Abstract

This study presents the optimization of the intake manifold and the optimized flow rate of the acetylene gas which acts as a low reactivity fuel to achieve the superior performance and emission characteristics used in the Reactivity controlled compression ignition (RCCI) engine. Intake manifold is one of the engine components which are an important factor in determining the quality of combustion. A very recent evolution of the RCCI engine using the low temperature combustion technique requires a low reactivity fuel which is injected through the secondary fuel injector. The secondary fuel injector must be designed and optimized to allow the acetylene gas to maximize the engine performance and the amount of acetylene gas in liters per minute required for better combustion. If the secondary fuel injector is mounted apart from the critical point, then the performance of the RCCI engine may be poor and also if the acetylene gas is not supplied properly, there is a risk of poor combustion and also if the acetylene gas is supplied excessively, there is a risk of knocking along with the backfire due to the excess fuel charge accumulation during the combustion process. Physical testing of the secondary fuel injector in the intake manifold with different angles, distance and flow rate of supply of acetylene gas is time and cost consuming process. To mitigate this issue optimization is done through computational fluid dynamics principles comes in handy to minimize time and money. In our study, ANSYS-FLUENT software is used for simulation purposes. Optimization of acetylene gas injector distance is carried out by analyzing the pressure contours at the entrance of the combustion chamber. The optimized flow rate of acetylene gas and the injector inclination is found by analyzing the flow contours of turbulent kinetic energy and turbulent dissipation rate.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Due to the industrial revolution that has taken place over the last decades, the role of the transport and power sectors is very significant. The invention of an internal combustion engine is a milestone in the transport and power sector that makes it easy to convert the fuel from well to the wheel of the vehicle. The fuel economy of the internal combustion engine is significantly increased by the use of new combustion technologies and by the improvement of the design of the existing engine [1]. However, a drastic increase in demand for power is required to develop new combustion and fuel technologies to meet demand. It is further addressed that pollutants such as HC, CO, NOx, smoke and other particulate matter (PM) emitted at the end of the combustion cycle are very harmful to human life [2]. A number of experiments have been performed using alternative fuels and fuel additives to improve efficiency and reduce emissions [3]. In the later stage of engine research, includes the variation of compression ratio, exhaust gas recirculation (EGR), improving the turbulence inside the cylinder and adopting new combustion strategies. However these investigations are concluded that by using one of these methods resulting the reduction of some emission components or improvement of performance in the back which increasing the some other emission components [4]. For example, by using biofuels as an alternative to diesel engines to reduce CO, HC and smoke emissions, they pay the price to increase NOx emissions [5].Belgiorno et al. [6, 7] investigated the CI engine using two oxygenated fuel blends and reduced the CO emissions and soot emissions simultaneously. Beatrice et al. [8] identified optimised engine boundary conditions such as boost pressure, injection pressure, nozzle flow number, peak fire pressure and inlet turbine temperature to achieve a power density of 100 kW/l in light duty diesel engines. Belgiorno et al. [6, 7] optimized the efficiency-NOx trade off in conventional and partially premixed combustion modes by finding the engine calibration parameters. Belgiorno et al. [9] improved the fuel/air mixing in the combustion chamber by making additive manufacturing enabled innovative piston bowl in order to achieve better performance and emission characteristics. It is therefore recommended that two or more methods be combined simultaneously to achieve the desired parameters [10].

Due to stringent emissions regulations, low temperature combustion is more popular than conventional combustion among engine researchers [11]. In Dual fuel mode LTC can be achieved as the LTC requires 2 different reactivity fuels. Reactivity controlled compression ignition (RCCI) is a new combustion strategy for Dual Fuel Mode combustion. In the RCCI engine, low-reactivity fuel such as gaseous fuels is allowed through the intake manifold along with the air, and high-reactivity fuel such as diesel and other similar forms of diesel fuel is directly injected into the cylinder. Most researchers suggest that the use of gaseous fuel in dual fuel combustion will reduce the usage of conventional fuel [12]. İlhak et al. [13] experimented with the Spark Ignition engine fueled by gasoline, ethanol and acetylene at 25% and 50% loads, and the results show that acetylene gives better performance and emission characteristics than other fuels. Choudhary et al. [14] explored the use of acetylene gas in the CI engine in addition to diesel for various compression ratios. The brake thermal efficiency is maximum at the compression ratio of 19.5:1. So from the above literatures, the possibility of using acetylene in the CI engine is demonstrated. The requirements of these engines shall be the homogeneous mixture at full load and the stratified mixture at partial loads during combustion. To generate the homogeneous and stratified mixture, it is required to find the optimum flow rate of mixture elements as well as the acquired energy to make turbulence and swirl inside the cylinder.

