Abstract

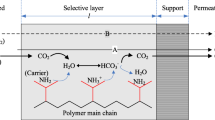

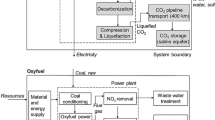

This paper describes the present use of carbon capture and storage in industries such as iron and steel and cement industry. It also describes how implications of carbon capture and sequestration can lead to reduction in global warming and can reduce the hazardous effects of carbon on environment. The major processes involved in carbon capture and sequestration are pre-combustion, post-combustion, and oxy-fuel have also been discussed. Also, the paper highlights how different membranes can contribute towards carbon capture and sequestration. Polymer, carbon molecular sieve, and organic microporous membrane advantages and drawbacks have also been discussed. For gas separation, the major membranes discussed are polymer, carbon sieve, and microporous organic membrane along with their use in different industries. Major focus still relies on how advancement of membrane can be done to have an optimal strategy for carbon capture and sequestration.

Similar content being viewed by others

References

A. Sood, S. Vyas, A review: carbon capture and sequestration (CCS) in India. Int J Mech Eng Technol 8(2), 1–7 (2017)

D. Cebrucean, V. Cebrucean, I. Ionel, CO2 capture and storage from fossil fuel power plants. Energy Procedia 63, 18–26 (2014)

D.W. Keith, G. Holmes, D. St. Angelo, K. Heidel, A process for capturing CO2 from the atmosphere. Joule 2(8), 1573–1594 (2018). https://doi.org/10.1016/j.joule.2018.05.006

X. He, A review of material development in the field of carbon capture and the application of membrane-based processes in power plants and energy-intensive industries. Energy Sustain Soc 8, 34 (2018)

Birat, J.P., 2010 Carbon dioxide (CO2) capture and storage technology in the iron and steel industry Developments and innovation in carbon dioxide (CO2) capture and storage technology, 492–521

X. He, Q. Yu, M.B. Hägg, in Encyclopedia of Membrane Science and Technology, ed. by H. EMV, V. V. Tarabara. CO2 Capture (Wiley, 2013b), pp. 1–2390

J.L. Míguez, J. Porteiro, R. Pérez-Orozco, M.A. Gómez, Technology evolution in membrane-based CCS. Energies 11, 1–18 (2018)

Figueroa, J.D., Fout, T., Plasynski, S.,McIlvried, H., Srivastava, R.D., 2008. Advances in CO2 capture technology—The U.S. Department of Energy’s Carbon Sequestration Program. Int J Greenh Gas Control.2, 9–\

D.Y.C. Leung, G. Caramanna, M.M. Maroto-Valer, An overview of current status of carbon dioxide capture and storage technologies. Renew Sust Energ Rev 39, 426–443 (2014)

J.C.M. Pires, F.G. Martins, M.C.M. Alvim-Ferraz, M. Simões, Recent developments on carbon capture and storage: an overview. Chem Eng Res Des 89, 1446–1460 (2011)

B. Zheng, J. Xu, Carbon capture and storage development trends from a techno-paradigm perspective. Energies 7, 5221–5250 (2014)

Y. Tan, W. Nookuea, H. Li, E. Thorin, J. Yan, Property impacts on carbon capture and storage (CCS) processes: a review. Energy Convers Manag 118, 204–222 (2016)

C. Strazza, A. Del Borghi, M. Gallo, Development of specific rules for the application of life cycle assessment to carbon capture and storage. Energies 6, 1250–1265 (2013)

Y. Li, Q.M. Wang, P.B. Wang, Evaluation of post-combustion CO2 capture technologies. Adv Mater Res 734–737, 1881–1886 (2013)

A.B. Rao, E.S. Rubin, A technical, economic, and environmental assessment of amine-based CO2 capture technology for power plant greenhouse gas control. Environ Sci Technol 36, 4467–4475 (2002)

D. Jansen, M. Gazzani, G. Manzolini, E.V. Dijk, M. Carbo, Pre-combustion CO2 capture. Int J Greenh Gas Control 40, 167–187 (2015)

