Abstract

In addition to cement, sand, gravel, and water, the current investigation of the influence of additives on the compressive strength of concrete at 28 days includes fly ash, silica fume, and slag. 315 concrete compositions with various amounts of additives are trained and tested using an artificial neural network. Concrete strength is largely affected by the specific gravity of cement and the specific gravity of fine and coarse particles, according to the studies. For greater compressive strength, it is preferable to use materials with a higher specific gravity. Compressive strength has grown as the amount of silica fumes has increased. Increased amounts of slag or superplasticizer resulted in the same behavior. When the amount of fly ash was increased, the compressive strength of the material decreased.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Over the last two decades, there has been a greater focus on reducing carbon dioxide emissions into the atmosphere on a global level. As a result of the use of mineral additives in cement production and the substitution of cement with additives in concrete mixes, the cement industry contributes for around 5% of all emission sources (Jayant, 2013). Concrete's mechanical characteristics have been influenced by these additives. Compressive strength is one of the most essential mechanical properties of concrete.

In addition, several infrastructures, such as bridges, dams, and building foundations, require high-strength concrete. These infrastructures have massive dimensions, which are accompanied by high temperatures during casting. As a result, the temperature difference between the inside of structural members (at early ages) and the outside environment is large. Thermal cracking can occur as a result of this situation. Reducing the amount of cement used is one option. As a result, using alternative cement additives to minimize the amount of cement in the concrete mixture has become popular (Al-Gburi, 2015; Mustafa, 2018).

The influence of concrete mixture components (cement, sand, and gravel) on the mechanical properties of concrete has been studied extensively (Jayant, 2013; Kaveh & Khalegi, 2000; Mustafa, 2018). Moreover, various research have looked into the effects of additives on concrete characteristics. Some of these additives, such as silica fume and slag, generate higher concrete strength resistance (Bhanjaa & Sengupta, 2005; Bharatkumar et al., 2005; Lam et al., 1998). Some of them, such as fly ash, have had the reverse impact, lowering concrete strength (Atiş, 2005; Babu & Yerramala, 2012; Yazici, 2008; Yazici et al., 2012).

It takes a long time and a lot of money to cast concrete mixes. It is possible that the variables under investigation have several effects. As a result, it is essential to understand which parameter has the greatest impact and concentrate on its consequences. The effect of the specific weight of concrete mixture components and additives has been overlooked in previous investigations. The goal of this research was to determine the impact of cement specific weight, fine and coarse aggregate, and mineral additives on concrete strength.

The specific gravity of a material at a given temperature (23C) is the ratio of the mass of a unit volume of that material to the mass of the same volume of water at the same temperature (ASTM C128-15, 2015). It is a non-dimensional value that is used to determine the material's strength and quality. It is frequently important to determine an aggregate's porosity. Pore size is expressed as a percentage of the total material size divided by the size of the pores. It is impossible to calculate the volume of pores in any material. The specific gravity can be used to determine the relationship between the pores and bulk solids. The volume of the mixture increases when cement is replaced by a mineral additive with a lower density based on mass-to-mass. The specific gravity of mineral additive is lower than that of cement, which must be taken into account while proportioning the mix. If the strength and durability qualities of the concrete are maintained, the addition of cementations may actually result in a reduction in the number of cementations (in terms of mass) per unit volume of concrete. This is significant in terms of making the best use of cementation ingredients in concrete (Jayant, 2013). The efficiency factor for mineral admixture is defined as the quantity of cement in the concrete mixture that can be replaced by one part mineral admixture without affecting the attribute being studied, which is usually compressive strength. In many technical applications, the back-propagation neural network and neural networks with genetic algorithm approach has been applied (Iranmanesh & Kaveh, 1999; Kaveh & Iranmanesh, 1998; Kaveh & Rahimi Bondarabady, 2004; Kaveh and Raiessi Dehkordi, 2003; Kaveh & Servati, 2001; Kaveh et al. 2001a, 2001b; Kaveh et al., 2008; Rofooei et al., 2011).

Aims and purposes

This paper's goals and objectives are to:

-

Clarify and investigate the influence of the most important parameter on concrete compressive strength.

-

Investigate the impact of substituting additives for cement on the compressive strength of concrete.