Like an internal combustion engine, the invention of computers has made an information revolution. In the present study the role of computational optimization of the engine intake manifold is to determine the optimum combinations of angle, flow rate and distance. Gocmen et al. [15] investigated and modified the intake manifold for multi cylinder engine by accessing pressure drop areas using ANSYS FLUENT CFD tool. Sadeq et al. [16] examined the emission and performance of conventional diesel engines by adopting a range of helical-spiral intakes of different diameters to improve swirl and turbulence in the combustion chamber. The result indicates improved performance and emission characteristics compared to the standard intake manifold. Silva et al. [17] optimized the intake manifold runner length based on volumetric efficiency across different speed ranges using the 1D GT-POWER simulation platform. The shorter length with high speed rotation is suggested from the volumetric efficiency curves. Very few researchers have concentrated on optimizing the intake manifold for diesel engine operating in dual fuel mode. Muralikrishna et al. [18], investigated on in-cylinder flow characteristics with varying inclinations (0°, 30°, 60°, and 90°) using particle image velocimetry. The result shows that 60° manifold inclination has the highest turbulent kinetic energy compared to other inclinations. Chen et al. [19] optimized the methanol injecting position by analyzing the unevenness degree of Indicated Mean Effective Pressure in a diesel methanol dual fuel engine. Adithya et al. [20] investigated the optimum runner length of the intake manifold using Chrysler Ram Theory and Helmholtz Resonator Theory to improve the mass flow rate of the air and the mixture of biogas in order to improve volumetric efficiency. It is observed that the length of the runner is determined by assuming that the speed of the pressure wave is equal to the sound wave (343 m/s).

It is noted from the above literature that the use of RCCI combustion technology leads to the achievement of favorable performance and emission characteristics, in particular the attainment of ultra-low NOx emissions. In addition, the use of gaseous fuels such as acetylene gas as a secondary fuel improves the rate of combustion and improves performance and emission characteristics. The majority of researchers concentrate on optimizing the intake manifold used for traditional diesel engine operation. In the present study, the use of the RCCI combustion strategy is carried out in conjunction with gaseous fuel such as acetylene gas supplied through the intake manifold. So there is a wide research gap to optimize the intake manifold for dual fuel RCCI engine combustion. In the case of RCCI engine combustion, it is required to inject LRF by separate port or along with the intake air into the engine prior to the entry of HRF in order to generate reactivity stratification. Due to the wide flammability limits of the gasses and the possibility of backfire, the RCCI engine works with gasses such as acetylene as an LRF, and the injector needs to be placed at an optimal distance and angle well before running the engine. The flow must be uniflow in the intake manifold in order to achieve better combustion characteristics and to avoid the back fire of acetylene. In uniflow, the mixture of air and acetylene flow through the intake manifold proceeds in a single unidirectional flow without reversal. This provides the thermodynamic advantage of the stabilized temperature inside the intake manifold rather than being alternately heated and cooled by molecules collision. In this study, the optimization of the position and flow rate of the acetylene gas injector is carried out numerically using the CFD principles. The CFD model analysis is carried out by the acetylene injector, which is positioned in the intake manifold on three different distances as 243.5 mm, 288.5 mm and 333.5 mm from the intake valve. In addition, for each distance, the injector is placed at 3 different angles as 45° − 60° and 90°, in order to achieve an optimized configuration of the injector.

2 CFD model

The “L” shaped intake manifold 3D model is designed using the CAD software SOLIDWORKS, which is used to allow the mixture of air and acetylene in the combustion chamber. The total length of the intake manifold shall be taken as 361 mm and the effective inside diameter as 35 mm. The length and diameter of the acetylene (LRF) injector is 37 mm and 7 mm respectively. There is no problem letting air only through the intake manifold. However, as per the RCCI engine combustion strategy, acetylene gas (LRF) must be injected during the suction stroke [21].

