Abstract

Metal soap formation is one of the most wide-spread degradation mechanisms observed in historical oil paintings, affecting works of art from museum collections worldwide. Metal soaps develop from a chemical reaction between metal ions present in the pigments and saturated fatty acids, which are released by the oil binder. The presence of large metal soap crystals inside paint layers or at the paint surface can be detrimental for the visual appearance of artworks. Moreover, metal soaps can possibly trigger mechanical damage, ultimately resulting in flaking of the paint. This paper departs from a recently proposed computational model to predict chemo-mechanical degradation in historical oil paintings, as presented in Eumelen et al. (J Mech Phys Solids 132:103683, 2019). The model describes metal soap formation and growth, which are phenomena that are driven by the diffusion of saturated fatty acids and proceed by a nucleation process from a crystalline nucleus of small size. This results into a chemically-induced strain in the paint, which may promote crack nucleation and propagation. The proposed model is here used to investigate the effects of saturated fatty acid concentration and initial nucleus geometry on the amount of chemo-mechanical damage generated. Numerical simulations show that both factors have a marginal influence on the growth rate of the metal soap crystal, but play a significant role on the extent of fracture induced in the paint.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

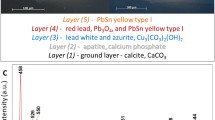

This work is motivated by the degradation of historical oil paintings associated with metal soap formation and growth. Oil paintings generally consist of multiple layers of paint, composed of metal-based pigment particles embedded in an oil binding medium, which are supported by a canvas or wooden substrate. Metal soaps form as a result of the chemical reaction between metal ions released from pigments or driers and saturated fatty acids extricated by the drying oil [1]. The initial reaction leading to metal soap formation is hypothesised to be reversible and to result into metal soaps in an amorphous state. Metal soaps can subsequently crystallize into insoluble aggregates by means of an irreversible reaction [2], thereby progressively growing into crystals of large size that deform pictorial layers and protrude through the paint surface. This growth process generates so-called chemically-induced strains in the paint system, ultimately causing damage and flaking of the paint [3,4,5]. Figure 1 shows a clear example of a metal soap crystal originating in the ground layer and breaking through several layers of paint until it reached the top of the paint surface, as was observed in the Portrait of Marten Soolmans (1634) by Rembrandt van Rijn (Rijksmuseum, Amsterdam) [6].

a Rembrandt van Rijn, Portrait of Marten Soolmans, 1634, oil on canvas, 207.5 cm x 132 cm, Rijksmuseum, Amsterdam, The Netherlands. After treatment. b Micro-detail of the painting (before treatment) showing tiny whitish globules of lead soaps protruding through the black paint surface. c, d A paint cross-section is taken at the top left of the painting, showing a large metal soap protrusion (diameter circa 150 \( \mu \)m). The light microscopic images of the metal soap aggregate are taken under c normal light illumination (bright field) and d ultraviolet illumination (365 nm). See [6]. Photos: copyright Rijksmuseum

Eumelen et al. [7] have recently presented a computational multi-physics model to predict the chemo-mechanical degradation of historical oil paintings as a result of metal soap formation and growth. The methodology allows to describe the growth of a metal soap crystal and shows the associated crack formation, revealing that the amount of chemo-mechanical damage is significantly affected by the stiffness mismatch between the paint material and the metal soap, the fracture strength and toughness, the chemically-induced strain, and the reaction rate. Two additional factors that may play a relevant role in determining the metal soap-induced fracture response of a painting are the concentration of saturated fatty acids, which represents the “driving force” of the chemical reaction, and the geometrical characteristics of the metal soap nucleus around which the growth of a crystal initiates. In the present communication, the model proposed in [7] is used to investigate the effect of these two parameters on the degradation process of a paint layer.

This paper is organized as follows. A review of the chemo-mechanical model proposed in Eumelen et al. [7] is presented in Sect. 2. Section 3 describes the geometry and material parameters used in the numerical simulations, and the results are discussed in Sect. 4. Conclusions are finally presented in Sect. 5.

