Abstract

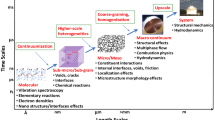

In porous solid energetic materials, the mechanical processing technique (e.g. casting, pressing) creates defects such as voids, cracks, interfaces, and inclusions; these defects in the microstructure strongly influence the sensitivity of the material to imposed loading. Energy localization at defects causes hotspots; the ignition and growth of hotspots in the microstructure (i.e. the meso-scale) play a crucial role in the macroscale initiation of the material. Predictive models of shock response of energetic materials must connect the meso-scale heterogeneities (structure) and hotspot physics (properties) to macro-scale response (performance and safety). To achieve this structure–property–performance (S–P–P) linkage, SEM-imaged samples of neat pressed HMX are obtained, and morphometry is performed to quantify the microstructure. Since the microstructure is stochastic, the aleatory uncertainties in the morphological parameters are quantified. The link between the microstructure and the key meso-scale quantity of interest—the hotspot ignition and growth rates—is established using reactive meso-scale computations to construct meso-informed surrogate models for energy localization. The surrogate models are used to close homogenized macro-scale governing equations. The performance of the HE at the macro-scale, i.e. its sensitivity to shock loading, is measured via run-to-detonation distances (in Pop plots) and the critical energy required for initiation (in James plots). The predicted critical energy for the material is compared with experimental data. The methods established in this paper can be useful not only for establishing structure–property–performance (S–P–P) linkages for pressed energetic materials, but also for other heterogenous reactive composites such as propellants and plastic-bonded explosives.

Similar content being viewed by others

References

Addessio F, Luscher D, Cawkwell M, Ramos K (2017) A single-crystal model for the high-strain rate deformation of cyclotrimethylene trinitramine including phase transformations and plastic slip. J Appl Phys 121:185902

Anas Nassar NKR, Sen O, Udaykumar HS (2018) Multiscale shock-to-detonation simulation of pressed HMX, Part II: machine learned surrogate model for effect of loading and void size. Shock Waves 29(4):537–558

Barnes BC, Leiter KW, Larentzos JP, Brennan JK (2020) Forging of hierarchical multiscale capabilities for simulation of energetic materials. Propellants Explos Pyrotech 45:177–195

Barua A, Kim S, Horie Y, Zhou M (2013) Ignition criterion for heterogeneous energetic materials based on hotspot size-temperature threshold. J Appl Phys 113:064906

Bassett WP, Dlott DD (2016) Shock initiation of explosives: temperature spikes and growth spurts. Appl Phys Lett 109:091903

Campbell AW, Davis WC, Ramsay JB, Travis JR (1961) Shock initiation of solid explosives. Phys Fluids 4:511–521

Fehlberg E (1968) Classical fifth-, sixth-, seventh-, and eighth-order Runge-Kutta formulas with stepsize control. National Aeronautics and Space Administration.

Garcia F, Vandersall KS, Tarver CM (2014) Shock initiation experiments with ignition and growth modeling on low density HMX, J Phys: Conf Ser. IOP Publishing, p. 052048.

Gaul NJ (2014) Modified Bayesian Kriging for noisy response problems and Bayesian confidence-based reliability-based design optimization.

Handley CA, Lambourn BD, Whitworth NJ, James HR, Belfield WJ (2018) Understanding the shock and detonation response of high explosives at the continuum and meso scales. Appl Phys Rev 5:011303

James HR (1996) An extension to the critical energy criterion used to predict shock initiation thresholds. Propellants Explos Pyrotech 21:8–13

Johnson JN, Tang PK, Forest CA (1985) Shock-wave initiation of heterogeneous reactive solids. J Appl Phys 57:4323–4334

Kapahi A, Udaykumar HS (2013) Dynamics of void collapse in shocked energetic materials: physics of void–void interactions. Shock Waves 23:537–558

Kapahi A, Udaykumar H (2015) Three-dimensional simulations of dynamics of void collapse in energetic materials. Shock Waves 25:177–187

Kapila A, Schwendeman D, Bdzil J, Henshaw W (2007) A study of detonation diffraction in the ignition-and-growth model. Combust Theor Model 11:781–822

Kendall MG (1938) A new measure of rank correlation. Biometrika 30:81–93

Kim S, Miller C, Horie Y, Molek C, Welle E, Zhou M (2016) Computational prediction of probabilistic ignition threshold of pressed granular octahydro-1, 3, 5, 7-tetranitro-1, 2, 3, 5-tetrazocine (HMX) under shock loading. J Appl Phys 120:115902

Kim S, Wei Y, Horie Y, Zhou M (2018) Prediction of shock initiation thresholds and ignition probability of polymer-bonded explosives using mesoscale simulations. J Mech Phys Solids 114:97–116

Kleijnen JPC (2009) Kriging metamodeling in simulation: a review. Eur J Oper Res 192:707–716

Lee EL, Tarver CM (1980) Phenomenological model of shock initiation in heterogeneous explosives. Phys Fluids 23:2362–2372

Lee S, Sen O, Rai NK, Gaul NJ, Choi KK, Udaykumar HS, (2019a) Effects of parametric uncertainty on multi-scale model predictions of shock response of a pressed energetic material. J Appl Phys, p. 125.