Figure 1 display the line diagram of the different locations of the injector. The renormalized group (RNG) k-Epsilon, the standard wall turbulence model, was one of the conclusions used for intake manifold design and optimization [22]. An implicit discretization procedure was applied to solve the problem of a discrete Navier–Stokes equation on a Cartesian grid. General equations used to construct pipe flow models included mass, momentum, and energy conversion equations.

2.1 Mesh independence study

Mesh size (mesh density) is an important factor in evaluating the precision of the simulation results. When the mesh size increases the possibility for a convergence result is high. So there is a need to find the independent mesh size required to achieve the accurate results. The reliability of the mesh size given for the simulation is needs to be checked. The coarse mesh (large element size) causes the geometry of the model to distort, so that the eddies generated in the actual flow are not obtained. So, accurate simulation results are not possible. On the contrary, the fine mesh (smaller element size) that makes the simulation need to run for a long time. In order to solve the above two simulation issues, an optimum mesh size is required.

In order to evaluate the independent mesh size, the mesh size is gradually increased from the coarse mesh in order to converge the result from the subsequent mesh size. Figure 2 shows the mesh independency for pressure, turbulent kinetic energy and turbulent dissipation rate that will be calculated using the CFD simulation in the upcoming sections. From the independent mesh size evaluation graph that starts from mesh size 300,000 plots to match the higher mesh size value. At mesh size 310,000, the plot merges exactly with the larger mesh size. It is therefore concluded that the mesh size 310,000 is sufficient for mesh independence.

Figure 3 demonstrates the computational view of CFD mesh. The density of the elements is larger in the area of the injector and the density of the elements is low in the intake manifold pipeline. The mesh quantity would be the same for both the width and angle of the injector since the volume of the intake manifold and the injector in both places is merely equal.

2.2 CFD simulation

Figure 4 display the transport model of the species which the point ‘A’ indicates the air inlet, point ‘B’ indicates the acetylene inlet and the point ‘C’ indicates the air and acetylene mixture ready to enter combustion chamber. The point ‘B’ is variable distance of 243.5 mm, 288.5 mm and 333.5 mm with the variable angles of 45°, 60° and 90°. The Table 1 shows the input parameters required to start the simulation.

The boundary conditions are set for finding the required parameters at the outlet. The intake air velocity is 18 m/s and the temperature at the intake manifold entry is the room temperature (300 K). Low Reactivity Fuel (LRF) acetylene is supplied by a different positioned injector at a flow rate from 1 to 5 LPM with an increase of 1 LPM and the inlet pressure has been taken as the atmospheric pressure. The pressure loss due to wall friction is neglected for the simulation purpose. The time-independent steady flow of fluid (Air and Acetylene) is incompressible and there is no chemical reaction between air and acetylene during the suction stroke of the engine.

3 Result and discussion

The present simulation work is carried out in 2 phases. The first phase involves the location of the critical distance and the second phase involves the critical angle and the optimal flow rate of the acetylene gas which is injected into the intake manifold through the injector.

3.1 Estimation of critical distance of injector

The first phase of the simulation is used to determine the critical distance of the injector located in the manifold at three positions Fig. 1a–c with an intake valve distance of 243.5 mm, 288.5 mm and 333.5 mm. The aim of the simulation is to evaluate the high pressure at the outlet to improve the performance of the engine [23]. If the pressure inside the combustion chamber is high, the combustion is thermodynamically more efficient, because of the heat energy produced by the combustion reaction is converted into desired mechanical energy [24]. Moreover, according to the gas law (pv = mRT) if the pressure of the gas increases, the temperature of the gas will also increase. A sufficient amount of temperature rise will help the complete combustion.