2 Chemo-mechanical model

The computational model proposed in [7] is based on the coupling between a diffusion-reaction model and a mechanical model. The framework allows to simulate the spatial growth of a metal soap crystal, and computes the corresponding stress and strain fields generated inside a paint layer. Although the model formulation is three-dimensional, in order to keep computational times manageable, in this communication three-dimensional paint configurations are simplified to two-dimensional plane-stress models. The computational results are also applicable to two-dimensional plane-strain models, by converting the definitions for the effective elastic stiffnesses, Poisson’s ratios and growth strain accordingly [7]. The three-dimensional simulation of representative paint configurations remains a topic for future research. For clarity, the adopted assumptions and modelling strategy are reviewed below.

2.1 Modelling assumptions

The complex chemical processes resulting in metal soap formation are modelled in accordance with a series of assumptions. First, the paint is idealised as a homogeneous domain with a specific initial concentration of saturated fatty acids. Pigment particles are not explicitly modelled; their properties are incorporated in the effective behaviour of the paint material. Next, the metal soap growth process is assumed to depart from a pre-existing crystalline nucleus of a (small) specified size. The spatial growth of the metal soap crystal occurs by defining a moving reaction zone at the interface between the crystal and the paint material. Additionally, only the irreversible part of the chemical process leading to metal soap formation is modelled, i.e., the intermediate, amorphous state of the metal soap is neglected. This implies that crystalline metal soap immediately forms upon the reaction between metal ions and saturated fatty acids. Based on this assumption, the reaction scheme for the formation of crystalline metal soap can be written as [7]:

where M + nR designates a metal ion M reacting with n fatty acid chains R, as a result of which crystalline metal soap \({\rm{c- M(RCOO)}}_n\) forms. The crystallization rate is denoted as \(k_{\rm{crys}}\). For the preservation of museum collections, the indoor climate fluctuations, characterized by temperature and relative humidity variations, are typically kept within relatively strict bounds [8, 9]. As a first modelling step, the dependency of the metal soap reaction rate on these factors is therefore neglected in the present analyses. However, environmental conditions can generally influence both the mechanical properties [10] and the chemical characteristics [11, 12] of paint layers, and may affect the choice of conservation treatments [13]. The sensitivity of metal soap formation to temperature and relative humidity variations still needs to be better quantified in experiments in order to adequately account for this effect in the modelling of chemo-mechanical degradation of paint systems. Hence, this is a topic for future study.

2.2 Modelling strategy

The reaction scheme described above is translated into a diffusion-reaction model along the lines of [14]. The diffusion-reaction equation is expressed in terms of the concentration of free saturated fatty acids. The reaction kinetics is incorporated in a sink term, with its value being proportional to the rate of crystalline metal soap formation. In a second equation, the time evolution of the crystalline metal soap is specified as a function of the concentration of saturated fatty acids available for the reaction and the volume fraction of the paint material in which metal soap has not yet formed, see [7] for more details.

The spatial growth of a metal soap crystal, which occurs in a small reaction zone at the boundary of the crystal, induces a strain field (and a corresponding stress field) in the paint system. This coupling between the chemical and mechanical fields is quantified by defining a chemically-induced growth strain, which is taken proportional to the volume fraction of crystalline metal soap generated. Moreover, changes in the mechanical properties associated to crystalline metal soap formation are determined by using a rule of mixtures, in which the effective stiffness is calculated as the volume average of the properties of the chemical phases present in the specific material point. Mechanical equilibrium equations finally complete the chemo-mechanical modelling of the paint system.

