the size and disposition of these areolae vary with the species nature. The high porosity of the studied diatomite material was one of the main reasons for selecting it as a potential sorbent.

4.5 Fourier transform infrared spectroscopy (FTIR)

FTIR technique was used to confirm the presence of the functional groups of the diatomite before their use as dye adsorbent. The FTIR analyses spectra are gathered in Fig. 6. There are no significant differences between the positions of the basic characteristic bands. Based upon reviewing the analysis data, the characteristic peaks of diatomite are clearly detected at 3435, 1426, 1070, 800 and 454 cm−1. The band at 3435 cm−1 is due to stretching vibration of the hydroxyl groups in physically adsorbed water molecules (silanol group SiO–H) [29,30,31], and this group is responsible for the adsorption process [32]. The carbonates IR band appears at 1426 cm−1 [33]. The rocking and asymmetric stretching vibration band of siloxane (–Si–O–Si–) in diatomite appears at wave numbers 1070 cm−1 [30, 33, 34]. Other bands at 800 and 454 cm−1 are also characteristic of silica; the first one may be related to the stretching vibration of Al–O–Si [35], but it can be also attributed to O–H deformation or the free silica and/or symmetric stretching in SiO–H [31, 36, 37], whereas the second band is assigned to the bending vibrations of Si–O–Si [36].

Considering these functional groups on the surface of the diatomite witch facilitate the electrostatic attraction with the cationic MB, it is proposed that hydrogen bond would be formed between the raw diatomite and MB and contributes significantly to the high adsorption of dye [27].

4.6 N2-sorption study

The N2 adsorption–desorption isotherms of the studied OD diatomite at liquid nitrogen temperature are provided in Fig. 7. BET and external surface areas as well as pore volumes of the diatomite samples calculated on the basis of these isotherms are summarized in Table 5. As shown in Fig. 7, all the raw OD diatomite samples present the same Type IV nitrogen adsorption–desorption isotherm shape, exhibiting a characteristic feature as type II isotherms in addition to a steep uptake at P/Po of above 0.8 which can be assigned to the existence of macropores in the raw material. By comparing the different samples of OD diatomite, it is obvious that the OD05 has the larger BET surface area value (69.95 m2 g−1), which was expected to enhance the adsorption performance [38]. Besides, the Ouled Djilali diatomite (47.91–69.95m2/g) exhibits a higher SBET surface area value when compared to other diatomite materials from the literature, as shown in Table 6, and can be considered as a potential adsorbent for pollutants removal from wastewater, and environmental remediation.

4.7 Physicochemical tests

The following physical properties of OD diatomite samples have been determined in terms of apparent density (da); humidity (H), water and oil absorption (Ads H2O, Ads Oils), and chlorides percentage. The corresponding results are summarized in Table 7.

Based on the above results, the bulk density values range from 0.42 to 0.64 g/cm3. Water absorption values are between 15.89 and 45.45%, and the oils absorption values vary from 62.77 to 98.13%. The OD04 sample has the highest average water absorption, and the lowest bulk density (light-colored diatomite). However, the darkest-colored diatomite (OD05, OD08) has the lowest water absorption and highest bulk density. The two parameters show reversely proportional dependence [42]. In contrast, the values of oil absorption and the bulk density show proportional dependence.

The pH of the diatomite aqueous suspensions lies between 7.82 and 8.14, which may be related to the presence of alkaline oxides in the diatomite samples providing a neutral or slightly alkaline reaction of their aqueous suspensions [39].