Figure 5a–i displays the CFD simulation contours of the intake manifold pressure distribution at 1 LPM of acetylene gas supply. From the contours Fig. 5a–c, the 45° injector at the distance of 243.5 mm from intake valve produce a pressure of 188.4 Pa in the outlet which produces a higher pressure than 60° and 90° injectors. The higher pressure at the outlet is due to the intake air obstructed by the 1 LPM acetylene flowing through the 45° injector and it will lead the pressure rise in the inlet and the pressure wave to be transmitted to the outlet with some loss of pressure. From the Fig. 5d–f, the 45° injector at a distance of 288.5 mm from the intake valve has an outlet pressure of 112.5 Pa, which is lower among 60° and 90°, while the inlet region pressure is higher when the injector is positioned at a distance of 288.5 mm from intake valve and the acetylene entry making a sensible pressure drop at the outlet. For 90° injector, the specified pressure loss flow is minimal and the pressure at the outlet is 127.9 Pa, which is higher than 45° and 60° injectors. At a distance of 333.5 mm from intake valve which is shown in Fig. 5g–i, the outlet pressure decreases by increasing the inclination of the injector. The maximum outlet pressure 123.7 Pa is created by a 45° injector.

Figure 6a–i shows the simulation result of the pressure distribution at 2 LPM acetylene flow rate. The distance of 243.5 mm from intake valve by the color map shown in Figs. 6a–c, it is very clear that at 45° and 90° injectors having higher pressure (170.8 Pa and 172.5 Pa) at outlet. Although the pressure at the inlet region is high and the entry of the acetylene through the 60° injector creates enormous amount of pressure loss and the pressure at the outlet is 124.4 Pa.

From the Fig. 7a–c for the 3 LPM acetylene flow rate at 243.5 mm from the intake valve, it is shown that the 90° injector produced a maximum pressure of 192.3 Pa at outlet which is higher than other 2 kinds of injectors. The higher outlet pressure for 90° injector is due to the intake air obstruction made by the vertical (90°) position. This can be seen from the contour Fig. 7c that the high pressure region is in just before of the injector. This high pressure inlet wave travels to the outlet and produces a higher pressure.

The Fig.8a–i shows the pressure contours of 4 LPM of acetylene and air mixture. At 243.5 mm from the intake valve shown in Fig. 8a–c, all three injectors produce almost the same inlet pressure. Due to the more pressure drop which is created by 60° injector, the outlet pressure is 124.3 Pa. But due to the low pressure drop created by the 45° and 90° injectors, the outlet pressures are 213.9 Pa and 213.5 Pa respectively.

Figure 9a–i show that at a flow rate of 5 LPM of acetylene with an air mixture for a 90˚ injector, the pressure is 231.1 Pa. For the 60° injector, the pressure in the inlet region is still higher than the 45° and 90° injectors. But as usual the 60° injector created more pressure drop at the outlet and interestingly the 45° injector also created more pressure drop from the inlet due to the 5 LPM acetylene flow rate.

At a distance of 288.5 mm and 333.5 mm from the intake valve, the behavior of the fluid mixture at the outlet for the remaining acetylene flow rate is the same as in the conclusions of the 1 LPM section.

From all the simulation plots, in contrast to the pipe flow, the air and acetylene mixture pressure at the outlet does not depend on the inlet pressure. The pressure at the outlet varies depending on the position of the second fluid (acetylene) in contact with the first fluid (air) and the inclination between the two fluid pathways.

Figure 10 shows the graph compiling all the outlet pressure values for the position of the injector at different distances and angles. Overall for the entire flow rate and all the angles, except 60° the outlet pressure is increasing when the injector position is moving towards the intake valve. The pressure loss levels are lowest in 45° and 90° injector angles as it improves the swirl in the manifold [15]. It is very clear that, from the simulation contours and the graph, the maximum pressure achieved at all the flow rates at a distance of 243.5 mm from intake valve seems to be efficient, particularly for 45° and 90° injector angles.

3.2 Estimation of critical angle and flow rate of acetylene

In the second phase of finding the critical angle of the injector required to be positioned in the intake manifold at a distance of 243.5 mm from the intake valve and the flow rate of acetylene required for optimum performance of the RCCI engine. The generation of turbulence is determined by the mixing rate of acetylene gas with intake air and the position of the acetylene gas injector [25]. In order to achieve better combustion and emission characteristics for the RCCI engine, a pressurized charge is not only necessary during the intake stroke. There is no assurance that the pressure generated at the outlet is either air or acetylene or a mixture of air and acetylene. The formation of a homogeneous mixture largely depends on the collision in the inlet manifold between air and acetylene [26].To confirm the pressure is created by the mixture is assured by the k-epsilon turbulence model. According to the k-epsilon turbulence model, the turbulence kinetic energy (k) and the turbulent dissipation rate (TDR) referred to as epsilon are the factors required to decide the degree of mixture formation between 2 dissimilar fluids. It is further required to analyze a mixture which may have enough energy to produce turbulence inside the combustion chamber [27]. The amount of acetylene supplied in the intake valve is more than required for combustion, and the mixture creates an enormous amount of pressure and flammable characteristics of acetylene gas, which can lead either backfire or severe knocking in the engine.

