Abstract

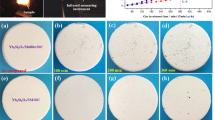

To improve the oxidation resistance of carbon fiber reinforced SiC ceramic matrix composites (Cf/SiC) at high-temperature and high-speed gas scour environment in burner rig tests, a novel bi-layer Yb2Si2O7/SiC EBC was prepared on the surface of Cf/SiC composites by chemical vapor deposition and sol–gel combined with air spraying method. Results show that bi-layer Yb2Si2O7/SiC coating showed better oxidation resistance for Cf/SiC samples in the first 20 thermal cycles (300 min), which can efficiently prevent the oxidation of Cf/SiC samples in a gas scour environment at 1773 K for 300 min with a weight loss of 5.93 × 10−3 g·cm−2. After 20 thermal cycles (≥ 300 min), the weight loss of the coated sample was rapidly increased due to the formation of penetrating cracks. After the corrosion of 36 thermal cycles (540 min), some obvious annular corrosion pit area were found on the surface of Yb2Si2O7 outer coating, and the center of the corrosion pit was easier to be the origin area of the cracks due to the greater impact force of the gas.

Graphical abstract

The corrosion performance of the bi-layer Yb2Si2O7/SiC EBC in burner rig tests was studied, and the corrosion mechanism was revealed.

Similar content being viewed by others

References

Li Y, Xiao P, Luo H et al (2016) Fatigue behavior and residual strength evolution of 2.5D C/C-SiC composites. J Eur Ceram Soc 36(16): 3977–3985. https://doi.org/10.1016/j.jeurceramsoc.2016.07.009

Tang PJ, Hu CL, Pang SY et al (2020) Interfacial modification and cyclic ablation behaviors of a SiC/ZrB2-SiC/SiC triple-layer coating for C/SiC composites at above 2000 °C. Corros Sci 169:108604. https://doi.org/10.1016/j.corsci.2020.108604

Fan XZ, Huang WZ, Liu HT et al (2017) Bond stability and oxidation resistance of BSAS-based coating on C/SiC composites. Surf Coat Tech 309:35–46. https://doi.org/10.1016/j.surfcoat.2016.10.080

Ding JX, Ma XK, Fan XM et al (2021) Failure behavior of interfacial domain in SiC-matrix based composites. J Mater Sci Technol 88:1–10. https://doi.org/10.1016/j.jmst.2021.02.010

Li Y, Xiao P, Li Z et al (2016) (2016) Strength evolution of cyclic loaded LSI-based C/C-SiC composites. Ceram Int 42(13):14505–14510. https://doi.org/10.1016/j.ceramint.2016.06.061

Yang X, Feng C (2015) Effects of ZrC coating on mechanical properties of PIP-C/SiC composites. J Alloy Compo 632:263–268. https://doi.org/10.1016/j.jallcom.2015.01.194

Rizvanbasha M, Udayakumar A, Stalin M et al (2020) Vapour phase synthesis and characterisation of Cf/SiC composites with selfhealing Si-B-C monolayer coating. Ceram Int 46(15):23785–23796. https://doi.org/10.1016/j.ceramint.2020.06.154

Wang KT, Cao LY, Huang JF et al (2013) A mullite/SiC oxidation protective coating for carbon/carbon composites. J Eur Ceram Soc 33(1):191–198. https://doi.org/10.1016/j.jeurceramsoc.2012.08.009

Li Y, Xiao P, Li Z et al (2017) Oxidation behavior of C/C composites with SiC/ZrSiO4-SiO2, coating. Trans Nonferrous Met Soc China 27(2):397–405. https://doi.org/10.1016/S1003-6326(17)60045-1

Liu J, Zhang LT, Liu QM et al (2014) Structure design and fabrication of environmental barrier coatings for crack resistance. J Eur Ceram Soc 34(8):2005–2012. https://doi.org/10.1016/j.jeurceramsoc.2013.12.049

Zhang MG, Fan WJ, Zou BL et al (2017) Microstructure and oxidation resistant behavior of Er2Si2O7, and Er2Si2O7/LaMgAl11O19, coatings deposited on Cf/SiC composites by APS at 1723K. J Alloy Compd 709:24–30. https://doi.org/10.1016/j.jallcom.2017.03.108

Li CY, Li GB, Ouyang HB et al (2019) ZrB2 particles reinforced glass coating for oxidation protection of carbon/carbon composites. J Adv Ceram 8(1): 102-111. https://link.springer.com/content/pdf/10.1007%2Fs40145-018-0298-9.pdf

Song DW, Paik UY, Guo XY et al (2016) Microstructure design for blended feedstock and its thermal durability in lanthanum zirconate based thermal barrier coatings. Surf Coat Tech 308:40–49. https://doi.org/10.1016/j.surfcoat.2016.07.112

Wang SX, Li W, Wang S et al (2016) Deposition of SiC/La2Zr2O7 multi-component coating on C/SiC substrate by combining sol-gel process and slurry. Surf Coat Tech 302:383–388. https://doi.org/10.1016/j.surfcoat.2016.05.079

Su LC, Yi CH (2013) Effects of CMAS penetration on the delamination cracks in EB-PVD thermal barrier coatings with curved interface. Ceram Int 43(12):8893–8897. https://doi.org/10.1016/j.ceramint.2017.04.025