Lee S, Sen O, Rai NK, Gaul NJ, Choi KK, Udaykumar HS (2019) Effects of parametric uncertainty on multi-scale model predictions of shock response of a pressed energetic material. J Appl Phys 125:235104

Lee Perry W, Clements B, Ma X, Mang JT (2018) Relating microstructure, temperature, and chemistry to explosive ignition and shock sensitivity. Combust Flame 190:171–176

Leiter KW, Barnes BC, Becker R, Knap J (2018) Accelerated scale-bridging through adaptive surrogate model evaluation. J Comput Sci 27:91–106

Levesque GA, Vitello P (2015) The effect of pore morphology on hot spot temperature. Propellants Explos Pyrotech 40:303–308

Mang JT, Hjelm RP (2013) Fractal networks of inter-granular voids in pressed TATB. Propellants Explos Pyrotech 38:831–840

Massoni J, Saurel R, Baudin G, Demol G (1999) A mechanistic model for shock initiation of solid explosives. Phys Fluids 11:710–736

Menikoff R (1999) Granular explosives and initiation sensitivity. Los Alamos National Lab, Los Alamos

Menikoff R (2004) Pore collapse and hot spots in HMX. IOP Institute of Physics Publishing Ltd, pp. 393–396.

Menikoff R, Sewell TD (2002) Constituent properties of HMX needed for mesoscale simulations. Combust Theor Model 6:103–125

Menikoff R, Shaw MS (2012) The SURF model and the curvature effect for PBX 9502. Combust Theor Model 16:1140–1169

Molek C, Welle E, Wixom R, Ritchey M, Samuels P, Horie Y (2017) Microstructural characterization of pressed HMX material sets at differing densities, AIP Conference Proceedings. AIP Publishing, p. 040007.

Molek CD, Hardin DB, Mares JO, Vitarelli JP (2018) Microstructural effects on initiation threshold behavior of HMX based materials. Proceedings of the 16th Symposium (International) on Detonation, Cambridge, MA., p. 60.

Molek CD, Welle E, Eglin Air Force Base (2018) Personal comunication. Images courtesy of Ryan Wixom, Sandia National Laboratories.

Molek CD, Welle EJ, Mares JO, Vitarelli J, Hardin DB, Stuthers M (2020) Impact of void structure on initiation sensitivity. Propell Explos Pyrot 45:236–242

Nassar A, Rai NK, Sen O, Udaykumar H (2018a) Modeling mesoscale energy localization in shocked HMX, part I: machine-learned surrogate models for the effects of loading and void sizes. Shock Waves, pp. 1–22.

Nassar A, Rai NK, Sen O, Udaykumar H (2018) Modeling mesoscale energy localization in shocked HMX, part I: machine-learned surrogate models for the effects of loading and void sizes. J Shock Waves 29:537–558

Nassar A, Rai NK, Sen O, Udaykumar HS (2018) Modeling mesoscale energy localization in shocked HMX, part I: machine-learned surrogate models for the effects of loading and void sizes. Shock Waves 29:537–558

Nassar A, Rai NK, Sen O, Udaykumar H (2019) Modeling mesoscale energy localization in shocked HMX, Part I: machine-learned surrogate models for the effects of loading and void sizes. Shock Waves 29:537–558

Nichols A, Tarver CM (2002) A statistical hot spot reactive flow model for shock initiation and detonation of solid high explosives. Lawrence Livermore National Lab, CA

Odgaard A, Jensen EB, Gundersen HJ (1990) Estimation of structural anisotropy based on volume orientation. A new concept J Microsc 157:149–162

Omre H (1987) Bayesian kriging? Merging observations and qualified guesses in kriging. Math Geol 19:25–39

Rai NK, Udaykumar HS (2015) Mesoscale simulation of reactive pressed energetic materials under shock loading. J Appl Phys 118:245905

Rai NK, Udaykumar HS (2018) Three-dimensional simulations of void collapse in energetic materials. Phys Rev Fluids 3:033201

