Abstract

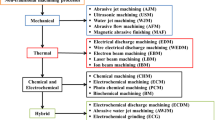

Due to its ability to generate complex shape profiles and contours in many of the advanced engineering materials having higher strength-to-weight ratio, and corrosion and wear resistance properties, wire-electrical discharge machining (WEDM) has emerged out as one of the most suitable non-traditional material removal processes in modern-day manufacturing industries. Optimization of a WEDM process appears to be a difficult task because of multiple conflicting responses, interaction between the input parameters and responses, and varying relative importance assigned to the responses. To resolve the issue, based on a past experimental data, this paper focuses on applications of three multi-criteria decision making (MCDM) methods, i.e., combined compromise solution (CoCoSo), combinative distance-based assessment (CODAS) and multi-attributive ideal-real comparative analysis (MAIRCA) in intuitionistic fuzzy (IF) environment to optimize a WEDM process. The derived results reveal that all the three IF-MCDM techniques identify the same combination of WEDM process parameters (pulse-on time = 115 μs, pulse-off time = 55 μs, wire feed = 3 m/min and wire tension = 7 kg-F) as the optimal choice for having the compromised values of cutting speed, kerf width and surface roughness. A sensitivity analysis with respect to varying criteria weights singles out IF-CoSoSo as the most robust MCDM technique. Excellent Spearman’s rank correlation coefficients (> 0.90) between the considered MCDM techniques ensure their almost similar performance in optimizing the said WEDM process in IF environment.

Similar content being viewed by others

Data availability

The manuscript has no associated data to deposit.

References

Abhilash PM, Chakradhar D (2022) Multi-response optimization of wire EDM of Inconel 718 using a hybrid entropy weighted GRA-TOPSIS method. Process Integr Optimiz Sustain 6:61–72

Asgar ME, Singholi AKS (2018) Parameter study and optimization of WEDM process: a review. Mater Sci Eng 404:012007

Atanassov KT (1986) Intutionistic fuzzy sets. Fuzzy Sets Syst 20:87–96

BüyükKözkan G, Göçer F (2021) Prioritizing the strategies to enhance smart city logistics by intuitionistic fuzzy CODAS. Atlantis Stud Uncertain Model 1:805–811

Chakraborty S, Bhattacharyya O, Zavadskas EK, Antucheviciene J (2015) Application of WASPAS method as an optimization tool in non-traditional machining processes. Inform Technol Control 44(1):77–88

Chatterjee K, Pamučar D, Zavadskas EK (2018) Evaluating the performance of suppliers based on using the R’AMATEL-MAIRCA method for green supply chain implementation in electronics industry. J Clean Prod 184:101–129

Chaudhary T, Siddiquee AN, Chanda AK (2019) Effect of wire tension on different output responses during wire electric discharge machining on AISI 304 stainless steel. Defence Technol 15:541–544

Diyaley S, Shilal P, Shivakoti I, Ghadai RK, Kalita K (2017) PSI and TOPSIS based selection of process parameters in WEDM. Periodica Polytechnica Mechanical Engineering 61:255–260

Ecer F (2022) An extended MAIRCA method using intuitionistic fuzzy sets for coronavirus vaccine selection in the age of COVID-19. Neural Comput Appl 34:5603–5623

Fuse K, Dalsaniya A, Modi D, Vora J, Pimenov DY, Giasin K, Prajapati P, Chaudhari R, Wojciechowski S (2021) Integration of fuzzy AHP and fuzzy TOPSIS methods for wire electric discharge machining of titanium (Ti6Al4V) alloy using RSM. Materials 14:7408

Ghorabaee MK, Zavadskas EK, Turskis Z, Antucheviciene J (2016) A new combinative distance-based assessment (CODAS) method for multi-criteria decision making. Econom Comput Econom Cybernet Stud Res 50(3):25–44

Gopal PM, Soorya Prakash K, Jayaraj S (2018) WEDM of Mg/CRT/ BN composites: Effect of materials and machining parameters. Mater Manuf Processes 33:77–84

Görçün OF, Senthil S, Küçükönder H (2021) Evaluation of tanker vehicle selection using a novel hybrid fuzzy MCDM technique. Decis Making Appl Manag Eng 4(2):140–162

