Abstract

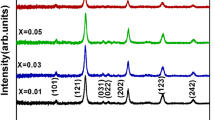

Present research presents CaTiO3 as an important negative temperature coefficient resistance (NTCR) thermistor material. Two routes were adopted such as solid state reaction and high energy ball milling (HEBM) for comparative analysis. X-ray diffraction (XRD), and Steinhart–Hart equation used for characterization of material formation and thermistor property. XRD pattern shows single phase orthorhombic symmetry or both samples. Electrical resistance found by LCR meter shows about NTCR behaviour and Steinhart–Hart model provides information for its suitability towards thermistor industry. To know the faster response nature time domain analysis performed on both samples. To the best knowledge, there are not much data available on properties of CaTiO3 as thermistor based temperature sensor material, which lead this research work. Enhanced sensing behaviour observed in CaTiO3 processed through HEBM. Both the samples signifies their strong potential in thermistor industry with sensitivity in the range of 4000–6700 K with exponential electrical resistance change in the specified temperature range.

Similar content being viewed by others

References

L. Tiabi-Benziada, A. Mezroua, R. Von Der Muhll, CaTiO3 related materials for resonators. Ceramics Silikáty 48(4), 180–184 (2004)

C. Carter, M. Norton, Ceramic Materials: Science and Engineering (Springer, New York, 2007)

A. Moulson, A. Herbert, Electroceramics: Materials, Properties, Applications, 2nd edn. (Wiley, New York, 2003)

G. Kelly, J. Alderman, C. Lyden, J. Barrett, Mi-crosystem packaging: lessons from conventional low cost IC packaging. J. Micromech. Microeng. 7, 99–103 (1997)

G. Gralik, A.E. Thomsen, C.A. Moraes, F. Raupp-Pereira, Processing and characterization of CaTiO3 perovskite ceramics. Process. Appl. Ceram. 8(2), 53–57 (2014)

R.F. Gonçalves, N.L.V. Carreno, M.T. Escote, K.P. Lopes, A. Valentini, E.R. Leite, E. Longo, M.A. Machado, Fotoluminescência e adsorção de CO2 em nanopartículas de CaTiO3 dopadas com lan-tânio. Quím. Nova 27, 862–864 (2004)

G. Mi, Y. Murakami, D. Shindo, F. Saito, Microstructural investigation of CaTiO3 Formedmechano chemically by grinding of a CaO–TiO2 mixture. Powder Technol. 104(1), 75–78 (1999)

A. Feteira, Negative temperature coefficient resis-tance (NTCR) ceramic thermistors: an industrial per- spective. J. Am. Ceram. Soc. 92(5), 967–983 (2009)

P.S. Anjana, T. Sherin, M.T. Sebastian, J. Jame, Synthetic minerals for electronic applications. Earth Sci. India I(I), 43–45 (2008)

L.B. Kong, W. Zhu, O.K. Tan, Preparation and characterization of Pb(Zr0.52Ti0.48)O3 ceramics from high-energy ball milling powders. Mater. Lett. 42, 232–236 (2000)

R.M. German, Sintering Theory and Practice (Wiley, New York, 1996)

J. Wang, J.M. Xue, D.M. Wan et al., Mechanically activating nucleation and growth of complex perovskites. J. Solid State Chem. 154, 321–328 (2000)

J.R.R. Siqueira, A.Z. Simões, B.D. Stojanovic et al., Influence of milling time on mechanically assisted synthesis of Pb0.91Ca0.1TiO3 powders. Ceram. Int. 33, 937–941 (2007)

S.K.S. Parashar, R.N.P. Choudhary, B.S. Murty, Ferroelectric phase transition in Pb0.92Gd0.08(Zr0.53Ti0.47)0.98O3. J. Appl. Phys. 94, 6091 (2003)

C. Suryanarayana, Mechanical alloying and milling. Prog. Mater. Sci. 46, 1–184 (2001)

A. Abreu Jr., S.M. Zanetti, M.A.S. Oliveira, G.P. Thim, Effect of ureaon lead zirconate titanate—Pb(Zr0.52Ti0.48)O3—nanopowders synthesized by the Pechini method. J. Eur. Ceram. Soc. 25, 743–750 (2005)

