Abstract

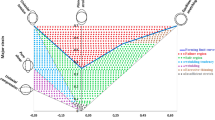

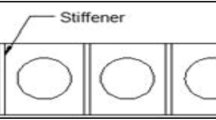

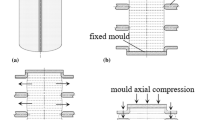

Mechanical properties and creep behavior of Q460E continuous casting slab were studied by means of uniaxial tensile tests on a Gleeble-3800 thermomechanical simulator from 1000 to 1100 °C. The high-temperature creep constitutional equation was derived based on experimental data. The parameters in the equation were calculated by using the regression analysis inverse-estimation method. The experimental curves in the primary and secondary creep stages are fitted well. A three-dimensional elastic–plastic and creep finite element model was proposed in order to investigate the bulging deformation of slab and the bulging deformation at the beginning position of bending segment on the slab continuous casting machine was computed accurately. The results indicate that the maximum bulging deformation appears at the geometric center of the slab. The maximum value of the bulging deformation obtained by the elastic–plastic analysis is 1.301 mm. Considering the creep effect, the deformation increases to 1.827 mm which is about 1.4 times the value obtained by the elastic–plastic analysis. The calculation of bulging deformation using the elastic–plastic creep model is more reliable and accurate.

Similar content being viewed by others

References

H.A. Lanjewar, P. Tripathi, M. Singhai, P.K. Patra, J. Mater. Eng. Perform. 23 (2014) 3600–3609.

H. Tomono, Ironmak. Steelmak. 42 (2015) 242–251.

F. Pascon, A.M. Habraken, Comput. Methods Appl. Mech. Engrg. 196 (2007) 2285–2299.

M.O. El-Bealy, Ironmak. Steelmak. 40 (2013) 167–188.

D.R.H. Jones, M.F. Ashby, Engineering materials 1: An introduction to properties, applications and design, Elsevier Science, New York, 2011.

N.S. Ottosen, M. Ristinmaa, The mechanics of constitutive modeling, Elsevier, Amsterdam, 2005.

X.Z. Zhang, L. Guo, ISIJ Int. 57 (2017) 76–83.

L. Guo, X.Z. Zhang, C.X. Feng, J. Iron Steel Res. Int. 24 (2017) 595–600.

K. Okamura, H. Kawashima, ISIJ Int. 29 (1989) 666–672.

A. Grill, K. Schwerdtfeger, Ironmak. Steelmak. 6 (1979) 131–135.

J.S. Ha, J.R. Cho, B.Y. Lee, M.Y. Ha, J. Mater. Process. Technol. 113 (2001) 257–261.

C.S. Li, B.G. Thomas, Metall. Mater. Trans. B 35 (2004) 1151–1172.

S. Koric, B.G. Thomas, J. Mater. Process. Technol. 197 (2008) 408–418.

T. Suzuki, K.H. Tacke, K. Wunnenberg, K. Schwerdtgeger, Ironmak. Steelmak. 15 (1988) 90–100.

A.S. Mammar, D. Gruber, H. Harmuth, S. Jin, Ceram. Int. 42 (2016) 6791–6799.

J. Brnic, G. Turkalj, M. Canadija, D. Lanc, J. Constr. Steel Res. 67 (2011) 1948–1952.

J. Brnic, M. Canadija, G. Turkalj, D. Lanc, Bull. Mater. Sci. 33 (2010) 475–481.

A.G. dos Reis, D.A.P. Reis, A.J. Abdalla, J. Otubo, Mater. Charact. 107 (2015) 350–357.

M. Cowan, K. Khandelwal, Eng. Struct. 80 (2014) 426–434.

Z.H. Dong, D.F. Chen, M.J. Long, X. Zhang, J.L. Shen, Chin. J. Mater. Res. 27 (2013) 273–278.

H.S. Di, X.D. Kang, G.D. Wang, X.H. Liu, J. Northeast. Univ. Nat. Sci. 25 (2004) 40–43.

H. Xu, J. Yuan, Y.Z. Ni, J. Mater. Sci. Eng. 31 (2013) 568–571.

C.S. Liu, T.W. Yang, W.H. Wu, Scripta Mater. 37 (1997) 425–429.

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (51275446) and Hebei Provincial Natural Science Foundation of China (E2016203492).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Guo, L., Sui, Yh. & Zhang, Xz. High-temperature creep constitutional model of Q460E steel and effect of creep on bulging deformation of continuous casting slab. J. Iron Steel Res. Int. 25, 1123–1130 (2018). https://doi.org/10.1007/s42243-018-0169-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-018-0169-1