Guha S, Das PP, Routara BC (2021) Parametric optimization of wire electric discharge machining on AISI4140 alloy steel using regression analysis and grey-fuzzy approach. Mater Today Proc 46:4734–4740

Gupta NK, Somani N, Prakash C, Singh R, Walia AS, Singh S, Pruncu CI (2021) Revealing the WEDM process parameters for the machining of pure and heat-treated titanium (Ti-6Al-4V) alloy. Materials 14:2292

Ho KH, Newman ST, Rahimifard S, Allen RD (2004) State of the art in wire electrical discharge machining (WEDM). Int J Mach Tools Manuf 44:1247–1259

Hussain SAI, Sen B, Das Gupta A, Mandal UK (2020) Novel multi-objective decision-making and trade-off approach for selecting optimal machining parameters of Inconel-800 superalloy. Arab J Sci Eng 45:5833–5847

Juliyana SJ, Prakash J, Sadhana AD, Rubi CS (2022) Multi-objective optimization of process parameters of wire EDM for machining of AMCs (LM5/ZrO2) using grey relational analysis. Mater Today Proc 52:1494–1498

Kalita K, Chakraborty S, Ghadai RK, Chakraborty S (2022) Parametric optimization of non-traditional machining processes using multi-criteria decision making techniques: literature review and future directions. Multiscale Multidiscipl Model Exp Des 6:1–40

Karagoz S, Deveci M, Simic V, Aydin N, Bolukbas U (2020) A novel intuitionistic fuzzy MCDM-based CODAS approach for locating an authorized dismantling center: a case study of Istanbul. Waste Manag Res 38(6):660–672

Karatas MA (2022) Wire EDM cutting of Inconel 718 nickel-based superalloy: kerf and MRR analysis. Multidiscip Model Mater Struct 18(4):653–672

Karthik S, Soorya Prakash K, Gopal PM, Jothi S (2019) Influence of materials and machining parameters on WEDM of Al/AlCoCrFeNiMo0.5 MMC. Mater Manuf Process 34:759–768

Kumar S, Dhanabalan S, Narayanan CS (2019) Application of ANFIS and GRA for multi-objective optimization of optimal wire-EDM parameters while machining Ti-6Al-4V alloy. SN Appl Sci 1:298

Majumder H, Maity K (2017) Optimization of machining condition in WEDM for titanium grade 6 using MOORA coupled with PCA—a multivariate hybrid approach. J Adv Manuf Syst 16:81–99

Mandal A, Dixit AR (2014) State of art in wire electrical discharge machining process and performance. Int J Mach Mach Mater 16(1):1–21

Medhi T, Hussain SAI, Roy BS, Saha SC (2020) Selection of best process parameters for friction stir welded dissimilar Al-Cu alloy: a novel MCDM amalgamated MORSM approach. J Braz Soc Mech Sci Eng 42:546

Mohite NT, Patil GV, Kallol AN (2022) The use of entropy-based GRA approach to analyze and optimize the wire electrical discharge machining process for Nitronic-30. Mater Today Proc 49:1426–1430

Muniappan A, Thiagarajan C, Somasundaram SS (2017) Parametric optimization of kerf width and surface roughness in wire electrical discharge machining (WEDM) of hybrid aluminium (Al6061/SiC/Graphite) composite using Taguchi-based gray relational analysis. Int J Mech Mechatron Eng 16:95–103

Muniappan A, Sriram M, Thiagarajan C, Bharathi Raja G, Shaafi T (2018) Optimization of WEDM process parameters on machining of AZ91 magnesium alloy using MOORA method. Mater Sci Eng 390:012107

Pamučar D, Mihajlović M, Obradović R, Atanasković P (2017) Novel approach to group multi-criteria decision making based on interval rough numbers: Hybrid DEMATEL-ANP-MAIRCA model. Expert Syst Appl 88:58–80

Patel JD, Maniya KD (2018) Use of multi criteria decision making method for selection of wire cut electrical discharge machining process. Int J Pure Appl Math 118(20):383–389

Patel JD, Maniya KD (2019) WEDM process parameter selection using preference ranking method: a comparative study. Int J Manuf Res 14:118–144