C. Alie, L. Backham, E. Croiset, P.L. Douglas, Simulation of CO2 capture using MEA scrubbing: a flow sheet decomposition method. Energy Convers Manag 46, 475–487 (2005)

J. Gomes, S. Santos, J. Bordado, Choosing amine-based absorbents for CO2 capture. Environ Technol 36, 19–25 (2015)

N.S. Kwak, J.H. Lee, I.Y. Lee, K.R. Jang, J.G. Shim, A study of the CO2 capture pilot plant by amine absorption. Energy 47, 41–46 (2012)

F. Vega, A. Sanna, B. Navarrete, M.M. Maroto-Valer, V.J. Cortés, Degradation of amine-based solvents inCO2 capture process by chemical absorption. Greenh Gases Sci Technol 4, 707–733 (2014)

G. Xu, F. Liang, Y. Yang, Y. Hu, K. Zhang, W. Liu, An improved CO2 separation and purification system based on cryogenic separation and distillation theory. Energies 7, 3484–3502 (2014)

Y. Tan, W. Nookuea, H. Li, E. Thorin, J. Yan, Evaluation of viscosity and thermal conductivity models forCO2 mixtures applied in CO2 cryogenic process in carbon capture and storage (CCS). Appl Therm Eng 123, 721–733 (2017)

J.A. Swisher, A.S. Bhown, Analysis and optimal design of membrane-based CO2 capture processes for coal and natural gas-derived flue gas. Energy Procedia 63, 225–234 (2014)

N. Du, H.B. Park, M.M. Dal-Cin, M.D. Guiver, Advances in high permeability polymeric membrane materials for CO2separations. Energy Environ Sci 5(6), 7306–7322 (2012)

T.K. Carlisle, E.F. Wiesenauer, G.D. Nicodemus, D.L. Gin, R.D. Noble, Ideal CO2/light gas separation performance of poly(vinylimidazolium) membranes and poly(vinylimidazolium)-ionic liquid composite films. Ind Eng Chem Res 52(3), 1023–1032 (2012)

X. He, Q. Yu, M.-B. Hägg, in Encyclopedia of Membrane Science and Technology, ed. by E. M. V. Hoek, V. V. Tarabara. CO2 Capture (Wiley, 2013b)

B. Belaissaoui, E. Favre, Membrane separation processes for post-combustion carbon dioxide capture: state of the art and critical overview. Oil Gas Sci Technol – Rev IFP Energiesnouvelles 69(6), 1005–1020 (2014)

Khalilpour, R., Mumford, K., Zhai, H., Abbas, A., Stevens, G., 2015. Rubin, E.S., Membrane-based carbon capture from flue gas: a review. J Clean Prod 103, 286–300

K. Ramasubramanian, W.S.W. Ho, Recent developments on membranes for post-combustion carbon capture. Curr Opin Chemeng 1(1), 47–54 (2011)

M. Wang, J. Zhao, X. Wang, A. Liu, K.K. Gleason, Recent progress on submicron gas-selective polymeric membranes. J Mater Chem A 5(19), 8860–8886 (2017)

M.C. Ferrari, D. Bocciardo, S. Brandani, Integration of multi-stage membrane carbon capture processes to coal-fired power plants using highly permeable polymers. Green Energy Environ 1(3), 211–221 (2016)

S. Roussanaly, R. Anantharaman, K. Lindqvist, H. Zhai, E. Rubin, Membrane properties required for post-combustion CO 2 capture at coal-fired power plants. J Membr Sci 511, 250–264 (2016)

J.L. Li, B.H. Chen, Review of CO2 absorption using chemical solvents in hollow fiber membrane contractors. Sep Purif Technol 41(2), 109–122 (2005)

G.H. Bakeri, A.F. Ismail, M. Sharialy-Miassar, T. Matsuaro, Effect of polymer concentration on the structure and performance of polyetherimide hollow fiber membrane. J Membr Sci 363(1–2), 103–111 (2010)

E. Favre, Membrane processes and post combustion carbon dioxide capture: challenges and prospects. Chem Eng J 171(3), 782–793 (2011)

