Abstract

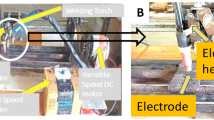

The gas tungsten constricted arc welding (GTCAW) parameters namely Main Current, Delta Current, Delta Current Frequency and Welding Speed were optimized to obtain full penetration and optimum weld bead geometry using Response Surface Methodology (RSM) to join thin Inconel 718 alloy sheets (2 mm thick). Empirical relationships were formulated to predict the weld bead characteristics such as width of bead, depth of penetration, width of heat affected zone (HAZ) and area of fusion zone (FZ). The weld bead characteristics were predicted with good accuracy using developed empirical relationships. The direct and interaction effect of GTCAW parameters on weld bead geometry is discussed in this paper.

Similar content being viewed by others

Data availability

Not Applicable.

References

Antony J (2003) Design of experiments for engineers and scientists. Heinemann, Oxford

Balasubramanian M, Jayabalan V, Balasubramanian V (2008a) Developing mathematical models to predict tensile properties of pulsed current gas tungsten arc welded Ti-6Al-4V alloy. Mater Des 29:92–97. https://doi.org/10.1016/j.matdes.2006.12.001

Balasubramanian M, Jayabalan V, Balasubramanian V (2008b) Developing mathematical models to predict grain size and hardness of argon tungsten pulsed current arc welded titanium alloy. J Mater Proc Techno 196:222–229. https://doi.org/10.1016/j.jmatprotec.2007.05.039

Benyounis KY, Olabi AG, Hashmi MSJ (2005) Optimizing the laser-welded butt joints of medium carbon steel using RSM. J Mater Proc Techno 164:986–989. https://doi.org/10.1016/j.jmatprotec.2005.02.067

Cao X, Rivaux B, Jahazi M, Cuddy J, Birur A (2009) Effect of pre- and post-weld heat treatment on metallurgical and tensile properties of Inconel 718 alloy butt joints welded using 4 kW Nd: YAG laser. J Mater Sci 44:4557–4571. https://doi.org/10.1007/s10853-009-3691-5

Cortés R, Barragán ER, López VH, Ambriz RR, Jaramillo D (2017) Mechanical properties of Inconel 718 welds performed by gas tungsten arc welding. Inter J Adv Manuf Technol 94:3949–3961. https://doi.org/10.1007/s00170-017-1128-x

Dong JX, Xie XS, Thompson RG (2000) The influence of sulfur on stress-rupture fracture in Inconel 718 superalloys. Metall Mater Trans A 31(9):2135–2144

French R, Marin-Reyes H, Rendell-Read A (2017) A robotic re-manufacturing system for high-value aerospace repair and overhaul. Trans Intell Weld Manuf 1:36–47. https://doi.org/10.1007/978-981-10-5355-9_3

Henderson MB, Arrell D, Larsson R, Heobel M, Marchant G (2004) Nickel based superalloy welding practices for industrial gas turbine applications. Sci Technol Weld Join 9(1):13–21. https://doi.org/10.1179/136217104225017099

Hong JK, Park JH, Park NK, Eom IS, Kim MB, Kang CY (2008) Microstructures and mechanical properties of Inconel 718 welds by CO2 laser welding. J Mater Proc Techno 201:515–520. https://doi.org/10.1016/j.jmatprotec.2007.11.224

Kiaee N, Aghaie-Khafri M (2014) Optimization of gas tungsten arc welding process by response surface methodology. Mater Des 54:25–31. https://doi.org/10.1016/j.matdes.2013.08.032

Leary R, Merson E, Birmingham K, Harvey D, Brydson R (2010a) Microstructural and microtextural analysis of InterPulse GTCAW welds in Cp-Ti and Ti–6Al–4V. Mater Sci Eng A 527:7694–7705. https://doi.org/10.1016/j.msea.2010.08.036

Leary R, Merson E, Brydson R (2010) Microtextures and grain boundary misorientation distributions in controlled heat input titanium alloy fusion welds. J Phys: Conf Ser 241:012103

Liu Y, Zhang H, Guo Q, Zhou X, Ma Z, Huang Y, Li H (2018) Microstructure evolution of Inconel 718 superalloy during hot working and its recent development tendency. Act Metall Sin 54:1653–1664. https://doi.org/10.11900/0412.1961.2018.00340

Mei Y, Liu Y, Liu C, Li C, Yu L, Guo Q, Li H (2016) Effect of base metal and welding speed on fusion zone microstructure and HAZ hot-cracking of electron-beam welded Inconel 718. Mater Des 89:964–977. https://doi.org/10.1016/j.matdes.2015.10.082

Montgomery DC (1997) Design and analysis of experiment. Wiley, New York

Padmanaban G, Balasubramanian V (2011) Optimization of pulsed current gas tungsten arc welding process parameters to attain maximum tensile strength in AZ31B magnesium alloy. Trans Nonferr Met Soc China 21:467–476. https://doi.org/10.1016/S1003-6326(11)60738-3

Pollock TM, Tin S (2006) Nickel-based superalloys for advanced turbine engines: chemistry. Microstruct Properties J Prop Power 22(2):361–374. https://doi.org/10.2514/1.18239

Radhakrishna CH, Rao KP (1994) Studies on creep/stress rupture behaviour of superalloy 718 weldments used in gas turbine applications. Mater High Temp 12(4):323–327. https://doi.org/10.1080/09603409.1994.11752536