Rai NK, Udaykumar HS (2019a) Void collapse generated meso-scale energy localization in shocked energetic materials: Non-dimensional parameters, regimes, and criticality of hotspots. Phys Fluids 31:016103

Rai NK, Udaykumar HS (2019b) Void collapse generated meso-scale energy localization in shocked energetic materials: non-dimensional parameters, regimes, and criticality of hotspots. Phys Fluids 31:016103

Rai NK, Schmidt M, Udaykumar HS (2017) High resolution simulations of void collapse in energetic materials: effect of primary and secondary collapse on initiation thresholds. Phys Rev Fluids 2(4):043202

Rai NK, Schmidt M, UdayKumar HS (2017) Collapse of elongated voids in porous energetic materials: effect of void orientation and aspect ratio on initiation. Phys Rev Fluids 2(4):043201

Rai NK, Schmidt MJ, Udaykumar HS (2017a) Collapse of elongated voids in porous energetic materials: effects of void orientation and aspect ratio on initiation. Phys Rev Fluids 2:043201

Rai NK, Schmidt MJ, Udaykumar HS (2017b) High-resolution simulations of cylindrical void collapse in energetic materials: effect of primary and secondary collapse on initiation thresholds. Phys Rev Fluids 2:043202

Roy S, Rai NK, Sen O, Hardin DB, Diggs AS, Udaykumar HS (2019) Modeling mesoscale energy localization in shocked HMX, Part II: training machine-learned surrogate models for void shape and void–void interaction effects. Shock Waves 16:1–23

Roy S, Rai N, Sen O, Udaykumar H (2020) Structure–property linkage in shocked multi-material flows using a level-set-based Eulerian image-to-computation framework. Shock Waves 2020:1–30

Sen O, Davis S, Jacobs G, Udaykumar HS (2015) Evaluation of convergence behavior of metamodeling techniques for bridging scales in multi-scale multimaterial simulation. J Comput Phys 294:585–604

Sen O, Gaul NJ, Choi KK, Jacobs G, Udaykumar HS (2017) Evaluation of kriging based surrogate models constructed from mesoscale computations of shock interaction with particles. J Comput Phys 336:235–260

Sen O, Rai N, Diggs A, Hardin D, Udaykumar HS (2018) Multi-scale shock-to-detonation simulation of pressed energetic material: a meso-informed ignition and growth model. J Appl Phys 124:085110

Sewell TD, Menikoff R (2003) Complete equation of state for beta-HMX and implications for initiation. Am Inst Phys, p. 157.

Springer HK, Tarver CM, Bastea S (2015) Effects of high shock pressures and pore morphology. AIP Conference Proceedings 1793.

Strang G (1968) On the construction and comparison of difference schemes. SIAM J Numer Anal 5:506–517

Swantek AB, Austin JM (2010) Collapse of void arrays under stress wave loading. J Fluid Mech 649:399–427

Tarver CM, Chidester SK, Nichols AL (1996) Critical conditions for impact- and shock-induced hot spots in solid explosives†. J Phys Chem 100:5794–5799

Vandersall KS, Garcia F, Fried LE, Tarver CM (2014) Double shock experiments and reactive flow modeling on LX-17 to understand the reacted equation of state. J Phys Conf Ser 500.

Vanpoperynghe J, Sorel J, Aveille J, Adenis J (1985) Shock initiation of TATB and HMX explosive compositions, 8th Symposium (International) on Detonation, pp. 892–913.

Walker FE, Wasley RJ (1976) A general model for the shock initiation of explosives. Propellants Explos Pyrotech 1:73–80

Welle EJ, Molek CD, Wixom RR, Samuels P (2014) Microstructural effects on the ignition behavior of HMX. IOP Publishing.

Welle EJ, Wixom RR, Samuels P, Langhals JT (2015) Microstructure effects on the initiation threshold behavior of HMX and PBXN-5. 15th International Detonation Symposium 71.

Zhang J, Jackson TL (2017) Direct detonation initiation with thermal deposition due to pore collapse in energetic materials—towards the coupling between micro- and macroscale. Combust Theor Model 21:248–273

Zhao L, Choi KK, Lee I (2011) Metamodeling method using dynamic kriging for design optimization. AIAA J 49:2034–2046

Acknowledgements

The authors gratefully acknowledge the financial support from the Air Force Research Laboratory Munitions Directorate (AFRL/RWML), Eglin AFB, under contract number FA8651-16-1-0005 (Program manager: Dr. David B. Hardin). Portions of this work are based upon work supported by the Air Force Office of Scientific Research under award number FA9550-15RWCOR123 and FA955018-18RWCOR108. We thank Dr. Ryan Wixom for generating SEM micrographs for Class III and FEM materials.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