Khalilpour, R., Abbas, A., Lai, Z.P., Pinnau, I., Modelling and parametric analysis of hollow fiber membrane system for carbon capture from multicomponent flue gas processing system engineering, 58(5), 1550–1561

R. Wang, H.Y. Zhang, P.H.M. Feronand, D.T. Liomg, Influence of membrane writing on CO2 capture in microporous hollow fiber membrane contactors. Sep Purif Technol 46(1–2), 33–40 (2005)

X. Wang, X. Han, Application of polymeric membrane in CO2 capture from post combustion. Adv Chem Eng Sci 2, 336–341 (2012)

M. Duval, B. Folkers, M.H.V. Mulder, G. Desgrandchamps, C.A. Smolders, Absorbent filled membranes for gas separation, properties of polymeric membranes by incorporation of microporous absorbent. J. Member. Sci. 80(1), 189–198 (1993)

R. Abedini, A. Mezhadmagshadam, Application of membrane in gas separation processes, its suitability and mechanisms. Petrol Coal 52, 69–80 (2010)

Faculty.uscupstate.edu/elever/polymer%20resources/Glasstrans.html, Accessed 31 Jan 2001

A. Mushtaq, H.B. Mukhtar, A.M. Shariff, H.A. Mannan, A review: development of polymeric blend membrane for removal of CO2 from natural gas. Int J Eng Technol 13(2), 53–60 (2013)

L.Y. Chu, Thermo-responsive membranes for chiral resolution. Smart Membr Mater Syst, 121–143 (2011). https://doi.org/10.1007/978-3-642-18114-6_5

M. Yoshikawa, K. Murakoshi, T. Kogita, K. Hanaoka, M.D. Guiver, G.P. Robertson, Chiral separation membranes from modified polysulfone having myrtenal-derived terpenoid side groups. Eur Polym J 42, 2532–2539 (2006)

M.A. Hillmyer, Nanoporous materials from block copolymer precursors. Adv Polym Sci, 137–181 (2005). https://doi.org/10.1007/12_002

A.S. Zalusky, R. Olayo-Valles, J.H. Wolf, M.A. Hillmyer, Ordered nanoporous polymers from polystyrene–polylactide block copolymers. J Am Chem Soc 124, 12761–12773 (2002)

J. Rzayev, M.A. Hillmyer, Nanoporous polystyrene containing hydrophilic pores from an ABC triblock copolymer precursor. Macromolecules 38(1), 3–5 (2005)

G. Liu, J. Ding, A. Guo, M. Herfort, D. Bazzett-Jones, Macromolecules 30, 1851 (1997)

Young, J.S., Berchtold, K.A., Eric, P., Greenberg, A.R. James, A., Onorato, F., Hopkins, S., 2005. Novel polymeric-metallic composite membranes for CO2 separations at elevated temperatures. 2005 AIChE spring National Meeting, conference proceedings. 1489-1494

Peinemann, K., Nunes, S.P., 2007. Membranes for energy conversion. Wiley-VCH Verlag GmbH & Co. KGaA. 2, 1–286

C. Dye, Robert & Jorgensen, Betty & Pesiri, David. 2004. Meniscus membranes for separations

M. Ulbricht, Advanced functional polymer membranes. Polymer 47(7), 2217–2262 (2006)

Wang, H., Yeager G.W.:US20070556901 2007

Ekiner, O.M., Del, W., 1999. Gas separation membranes of blends of polyethersulfones with aromatic polyimides. 1-10

S.E. Kentish, C.A. Scholes, G.W. Stevens, Carbon dioxide separation through polymeric membrane systems for flue gas applications. Recent Patent Chem Eng 1(1), 52–66 (2008)

G.A. Grant, P.R. Fisher, J.E. Barrett, P.C. Wilson, Removal of paclobutrazol from irrigation water using granular-activated carbon. Irrig Sci 2018(36), 159–166 (2018)

