Abstract

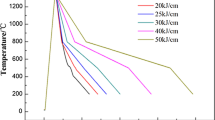

The morphology and characteristics of granular bainite (GB) in pipeline steels at different continuous cooling rates were investigated by scanning electron microscopy, transmission electron microscopy and electron back-scattered diffraction (EBSD). The results show that the morphology of ferrite matrix in GB turned from the lath sheaf structure into the nearly equiaxed large grain with the cooling rate decreasing from high (60 °C/s) to low (5–10 °C/s). At the medium cooling rate (20–40 °C/s), GB consisted of the irregular ferrite matrix, the granular martensite/austenite (M/A) constituents and abundant substructures inside. The formation of the irregular ferrite and substructure was attributed to the high-temperature recovery which occurred at relatively high-temperature stage before phase transformation. The granular morphology of M/A constituents was formed from the carbon-rich triple junctions which were produced by the multidirectional substructure interfaces converged with each other. Particularly, some martensite in M/A constituents was misoriented from the adjacent ferrite by very small misorientation angle, which could be characterized by the mean band contrast function of EBSD qualitatively or semiquantitatively.

Similar content being viewed by others

References

Z.X. Qiao, Y.C. Liu, L.M. Yu, Z.M. Gao, J. Alloy. Compd. 475 (2009) 560–564.

G. Krauss, S.W. Thompson, ISIJ Int. 35 (1995) 937–945.

E.V. Morales, R.A. Silva, I.S. Bott, S. Paciornik, Mater. Sci. Eng. A 585 (2013) 253–260.

Q.B. Yu, G.S. Duan, Y. Sun, X.P. Zhao, B. Wang, Iron and Steel 43 (2008) No. 7, 68–71.

C.H. Lee, H.K.D.H. Bhadeshia, H.C. Lee, Mater. Sci. Eng. A 360 (2003) 249–257.

R.Y. Zhang, J.D. Boyd, Metall. Mater. Trans. A 41 (2010) 1448–1459.

C.J. Cheng, X.M. Wang, Z.J. Zhou, X. Liang, C.L. Miao, X.L. He, Acta Metall. Sin. 44 (2008) 287–291.

Y.T. Zhao, C.J. Shang, S.W. Yang, X.M. Wang, X.L. He, Mater. Sci. Eng. A 433 (2006) 169–174.

W. Wang, Y. Shan, K. Yang, Mater. Sci. Eng. A 502 (2009) 38–44.

M.A. Smirnov, I.Y. Pyshmintsev, A.N. Boryakova, Metallurgist 54 (2010) 7–8.

J.P. Wang, Z.G. Yang, B.Z. Bai, H.S. Fang, Mater. Sci. Eng. A 369 (2004) 112–118.

W. Wang, W. Yan, L. Zhu, P. Hu, Y. Shan, K. Yang, Mater. Des. 30 (2009) 3436–3443.

L. Fan, D.H. Zhou, T.L. Wang, S.R. Li, Q.F. Wang, Mater. Sci. Eng. A 590 (2014) 224–231.

M.C. Zhao, K. Yang, F.R. Xiao, Y.Y. Shan, Mater. Sci. Eng. A 355 (2003) 126–136.

H.J. Jun, J.S. Kang, D.H. Seo, K.B. Kang, C.G. Park, Mater. Sci. Eng. A 422 (2006) 157–162.

S.W. Thompso, D.J. Colvin, G. Krauss, Metall. Mater. Trans. A 27 (1996) 1557–1571.

F.G. Caballero, H. Roelofs, S. Hasler, C. Capdevila, J. Chao, J. Cornide, C. Garcia-Mateo, Mater. Sci. Technol. 28 (2012) 95–102.

S. Zajac, V. Schwinn, K.H. Tacke, Mater. Sci. Forum 500–501 (2005) 387–394.

Y.M. Kim, H. Lee, N.J. Kim, Mater. Sci. Eng. A 478 (2008) 361–370.

J. Hu, L.X. Du, J.J. Wang, H. Xie, C.R. Gao, R.D.K. Misra, Mater. Sci. Eng. A 585 (2013) 197–204.

F.R. Xiao, B. Liao, G.Y. Qiao, C.L. Zhang, Y.Y. Shan, Y. Zhong, K. Yang, Multidiscip. Model. Mater. Struct. 2 (2006) 389–410.

Z.G. Yang, H.S. Fang, Curr. Opin. Solid State Mater. Sci. 9 (2005) 277–286.

H.S. Fang, C. Feng, Y.K. Zhang, Z.G. Tang, B.Z. Bai, J. Iron Steel Res. Int. 15 (2008) No. 6, 1–9.

P. Cizek, Acta Mater. 106 (2016) 129–143.

D.P. Cheprasov, V.V. Svishchenko, E.V. Kozlov, A.A. Ivanaiskii, Met. Sci. Heat Treat. 5 (2006) 3–7.

M. Mohammadijoo, J. Valloton, L. Collins, H. Henein, D.G. Ivey, Mater. Charact. 142 (2018) 321–331.

N. Huda, A. R.H. Midawi, J Gianetto, R. Lazor, A.P. Gerlich, Mater. Sci. Eng. A 662 (2016) 481–491.

C.M. Wang, X.F. Wu, J. Liu, N.A. Xu, Mater. Sci. Eng. A 438–440 (2006) 267–271.

B.Z. Li, C.S. Li, X. Jin, J. Zhang, J. Iron Steel Res. Int. (2019-3-12). https://doi.org/10.1007/s42243-019-00244-8.

B. Wang, J. Lian, Mater. Sci. Eng. A 592 (2014) 50–56.

Y.W. Chen, Y.T. Tsai, P.Y. Tung, S.P. Tsai, C.Y. Chen, S.H. Wang, J.R. Yang, Mater. Charact. 139 (2018) 49–58.

S.G. Lee, S.S. Sohn, B. Kim, W.G. Kim, K.K. Um, S. Lee, Mater. Sci. Eng. A 10 (2018) 1–21.

H. Zhao, B.P. Wynne, E.J. Palmiere, Mater. Charact. 123 (2017) 339–348.

J.Y. Kang, D.H. Kim, S. Baik, T.H. Ahn, Y.W. Kim, H.N. Han, K.H. Oh, H.C. Lee, S.H. Han, ISIJ Int. 51 (2011) 130–136.

Acknowledgements

This work was financially supported by the National Key Research and Development Program of China (No. 2017YFB0304900).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jia, Sj., Li, B., Liu, Qy. et al. Effects of continuous cooling rate on morphology of granular bainite in pipeline steels. J. Iron Steel Res. Int. 27, 681–690 (2020). https://doi.org/10.1007/s42243-019-00346-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-019-00346-3