-

Determine the impact of the concrete mix's specific gravity on concrete strength.

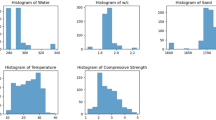

Data preparation for the neural network

To improve the training of the neural network, the data were preprocessed via scaling.

The input and output data were scaled in the intervals 0.1 and 0.9 to avoid the sluggish rate of learning around end points, notably in the output range, due to the sigmoid function's trait of being asymptotic to values 0 and 1. The linear scaling equation is written as follows:

Equation (1) was used in this study for a variable limited to minimum (\(p_{\min }\)) and maximum (\(p_{\max }\)) input values given in Table 4.4, with:

Any new input data should be scaled before being submitted to the network, and the associated predicted values should be unscaled before being used.

Back-propagation algorithm

The BPNN is trained using the back-propagation algorithm (back-propagation neural network). Using the gradient descent method, this program searches for the smallest error function in weight space. A solution to the learning issue is considered to be a combination of weights that minimizes the error function. Hudson et al. (2021) and Hagan et al., (1996) define the algorithm in the following steps:

-

1.

It calculates the input to the hidden layer once the input vector is supplied to the input layer., \({h}_{j}^{H}\), as:

$$h_{j}^{H} = \theta_{j} + \mathop \sum \limits_{i = 1}^{{{\text{NI}}}} w_{ji} p_{i} ,$$(3)

where pi reflects the value of the input parameter, \(\theta_{j}\) represents the hidden layer's bias function, NI represents the number of neuron in the input layer and wji indicates the difference in weight between the input and hidden layers.

Each neuron in the hidden layer takes its input, passes it through a function, and creates an output, which is determined by

The input to the output layer's neurons, \({h}_{k}^{0}\), is now calculated as

where \(\theta_{k}\) represents the bias function of output layer, wkj represents the weight factor between hidden and output layer, and NH represents the number of neuron in the hidden layer.

The network output, \({y}_{k}\), is then given by:

where f represents the activation function.

Learning an ANN

Previous research (Atiş, 2005; Atan & Awang, 2011; Bhikshma & Florence, 2013; Burden, 2006; Duval & Kadri, 1998; Gesoğlu et al., 2009; Kesharwani et al., 2017; Ren & Wang, 2014; Babu & Yerramala, 2012; Bhanjaa & Sengupta, 2005; Bharatkumar et al., 2005; Lam et al., 1998; Liu, 2010; Özcan et al., 2009; Uygunolu et al., 2012; Yazici, 2008; Yazici et al., 2012) as stated in Table 1, the selection factors were used in the creation of the concrete mixtures. The three hundred and fifteen mixes were sorted into two groups: the artificial neural network ANN was trained using 283 concrete mixtures. The accuracy of the training mixtures was 94%, as shown in Fig. 1a. ANN was put to the test with 32 different concrete compositions. Figures 1 and 2 show that the compressive strength produced from the ANN was 93 percent accurate when compared to earlier experimental research (Fig. 1b). The back-propagation approach is used to train Perceptron Multilayer Networks. The current study uses the multi-layer feed-forward back-propagation technique to create and train the neural network. The sigmoid transform function was also utilized, as explained in Al-Gburi, (2015), Al-Gburi et al., (2012), Yousif and Al-Jurmaa (2010). The ANN model was built with one hidden layer. There were fifteen input parameters and one output parameter in the ANN model. The available data sets were used for the training, testing, and validation processes.

Relative importance

Although we can use techniques like multiple regression or discriminant analysis to evaluate neural network prediction or classification success rates, no method that analyzes the relative relevance of the input parameters employed by the network to reach its conclusions has been accepted. One of the most advantages of ANN-based models is that they make sensitivity analysis easier to analyze the relative importance of their input variables (Kim & Ahna, 2009). One of the most interesting properties of ANN-based models is that they make sensitivity analysis of the relative relevance of their input variables more easier (Kim & Ahna, 2009). To determine the most significant input–output relationship that has been manually carried out, sensitivity studies use a "leave one out" technique. It is used to offer information on the relative importance of the input factors in each geometrical dimension's parameter on compressive strength, see (Bharatkumar et al., 2005; Lam et al., 1998; Mustafa, 2018). In this work, the relative importance of the input parameters is determined using the partitioning weights approach established by Garson (1991) and later adapted by Goh (1995). The weights of the connections between ANN layers are used in this method to calculate the maximum change in output caused by changes in specific input variables. To determine the relative importance of the various input parameters, this approach is interested in the connection weight between ANN layers.