S.H. Han, H.J. Kwon, K.Y. Kim, J.G. Seong, C.H. Park, S. Kim, C.M. Doherty, A.W. Thornton, A.J. Hill, A.E. Lozano, K.A. Berchtold, Y.M. Lee, Tuning microcavities in thermally rearranged polymer membranes for CO2 capture. Phys Chem Chem Phys 14(13), 4365–4373 (2012)

S. Kim, Y. Lee, Thermally rearranged (TR) polymer membranes with nanoengineered cavities tuned for CO2 separation. J Nanopart Res 14(7), 1–11 (2012)

H.B. Park, S.H. Han, C.H. Jung, Y.M. Lee, A.J. Hill, Thermally rearranged (TR) polymer membranes for CO2 separation. J Membr Sci 359(1–2), 11–24 (2010)

H.B. Park, C.H. Jung, Y.M. Lee, A.J. Hill, S.J. Pas, S.T. Mudie, E. Van Wagner, B.D. Freeman, D.J. Cookson, Polymers with cavities tuned for fast selective transport of small molecules and ions. Science 318(5848), 254–258 (2007)

N.B. McKeown, Polymers of intrinsic microporosity. ISRN Mater Sci 2012, 16 (2012)

P.M. Budd, E.S. Elabas, B.S. Ghanem, S. Makhseed, N.B. McKeown, K.J. Msayib, C.E. Tattershall, D. Wang, Solution-processed, organophilic membrane derived from a polymer of intrinsic microporosity. Adv Mater 16(5), 456–459 (2004)

J. Ahn, W.J. Chung, I. Pinnau, J. Song, N. Du, G.P. Robertson, M.D. Guiver, Gas transport behavior of mixed-matrix membranes composed of silica nanoparticles in a polymer of intrinsic microporosity (PIM-1). J Membr Sci 346(2), 280–287 (2010)

W.F. Yong, F.Y. Li, Y.C. Xiao, T.S. Chung, Y.W. Tong, High performance PIM-1/Matrimid hollow fiber membranes for CO2/CH4, O2/N2 and CO2/N2 separation. J Membr Sci 443, 156–169.R (2013)

N.B. McKeown, P.M. Budd, K.J. Msayib, B.S. Ghanem, H.J. Kingston, C.E. Tattershall, S. Makhseed, K.J. Reynolds, D. Fritsch, Polymers of intrinsic microporosity (PIMs): bridging the void between microporous and polymeric materials. Chem Eur J 11(9), 2610–2620 (2005)

N. Du, H.B. Park, G.P. Robertson, M.M. Dal-Cin, T. Visser, L. Scoles, M.D. Guiver, Polymer nanosieve membranes for CO2-capture applications. Nat Mater 10(5), 372–375 (2011)

W. Zhou, L. Zhang, P. Wu, Y. Cai, X. Zhao, C. Yao, Study on permeability stability of sand-based, microporous, ceramic filter membrane. Materials 12, 1–14 (2019)

S. Wu, K. Song, J. Guan, Q. Kan, Synthesis and characterization of super-microporous material with enhanced hydrothermal stability. Bull Mater Sci 34(4), 979–983 (2011)

Y.S. Do, W.H. Lee, J.G. Seong, J.S. Kim, H.H. Wang, C.M. Doherty, A.J. Hill, Y.M. Lee, Thermally rearranged (TR) bismaleimide-based network polymers for gas separation membranes. Chem Commun 52(93), 13556–13559 (2016)

B.S. Karnik, S.H. Davies, K.C. Chen, D.R. Jaglowski, M.J. Baumann, S.J. Masten, Effects of ozonation on the permeate flux of nano-crystaline ceramic membranes. Water Res 39, 728–734 (2005)

A. Reina, X. Jia, J. Ho, D. Nezich, H. Son, V. Bulovic, M.S. Dresselhaus, J. Kong, Large area, few-layer. Graphene films on arbitrary substrates by chemical vapor deposition. Nano Lett 9, 30–35 (2009)

S. Milenkovic, A.J. Smith, A.W. Hassel, Single crystalline molybdenum nanowires, nanowire arrays and nanopore arrays in nickel-aluminium. J Nanosci Nanotechnol 9, 3411–3417 (2009)