The turbulence generation and dissolving rate of acetylene gas can be measured for various injector angles using CFD principle [28]. Optimized position and angle of the injector will reduce the flow resistance as well as increase the swirl intensity throughout the flow in the intake manifold and also inside the combustion chamber. Turbulence kinetic Energy (TKE) is a measure of swirl creating ability in the flow through the medium. TKE can be produced either by fluid shear, friction or buoyancy or through external fluid mixing at a frequency other than primary fluid. TKE is the mean kinetic energy per unit mass associated with eddies in turbulent flow. Physically, the TKE is calculated using the Eq. (1) which is characterized by measured root mean square (RMS) velocity fluctuations.

Where, u and v are fluctuating velocity components in the x and y directions respectively. Here, density ‘ρ’ is the effective density of the air and acetylene during the formation of the mixture. Then TKE is transferred down to the turbulence energy cascade, and dissipated by viscous forces. The rate of TKE (k) dissipated in to viscous forces referred to as TDR (epsilon). So it is required to analyze the rate of turbulence dissipation (epsilon) for identifying the induced turbulent kinetic energy which is converted in to viscous forces or not.

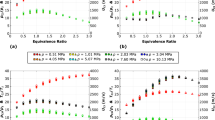

Figure 11, 12, 13, 14 and 15 shows the data obtained from the CFD simulation indicating the variation of the TKE(k) and TDR(epsilon) with different acetylene gas flow rates and the injection distance of 243.5 mm, 288.5 mm and 333.5 mm from the intake valve and corresponding inclinations (45°, 60° and 90°). From the graphs it is showing that the TKE and TDR are varying in the same proportion for all the acetylene flow rate. So there is no energy conversion problem in the geometry of the intake manifold. It is already dicussed from the pressure contours that the outlet pressure is achieving higher for the 45° and 90° injectors at a distance of 243.5 mm from the intake valve. Thus it is also necessary to verify that the maximum pressure created by the injectors is able to produce enough TKE and TDR to achieve a better mixture of air and acetylene. The plot clearly shows that, relative to other angle acetylene gas injection, up to the mass flow rates of 4 LPM acetylene gas with an injection angle 45° would produce more turbulent kinetic energy. This is because of the fluid composition of the acetylene gas in such a way that it causes fluid shear, friction and buoyancy with intake air leading to more eddies in the intake manifold [29]. The 3 LPM flow rate of acetylene the TKE and TDR is achieving maximum for 45° injector compared to the other injectors at a distance of 243.5 mm from intake manifold. The magnitude of the TKE increases with an increase in the flow rate of upto 3 LPM with an injection angle of 45° and the distance of 243.5 mm. But by increasing the distance from the intake valve the TKE and the corresponding TDR decrease. Which indicates that the 45° injector at a distance of 243.5 mm has a higher TKE. Moreover from the k-epsilon variation graphs at 3 LPM, the maximum TKE value is 154.16 m2/s2 and the corresponding TDR value is 132257.41 m2/s3. So air and acetylene mixture able to create maximum turbulence and swirl inside the combustion chamber.

4 Conclusion

The mixing pattern of air and acetylene in the intake manifold is analysed using ANSYS-FLUENT software in order to achieve better combustion characteristics of DI diesel engine operating on RCCI mode. The Acetylene gas (LRF) supplied virtually with the flow rates varying from 1 to 5 LPM through the injector positioned at a three different distances as 243.5 mm, 288.5 mm and 333.5 mm from the intake valve. In addition, for each distance, the injector is placed at three different angles as 45°, 60° and 90°. By seeing the pressure CFD simulation contours Pressure at the outlet of intake manifold does not depend on the pressure at inlet. So the pressurized air and acetylene injection will not make any sense to increase the pressure in RCCI engine combustion chamber. The pressure at outlet depends upon the position and angle of the secondary fuel injector. The maximum pressure at the outlet is obtained at a distance of 243.5 mm from the intake valve at an injector inclination of 45°and 90°. The maximum TKE and TDR is obtained at 45° injector angle with the acetylene flow rate of 3 LPM. By combining all the results, the supply of 3 LPM acetylene flow rate with an injector angle of 45° at a distance of 243.5 mm from intake valve gives the better performance, emission and combustion characteristics for RCCI engine fueled by acetylene gas as a low reactivity fuel.