The SGC is the most influential factor in the sensitivity to the compressive strength of concrete, according to the findings in the study provided in Table 1. The cement content C and the SGCAgg are followed by an SGFAgg and then the cement content C and the SGCAgg. The rest of the additive factors are in low effect ratios, as indicated in Fig. 2. Concrete strength is influenced mainly by the SGC and aggregates (fine and coarse). As a result, the remaining mineral additions have a minimal effect on compressive strength. Additives can be used to replace high-cost cement without affecting the strength of the concrete.

Results

Effect of specific gravity of cement

As seen in Fig. 3, increasing the cement's specific gravity increased the concrete's compressive strength. Depending on the amount of moisture in the cement, the specific gravity might rise or fall. The greater the specific gravity, the more water is required. It will result in a lower quantity of water in the cement, enhancing the compressive strength. Furthermore, the higher cement concentration resulted in an increase in concrete compression strength, which is consistent with Salem and Pandey's findings (2015).

Effect of specific gravity of fine aggregate

As illustrated in Fig. 4, increasing the specific gravity of fine particles reduced concrete strength. Maina et al. (2018). discovered the similar perception in behavior. The strength behavior changed as the cement content was increased to over 450 kg/m3. With an increase in the specific weight of fine aggregate, the compressive strength increased.

Effect of specific gravity of coarse aggregate

The concrete strength is influenced by the specific gravity of coarse material. When the specific gravity of the coarse aggregate was the highest, the compressive strength increased, as shown in Fig. 5. Al-Oraimi et al., 2006; Ryu & Monteiro, 2002 both found the same indication.

Effect of silica fume

When silica fume is added to a concrete mix with a little amount of cement, the compressive strength is reduced (by a significant amount). Figure 6 shows how the influence of silica fume changes as the cement content is increased, resulting in increased concrete strength. Atiş (2005), Babu and Yerramala (2012), Tanyildizia and Evik (2010), and Uygunolu et al. (2012) demonstrate the same indication of the impacts of silica fume alone on the concrete mix. The specific gravity of silica, on the other hand, is lower than the specific gravity of cement. As a result, replacing the same amount of cement with the same amount of silica reduces the strength of the concrete. Previous research has concentrated on the effect of varied amounts of silica fume on concrete strength while ignoring the effect of silica fume specific gravity. The specific gravity of silica fume is the most influential, as shown in Figs. 2 and 7. Concrete strength increased as the specific weight of the concrete increased.

Effect fly ash (FA)

The water–cement ratio of concrete has been reduced as a result of increased FA content less than the reduced amount of cement, resulting in a direct reduction in concrete strength. As the amount of fly ash in the mixture increased, the compressive strength decreased, as seen in Fig. 8. This is comparable to the behavior described in Atiş (2005), Liu (2010), and Siddique (2003). Increasing the specific gravity of fly ash, on the other hand, increased concrete strength, as shown in Fig. 9. This behavior is consistent with the findings of Jayant (2013), Bhanjaa and Sengupta (2005), Yazici (2008) and Atiş (2005).

Effect of slag

As seen in Fig. 10, adding more slag to the mix improved the concrete's strength. These findings are consistent with Akcaozoglu and Atis (2011), Bharatkumar et al., (2005). Most standards limit the amount of BFS added to slag cement to 70%, see (Jayant, 2013). Furthermore, increasing the fineness of GGBS might result in higher compressive strength.

Effect of superplasticizer

Increased superplasticizer content resulted in increased concrete strength (see Fig. 11). These findings are consistent with Alsadey (2012) and Dumne (2014).

Conclusions

The study demonstrated the feasibility of employing an artificial neural network to investigate the impact of concrete mixture additions on concrete compressive strength. The specific gravity of cement has been shown to be the most important factor in the compressive strength of concrete. Following that, there is a significant variation in the specific gravity of aggregate and sand. The amount of cement used as a variable in compressive strength was next. The specific gravity of the additions exhibited the similar tendency, resulting in increased compressive strength. The artificial neural network's results were found to match the analysis of previous experimental results. As a result, using an artificial neural network to understand the behavior of complicated data without having to do costly practical testing is critical.