M. Li, J. Zhai, H. Liu, Y. Song, L. Jiang, D. Zhu, Electrochemical deposition of conductive superhydrophobic zinc oxide thin films. J Phys Chem B 2003(107), 9954–9957 (2003)

M.E. Boot-Handford, J.C. Abanades, E.J. Anthony, M.J. Blunt, S. Brandani, N. Mac Dowell, J.R. Fernandez, M.C. Ferrari, R. Gross, J.P. Hallett, R.S. Haszeldine, P. Heptonstall, A. Lyngfelt, Z. Makuch, E. Mangano, R.T.J. Porter, M. Pourkashanian, G.T. Rochelle, N. Shah, J.G. Yao, P.S. Fennell, Carbon capture and storage update. Energy Environ Sci 7(1), 130–189 (2014)

M.C. Campo, F.D. Magalhães, A. Mendes, Carbon molecular sieve membranes from cellophane paper. J Membr Sci 350(1–2), 180–188 (2010)

J.E. Koresh, A. Soffer, Molecular-sieve carbon perm-selective membrane. 1. Presentation of a new device for gas–mixture separation. Sep Sci Technol 18(1983), 723–734 (1983)

J.E. Koresh, A. Soffer, Mechanism of permeation through molecular-sieve carbon membrane. Part 1. The effect of adsorption and the dependence on pressure. J Chem Soc Faraday Trans 1(82), 2057–2063 (1986)

C.W. Jones, W.J. Koros, Carbon molecular sieve gas separation membranes-II. Regeneration following organic exposure. Carbon 32(8), 1427–1432 (1994)

J. Koresh, A. Soffer, Study of molecular sieve carbons. Part 1.—Pore structure, gradual pore opening and mechanism of molecular sieving. Journal of the chemical society, faraday transactions 1: Physical chemistry in condensed phases 76, 2457 (1980)

A. Kapoor, R.T. Yang, Kinetic separation of methane—carbon dioxide mixture by adsorption on molecular sieve carbon. Chem Eng Sci 44(8), 1723–1733 (1989)

H. Marsh, F. Rodriguez-Reinoso (eds.), Science of Carbon Materials (Universidad de Alicante, Secretariado de Publications, Spain, 2000), p. 673

Soffer, A., Koresh, J., Saggy, S., 1987. Separation devices. U.S. Patent 4,685,940

X. He, M.B. Hägg, Hybrid fixed–site–carrier membranes for CO2/CH4 separation. ProcEng 44, 118–119 (2012b)

J.E. Koresh, A. Soffer, The carbon molecular sieve membranes. General properties and the permeability of CH4/H2 Mixture. Sep Sci Technol 22(2–3), 973–982 (1987)

J.N. Barsema, N.F.A. van der Vegt, G.H. Koops, M. Wessling, Ag-functionalized carbon molecular-sieve membranes based on polyelectrolyte/polyimide blend precursors. Adv Funct Mater 15(1), 69–75 (2005). https://doi.org/10.1002/adfm.200305155

X. He, J.A. Lie, E. Sheridan, M.B. Hagg, Preparation and characterization of hollow fiber carbon membranes from cellulose acetate precursors. Ind Eng Chem Res 50(4), 2080–2087 (2011)

Kiyono, M., Williams, P.J., Koros, W.J., 2010. Effect of pyrolysis atmosphere on separation performance of carbon molecular sieve membranes. J Membr Sci 3(59(1–2)):2–10

J.A. Lie, M.B. Hagg, Carbon membranes from cellulose and metal loaded cellulose. Carbon 43(12), 2600–2607 (2005)

K.M. Steel, W.J. Koros, Investigation of porosity of carbon materials and related effects on gas separation properties. Carbon 41(2), 253–266 (2003)

H.H. Tseng, A.K. Itta, Modification of carbon molecular sieve membranestructure by self-assisted deposition carbon segment for gas separation. JMembrSci 389, 223–233 (2012)