1.1 Governing equations at the meso- and macro-scales

The conservation laws for mass, momentum, and energy that apply at both meso- and the macro-scales in the MES-IG model are cast in Eulerian form, viz.:

and

where ρ, and \({u}_{i}\) denote the density, and the velocity components, respectively, \(E=e+\frac{1}{2}{u}_{i}{u}_{i}\) is the specific total energy, and e is the specific internal energy. The source term \(\dot{\mathcal{E}}\) in Eq. (A3 is the rise in specific internal energy of the system due to heat released in the decomposition of solid HMX into gaseous reaction products. The Cauchy stress tensor, \({\sigma }_{ij}\) is of the form:

where \({S}_{ij}\) is the deviatoric stress tensor and p is the pressure.

The chemical species are evolved in time by solving the conservation equation

where \({Y}_{i}\) is the mass fraction of the \({i}^{th}\) species and \({\dot{Y}}_{i}\) is the production rate source term for the \({i}^{th}\) species. The numerical stiffness in solving the reactive set of equations is circumvented using a Strang operator splitting approach (Strang 1968), where first the advection of species is performed using the flow time step to obtain predicted species values:

In a second step, the evolution of the species mass fraction due to chemical reactions is calculated

The species evolution Eq. (A7) is advanced in time using a 5th order Runge–Kutta Fehlberg method (Fehlberg 1968), which uses an internal adaptive time-stepping scheme to deal with the stiffness of the chemical kinetic equations.

At the meso-scale, in the high-resolution reactive void collapse calculations performed in the setup shown in Fig. 7a, the HMX and void spaces are delineated using a sharp-interface Eulerian framework presented in previous work (Kapahi and Udaykumar 2015, 2013; Rai et al. , 2017; Rai and Udaykumar 2015, 2018). The collapse of voids due to shock loading and the formation of hot spots are modeled with the solid HMX modeled as an elasto-plastic material of constant yield strength, \({\sigma }_{y}\). Shock heating can lead to the melting of HMX; therefore, thermal softening of HMX is modeled using the Kraut–Kennedy relation (Menikoff and Sewell 2002). The pressure at the meso-scale is obtained from a Birch–Murnaghan equation of state (Menikoff and Sewell 2002; Sewell and Menikoff 2003),

where

and

where \(\Gamma \) is the Gruneisen co-efficient, and T is the temperature. The isochoric specific heat \({C}_{v}\) is computed from the isobaric specific heat \({C}_{p}\) using the following equation:

where α is the thermal expansion co-efficient, and \({K}_{T}\) is the bulk modulus.

The chemical decomposition of HMX is modeled using a three-step mechanism proposed by Tarver et al. (1996). A detailed description of the implementation of the three-step model in the current numerical framework is presented in previous work (Rai et al. 2017a). Here, a brief overview of the reaction model and its implementation is provided.

Chemical decomposition of HMX takes place in three steps involving four different species:

and

The solid HMX (species 1, mass fraction \({Y}_{1}\)) under high temperature decomposes into fragments (species 2, \({Y}_{2}\)). The fragments are further decomposed to intermediate gases (species 3, \({Y}_{3}\)) which are later converted to the final gases (species 4, \({Y}_{4}\)) through exothermic reactions leading to high temperatures in the hotspot.

The change in temperature due to chemical decomposition of HMX is calculated by solving the evolution equation,

where k is the thermal conductivity of HMX and \({\dot{Q}}_{R}\) is the total heat release rate because of the chemical reaction. The source term in Eq. (A3) is computed by setting \(\dot{\mathcal{E}}={C}_{v}\dot{T}\).

At the macro-scale, the material is a homogenized mixture of solid HMX and gaseous reaction products. The mixture is assumed to behave hydro-dynamically (Kapila et al. 2007; Lee and Tarver 1980), i.e., \({S}_{ij}\) is neglected in comparison to \(p{\delta }_{ij}\) in Eq. (A4). The chemical heat release due to the decomposition of HMX into gaseous products is accounted for by transitioning the mixture from a cold, unreacted solid Hugoniot to a product Hugoniot. The equations of state for the reactants and the products are given by a Cochran–Chan and a JWL equation of state, as described in Sen et al. (2018b).

Rights and permissions

About this article

Cite this article

Roy, S., Sen, O., Rai, N.K. et al. Structure–property–performance linkages for heterogenous energetic materials through multi-scale modeling. Multiscale and Multidiscip. Model. Exp. and Des. 3, 265–293 (2020). https://doi.org/10.1007/s41939-020-00075-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41939-020-00075-1