Abstract

Solid-state electrochemistry (SSE) is an interdisciplinary field bridging electrochemistry and solid-state ionics and deals primarily with the properties of solids that conduct ions in the case of ionic conducting solid electrolytes and electrons and/or electron holes in the case of mixed ionic and electronic conducting materials. However, in solid-state devices such as solid oxide fuel cells (SOFCs), there are unique electrochemical features due to the high operating temperature (600–1 000 °C) and solid electrolytes and electrodes. The solid-to-solid contact at the electrode/electrolyte interface is one of the most distinguished features of SOFCs and is one of the fundamental reasons for the occurance of most importance phenomena such as shift of the equipotential lines, the constriction effect, polarization-induced interface formation, etc. in SOFCs. The restriction in placing the reference electrode in solid electrolyte cells further complicates the SSE in SOFCs. In addition, the migration species at the solid electrode/electrolyte interface is oxygen ions, while in the case of the liquid electrolyte system, the migration species is electrons. The increased knowledge and understanding of SSE phenomena have guided the development of SOFC technologies in the last 30–40 years, but thus far, no up-to-date reviews on this important topic have appeared. The purpose of the current article is to review and update the progress and achievements in the SSE in SOFCs, largely based on the author’s past few decades of research and understanding in the field, and to serve as an introduction to the basics of the SSE in solid electrolyte devices such as SOFCs.

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Solid-state electrochemistry (SSE) is an interdisciplinary field bridging electrochemistry and solid-state ionics and has been extensively covered by a number of monographs and reviews [1,2,3,4,5]. By definition, SSE is a discipline dealing with the properties of solids that conduct ions and electrons or electron holes in ionic and/or electronic conducting materials [2]. In materials science, SSE is similar to solid-state ionics dealing with the preparation, characterization, theory and application of solid ionic conducting materials [6] but also refers to the electrochemical activity and behavior of materials in solid states such as the density and mobility of charge carriers associated with the defect chemistry, intercalation and redox changes [7,8,9,10,11,12]. The SSE principle is particularly relevant to the development of solid electrolyte-based devices such as solid-state sensors, solid oxide electrolysis and fuel cells (SOECs and SOFCs) and solid-state batteries. In solid-state Li-ion batteries, the solid electrolytes belong to a class of composite solid electrolytes, which consist of heterogeneous mixtures of single-phase solid electrolytes or other components such as inorganic and polymer-based composites. The SSE and the ion conduction mechanism of composite solid electrolytes are most critical for solid-state devices such as Li-ion batteries and have recently been extensively studied and reviewed [13].

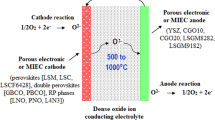

Among the single-phase solid electrolyte systems, high-temperature SOFCs are the most represented and extensively investigated solid-state devices. SOFCs are energy conversion technologies that electrochemically convert the chemical energy of hydrogen and hydrocarbon fuels into electrical energy with the highest efficiency among the fuel cell family [14,15,16,17,18]. A basic solid oxide cell consists of only ceramic materials and operates in the temperature range of 600–1 000 °C. The most common ceramic materials in a typical SOFC are the dense oxide ion conducting yttria-stabilized zirconia (YSZ) electrolyte, porous lanthanum strontium manganite (LSM) cathode and porous nickel/YSZ (Ni/YSZ) cermet anode [18, 19]. The working principle of an SOFC can be illustrated in a H2-O2 fuel cell. In this fuel cell, oxygen molecules, O2, are ionized to oxygen ions, O2−, by taking two electrons and are incorporated into the oxygen lattice site of an oxide ion conducting electrolyte by occupying an oxygen vacancy. This O2 reduction reaction (ORR) can be expressed as follows in Kröger–Vink notation:

where \({\mathrm{V}}_{\mathrm{O}}^{\cdot \cdot}\) is a vacant oxygen lattice site or oxygen vacancy and \({\mathrm{O}}_{\mathrm{O}}^{x}\) is an oxygen ion at a regular oxygen site in the electrolyte lattice. At the same time, oxygen ions flow from the LSM cathode to the Ni/YSZ cermet anode through the dense YSZ electrolyte via oxygen vacancies:

At the anode, the H2 oxidation reaction (HOR) occurs through the combination of H2 molecules with the oxygen ions that migrated from the cathode, forming H2O and releasing two electrons and an oxygen vacancy back to the electrolyte:

The overall reaction is thus the combination of hydrogen from the anode and oxygen from the cathode via oxygen vacancy migration through the electrolyte to form water on the anode side:

The electrons flow from the anode (the negative electrode) to the cathode (the positive electrode) to produce an electrical energy output. Figure 1 illustrates the scheme of and electrode reactions occurring in an SOFC.

