Abstract

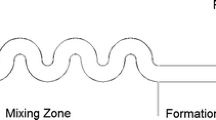

When fluids flow in microchannels, due to the relative low hydraulic diameter and low flow velocity, the flow is usually laminar flow, which hinders the effective mixing between two liquid-liquid phases. In this paper, the mixing efficiency at both droplet forming stage and droplet moving stage are investigated with the volume of fluid (VOF) method. The user defined scalar (UDS) is defined in the dispersed phase to analyze the mixing efficiency quantitatively. The droplet moves in the microchannel with the constant velocity, while serpentine microchannels are designed with different bend radius ranging. \( \overline{R} \) and εd are defined as the ratio of the bend radius to the width of the microchannel, and the ratio of the dispersed phase velocity to the droplet moving velocity, respectively. They are used for illustrating the effect of the bend radius and the dispersed phase fraction on the mixing efficiency in the droplet. Results indicate that the smaller dispersed phase fraction and smaller bend radius show the better mixing efficiency. However, the droplet production frequency changes in a parabolic trend with the variation of the dispersed phase fraction. The suitable dispersed phase fraction should be less than 0.5 in order to achieve a higher mixing efficiency and higher droplet formation frequency. In addition, the pressure drop in microchannel is increased with the decrease of the bend radius. The pressure drop observed in the micorchannel with square turn (\( \overline{R} \) = 0) and the microchannel with a bend radius of \( \overline{R} \) = 1 is nearly the same. This paper can be referred by someone dealing with the micromixer design and mass transfer in micro scale.

Similar content being viewed by others

References

Ward K, Fan ZH (2015) Mixing in microfluidic devices and enhancement methods. J Micromech Microeng 25(9):094001

Cai G, Xue L, Zhang H, Lin J (2017) A review on micromixers. Micromachines 8(9):274

Ritter P, Osorio-Nesme A, Delgado A (2016) 3D numerical simulations of passive mixing in a microchannel with nozzle-diffuser-like obstacles. Int J Heat Mass Transf 101:1075–1085

Li T, Chen X (2017) Numerical investigation of 3D novel chaotic micromixers with obstacles. Int J Heat Mass Transf 115:278–282

Wang L, Ma S, Wang X, Bi H, Han X (2015) Mixing enhancement of a passive microfluidic mixer containing triangle baffles. Asia Pac J Chem Eng 9(6):877–885

Plouffe P, Roberge DM, Macchi A (2016) Liquid-liquid flow regimes and mass transfer in various micro-reactors. Chem Eng J 300:9–19

Akgonul S, Ozbey A, Karimzadehkhouei M, Gozuacik D, Kosar A (2017) The effect of asymmetry on micromixing in curvilinear microchannels. Microfluid Nanofluid 21(7):1–15

Vatankhah P, Shamloo A (2018) Parametric study on mixing process in an in-plane spiral micromixer utilizing chaotic advection. Anal Chim Acta 1022:96–105

Hossain S, Kim KY (2015) Mixing analysis in a three-dimensional serpentine split-and-recombine micromixer. Chem Eng Res Des 100:95–103

Raza W, Ma SB, Kim KY (2018) Multi-objective optimizations of a serpentine micromixer with crossing channels at low and high Reynolds numbers. Micromachines 9(3):110

Afzal A, Kim KY (2015) Optimization of pulsatile flow and geometry of a convergent–divergent micromixer. Chem Eng J 281:134–143

Harshe YM, Van Eijk MJ, Kleijn CR, Kreutzer MT, Boukany PE (2016) Scaling of mixing time for droplets of different sizes traveling through a serpentine microchannel. RSC Adv 6(101):98812–98815

Yang L, Li S, Liua J, Cheng J (2018) Fluid mixing in droplet-based microfluidics with T junction and convergent-divergent sinusoidal microchannels. Electrophoresis 39(3):512–520

Chen X, Li T, Zeng H, Hu Z, Fu B (2016) Numerical and experimental investigation on micromixers with serpentine microchannels. Int J Heat Mass Transf 98:131–140