M. Yoshimune, I. Fujiwara, K. Haraya, Carbon molecular sieve membranes derived from trimethylsilyl substituted poly(phenylene oxide)for gas separation. Carbon 45(3), 553–560 (2007)

L. Xu, M. Rungta, M.K. Brayden, M.V. Martinez, B.A. Stears, G.A. Barbay, W.J. Koros, Olefins-selective asymmetric carbon molecular sieve hollow fiber membranes for hybrid membrane-distillation processes for olefin/paraffin separations. J Membr Sci 423–424, 314–323 (2012b)

L. Xu, M. Rungta, W.J. Koros, Matrimid derived carbon molecular sieve hollow fiber membranes for ethylene/ethane separation. J Membr Sci 380(1–2), 138–147 (2011)

D.Y. Koh, B.A. McCool, H.W. Deckman, R.P. Lively, Reverse osmosis molecular differentiation of organic liquids using carbon molecular sieve membranes. Science 353(6301), 804–807 (2016)

H. Richter, H. Voss, N. Kaltenborn, S. Kämnitz, A. Wollbrink, A. Feldhoff, J. Caro, S. Roitsch, I. Voigt, High-flux carbon molecular sieve membranes for gas separation. Angew Chem Int Ed 56(27), 7760–7763 (2017)

IEA (2011) Technology roadmap carbon capture and storage in industrial applications 1–52

M.C. Romano, R. Anantharaman, A. Arasto, D.C. Ozcan, H. Ahn, J.W. Dijkstra, D. Boavida, Application of advanced technologies for CO2 capture from industrial sources. Energy Procedia 37, 7176–7185 (2013)

IPCC, in Prepared by Working Group III of the Intergovernmental Panel on Climate Change, ed. by B. Metz, O. Davidson, H. C. de Coninck, M. Loos, L. A. Meyer. IPCC special report on carbon dioxide capture and storage (Cambridge University Press, Cambridge, United Kingdom and New York, NY, USA, 2005)

T. Brown, A. Gambhir, N. Florin, P. Fennell, Reducing CO2 emissions from heavy industry: a review of technologies and considerations for policy makers. Imperial College London, 1–32 (2012)

M. Naranjo, D.T. Brownlow, A. Garza, CO2 capture and sequestration in the cement industry. Energy Procedia 4, 2716–2723 (2011)

S. Joshi, P. Hadiya, M. Shah, A. Sircar, Techno-economical and experimental analysis of biodiesel production from used cooking oil. BioPhys Econ Resour Qual 4(1), 1–6 (2019). https://doi.org/10.1007/s41247-018-0050-7

J.A. Lie, T. Vassbotn, M.B. Hägg, D. Grainger, T.J. Kim, T. Mejdell, Optimization of a membrane process for CO2 capture in the steelmaking industry. IJGGC 1, 309–317 (2007)

S. Roussanaly, R. Anantharaman, Cost-optimal CO2 capture ratio for membrane-based capture from different CO2 sources. Chem Eng J 327, 618–628 (2017)

D.M. D’Alessandro, B. Smit, J.R. Long, Carbon dioxide capture: prospects for new materials. Angew Chem Int Ed 49(35), 6058–6082 (2010)

Acknowledgments

The authors are grateful to Indus University and School of Technology, Pandit Deendayal Petroleum University for the permission to publish this research.

Availability of data and material

All relevant data and material are presented in the main paper.

Author information

Authors and Affiliations

Contributions

All the authors make substantial contribution in this manuscript. SS, MS, AS, and MS participated in drafting the manuscript. SS, MS, and AS wrote the main manuscript; all the authors discussed the results and implication on the manuscript at all stages.

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no competing interests.

Consent for publication

Not applicable.

Ethics approval and consent to participate

Not applicable.

Rights and permissions

About this article

Cite this article

Shah, S., Shah, M., Shah, A. et al. Evolution in the membrane-based materials and comprehensive review on carbon capture and storage in industries. emergent mater. 3, 33–44 (2020). https://doi.org/10.1007/s42247-020-00069-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42247-020-00069-2