The chemical and mechanical models are solved with the aid of the finite element method (FEM). Accordingly, the paint geometry is discretized into plane-stress continuum elements that simulate the two-dimensional bulk responses of the metal soap and paint materials. In accordance with the approach originally proposed in [15], cohesive interface elements are placed in between all continuum elements modelling the paint configuration, see Fig. 2, thereby allowing to describe the nucleation and propagation of relatively complex, discrete cracking patterns. The mesh density used in the FEM simulations is similar to that of the simulations presented in [7], whereby it has been confirmed that the spatial discretization is sufficiently fine for obtaining converged numerical results. The constitutive behaviour of a crack is simulated with the interface damage model proposed in [16]. The appearance of cracks locally hampers the diffusion of saturated fatty acids; this effect is accounted for by making the flux-concentration relation of the fatty acid at the crack surfaces a function of the mechanical damage generated, see [7] for more details.

The numerical solution procedure is based on a staggered scheme, in which the chemical and mechanical fields are analysed sequentially in an incremental-iterative fashion, as summarized in Table 1.

Model of a paint layer containing a metal soap crystal. The geometry is discretized by continuum finite elements, which model the bulk behaviour of the paint and the metal soap. The cohesive elements placed in between the continuum elements (as schematically indicated by the dashed lines in the inset) simulate possible crack formation

3 Numerical simulations

3.1 Material parameters

Most of the material parameters adopted in the numerical simulations were taken from different sources in the literature [17,18,19] and refer to lead-based pigment particles in combination with a stearic acid, forming lead stearate. The parameters for which experimental data are not available have been estimated by means of engineering judgement. The specific parameter values are summarised in Table 2, see [7] for more details on the assumptions taken for the parameter selection.

3.2 Geometry and initial and boundary conditions

The numerical analyses depart from the reference configuration studied in [7], which is schematically illustrated in Fig. 3a. The paint layer is idealized as a rectangular domain of width 2l and thickness l, with \(l=15\mu \)m. The thickness of the paint layer is chosen to be representative of paint layers in historical paintings [20]. A small nucleus of crystallized metal soap is considered to be initially present, with its location taken in the center of the paint layer for simplicity. The shape of the nucleus is circular, with an initial radius \(r_{0}=l/10=1.5\mu \)m. The effect of the initial nucleus size on the chemo-mechanical degradation process has been investigated in [7], which has demonstrated that it governs the specific moment in time at which the fracture process initiates, but it does not affect the crack growth rate and the corresponding maximum crack opening. Note that, due to symmetry, only half of the paint configuration has been modelled.

For the diffusion-reaction analysis, the initial condition is formulated by assuming a uniform fatty acids concentration \( c_0 = 91 \) mol/m\(^3 \) [7] throughout the entire domain. In addition, at the right domain boundary a uniform saturated fatty acid concentration profile \(\hat{c}= c_{0 }= 91 \) mol/m\(^3\) is imposed. The remaining boundaries are characterized by a zero-flux boundary condition.

For the mechanical analysis, it is assumed that the paint layer is initially stress-free. Further, a zero horizontal displacement is assumed at the left and right domain boundaries, which respectively represent the symmetry condition and the constraining effect provided by the adjacent paint material. The bottom domain boundary is constrained in the vertical direction, in order to mimic the support provided to the paint layer by the substrate.

Departing from the reference model, the influence on metal soap development and crack formation by the geometry of the metal soap nucleus and the fatty acid concentration profile applied at the right domain boundary is investigated through a parameter variation study. The effect of the geometrical characteristics of the metal soap nucleus is explored by additionally considering elliptical nuclei of width-to-height aspect ratios 2:1 and 1:2, whereby the height of the ellipse is kept the same for all three cases, see Fig. 3b. The assumed nucleus geometries are considered to be representative of metal soap aggregates observed in-situ. The influence of the fatty acid concentration profile is investigated by considering two additional concentration profiles at the right domain boundary, namely a linear profile \(\hat{c}(y) = 2c_{0}y/l \) and a sinusoidal profile \(\hat{c} (y)= c_{0}\pi /2 \sin (\pi y/l) \), see Fig. 3c. Note that all three profiles are characterized by the same average concentration value \(c_0\).