4.8 Discoloration capacity

After examining the textural, structural and physicochemical properties of the OD diatomite powders, which significantly affect their behavior in environmental applications, these samples were subjected to a discoloration study in order to evaluate their adsorption performance by means of methylene blue (MB) dye ions recovery tests from aqueous solution, and to explore the adsorbent–adsorbate interactions. Adsorption isotherm (Fig. 8) was obtained by varying the MB initial concentration at a fixed temperature (25 °C), with maintaining a constant dose of adsorbent, the solid/liquid ratio kept at 2.0 g/L. The adsorption isotherm was categorized as an L-shape according to the Giles et al. classification [44] which suggests that the studied OD diatomite samples exhibit a high adsorption affinity toward the MB dye in solution without major competition from water molecules for the solid active sites [45]. The nonlinear forms of Langmuir, Freundlich, Sips and Temkin models were used to more interpret the obtained data and to make it easier to understand the adsorption mechanism (Fig. 8a–d). According to the isotherm constants and parameters presented in Table 8, it can be noticed that the Langmuir and Sips equations are more suitable than the Freundlich and Temkin equations for the adsorption system studied in this work. The finding regarding the Langmuir fitting can be attributed to the homogenous distribution of active sites on the diatomite surface [46]. This suggests that the adsorption process of MB dye onto diatomite surfaces is favorable and monolayer in nature over the whole range of tested concentrations, induced by homogeneous solid surface energy along with no interaction between adsorbed species.

From the Langmuir model, a reasonably good maximum adsorption capacity of the studied OD diatomite samples was obtained ranging between 79.66 and 116.59 mg/g. As expected, OD05 sample exhibited the higher Q°max (116.59 mg/g) value than the other Ouled Djilali diatomite adsorbents. Obviously, adsorption efficiency is greatly related to SBET and to the total volume registered values (Table 5), whereas the enhancement of these two parameters contributes to the enhancement of the adsorption capacity of the MB dye [28].

As diatomite is a natural material, it must be compared with other natural materials such as zeolite, phosphor, gypsum, clay, and other siliceous adsorbents. Table 9 shows the comparison of the adsorption capacities of some adsorbents. It is clear from the comparison that the OD05 (116.59 mg/g) possesses a higher adsorption capacity than other reported adsorbents, after the Jordanian diatomite (198 mg/g). This is probably due to the fact that the diatomite surface can interact with MB in different ways; (1) electrostatic attraction, (2) chemical adsorption via conjugation, hydrogen bonding, and pore filling mechanism [27]. It seems that the amount of MB dye loaded on the diatomite surface depends on the nature of the surface (determined by the mentioned method: FTIR, SEM, BET), which varies from a sample to another (SBET, Vt, and the silica percentage).

5 Conclusions and suggestions

In this study, representative raw diatomite samples were collected from Ouled Djilali (OD), Mostaganem (Lower Chelif basin, Algeria northwestern), and subjected to characterization by several methods. Results show that the silica (SiO2) constitutes the major component of the OD diatomite with a significant amount of carbonate (CaO) beside other minor constituents.

As crystalline phases, were obtained the main accompanied minerals: calcite, dolomite, illite, and kaolinite, with less important presence of pyrite, chlorite, and albite. An interesting texture with relatively good surface area and pore volume was estimated for the studied diatomite products, along with a porous framework structure rich in intact diatom frustules (centric and pennate forms). All samples showed a high sorption capacity for oils and water.

When applied as an adsorbent for the methylene blue (MB) dye removal study, OD diatomite samples displayed good adsorption ability, evidencing good interactions between with MB dye adsorbate. The isotherm data fitted well the Langmuir model, and the calculated adsorption capacity of MB dye reached 116.59 mg/g (OD05) at 25 °C and pH 7.0. The obtained performances were comparable to those regarding several interesting materials reported in the literature.

These preliminary findings highlighted the potential use of the studied Ouled Djilali diatomite as promising low-cost and ecofriendly adsorbent for dyes separation from wastewater containing toxic contaminants. A conclusion can be also stated about the variation in diatomite characteristics, in the same deposit, with the variation in the geological layer or depth, fact which has to consider the suitable destination to choose for any industrial application.

References

Ma L, Chen Q, Zhu J, Xi Y, He H, Zhu R, Tao Q, Ayoko GA (2016) Adsorption of phenol and Cu (II) onto cationic and zwitterionic surfactant modified montmorillonite in single and binary systems. Chem Eng J 283:880–888. https://doi.org/10.1016/j.cej.2015.08.009

Akti F (2018) Photocatalytic degradation of remazol yellow using polyaniline–doped tin oxide hybrid photocatalysts with diatomite support. Appl Surf Sci 455:931–939. https://doi.org/10.1016/j.apsusc.2018.06.019

Namasivayam C, Prabha D, Kumutha M (1998) Removal of direct red and acid brillant blue by adsorption onto banana pith. Bioresour Technol 64:77–79

