Abstract

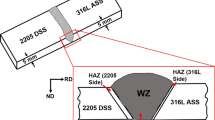

The morphology and distribution of residual austenite in the welded zone of 9% Cr/CrMoV dissimilar welded joint were observed by color metallographic method. Moreover, the details of the distribution, shape, length, length-to-width ratio, and the content of residual austenite in each welding layer were systematically characterized using Image-Pro Plus image analysis software. Different from the techniques such as X-ray diffraction, vibrating sample magnetometer, and electron backscatter diffraction that only involve the content of residual austenite, color metallographic method can offer much more details of the residual austenite, including the location, shape, size, and content, helping evaluate the overall characteristics of the residual austenite produced in the weld. It is interesting that a large amount of block-like and film-like residual austenite was found in the root of each welding layer, while rare at the top. The area fraction of residual austenite located in this zone was approximately 7.5% compared with only 0.5% at the top. In addition, the average area, length, and length-to-width ratio of dispersed residual austenite were quantitatively evaluated to be (4.7 ± 0.6) μm2, (5.1 ± 0.6) μm, and (1.1 ± 0.1) μm, respectively. This variety of residual austenite was resulted from the tempering effect by latter welding layer on the previous one and different cooling rates in these two regions during the welding process.

Similar content being viewed by others

References

Y. Yang, Q. Cai, D. Tang, H. Wu, Int. J. Miner. Metall. Mater. 17 (2010) 587–595.

P. Liu, F. Lu, X. Liu, H. Ji, Y. Gao, J. Alloy. Compd. 584 (2014) 430–437.

Q. Wu, F. Lu, H. Cui, X. Liu, P. Wang, Y. Gao, Mater. Lett. 141 (2015) 242–244.

K. Amini, S. Nategh, A. Shafyei, A. Rezaeian, Int. J. Miner. Metall. Mater. 19 (2012) 30–37.

Q. Hao, S. Qin, Y. Liu, X. Zuo, N. Chen, W. Huang, Y. Rong, Mater. Sci. Eng. A 662 (2016) 16–25.

M.Y. Zhang, F.X. Zhu, D.S. Zheng, J. Iron Steel Res. Int. 18 (2011) No. 8, 73–78.

D.N. Zou, Y. Han, W. Zhang, X.D. Fang, J. Iron Steel Res. Int. 17 (2010) No. 8, 50–54.

A. Akhharizadeh, M. Golozar, A. Shafeie, M. Kholghy, J. Iron Steel Res. Int. 16 (2009) No. 6, 29–32.

E. Galindo-Nava, P. Rivera-Díaz-Del-Castillo, Acta Mater. 98 (2015) 81–93.

Q. Zhou, L. Qian, J. Tan, J. Meng, F. Zhang, Mater. Sci. Eng. A 578 (2013) 370–376.

I. Timokhina, P. Hodgson, E. Pereloma, Metall. Mater. Trans. A 35 (2004) 2331–2341.

H. Jiang, H. Wu, D. Tang, Q. Liu, Int. J. Miner. Metall. Mater. 15 (2008) 574–579.

L. Zhao, N.V. Dijk, E. Brück, J. Sietsma, S.V.D. Zwaag, Mater. Sci. Eng. A 313 (2001) 145–152.

Y. Qu, X. Huang, B. Cao, Z. Cai, J. Pan, J. Mech. Eng. 14 (2011) 44–48.

G. Chen, W. Yang, S. Guo, Z. Sun, Int. J. Miner. Metall. Mater. 14 (2007) 36–40.

A. Lambert-Perlade, A. Gourgues, A. Pineau, Acta Mater. 52 (2004) 2337–2348.

C.G. Lee, S.J. Kim, T.H. Lee, S. Lee, Mater. Sci. Eng. A 371 (2004) 16–23.

A. Varshney, S. Sangal, S. Kundu, K. Mondal, Mater. Des. 99 (2016) 439–448.

Y. Shen, L. Qiu, X. Sun, L. Zuo, P. Liaw, D. Raabe, Mater. Sci. Eng. A 636 (2015) 551–564.

A. Ray, S. Dhua, Mater. Charact. 37 (1996) 1–8.

J. Oñoro, Int. J. Pres. Ves. Pip. 83 (2006) 540–545.

X. Liu, H. Ji, P. Liu, P. Wang, F. Lu, Y. Gao, Int. J. Miner. Metall. Mater. 21 (2014) 563–568.

P. Liu, F. Lu, X. Liu, Y. Gao, Int. J. Miner. Metall. Mater. 20 (2013) 1164–1169.

Q. Wu, F. Lu, H. Cui, X. Liu, P. Wang, X. Tang, Mater. Des. 59 (2014) 165–175.

K. Furuya, M. Ida, M. Miyashita, H. Nakamura, J. Nucl. Mater. 386–388 (2009) 963–966.

W. Liu, X. Liu, F.G. Lu, X. Tang, H.C. Cui, Y.L. Gao, Mater. Sci. Eng. A 644 (2015) 337–346.

Q. Guo, F.G. Lu, X. Liu, R. Yang, H.C. Cui, Y.L. Gao, Mater. Sci. Eng. A 638 (2015) 240–250.

Y.H. Wei, S.F. Qiao, F.G. Lu, W. Liu, Mater. Des. 97 (2016) 268–278.

F.G. Lu, P. Liu, H.J. Ji, Y.M. Ding, X.J. Xu, Y.L. Gao, Mater. Charact. 92 (2014) 149–158.

X. Deng, F.G. Lu, H.C. Cui, X. Tang, Z. Li, Mater. Sci. Eng. A 651 (2016) 1018–1030.

D.T.J. Hurle, Solid State Electron 3 (1961) 37–44.

Y. Chang, Z.H. Meng, L. Ying, X.D. Li, N. Ma, P. Hu, J. Iron Steel Res. Int. 18 (2011) No. 5, 59–63.

J.P. Lin, J.Y. Min, Y.E. You, L.J. Xin, L. Ding, J. Iron Steel Res. Int. 18 (2011) S1, 851–854.

Acknowledgements

The authors gratefully acknowledge the financial support by Shanghai Science and Technology Committee (No. 13DZ1101502), and the Program for Professor of Special Appointment (Eastern Scholar) at Shanghai Institutions of Higher Learning (No. TP2014042), China.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ding, K., Ji, Hj., Zhang, Ql. et al. Anomalous residual austenite formation in root of welding layers of 9% Cr/CrMoV dissimilar welded joint. J. Iron Steel Res. Int. 25, 839–846 (2018). https://doi.org/10.1007/s42243-018-0121-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-018-0121-4