Radhakrishna CH, Rao KP, Srinivas S (1995) Laves phase in superalloy 718 weld metals. J Mater Sci Lett 14:1810–1812. https://doi.org/10.1007/BF00271015

Rajakumar S, Balasubramanian V (2012) Multi-response optimization of friction-stir-welded AA1100 aluminium alloy joints. J Mater Eng Perform 21:809–822. https://doi.org/10.1007/s11665-011-9979-z

Ram GDJ, Reddy AV, Rao KP, Reddy GM (2005) Microstructure and mechanical properties of Inconel 718 electron beam welds. Mater Sci Techno 21:1132–1138. https://doi.org/10.1179/174328405X62260

Ram GDJ, Venugopal Reddy A, Prasad Rao K, Madhusudhan Reddy G (2004) Control of Laves phase in Inconel 718 GTA welds with current pulsing. Sci Techno Weld Join 9:390–398. https://doi.org/10.1179/136217104225021788

Ram GDJ, Venugopal Reddy A, Prasad Rao K, Reddy GM, Sarin Sundar JK (2005) Microstructure and tensile properties of Inconel 718 pulsed Nd-YAG laser welds. J Mater Proc Techno 167:73–82. https://doi.org/10.1016/j.jmatprotec.2004.09.081

Razal Rose A, Manisekar K, Balasubramanian V, Rajakumar S (2012) Prediction and optimization of pulsed current tungsten inert gas welding parameters to attain maximum tensile strength in AZ61A magnesium alloy. Mater Des 37:334–348. https://doi.org/10.1016/j.matdes.2012.01.007

Reddy GM, Srinivasa Murthy CV, Srinivasa Rao K, Prasad Rao K (2008) Improvement of mechanical properties of Inconel 718 electron beam welds—influence of welding techniques and post weld heat treatment. Inter J Adv Manuf Techno 43:671–680. https://doi.org/10.1007/s00170-008-1751-7

Rodríguez NK, Barragán ER, Lijanova IV, Cortés R, Ambriz RR, Méndez C, Jaramillo D (2017) Heat Input Effect on the Mechanical Properties of Inconel 718 Gas Tungsten Arc Welds. Proceed 17th Inter Conf New Trends in Fat and Fract 255–262. https://doi.org/10.1007/978-3-319-70365-7_29

Sivaprasad K, Ganesh Sundara Raman S, Mastanaiah P, Madhusudhan Reddy G (2006) Influence of magnetic arc oscillation and current pulsing on microstructure and high temperature tensile strength of alloy 718 TIG weldments. Mater Sci Eng A 428:327–331. https://doi.org/10.1016/j.msea.2006.05.046

Sonar T, Balasubramanian V, Malarvizhi S, Venkateswaran T, Sivakumar D (2019) Effect of delta current and delta current frequency on tensile properties and microstructure of gas tungsten constricted arc (GTCA) welded Inconel 718 sheets. J Mech Behav Mater 28:186–200. https://doi.org/10.1515/jmbm-2019-0020

Sonar T, Balasubramanian V, Malarvizhi S, Venkateswaran T, Sivakumar D (2020) Effect of heat input on microstructural evolution and tensile properties of gas tungsten constricted arc (GTCA) welded Inconel 718 sheets. Metall Micro Anal 9:369–392. https://doi.org/10.1007/s13632-020-00654-1

Sudarshan Rao G, Saravanan K, Harikrishnan G, Sharma VMJ, Ramesh Narayan P, Sreekumar K, Sinha P (2012) Local deformation behaviour of Inconel 718 TIG weldments at room temperature and 550 °C. Mater Sci Forum 710:439–444. https://doi.org/10.4028/www.scientific.net/MSF.710.439

Xie X.S, Dong JX, Zhang MC (2007) Research and Development of Inconel 718 Type Superalloy. Mater Sci Forum 539:262–269 https://doi.org/10.4028/www.scientific.net/MSF.539-543.262

Zhang YN, Cao X, Wanjara P (2013) Microstructure and hardness of fiber laser deposited Inconel 718 using filler wire. Inter J Adv Manuf Techno 69:2569–2581. https://doi.org/10.1007/s00170-013-5171-y

Acknowledgements

The authors express their deep sense of gratitude to the Director, Vikram Sarabhai Space Centre (VSSC), ISRO, Thiruvananthapuram, Kerala for providing base material to carry out this investigation and financial support through R & D project under RESPOND scheme (Project No. ISRO/RES/3/728/16–17).

Funding

This project work is funded by Indian Space Research Organization (ISRO) India. Project No. ISRO/RES/3/728/16–17.

Author information

Authors and Affiliations

Contributions

(optional: please review the submission guidelines from the journal whether statements are mandatory): Not Applicable.

Corresponding author

Ethics declarations

Conflict of interest

Not Applicable.

Code availability

(software application or custom code): Not Applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sonar, T., Balasubramanian, V., Malarvizhi, S. et al. Multi-response mathematical modelling, optimization and prediction of weld bead geometry in gas tungsten constricted arc welding (GTCAW) of Inconel 718 alloy sheets for aero-engine components. Multiscale and Multidiscip. Model. Exp. and Des. 3, 201–226 (2020). https://doi.org/10.1007/s41939-020-00073-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41939-020-00073-3