Sharma YC, Upadhyay Uma SN, Gode F (2009) Adsorptive removal of a basic dye from water and wastewater by activated carbon. J appl Sci in Environ Sanit 4(1):21–28

Lin SH, Juang RS (2009) Adsorption of phenol and its derivatives from water using synthetic resins and low-cost natural adsorbents: a review. J Environ Manag 90:1336–1349. https://doi.org/10.1016/j.jenvman.2008.09.003

Yu F, Ma J, Wang J, Zhang M, Zheng J (2016) Magnetic iron oxide nanoparticles functionalized multi-walled carbon nanotubes for toluene, ethylbenzene and xylene removal from aqueous solution. J Chemoph. https://doi.org/10.1016/j.chemosphere.2015.12.018

Cheng WP, Gao W, Cui X, Ma JH, Li RF (2016) Phenol adsorption equilibrium and kinetics on zeolite X/activated carbon composite. J Taiwan Inst Chem Eng 000(2016):1–7. https://doi.org/10.1016/j.jtice.2016.02.004

Ouakouak A, Rihani K, Youcef L, Hamdi N, Guergazi S (2020) Adsorption characteristics of Cu (II) onto CaCl2 pretreated Algerian bentonite. Mater Res Exp. https://doi.org/10.1088/2053-1591/ab5ee4

Sarioglu M, Atay UA (2006) Removal of methylene blue by using biosolid. Global NEST J 8(2):113–120

Tahir H, Sultan M, Jahanzeb Q (2008) Removal of basic dye methylene blue by using bioabsorbents Ulva lactucaand Sargassum. Afr J Biotechnol 7(15):2649–2655

Gupta VK, Mohan D, Sharma S, Sharma M (2000) Utilization of Bagasse Fly Ash ( a sugar industry waste) for the removal of copper and zinc from wastewater. Sep Purif Technol 18:131–140

Benaïssa H. (2008) Effect of pH on the removal of methylene blue from synthetic aqueous solution by a natural waste material: almond pee. Sci Stud Res IX(2), ISSN 1582–540X.

Bessedik M, Belkebir L, Mansour B (2002) Révision de l’âge miocène inférieur (au sens des anciens auteurs) des dépôts du bassin du Bas Chélif (Oran, Algérie): conséquences biostratigraphiques et géodynamiques. Mémo Serv géolog d’Algérie 11:167–186

Mansour B, Bessedik M, Saint Martin J-P, Belkebir L (2008) Signification paléoécologique des assemblages de diatomées du Messinien du Dahra sud-occidental (bassin du Chélif, Algérie nord-occidentale). Geodiversity 30(1): 117–139 (annexes available on: www.geodiversitas.com ).

Moret L (ed) (1964) Manuel de paléontologie végétale. Masson et Cie, Paris

Hamdi B (1998) Etude physico-chimique de la surface des diatomites, Thèse de doctorat d’état en science .U.S.T.H.B, Algérie

He Y, Jiang DB, Jiang DY, Chena J, Zhang YX (2018) Evaluation of MnO2-templated iron oxide-coated diatomites for their catalytic performance in heterogeneous photo Fenton-like system. J Hazard Mater 344:230–240

Wang Z, Lin Y, Wu D, Kong H (2016) Hydrous iron oxide modified diatomite as an active filtration medium for phosphate capture. Chemosph 144:1290–1298

Rabbani M, Rafiee F, Ghafuri H, Rahimi R (2016) Synthesis of Fe3O4 nonoparticles via a fast and facile mechanochemicl method: modification of surface with porphyrin and photocatalytic study. Mater Lett 166: 247–250. Doi: https://doi.org/10.1016/j.matlet.2015.12.087

Barbosa IA, Zanatta LD, Espimpolo DM, Silva DL, Nascimento LF, Zanardi FB, Sousa Filho PC, Serra OA, Iamamoto Y (2017) Magnetic diatomite (Kieselguhr)/Fe2O3/TiO2 composite as an efficient photo-Fenton system for dye degradation. Solid State Sci 72(2017):14–20

Rouchy JM, Caruso A, Pierre C, Blanc-Valleron MM, Bassetti MA (2007) The end of the Messinian salinity crisis: evidences from the Chelif Basin (Algeria). Palaeogeogr Palaeoclimatol Palaeoecol 254:386–417

Perrodon A (1957) Etude géologique des bassins néogènes sub-littoraux de l’Algérie occidentale. Pub. Serv. Carte géol. Algérie, n. s. Alger, Bull. 12,382p.