4 Results and discussion

4.1 Influence of nucleus geometry

The effect of nucleus geometry on metal soap formation is investigated by considering a set of nuclei characterized by different width-to-height aspect ratios, as illustrated in Fig. 3b, whereby the case of a circular nucleus corresponds to the reference simulation presented in [7]. Figure 4 shows the progressive growth of the metal soap crystal and the resulting fracturing of the paint, for a nucleus with a width-to-height aspect ratio 1:1 (left column), 2:1 (center column) and 1:2 (right column). The evolution of the process is described in terms of a dimensionless time parameter, defined as \(\bar{t}=t{\mathcal{D}}/l^{2}\), with t the real time, \({\mathcal{D}}\) the diffusion coefficient and l the thickness of the simulated domain. The contour plot variable indicates the volume fraction \( \phi \) of crystallized metal soap. The fully crystallized material can be identified by the red color (\(\phi =1\)), while the original paint material corresponds to the blue color (\(\phi =0\)). Notice further the narrow transition zone in which the chemical reaction occurs at the interface between the metal soap crystal and the paint, with \(0<\phi <1\). It can be clearly seen that the growth of the metal soap crystal eventually causes a significant deformation of the paint surface. This effect is also observed in cross-sections of metal soap crystals taken from real artworks, as for instance shown in Fig. 1.

Figure 5a illustrates the time evolution of the average radius \(r=(r_{x}+r_{y})/2\) of the metal soap crystal, as expressed in its dimensionless form \(\bar{r}=r/l\). From the similarity in the slopes of the three curves it is concluded that the initial nucleus geometry has a minor influence on the growth rate of the crystal.

Time evolution of the paint configuration (with the deformation plotted at true scale) illustrating the growth of the metal soap crystal and the fracture and surface deflection of the paint material. The contour plot variable \(\phi \) refers to the volume fraction of crystallized metal soap. The results refer to a metal soap nucleus of initial aspect ratio 1:1 (left column), 2:1 (center column) and 1:2 (right column)

Figure 5b presents the time evolution of the maximal normal opening \(\bar{v}_{1}\) of the predominant crack in the paint system, which appears right above the metal soap crystal as a result of the stress generated by crystal growth reaching the tensile strength of the paint material, see Fig. 4. The normal crack opening is presented in its dimensionless form, \(\bar{v}_{1}=v_{1}/l\). While the onset of damage occurs approximately at the same time for the three nucleus geometries considered, the crack opening clearly increases for a decreasing width-to-height aspect ratio of the nucleus. This is, because a metal soap aggregate developing an elliptical shape characterized by a large width (aspect ratio 2:1) introduces a relatively low tensile stress in the top of the domain. Correspondingly, for a nucleus aspect ratio of 2:1 the crack turns out to be almost not visible, see Fig. 4. When a crack is about to penetrate the approaching metal soap crystal, the crack faces at the crack tip close. Crack closure is due to the volumetric expansion of the metal soap crystal. This locally induces compressive stresses around the crack tip, in the zone adjacent to the crystal boundary, which leads to crack closure. This mechanism can be clearly observed for the case of a nucleus with an aspect ratio 1:2, illustrating that the normalized crack length of the predominant crack reduces from \( l_c/l = 0.133\) at \(\overline{t}= 4.5\)-see Fig. 4c- to \( l_c/l =0.119 \) at \(\overline{t}= 6\)-see Fig. 4d.

4.2 Influence of fatty acid concentration profile

The influence of the saturated fatty acid concentration prescribed at the right domain boundary on the amount of developed chemo-mechanical damage is investigated by considering three different concentration profiles, which are uniform, linear and sinusoidal, as illustrated in Fig. 3c. The uniform concentration profile corresponds to the reference simulation presented in [7]. The deformed configuration of the paint layer is shown in Fig. 6 at different values of the dimensionless time \( \overline{t} \). Similar to what is observed in Fig. 4, the metal soap crystal gradually grows, deforming the top surface of the paint and generating a vertical crack in the top part of the sample. For the uniform and sinusoidal fatty acid profiles the shape of the metal soap crystal develops in a smooth, almost circular fashion. Conversely, for a linear fatty acid profile the metal soap aggregate gradually grows into a more irregular shape.