As shown above, both the ORR and HOR require the supply and release of oxygen ions and electrons. Thus, the oxidation/reduction efficiency critically depends on the ionic conductivity of the solid electrolyte and mixed ionic and electronic conductivity of the electrodes, i.e., the SSE of the materials. In addition, SOFC devices are characterized by high operating temperatures, solid-state electrodes, solid-state electrolytes, and gaseous reactants and products. The gaseous phase reaction occurs at the porous electrode/dense electrolyte interface, and the ionic/electronic transport properties are critically related to the microstructure of the cell, such as the tortuosity and three- or triple-phase boundary (TPB) areas [20], and to the surface chemistry, such as segregation [21, 22]. The solid-to-solid (StS) contact between the porous electrode and dense electrolyte is in general not necessarily continuous and may be restricted to only a fraction of the interface. Such restriction in the contacted interface will cause misalignment and asymmetric contact between the working and counter electrodes and result in a significant change in the equipotential line. Such a change in the potential distribution across the solid electrolyte is further complicated by the limitation of the placement and positioning of the reference electrode (RE) due to the use of solid electrolytes. In contrast to aqueous electrolyte systems, incorporating the RE into the electrolyte bulk is extremely difficult and inconvenient, and instead, in most cases, the RE can only be placed on an external surface of the solid electrolyte. This not only restricts the electrochemical techniques that can be used in high-temperature SOFCs but also significantly affects the electrical potential line distribution in cells, which in turn affects the electrochemical behavior of the reaction at the interface. Additionally, very different from the interface in liquid-state electrochemistry (LSE), the physical boundary between the porous electrode and dense electrolyte cannot be clearly defined due to the MIEC properties of the electrodes. For example, in the case of the Ni/YSZ anode and the YSZ electrolyte, the interface is extended into the electrode bulk due to the YSZ-to-YSZ network in the cermet (see Fig. 1).

As is well known, the peak power performances or densities obtained in stacks are generally lower than those observed in single cells [23]. The cause for the differences in the power performances can be attributed to the contacts between the electrode coating and current collector, particularly between the cathode and current collector or interconnect interface [24,25,26,27]. An early study showed that increasing the contact area between the Pr0.8Sr0.2MnO3 cathode and current collector from 4.6% to 27.2% resulted in a reduction in the cell resistance from 1.43 to 0.19 Ω cm2 and a decrease in the overall cell overpotential from 225 to 119 mV at 250 mA cm−2 and 800 °C [25]. Such a significant effect of the contact area on both the cell ohmic and polarization resistances is also called the constriction effect in SOFCs. More recently, this constriction effect on the ohmic and polarization resistances in a stack was further confirmed in a detailed analysis of the cathode contact in the temperature range of 650–800 °C [28]. The results showed that the cell ohmic resistance increases with decreasing temperature, while the cell polarization resistance shows a minimum at 700 °C for the stack with a 35% reduction in the contact area. The fundamental reason for this contact area effect is related to the intrinsic relationship between the StS contact and the location of the equipotential line in the solid electrolyte.

In SOFCs, the microstructure and phase change, particularly at the electrode and electrolyte interfaces, are interrelated with the operation parameters, such as the polarization current, temperature, fuel type, oxygen partial pressure, deposition and poisoning of contaminants. Some changes are intrinsically related to the defect chemistry of the materials involved, such as enhanced grain boundary diffusion, deposition and poisoning of contaminants, and correlation between the oxygen ion conductivity and reactivity for the ORR [17, 29,30,31]. However, some of the microstructural changes and interfacial phenomena are not particularly related to the classic defect chemistry and are unique to solid-state electrolyte cells such as SOFCs. For example, polarization-induced microstructure changes and reactions at electrode/electrolyte interfaces occur under SOFC operating conditions and critically influence the performance and durability of SOFCs [32, 33]. The knowledge and understanding of the unique features and phenomena of the SSE in SOFCs, including the constriction effect, RE placement and reliability, and, most recently, surface segregation effect, have been significantly increased, which has guided the development of SOFC technologies in the last 30–40 years. However, there appear to be no comprehensive and up-to-date reviews on the SSE despite its importance in solid-state electrolyte devices such as SOFCs.

The purpose of the current article is twofold: to summarize the progress and achievements in the SSE in SOFCs, viewed from a prospective angle and largely based on the author’s past few decades of research and understanding in the field, and to serve as an introductory note to anyone interested in this interdisciplinary and important field. This review will start with a brief introduction to the defect chemistry in electrode and electrolyte materials in SOFCs. Then, the issues related to the cell configuration and RE placement, the electrical potential line distribution and its implication for the polarization and impedance separation in solid oxide cells, the constriction effect, surface segregation and polarization-induced interface formation under SOFC operating conditions will be discussed.