Langmuir I (1918) The adsorption of gases on plane surfaces of glass, mica and platinum. J Am Chem Soc 40(1918):1361–1367

Freundlich HMF (1906) Uber die adsorption in losungen. Z Phys Chem (Leipzig) 571:385–470

Sips R (1948) The structure of a catalyst surface. J Chem Phys 16:490–495

Temkin M.l. (1941) Adsorption equilibrium and the kinetics of processes on nonhomogeneous surfaces and in the interaction between adsorbed molecules. Russian J Phys Chem (USSR) 15:296–332

Eltaweil AS, Elshishini HM, Ghatass ZF, Elsubruiti GM (2020) (2020) Ultra-high adsorption capacity and selective removal of Congo red over aminated graphene oxide modified Mn-doped UiO-66 MOF. Powder Technol. https://doi.org/10.1016/j.powtec.2020.10.084

Eltaweil AS, Elgarhy GS, El-Subruiti GM, Omer AM (2020) Carboxymethyl cellulose/carboxylated graphene oxide composite microbeads for efficient adsorption of cationic methylene blue dye. Int J Biol Macromol 154:307–318

Fu X, Liu Z, Wu B, Wang J, Lei J (2016) Preparation and thermal properties of stearic acid/diatomite composites as form-stable phase change materials for thermal energy storage via direct impregnation method. J Therm Anal Calorim 123:1173–1181. https://doi.org/10.1007/s10973-015-5030-1

Yuan P, Wu DQ, He HP, Lin ZY (2003) The hydroxyl species and acid sites on diatomite surface: a combined IR and Raman study. Appl Surf Sci 227:30–39. https://doi.org/10.1016/j.apsusc.2003.10.031

Inchaurrondo N, Font J, Ramos CP, Haur P (2016) Natural diatomite: efficient green catalyst for Fenton-like oxidation of Orange II. Appl Catal B Environ 181:481–494. https://doi.org/10.1016/j.apcatb.2015.08.022

Badii K, Ardejani FD, Sabri MA, Limaee NY, Shafaei SZ (2010) Adsorption of acid blue 25 dye on diatomite in aqueous solution. Indian J Chem Technol 17:7–10

Benkacem T, Hamdi B, Chamayou A, Balard H, Calvet R (2016) Physicochemical characterization of a diatomaceous upon an acid treatment: a focus on surface properties by inverse gas chromatography. Powder Technol 294(2016):498–507. https://doi.org/10.1016/j.powtec.2016.03.006

Zhang S, Cui M, Zhang Y, Yu Z, Meng C (2016) Synthesis of zeolite Y from diatomite and its modification by dimethylglyoxime for the removal of Ni(II) from aqueous solution. J Sol-Gel Sci Technol 80:215–225. https://doi.org/10.1007/s10971-016-4080-6

Vassileva P, Gentscheva G, Ivanova E, Tzvetkova P, Voykova D, Apostolova M (2011) Characterization of natural diatomites from Bulgaria. Compt Rend Acad Bulg Sci 64-N06–2011. https://www.researchgate.net/publication/280577650.

Yu ZH, Zhang YF, Zhai SR, Wang Y, Pan YZ, Meng CG (2015) Amino-modified mesoporous sorbents for efficient Cd (II) adsorption prepared using non-chemical diatomite as precursor. J Sol-Gel Sci Technol 78:110–119. https://doi.org/10.1007/s10971-015-3933-8

Khraisheh MAM, Al-degs YS, Mcminn WAM (2004) Remediation of wastewater containing heavy metals using raw and modified diatomite. Chem Eng J 99:177–184

Eltaweil AS, Ali Mohamed H, Abd El Monaem EM, El Subruiti GM (2020) Mesoporous magnetic biochar composite for enhanced adsorption of malachite green dye: characterization, adsorption kinetics, thermodynamics and isotherms. Adv Powder Technol. doi: https://doi.org/10.1016/j.apt.2020.01.005