Paulson DM, Saif M, Zishan M (2022) Optimization of wire-EDM process of titanium alloy-grade 5 using Taguchi’s method and grey relational analysis. Mater Today Proc 72:144–153

Peng X, Garg H (2022) Intuitionistic fuzzy soft decision making method based on CoCoSo and CRITIC for CCN cache placement strategy selection. Artif Intell Rev 55:1567–1604

Priyadarshini M, Vishwanatha HM, Biswas CK, Singhal P, Buddhi D, Behera A (2022) Effect of grey relational optimization of process parameters on surface and tribological characteristics of annealed AISI P20 tool steel machined using wire EDM. Int J Interact Des Manuf. https://doi.org/10.1007/s12008-022-00954-6

Ram Prasad AV, Ramji K, Kolli M, Vamsi Krishna G (2019) Multi-response optimization of machining process parameters for wire electrical discharge machining of lead-induced Ti-6Al-4V alloy using AHP-TOPSIS method. J Adv Manuf Syst 18:213–236

Rao MS, Venkaiah N (2018) Multi-response optimisation for MRR and Ra in WEDM process of Nimonic-263 super alloy. Int J Mater Prod Technol 56:187–206

Reddy YR, Reddy BCM (2018) Optimization of WEDM parameters for SUPER Ni-718 using GRA with neutrosophic sets. Int J Appl Eng Res 13(12):10924–10930

Saha A, Mondal SC (2016) Multi-objective optimization in WEDM process of nanostructured hardfacing materials through hybrid techniques. Measurement 94:46–59

Santhanakumar M, Adalarasan R, Raj SS, Rajmohan M (2017) An integrated approach of TOPSIS and response surface methodology for optimising the micro WEDM parameters. Int J Oper Res 28:18–34

Sen B, Hussain SAI, Gupta AD, Gupta MK, Pimenov DY, Mikołajczyk T (2021) Application of type-2 fuzzy AHP-ARAS for selecting optimal WEDM parameters. Metals 11:42

Shivakoti I, Peshwani B, Kibria G, Pradhan BB, Sharma A (2019) Parametric optimization of WEDM using MABAC method. In: Proc. of 8th International Conference on Modeling Simulation and Applied Optimization, Bahrain, pp 1–4

Singh R, Hussain SAI, Dash A, Rai RN (2020) Modelling and optimizing performance parameters in the wire-electro discharge machining of Al5083/B4C composite by multi-objective response surface methodology. J Braz Soc Mech Sci Eng 42:344

Singh R, Singh RP, Trehan R (2021) State of the art in processing of shape memory alloys with electrical discharge machining: a review. Proc Inst Mech Eng Part B J Eng Manuf 235(3):333–366

Sreeraj P, Kumaran ST, Kumar SS, Uthayakumar M, Pethuraj M (2022) Application of MCDM based hybrid optimization of WEDM process parameters. Mater Today Proc 50:1186–1192

Thangaraj M, Annamalai R, Moiduddin K, Alkindi M, Ramalingam S, Alghamdi O (2020) Enhancing the surface quality of micro titanium alloy specimen in WEDM process by adopting TGRA-based optimization. Materials 13:1440

Udaya Prakash J, Sivaprakasam P, Juliyana SJ, Ananth S, Rubi CS, Sadhana AD (2022) Multi-objective optimization using grey relational analysis for wire EDM of aluminium matrix composites. Mater Today Proc 72:2395–2401

Yazdani M, Zarate P, Zavadskas EK, Turskis Z (2019) A combined compromise solution (CoCoSo) method for multi-criteria decision-making problems. Manag Decis 57(9):2501–2519

Author information

Authors and Affiliations

Contributions

SC: Data collection and analysis, PPD: Data analysis and draft preparation, SC: Final draft preparation and technical editing

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chatterjee, S., Das, P.P. & Chakraborty, S. A comparative study on parametric optimization of a wire-electrical discharge machining process using MCDM methods in intuitionistic fuzzy environment. Multiscale and Multidiscip. Model. Exp. and Des. 7, 507–527 (2024). https://doi.org/10.1007/s41939-023-00218-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41939-023-00218-0