References

Akcaozoglu, S., & Atis, C. D. (2011). Effect of granulated blast furnace slag and fly ash addition on the strength properties of lightweight mortars containing waste pet aggregates. Construction and Building Materials, 25(10), 4052–4058.

Al-Gburi, M., Jonasson, J.-E., Yousif, S.T., & Nilsson, M. (2012). Simplified methods for crack risk analyses of early age concrete part 2: restraint factors for typical case wall-on-slab. Nordic Concrete Research, 46(2), 39–58. https://www.diva-portal.org/smash/get/diva2:975530/FULLTEXT01.pdf

Al-Gburi, M. (2015). Restraint effects in early age concrete structures. Doctoral Thesis, Luleå University of Technology, Luleå, Sweden (p. 201). http://www.diva-portal.org/smash/get/diva2:991716/FULLTEXT01.pdf

Al-Oraimi, S. K., Taha, R., & Hassan, H. F. (2006). The effect of the mineralogy of coarse aggregate on the mechanical properties of high-strength concrete. Construction and Building Materials, 20(7), 499–503.

Alsadey, S. (2012). Influence of superplasticizer on strength of concrete. International Journal of Research in Engineering and Technology (IJRET), 1(3), 164–166. https://www.researchgate.net/publication/285816594_Influence_of_superplasticizer_on_strength_of_concrete

ASTM C128-15. (2015). Standard test method for relative density (specific gravity) and absorption of fine aggregate. https://www.astm.org/Standards/C128

Atan, M.N., & Awang, H. (2011). The compressive and flexural strengths of self-compacting concrete using raw rice husk ash. Journal of Engineering Science and Technology, 6(6), 720–732. https://jestec.taylors.edu.my/Vol%206%20Issue%206%20December%2011/Vol_6_6_720_732_MD%20NOR%20ATAN.pdf

Atiş, C. D. (2005). Strength properties of high-volume fly ash roller compacted and workable concrete, and influence of curing condition. Cement and Concrete Research, 35(6), 1112–1121.

Babu, K. G., & Yerramala, A. (2012). Strength properties of high workable and high volume fly ash roller compacted concrete. Journal of Engineering Research and Studies JERS, 3(3), 11–17.

Bhanjaa, S., & Sengupta, B. (2005). Influence of silica fume on the tensile strength of concrete. Cement and Concrete Research, 35(4), 743–747.

Bharatkumar, B. H., Raghuprasad, B. K., Ramachandramurthy, D. S., Narayanan, R., & Gopalakrishnan, S. (2005). Effect of fly ash and slag on the fracture characteristics of high performance concrete. Material and Structures, 38, 63–72. https://doi.org/10.1007/BF02480576

Bhikshma, G., & Florence, A. (2013). Studies on effect of maximum size of aggregate in higher grade concrete with high volume fly ash. Asian Journal Of Civil Engineering (BHRC), 14(3), 101–109. https://www.researchgate.net/publication/266501960_Studies_on_effect_of_maximum_size_of_aggregate_in_higher_grade_concrete_with_high_volume_fly_ash

Burden, D. (2006). The durability of concrete containing high levels of fly ash. MSc Thesis, The University of 24 New Brunswick, New Brunswick. https://trid.trb.org/view/795859

Dumne, S. M. (2014). Effect of superplasticizer on fresh and hardened properties of self-compacting concrete containing fly ash. American Journal of Engineering Research (AJER), 3(3), 205–211. https://www.ajer.org/papers/v3(3)/ZA33205211.pdf

Duval, R., & Kadri, E. H. (1998). Influence of silica fume on the workability and the compressive strength of high-performance concretes. Cement and Concrete Research, 28(4), 533–547.