The time evolutions of the normalized average crystal radius \(\bar{r}\) and the normalized maximum crack opening \(\bar{v}_{1}\) are shown in Fig 7a, b, respectively. The imposed concentration profile appears to have essentially no influence on the growth rate and average size of the crystal. The influence on the crack opening, however, is quite significant. This can be ascribed to the growth characteristics of the metal soap aggregate along the horizontal direction (dominant in the case of an aspect ratio 2:1). A larger crystal size in the horizontal direction (as observed for the linear concentration profile) generates a more uniform stress distribution, and therefore a lower stress in the top part of the paint, which leads to less crack development.The sinusoidal and constant concentration profiles, which are characterized by crystals of comparable shape, lead to a similar crack response until \(\bar{t}=4.5\), after which the crack starts to close for the constant concentration profile while it slightly advances for the sinusoidal concentration profile.

Time evolution of the paint configuration (with the deformation plotted at true scale) illustrating the growth of the metal soap crystal and the fracture and surface deflection of the paint material. The contour plot variable \(\phi \) refers to the volume fraction of crystallized metal soap. The results for the constant, linear and sinusoidal fatty acid concentration profiles at the right domain boundary are displayed in the left, central and right columns, respectively

5 Conclusions

Departing from a recent computational model on chemo-mechanical paint degradation by metal soap formation [7], this paper investigates the effect on chemo-mechanical damage by the geometrical features of the metal soap nucleus and the profile of the saturated fatty acid concentration imposed on the paint sample. Numerical simulations are performed on a system composed of a single metal soap nucleus embedded in a paint layer, thereby mimicking the growth of the metal soap crystal and the induced crack formation. It has been observed that both the fatty acid concentration profile and the aspect ratio of the metal soap nucleus have a significant influence on the amount of crack formation in the paint layer. On the contrary, the growth rate and the average radius of the metal soap crystal appear to be virtually insensitive to concentration profile and nucleus geometry.

In order to limit crack growth, it is worth investigating how particular conservation interventions (e.g., the use of specific solvents) and conservation procedures (e.g., controlling the indoor climate conditions) may influence the saturated fatty acid concentration profile and the rate of the chemical reaction. Another topic for future research is the accurate determination of material parameters of historical paints from dedicated, small-scale experiments, such as nano-indentation tests [21], which will support an accurate validation of the modelling results. Finally, the present model will be extended to incorporate the reversible part of the chemical reaction that relates to the formation of amorphous metal soap, which is expected to provide a more realistic representation of the time scale at which metal soap growth occurs.

References

Hermans JJ, Keune K, van Loon A, Iedema PD (2016) The crystallization of metal soaps and fatty acids in oil paint model systems. Phys Chem Chem Phys 18:10896–10905

Baij L, Hermans JJ, Keune K, Iedema PD (2018) Time-dependent ATR-FTIR spectroscopic studies on fatty acid diffusion and the formation of metal soaps in oil paint model systems. Angew Chem Int Edn 57(25):7351–7354

van Loon A, Noble P, Burnstock A (2012) Ageing and deterioration of traditional oil and tempera paints. In: Butterworth-Heinemann (ed) Conservation of easel paintings: principles and practice, pp 214–241

Maines CA, Rogala D, Lake S, Mecklenburg MF (2011) Deterioration in abstract expressionist paintings: analysis of zinc oxide paint layers in works from the collection of the Hirshhorn Museum and Sculpture Garden, Smithsonian Institution. MRS Proc 1319:275–284

Osmond G, Boon JJ, Puskar L, Drennan J (2012) Metal stearate distributions in modern artists’ oil paints: surface and cross-sectional investigation of reference paint films using conventional and synchrotron infrared microspectroscopy. Appl Spectrosc 66(10):1136–1144

Noble P, van Duijn E, Hermens E, Keune K, van Loon A, Smelt S, Tauber G, Erdmann R (2018) An exceptional commission: conservation history, treatment and painting technique of Rembrandt’s Marten and Oopjen, 1634. Rijksmuseum Bull 66(4):308–345