5 Inferences of the study

The aerodynamic phenomenon of the inlet air and acetylene mixture is greatly affecting the combustion parameters. The RCCI engine, which is using the acetylene gas injector placed at a distance of 243.5 mm and 45° inclination with 3 LPM acetylene flow rate produces more pressure at the entry of the intake valve. This higher pressure air and acetylene mixture is rising the in cylinder pressure. It is observed that many internal combustion engine performance, emission and combustion investigations, the higher cylinder pressure giving better performance, emission and combustion characteristics compared with lower in cylinder pressure. Moreover the degree of homogeneity of air and acetylene is important factor which is influenced by TKE and TDR. The higher TKE and TDR is achieving in the acetylene gas injector placed at a distance of 243.5 mm and 45° inclination with 3 LPM acetylene flow rate. The higher degree of homogeneity in between the air and acetylene makes the uniform combustion, when the high reactivity fuels like diesel injected at the end of the compression stroke. On the contrary, if the TKE and TDR of the air and acetylene mixture are low means that it will be automatically lower the degree of homogeniety in between the air and acetylene. This low degree of homogeneity mixture creates uneven charging pockets inside the combustion chamber and thus creates premature combustion, which leads to a reduction in performance and an increase in exhaust emissions.

The future scope of work is CFD analyze of the in-cylinder mixing of air-acetylene or some other gaseous fuel mixture and diesel fuel mixing phenomenon. And also physically modify the intake manifold according to the geometry obtained from the simulation and experimentally test the RCCI engine for better performance, combustion and emission characteristics.

References

Velumani V, Manieniyan V, Sivaprakasam S (2019) Effect of multi-walled carbon nanotubes in DI diesel engine. ARPN J Eng Appl Sci 14(7):1396–1399

Sukumar V, Manieniyan V, Senthilkumar R, Sivaprakasam S (2020) Production of bio oil from sweet lime empty fruit bunch by pyrolysis. Renew Energy 146:309–315

Deivajothi P, Manieniyan V, Sivaprakasam S (2019) Experimental investigation on DI diesel engine with fatty acid oil from by-product of vegetable oil refinery. Ain Shams Eng J 10(1):77–82

Manieniyan V, Sukumar V, Senthilkumar R, Sivaprakasam S (2019). Emission reduction using biodiesel blends with nano-additives and reformed exhaust gas recirculation (REGR) in DI diesel engine. Int J Ambient Energy, 1–7

Sukumar V, Manieniyan V, Sivaprakasam S (2019) Experimental studies on DI diesel engine fueled in sweet lime pyrolysis oil with biodiesel. Int J Appl Eng Res 14(5):1145–1150

Belgiorno G, Di Blasio G, Shamun S, Beatrice C, Tunestål P, Tunér M (2018) Performance and emissions of diesel-gasoline-ethanol blends in a light duty compression ignition engine. Fuel 217:78–90

Belgiorno G, Dimitrakopoulos N, Di Blasio G, Beatrice C, Tunestål P, Tunér M (2018) Effect of the engine calibration parameters on gasoline partially premixed combustion performance and emissions compared to conventional diesel combustion in a light-duty Euro 6 engine. Appl Energy 228:2221–2234

Beatrice C, Di Blasio G, Belgiorno G (2017) Experimental analysis of functional requirements to exceed the 100 kW/l in high-speed light-duty diesel engines. Fuel 207:591–601

Belgiorno G, Boscolo A, Dileo G, Numidi F, Pesce FC, Vassallo A, Di Blasio G (2020). Experimental study of additive-manufacturing-enabled innovative diesel combustion bowl features for achieving ultra-low emissions and high efficiency (No. 2020–37–0003). SAE Technical Paper

Di Blasio G, Beatrice C, Belgiorno G, Pesce FC, Vassallo A (2017) Functional requirements to exceed the 100 kW/l milestone for high power density automotive diesel engines. SAE Int J Engines 10(5):2342–2353