Garson, G. D. (1991). Interpreting neural network connection weights. Artificial Intelligence, 6, 47–51. https://www.semanticscholar.org/paper/Interpreting-neural-network-connection-weights-Garson/d5e392035d5f4b1ae37027cabfd1bfdf6733015b

Gesoğlu, M., Güneyisi, E., & Özbay, E. (2009). Properties of self-compacting concretes made with binary, ternary, and quaternary cementitious blends of fly ash, blast furnace slag, and silica fume. Construction and Building Materials, 23(5), 847–185.

Goh, A. T. C. (1995). Back-propagation neural networks for modeling complex systems. Artificial Intelligence in Engineering, 9(3), 143–151.

Hagan, M. T., Demuth, H. B., & Beale, M. H. (1996). Neural network design (2nd edn). Boston, MA: PWS Publishing. https://hagan.okstate.edu/NNDesign.pdf

Hudson, B., Hagan, M., & Demuth, H. (2021). Neural Network Toolbox for Use with MATLAB, User’s Guide, The Math works. https://se.mathworks.com/help/pdf_doc/nnet/nnet_ug.pdf/

Iranmanesh, A., & Kaveh, A. (1999). Structural optimization by gradient base neural networks. International Journal of Numerical Methods in Engineering, 46, 297–311.

Jayant D. B. (2013). Mineral admixtures in cement and concrete (1st edn, p. 309). https://www.routledge.com/Cement-and-Concrete-Mineral-Admixtures/Tokyay/p/book/9780367028008#:~:text=Cement%20and%20Concrete%20Mineral%20Admixtures%20concentrates%20mostly%20on%20natural%20pozzolans,and%20shales%20are%20also%20discussed

Kaveh, A., & Servati, H. (2001). Design of double layer grids using back-propagation neural networks. Computers and Structures, 79, 1561–1568. https://www.infona.pl/resource/bwmeta1.element.elsevier-e2fafe86-2f88-3a43-b17a-a7c7b088a052

Kaveh, A., Elmieh, R., & Servati, H. (2001a). Prediction of moment-rotation characteristic for semi-rigid connections using BP neural networks. Asian Journal of Civil Engineering, 2(2), 131–142. https://www.sid.ir/en/Journal/ViewPaper.aspx?ID=40312

Kaveh, A., Fazel-Dehkordi, D., & Servati, H. (2001b). Prediction of moment-rotation characteristic for saddle-like connections using BP neural networks. Asian Journal of Civil Engineering, 2(1), 11–30.https://www.sid.ir/en/Journal/ViewPaper.aspx?ID=39305

Kaveh, A., Rahimi Bondarabady, H. A. (2004). Wavefront reduction using graphs, neural networks and genetic algorithm. International Journal for Numerical Methods in Engineering, 60, 1803–1815. https://www.academia.edu/16715990/Wavefront_reduction_using_graphs_neural_networks_and_genetic_algorithm

Kaveh, A., Gholipour, Y., & Rahami, H. (2008). Optimal design of transmission towers using genetic algorithm and neural networks. International Journal of Space Structures, 23(1), 1–19. https://doi.org/10.1260/026635108785342073

Kaveh, A., & Iranmanesh, A. (1998). Comparative study of backpropagation and improved counterpropagation neural nets in structural analysis and optimization. International Journal of Space Structures, 13, 177–185. https://doi.org/10.1177/026635119801300401m

Kaveh, A., & Khalegi, H. A. (2000). Prediction of strength for concrete specimens using artificial neural network. Asian Journal of Civil Engineering, 2(2), 1–13.

Kaveh, A., & RaiessiDehkordi, M. (2003). RBF and BP neural networks for the analysis and design of domes. International Journal of Space Structures, 18(3), 181–194. https://doi.org/10.1260/026635103322437463

Kesharwani, K. C., Biswas, A. K., Chaurasiya, A., & Rabbani, A. (2017). Experimental study on use of fly ash in concrete. International Research Journal of Engineering and Technology, 4(9), 1527–1530. https://www.researchgate.net/publication/320853091_Experimental_Study_on_Use_of_Fly_Ash_in_Concrete

Kim, J., & Ahna, H. (2009). New perspective for neural networks: Application to a marketing management problem. Journal of Information Science and Engineering, 25, 1605–1616. https://www.researchgate.net/publication/220587367_A_New_Perspective_for_Neural_Networks_Application_to_a_Marketing_Management_Problem

Lam, L., Wong, Y. L., & Poon, C. S. (1998). Effect of fly ash and silica fume on compressive and fracture behaviors of concrete. Cement and Concrete Research, 28(2), 271–283.