Eumelen GJAM, Bosco E, Suiker ASJ, van Loon A, Iedema PD (2019) A computational model for chemo-mechanical degradation of historical oil paintings due to metal soap formation. J Mech Phys Solids 132:103683

Kirby AJ (2014) Environmental conditions for the safeguarding of collections: a background to the current debate on the control of relative humidity and temperature. Stud Conserv 59(4):205–212

Bickersteth J (2014) Envirionmental conditions for safeguarding collections: what should our set points be? Stud Conserv 59(4):218–224

Mecklenburg MF, Tumosa CS (1991) Mechanical behavior of paintings subjected to changes in temperature and relative humidity. In: Mecklenburg MF (ed) Art in transit: studies in the transport of paintings. National Gallery of Art, Washington, DC, pp 173–216

Keune K, Kramer RP, Huijbregts Z, Schellen HL, Stappers MHL, van Eikema Hommes MH (2016) Pigment degradation in oil paint induced by indoor climate: comparison of visual and computational backscattered electron images. Microsc Microanal 22(2):448–457

Modugno F, Di Gianvincenzo F, Degano I, van der Werf ID, Bonaduce I, van den Berg KJ (2019) On the influence of relative humidity on the oxidation and hydrolysis of fresh and aged oil paints. Sci Rep 9:5533

Lee J, Bonaduce I, Modugno F, La Nasa J, Ormsby B, van den Berg KJ (2018) Scientific investigation into the water sensitivity of twentieth century oil paints. Microchem J 138:282–295

Hille TS, Turteltaub S, Suiker ASJ (2011) Oxide growth and damage evolution in thermal barrier coatings. Eng Fract Mech 78(10):2139–2152

Xu X-P, Needleman A (1994) Numerical simulations of fast crack growth in brittle solids. J Mech Phys Solids 42(9):1397–1434

Cid Alfaro MV, Suiker ASJ, de Borst R, Remmers JJC (2009) Analysis of fracture and delamination in laminates using 3D numerical modelling. Eng Fract Mech 76(6):761–780

Lide DR (ed) (2003) CRC handbook of chemistry and physics, 84th edn, chapter 4. CRC Press, p 65

Hermans JJ (2017) Metal soaps in oil paint-structure, mechanisms and dynamics. PhD thesis, University of Amsterdam

Fuster-López L, Izzo FC, Piovesan M, Yusá-Marco DJ, Sperni L, Zendri E (2016) Study of the chemical composition and the mechanical behaviour of 20th century commercial artists’ oil paints containing manganese-based pigments. Microchem J 124:962–973

Shimazu Y, Keune K, Boon JJ, Townsend JH, van den Berg KJ (2008) The effects of lead and zinc white saponification on surface appearance of paints. In: 15th Triennial conference, vol II. Allied Publishers Pvt.Ltd, New Delhi, pp 626–632

Freeman A, Łukomski M, Beltran V (2019) Mechanical characterization of a cross-sectional \({T}i{O}_{2}\) acrylic-based paint by nano-indentation. J Am Inst Conserv 59:27–39

Funding

E.B. is grateful for the support by the Netherlands Organization for Scientific Research (NWO), Project 15873, within the funding scheme “NWO Veni Award”. A.S.J.S. has received funding from the European Union’s Horizon 2020 research and innovation programme under Grant Agreement N. 814624. J.J.H. is grateful for the support by NWO, Project 016.Veni.192.052. P.D.I., K.K. and A.v.L. finally acknowledge the support by NWO and the Netherlands Institute for Conservation Arts and Sciences (NICAS) via the Project 628.007.002.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Eumelen, G.J.A.M., Bosco, E., Suiker, A.S.J. et al. Computational modelling of metal soap formation in historical oil paintings: the influence of fatty acid concentration and nucleus geometry on the induced chemo-mechanical damage. SN Appl. Sci. 2, 1310 (2020). https://doi.org/10.1007/s42452-020-3038-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-020-3038-z