Soloiu V, Gaubert R, Moncada J, Wiley J, Williams J, Harp S, Mothershed D (2019) Reactivity controlled compression ignition and low temperature combustion of fischer-tropsch fuel blended with n-butanol. Renew Energy 134:1173–1189

Rosha P, Dhir A, Mohapatra SK (2018) Influence of gaseous fuel induction on the various engine characteristics of a dual fuel compression ignition engine: a review. Renew Sustain Energy Rev 82:3333–3349

İlhak Mİ, Doğan R, Akansu SO, Kahraman N (2020) Experimental study on an SI engine fueled by gasoline, ethanol and acetylene at partial loads. Fuel 261:116148

Choudhary KD, Nayyar A, Dasgupta MS (2018) Effect of compression ratio on combustion and emission characteristics of CI engine operated with acetylene in conjunction with diesel fuel. Fuel 214:489–496

Gocmen K, Soyhan HS (2020) An intake manifold geometry for enhancement of pressure drop in a diesel engine. Fuel 261:116193

Sadeq AM, Bassiony MA, Elbashir AM, Ahmed SF, Khraisheh M (2019) Combustion and emissions of a diesel engine utilizing novel intake manifold designs and running on alternative fuels. Fuel 255:115769

Silva EAA, Ochoa AAV, Henríquez JR (2019) Analysis and runners length optimization of the intake manifold of a 4-cylinder spark ignition engine. Energy Convers Manag 188:310–320

Krishna BM, Bijucherian A, Mallikarjuna J (2010) Effect of intake manifold inclination on intake valve flow characteristics of a single cylinder engine using particle image velocimetry. Int J Eng Appl Sci 6(2):119–125

Chen Z, Yao C, Yao A, Dou Z, Wang B, Wei H, Shi J (2017) The impact of methanol injecting position on cylinder-to-cylinder variation in a diesel methanol dual fuel engine. Fuel 191:150–163

Adithya K, Ahmed F, Padmanathan P, Mohan CG, Prakash R (2020) Design optimization of intake manifold of dual fuel engine. Mater Today Proc. https://doi.org/10.1016/j.matpr.2020.02.726

Ebrahimi M, Jazayeri SA (2019) Effect of hydrogen addition on RCCI combustion of a heavy duty diesel engine fueled with landfill gas and diesel oil. Int J Hydrog Energy 44(14):7607–7615

Chaubey A, Tiwari AC (2017) Design and CFD analysis of the intake manifold for the suzuki G13bb engine. Int J Res Appl Sci Eng Technol (IJRASET) 5:1258–1276

Abdullah NR, Shahruddin NS, Mamat AMI, Kasolang S, Zulkifli A, Mamat R (2013) Effects of air intake pressure to the fuel economy and exhaust emissions on a small SI engine. Procedia Eng 68:278–284

Chen J, Li J, Yuan L (2018) Effects of inlet pressure on ignition of spray combustion. Int J Aerosp Eng 2018:1–13

Jemni MA, Kantchev G, Abid MS (2011) Influence of intake manifold design on in-cylinder flow and engine performances in a bus diesel engine converted to LPG gas fuelled, using CFD analyses and experimental investigations. Energy 36(5):2701–2715

Cebula A, Świątek P, Kowalczyk S (2019) A numerical analysis of the air flow through the IC engine intake manifold. Prog Comput Fluid Dyn Int J 19(1):63–68

Bari S, Hossain SN, Saad I (2020) A review on improving airflow characteristics inside the combustion chamber of CI engines to improve the performance with higher viscous biofuels. Fuel 264:116769

Chintala V, Subramanian KA (2013) A CFD (computational fluid dynamics) study for optimization of gas injector orientation for performance improvement of a dual-fuel diesel engine. Energy 57:709–721

Wei T (2018) Integral properties of turbulent-kinetic-energy production and dissipation in turbulent wall-bounded flows. J Fluid Mech 854:449–473

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Sonachalam, M., Manieniyan, V. Optimization of critical angle, distance and flow rate of secondary fuel injection in DI diesel engine using computational fluid dynamics. SN Appl. Sci. 3, 126 (2021). https://doi.org/10.1007/s42452-020-04138-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-020-04138-3