Liu, M. (2010). Self-compacting concrete with different levels of pulverized fuel ash. Construction and Building Materials, 24(7), 1245–1252.

Maina, K., Gwaya, A. O., & Koteng, D. O. (2018). Effects of different fine aggregate on concrete strength. International Journal of Soft Computing and Engineering, 8(2), 16–21. https://www.ijsce.org/wp-content/uploads/papers/v8i2/B3133058218.pdf

Mustafa, T. (2018). Cement and concrete mineral admixtures (p. 318). https://www.adlibris.com/se/bok/cement-and-concrete-mineral-admixtures-9780367028008

Özcan, F., Atiş, C. D., Karahan, O., Uncuoğlu, E., & Tanyildizi, H. (2009). Comparison of artificial neural network and fuzzy logic models for prediction of long-term compressive strength of silica fume concrete. Advances in Engineering Software, 40(9), 856–863.

Ren, Z., & Wang, L. (2014) Research of high fly ash content in concrete with dipy construction formwork. In International Workshop on Sustainable Development and Concrete Technology (pp. 347–359). https://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.475.6788&rep=rep1&type=pdf

Rofooei, F. R., Kaveh, A., & Masteri Farahani, F. (2011). Estimating the vulnerability of concrete moment resisting frame structures using artificial neural networks. International Journal of Operational Research, 1(3), 433–448. https://www.semanticscholar.org/paper/ESTIMATING-THE-VULNERABILITY-OF-THE-CONCRETE-MOMENT-Rofooei-Kaveh/faa4dcd631c3eaef1e912e6b077992b8022ac29d

Ryu, J.-S., & Monteiro, P. J. M. (2002). Effect of specific gravity of coarse aggregate on interfacial transition zone, permeability, and strength of concrete. British Ceramic Transactions, 101(1), 30–34. https://doi.org/10.1179/096797801225000806

Salem, M. A., & Pandey, R. K. (2015). Influence of specific gravity on weight of proportions of concrete. International Journal of Engineering Research & Technology (IJERT), 4(02), 319–320. https://www.ijert.org/research/influence-of-specific-gravity-on-weight-of-proportions-of-concrete-IJERTV4IS020317.pdf

Siddique, R. (2003). Effect of fine aggregate replacement with class f fly ash on the mechanical properties of concrete. Cement and Concrete Research, 33(4), 539–547.

Tanyildizia, H., & Çevik, A. (2010). Modeling mechanical performance of lightweight concrete containing silica fume exposed to high temperature using genetic programming. Construction and Building Materials, 24(12), 2612–3261.

Uygunoğlu, T., Topcu, I. B., Gencel, O., & Brostow, W. (2012). The effect of fly ash content and types of aggregates on the properties of pre-fabricated concrete interlocking blocks (PCIBs). Construction and Building Materials, 30, 180–187.

Yazici, S., & Arel, H. S. (2012). Effects of fly ash fineness on the mechanical properties of concrete. Indian Academy of Sciences, 37(3), 389–403. https://www.ias.ac.in/article/fulltext/sadh/037/03/0389-0403

Yazici, H. (2008). The effect of silica fume and high-volume Class C fly ash on mechanical properties, chloride penetration and freeze–thaw resistance of self-compacting concrete. Construction and Building Materials, 22(4), 456–462.

Yousif, S. T., & Al-Jurmaa, M. A. (2010). Modeling of ultimate load for RC beams strengthened with carbon FRP using artificial neural networks. Al-Rafidain Engineering, 18(6), 28–41. https://www.semanticscholar.org/paper/Modeling-of-ultimate-load-for-R.C.-beams-with-FRP-Al/a836b7a3ed68704bb431f834dbf6ad7d0048167a

Funding

Open access funding provided by Lulea University of Technology. The authors have not disclosed any funding.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have not disclosed any competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Al-Gburi, M., Yusuf, S.A. Investigation of the effect of mineral additives on concrete strength using ANN. Asian J Civ Eng 23, 405–414 (2022). https://doi.org/10.1007/s42107-022-00431-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42107-022-00431-1