Martin DT, Bennett C, Hussain T (2021) A review on environmental barrier coatings: History, current state of the art and future developments. J Eur Ceram Soc 41(3):1747–1768. https://doi.org/10.1016/j.jeurceramsoc.2020.10.057

Ren JC, Feng E, Zhang YL et al (2020) Microstructure and anti-ablation performance of HfC-TaC and HfC-ZrC coatings synthesized by CVD on C/C composites. Ceram Int 46(8):10147–10158. https://doi.org/10.1016/j.ceramint.2020.01.006

Bernard B, Quet A, Bianchi L et al (2016) Thermal insulation properties of YSZ coatings: Suspension Plasma Spraying (SPS) versus Electron Beam Physical Vapor Deposition (EB-PVD) and Atmospheric Plasma Spraying (APS). Surf Coat Tech 318:122–128. https://doi.org/10.1016/j.surfcoat.2016.06.010

Wen ZL, Xiao P, Li Z et al (2015) Microstructure and oxidation behavior of sol-gel mullite coating on SiC-coated carbon/carbon composites. J Eur Ceram Soc 35(14):3789–3796. https://doi.org/10.1016/j.jeurceramsoc.2015.06.033

Chen PJ, Xiao P, Li Z et al (2020) Oxidation properties of tri-layer ytterbium-disilicate/mullite/silicon-carbide environment barrier coatings for Cf/SiC composites. Surf Coat Tech 402:126329. https://doi.org/10.1016/j.surfcoat.2020.126329

Stokes JL, Harder BJ, Wiesneret VL et al (2019) High-Temperature thermochemical interactions of molten silicates with Yb2Si2O7 and Y2Si2O7 environmental barrier coating materials. J Eur Ceram Soc 39(15):5059–5067. https://doi.org/10.1016/j.jeurceramsoc.2019.06.051

Wang YQ, Liu JL (2009) First-principles investigation on the corrosion resistance of rare earth disilicates in water vapor. J Eur Ceram Soc 29(11):2163–2167. https://doi.org/10.1016/j.jeurceramsoc.2009.02.005

Maier N, Nickel KG, Rixecke G (2007) High temperature water vapour corrosion of rare earth disilicates (Y, Yb, Lu)2Si2O7 in the presence of Al(OH)3 impurities. J Eur Ceram Soc 27(7):2705–2713. https://doi.org/10.1016/j.jeurceramsoc.2006.09.013

Jana P, Jayan PS, Mandal S et al (2017) Thermal cycling life and failure analysis of rare earth magnesium hexaaluminate based advanced thermal barrier coatings at 1400 °C. Surf Coat Tech 328:398–409. https://doi.org/10.1016/j.surfcoat.2017.09.019

Mack DE, Laquai R, Müller B et al (2019) Evolution of porosity, crack density, and CMAS penetration in thermal barrier coatings subjected to burner rig testing. J Am Ceram Soc 120:1–13

Chen PJ, Pan L, Xiao P et al (2019) Microstructure and anti-oxidation properties of Yb2Si2O7/SiC bilayer coating for C/SiC composites. Ceram Int 45(1):854–860. https://doi.org/10.1016/j.ceramint.2019.08.132

Zhao C, Wang F, Sun YJ et al (2013) Synthesis and characterization of β-Yb2Si2O7 powders. Ceram Int 39(5):5805–5811. https://doi.org/10.1016/j.ceramint.2013.01.001

Wen J, Zhou S, Lu Y et al (2018) Oxidation behavior and high-temperature flexural property of CVD-SiC-coated PIP-C/SiC composites. Ceram Int 44(14):16583–16588. https://doi.org/10.1016/j.ceramint.2018.06.082

Chen PJ, Xiao P, Li Z et al (2019) Microstructure and oxidation behavior of a novel bilayer (c-AlPO4–SiCw–mullite)/SiC coating for carbon fiber reinforced CMCs. J Eur Ceram Soc 39(14):3988–3999. https://doi.org/10.1016/j.jeurceramsoc.2019.06.026

Chen PJ, Xiao P, Li Z et al (2020) Effect of residual silicon on the oxidation resistance of bi-layer Yb2Si2O7/SiC coated C/SiC composites at high temperature. Corros Sci 170:108676. https://doi.org/10.1016/j.corsci.2020.108676

Chen PJ, Xiao P, Li Z et al (2019) Bonding strength and thermal shock resistance of a novel bilayer (c-AlPO4–SiCw–mullite)/SiC coated carbon fiber reinforced CMCs. J Am Ceram Soc 103:82–93. https://doi.org/10.1111/jace.16697

Funding

This work was funded by the Graduate degree thesis Innovation Foundation of Central South University (Grant No. 2019zzts855), the fund of the state Key Laboratory of Solidification Processing in NPU (Grant No. SKLSP202021), and the fund of the Hunan Key Laboratory of Advanced Fibers and Composites, Central South University (Grant No. XTXFKT2020-01).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chen, S., Chen, P., Duan, J. et al. Thermal cycling behavior of bi-layer Yb2Si2O7/SiC EBC-coated Cf/SiC composites in burner rig tests. Adv Compos Hybrid Mater 5, 2184–2192 (2022). https://doi.org/10.1007/s42114-021-00270-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42114-021-00270-9