Ibrahim S-S, Selim A-Q (2010) Producing a micro-porous diatomite by a simple classification calcination process. J Ore dress 12(23):24–32

Ababou N, Meziane D, Kherbeche A, Chaqroune A (2002) Etude de l’adsorption de colorants textiles sur une diatomite marocaine. Phys Chem News 6:130–134

Zaitan H, Feronnato C, Bianchi D, Achak O, Chafik T (2006) Etude des propriétés texturales et adsorbantes d’une diatomite marocaine: Application au traitement D’air chargé d’un polluant de type composé organique volatil. Annal Chim Sci Matér 31(2):183–196

Al-Ghouti MA, Khraisheh MAM, Allen SJ, Ahmad MN (2003) The removal of dyes from textile wastewater: a study of the physical characteristics and adsorption mechanisms of diatomaceous earth. J Environ Manag 69:229–238

Mohamed EA, Selim AQ, Zayed AM, Komarneni S, Mobarak M, Seliem MK (2018) Enhancing adsorption capacity of Egyptian diatomaceous earth by thermo-chemical purification: methylene blue uptake. J Colloid Interface Sci 534:408–419. https://doi.org/10.1016/j.jcis.2018.09.024

Giles CH, Smith D, Huitson A (1974) A general treatment and classification of the solute adsorption isotherm I. Theoretical. J Colloid Interface Sci 47(3):755–765

Fröhlich AC, Ocampo-Pérez R, Diaz-Blancas V, Salau NPG, Dotto GL (2020) Three-dimensional mass transfer modeling of ibuprofen adsorption on activated carbon prepared by sonication. Chem Eng J 341:65–74. https://doi.org/10.1016/j.cej.2018.02.020

Elass K, Laachach A, Alaoui A, Azzi M (2010) Removal of methylene blue from aqueous solution using ghassoul, a low-cost adsorbent. Appl Ecol Environ Res 8(2):153–163

Tsai W-T, Hsu H-C, Su T-Y, Lin K-Y, Lin C-M (2008) Removal of basic dye (methylene blue) from wastewaters utilizing beer brewery waste. J Hazard Mater 154:73–78

Gürses A, Doğar Ç, Yalçın M, Açıkyıldız M, Bayrak R, Karaca S (2006) The adsorption kinetics of the cationic dye, methylene blue, onto clay. J Hazard Mater B 131:217–228.

Ghosh D, Bhattacharyya K-G (2002) Adsorption of methylene blue on kaolinite. Appl Clay Sci 20:295–300

Jin X, Jiang M, Shan X, Pei Z, Chen Z (2008) Adsorption of methylene blue and orange II onto unmodified and surfactant-modified zeolite. J Colloid Interface Sci 328:243–247

Allam K, Gourai K, El Bouari A, Belhorma B, Bih L (2018) Adsorption of Methylene Blue on raw and activated Clay: case study of Bengurir clay. J Mater Environ Sci 9(6):1750–1761. https://doi.org/10.26872/jmes.2018.9.6.195

Barka N, Nounah A, Assabbane A, Aîtichou Y (2006) Evaluation du pouvoir adsorbant du phosphate naturel dans le traitement des rejets textiles: comparaison avec le charbon actif. Proc Covaphos II 4:195–203

Muhammad AR, Shehadeh I, Ahmed A, Al-Zamly A (2009) Removal of methylene blue from aqueous solution by using gypsum as a low cost adsorbent. World Acad Sci Eng Technol 55:608–613

Acknowledgements

Authors would like to thank the “Ecole Nationale Supérieure des Sciences de la Mer et de l’Aménagement du Littoral” (ENSSMAL) laboratories and the « Centre de Recherche scientifique et technique en Analyses Physico-Chimiques » (CRAPC) for their cooperative support. We sincerely would like to extend our acknowledgments to the editors and the reviewers for their careful review contributing to improving the quality of this paper.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Touina, A., Chernai, S., Mansour, B. et al. Characterization and efficient dye discoloration of Algerian diatomite from Ouled Djilali-Mostaganem. SN Appl. Sci. 3, 476 (2021). https://doi.org/10.1007/s42452-021-04334-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-021-04334-9