C.C. Koch, C. Suryanarayana, Nanocrystalline materials, in Microstructure and Properties of Materials. vol. 2(6), ed. by C. Suryanarayana (World Scientific Publishing Corp., Singapore, 2000), pp. 359–403

C. Suryanarayana (ed.), Mechanical alloying, in ASM Handbook, (Powder Metal Technologies and Applications), vol. 7, ed. by C. Suryanarayana (ASM International, Materials Park, 1998), pp. 80–90

C. Suryanarayana, C.C. Koch, Nanostructured materials, in Non-Equilibrium Processing of Materials, ed. by C. Suryanarayana (Elsevier Science Pub., Oxford, 1999), pp. 313–346

E. Ma, M. Atzmon, Phase transformation induced by mechanical alloying in binary systems. Mater. Chem. Phys. 39, 249–267 (1995)

S. Morrell, Y.T. Man, Using modeling and simulation for the design of full scale ball mill circuits. Miner. Eng. 10, 1311–1327 (1997)

A. Misra, J. Cheung, Particle motion and energy distribution in tumbling ball mills. Powder Technol. 105, 222–227 (1999)

E. Gaffet, M. Abdellaoui, N. Malhouroux-Gaffet, Formation of nanostructural material induced by mechanical processing. Mater. Trans. JIM 36, 198–209 (1995)

S.K.S. Parashar, R.N.P. Choudhary, B.S. Murty, Nanoscale structure-property relations in Sm modified lead zirconate titanate. J. Nanosci. Nanotechnol. 9, 3106–3111 (2009)

C. Suryanarayana, M.G. Norton, X-ray Diffraction: A Practical Approach (Plenum Press, New York, 1998)

B. Lonnberg, Characterization of milled Si3N4 powder using Xray peak broadening and surface area analysis. J. Mater. Sci. 29, 3224–3236 (1994)

L. Aymard, A. Dehahaye-Vidal, F. Portemer, F. Disma, Study of the formation reactions of silver-palladium alloys by grinding and post-milling isothermal annealing. J. Alloys Compd. 238, 116–127 (1996)

J.R. Macdonald, Impedance spectroscopy (Wiley, New York, 1987)

M.L. Moreira et al., Structural and optical properties of CaTiO3 perovskite based materials obtained by microwave assisted hydrothermal synthesis: an experimental and theoretical insight. Acta Materialia 57, 5174–5185 (2009)

M.S. Khalil, F.F. Hammad, Influence of Cu addition on the structure and dielectric properties of CaTiO3. Egypt J. Solids 25, 175–181 (2002)

S. Palaniandy, N.H. Jamil, Influence of milling conditions on the mechanochemical synthesis of CaTiO3 nanoparticles. J. Alloys Compd. 476, 894–902 (2009)

S. Sahoo, U. Dash, S.K.S. Parashar, S.M. Ali, Frequency and temperature dependent electrical characteristics of CaTiO3 nano-ceramic prepared by high-energy ball milling. J. Adv. Ceram. 2, 291–300 (2013)

J. Zhao, L. Li, Z. Gui, Influence of lithium modification on the properties of Y doped Sr0.5Pb0.5TiO3 thermistors. Sens. Actuators A 95, 46–50 (2001)

C.L Yuan, X.Y. Liu, J.W. Xu, X.W. Zhang and C.R. Zhou, Electrical properties of lead free thick film NTC thermistors based on BaFe0.9Sn0.1O3 ceramic, in International conference on Intelligent computing and integrated systems (IEEE, 2010), pp. 445–448

K.A. Stella, K. Krishnankutty, K. R. Dayas, A. Seema, Effect of Bi2O3 as sintering aid in modifying the NTC characteristics of MnCr2O4 compositions for temperature sensors, in Physics and technology of sensors (ISPTS), (IEEE, 2012), pp. 301–304

NTC thermistor design guide for discrete components & probes, Quality thermistor.Inc, USA

BetaTHERM Sensors Temperature solutions, NTC Thermistor theory, Finland

I. Brunets, O. Mrooz, O. Shpotyuk, H. Altenburg, Thick film NTC thermistors based on spinel type semiconducting electroceramics, in 24th International conference on microelectronics, Serbia, (IEEE, 2004), pp. 503–506