Qian JY, Chen MR, Liu XL, Jin ZJ (2019) A numerical investigation of the flow of nanofluids through a micro tesla valve. J Zheijang Univ Sci A 20(1):50–60

Burns JR, Ramshaw C (2001) The intensification of rapid reactions in multiphase systems using slug flow in capillaries. Lab Chip 1(1):10–15

Shestopalov I, Tice JD, Ismagilov RF (2004) Multi-step synthesis of nanoparticles performed on millisecond time scale in a microfluidic droplet-based system. Lab Chip 4(4):316–321

Morales MC, Zahn JD (2010) Droplet enhanced microfluidic-based DNA purification from bacterial lysates via phenol extraction. Microfluid Nanofluid 9(6):1041–1049

Zhao S, Riaud A, Luo G, Jin Y, Cheng Y (2015) Simulation of liquid mixing inside micro-droplets by a lattice boltzmann method. Chem Eng Sci 131:118–128

Tanthapanichakoon W, Aoki N, Matsuyama K, Mae K (2006) Design of mixing in microfluidic liquid slugs based on a new dimensionless number for precise reaction and mixing operations. Chem Eng Sci 61(13):4220–4232

Korczyk PM, Dolega ME, Jakiela S, Jankowski P, Garstecki P (2015) Scaling up the throughput of synthesis and extraction in droplet microfluidic reactors. Journal of Flow Chemistry 5(2):110–118

Tice JD, Song H, Lyon AD, Ismagilov RF (2003) Formation of droplets and mixing in multiphase microfluidics at low values of the Reynolds and the capillary numbers. Langmuir 19(22):9127–9133

Tung KY, Li CC, Yang JT (2009) Mixing and hydrodynamic analysis of a droplet in a planar serpentine micromixer. Microfluid Nanofluid 7(4):545–557

Fu Y, Bai L, Zhao S, Bi K, Jin Y, Cheng Y (2016) Droplet in droplet: LBM simulation of modulated liquid mixing. Chem Eng Sci 155:428–437

Madadelahi M, Shamloo A, Madadelahi M, Shamloo A (2017) Droplet-based flows in serpentine microchannels: chemical reactions and secondary flows. Int J Multiphase Flow 97:186–196

Wang J, Wang J, Feng L, Lin T (2015) Fluid mixing in droplet-based microfluidics with a serpentine microchannel. RSC Adv 5(126):104138–104144

Bai L, Zhao S, Fu Y, Cheng Y (2016) Experimental study of mass transfer in water/ionic liquid microdroplet systems using micro-LIF technique. Chem Eng J 298:281–290

Qian J, Li X, Gao Z, Jin Z (2019) Mixing efficiency analysis on droplet formation process in microchannels by numerical methods. Processes 7(1):33

Qian J, Li X, Wu Z, Jin Z, Zhang ZJ, Sunden B (2019) Slug formation analysis of liquid-liquid two-phase flow in T-junction microchannels, ASME Journal of Thermal Science and Engineering Applications. Online, https://doi.org/10.1115/1.4043385

Christopher GF, Noharuddin N, Taylor JA, Anna SL (2008) Experimental observations of the squeezing-to-dripping transition in T-shaped microfluidic junctions. Phys Rev E Stat Nonlinear Soft Matter Phys 78(3):036317

Nonino C, Savino S, Giudice SD (2009) Numerical assessment of the mixing performance of different serpentine microchannels. Heat Transfer Eng 30(1–2):101–112

Acknowledgments

This work is supported by the National Natural Science Foundation of China (NSFC) through Grant No. 51805470, the Fundamental Research Funds for the Central Universities through Grant No. 2018QNA4013, and the Youth Funds of the State Key Laboratory of Fluid Power and Mechatronic Systems (Zhejiang University) through Grant No. SKLoFP-QN-1801.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Qian, Jy., Li, Xj., Gao, Zx. et al. Mixing efficiency and pressure drop analysis of liquid-liquid two phases flow in serpentine microchannels. J Flow Chem 9, 187–197 (2019). https://doi.org/10.1007/s41981-019-00040-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41981-019-00040-1