G.M. Gouda, C.L. Nagendra, A new transition metal oxide sensor material for thermistor applications: Manganese-vanadium-oxide, in 1st International symposium on physics and technology of sensors. (IEEE, 2012), pp. 125–128

C.H. McMurtry, W.T. Terrell, W.T. Benecki, A Tin oxide thermistor for temperature sensing to 1800 °F. IEEE Trans. Ind. Gener. Appl. 2, 461–464 (1966)

C.L. Yuan, X.Y. Liu, J.W. Xu, X.W. Zhang, C.R. Zhou, Electrical properties of SrxBa1−xFe0.6Sn0.4O3−ε NTC thermistor. Bull. Mater. Sci. 35, 425–431 (2012)

K. Park, D.Y. Bang, J.G. Kim, J.Y. Kim, C.H. Lee, B.H. Choi, Influence of the composition and the sintering temperature on the Electrical resistivities of Ni-Mn-Co-(Fe) oxide NTC thermistors. Journal of the Korean physical society. 41, 251–256 (2002)

E.A. de Vasconcelos, S.A. Khan, W.Y. Zahang, H. Uchida, T. Katsube, Highly sensitive thermistors based on high purity polycrystalline cubic silicon carbide. Sens. Actuators A 83, 167–171 (2000)

C. Yuan, X. Liu, M. Liang, C. Zhou, H. Wang, Electrical properties of Sr–Bi–Mn–Fe–O thick film NTC thermistors prepared by screen printing. Sens. Actuators A 167, 291–296 (2011)

Z.P. Nenova, T.G. Nenova, Linearrization circuit of the thermistor connection. IEEE Trans. Instrum. Meas. 58, 441–449 (2009)

R.N. Jadhav, S.N. Mathad, V. Puri, Studies on the properties of Ni0.6Cu0.4Mn2O4 NTC ceramic due to Fe doping. Ceram. Int. 38, 5181–5188 (2012)

C.C. Wang, S.A. Akbar, W. Chen, J.R. Schorr, High temperature thermistors based on yitria and calcium zirconate. Sens. Actuator A 58, 237–243 (1997)

T. Nagai, M. Itoh, SiC thin film thermistor. IEEE Trans. Ind. Appl. 26, 1139–1143 (1990)

O. Aleksic, B. Radojcic, R. Ramovic, Electrode effect on NTC planar thermistor volume resistivity, in 25th International conference on microelectronics, balgrade, Serbia, (IEEE, 2006), pp. 580–583

YUKUTO NTC Thermistor, JOYIN, Taiwan

P. Padmini, N.S. Hari, T.R.N. Kutty, Cryogenic sensors from semiconducting barium titanate ceramics with strong negative temperature coefficient of resistance. Sens. Actuators A. 50, 39–44 (1995)

NTC thermistors, KEYSTONE thermometrics corporation, USA

S. Jagtap, S. Rana, U. Mulik, D. Amalanekar, Thick film NTC thermistor for wide range of temperature sensing. Microelectron. Int. 24, 7–13 (2007)

Intoduction to NTCs:NTC Thermistor, Philips Components, California

S.G.E. Wissmar, M. Kolahdouz, Y. Yamamoto, B. Tillack, C. Vieder, J.Y. Andersson, H.H. Radamsson, Monocrystalline SiGe for high performance uncooled thermistor, in Semiconductor device research symposium, (IEEE, 2007), pp.1–2

W.L. Brogan, Modern control theory (Pearson Education, London, 1974)

I.J. Nagrath, Control System Engineering (New Age International, New Delhi, 2006)

N.S. Norman, Control System Engineering (Wiley, NewYork, 2004)

K. Ogata, Modern Control Engineering (Prentice Hall, Upper Saddle River, 2010)

E.D. Boalt, Real time temperature control of oven using Matlab-Simulink, in Proceeding of the 11th WSEAS international conference on systems, Aglos Nikolaos, Crete Island, (2007), pp. 424–429

N.T.C. Thermistors, General Technical Information (EPCOS, Munich, 2009)

Thermistors in Single Supply Temperature Sensing Circuits. Microchip Technology Inc., 1999

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sahoo, S. Negative Temperature Coefficient Resistance of CaTiO3 for Thermistor Application. Trans. Electr. Electron. Mater. 21, 91–98 (2020). https://doi.org/10.1007/s42341-019-00159-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42341-019-00159-x