2 Basic Defect Chemistry in Electrode and Electrolyte Materials of SOFCs

The conduction of charge carriers such ions in a liquid electrolyte occurs through a distinct diffusion mode known as “vehicular”, in which a solvation sheath or cloud of polar molecules travels with the ion. Such a diffusion mode is also possible in the polymer-based electrolytes used in polymer electrolyte or proton exchange membrane fuel cells (PEMFCs) [34, 35]. The presence of a solvation sheath changes the effective radius of charge carriers and imposes certain characteristics on the electrochemical reaction at the interface. In solid electrolytes, no solvation sheath or cloud exists, and conduction of charged ions is usually mediated by hopping between adjacent lattice sites. In SOFCs, the major charged particles are electrons (or electron holes) and oxide ions. In the case of proton conducting electrolyte-based solid oxide cells or protonic ceramic fuel cells, the charged species also include protons, H+. The proton conduction issues in solid proton conducting electrolytes in SOFCs have been recently reviewed [36]. The ionic species are transported through the electrolyte between the two electrodes, and the electrodes carry the electrons to and from the reactive sites where the electrochemical reactions occur. The interconnect transfers electrons from the anode of one cell to the cathode of another cell to form a stack. Thus, the current caused by the flow of electrons is called electronic conduction, while the current due to the net motion of ions is termed ionic conduction. However, ceramic conductors have an intrinsic resistance to charge flow, and this resistance to charge flow leads to polarization loss for fuel cells. The polarization loss due to the resistance is generally termed ohmic loss or ohmic polarization. In fuel cells, the electrical conductivity, σ, is often used, which is the reciprocal of the electrical resistivity, ρ:

The conductivity for most materials can be expressed as the product of the concentration and mobility of charge carriers:

where n is the number of charge carriers, electrons (electron holes) or oxide ions in carriers per cm3; ze is the charge per carrier, where z is the valence and e is the electronic charge; v is the velocity (cm s−1) of charge carriers; and ξ is the electric field. The term v/ξ can be defined as the mobility of the charge carriers, μ (cm2 V−1 s−1). Thus, material conductivity is characterized by two major factors: the number of carriers available and the mobility of these carriers. For materials with more than one carrier, this is expressed as:

where ci is the mole number of charge carriers per unit volume, zi is the charge number (or valence) for the carrier (|zi| is always positive), and F is Faraday’s constant. The subscript i can refer to electrons, electron holes, ions, or vacancies.

In ceramic materials, electronic and ionic defects are charge carriers that enable the conduction of an electric current. These charge carriers can be formed within the material (intrinsic charge carriers), thus increasing the entropy of the system, or can be introduced into the material by doping (extrinsic charge carriers). Examples of ionic point defects are vacancies and interstitials. Electronic defects are negatively charged electrons and positively charged electron holes.

2.1 Electronic Conduction in Perovskite-Type Oxides

In a metallic conductor, valence electrons associated with atoms of the metal become detached, i.e., they are excited and promoted to the low-lying empty and available energy state above the Fermi level of electrons and become free electrons for electronic conduction. This occurs because for metals, the band structure is such that there are vacant energy states adjacent to the highest filled state at the Fermi level. Thus, very little energy is needed to excite electrons to the low-lying empty state.

Prior to a discussion of the conduction properties of oxide materials, a brief introduction to the perovskite structure is beneficial, as perovskites are the most common structured oxides in SOFCs. Figure 2 shows a typical perovskite structure. A perovskite is any material with the same type of crystal structure as calcium titanium, CaTiO3, with the general chemical formula of ABO3, where A and B are two cations of very different sizes, and O is an oxygen anion. The ideal cubic perovskite has the B cation in sixfold octahedral coordination (the coordination number or CN = 6), surrounded by an octahedron of oxygen anions, and the A cation in 12-fold cuboctahedral coordination (CN = 12). The A-site cations are typically from the alkaline earth or rare earth group, and B-site cations are generally transition metal group elements. The combination of the redox properties of transition metals with the acid–base properties of alkaline earth metals is fundamental to many interesting applications, including catalysis and fuel cells. In SOFCs, undercoordinated transition metal sites are considered vital in the ORR [31, 37]; nevertheless, the active sites on perovskite oxides for the ORR are much more complicated due to the critical role of the surface structure and composition in the reaction.

The deviation from the ideal cubic perovskite structure is governed by the Goldschmidt tolerance factor, t:

where rA, rB and rO are the ionic radii of A, B and O ions, respectively. Cubic symmetry is observed for 0.95 \(\leqslant\) t \(\leqslant\) 1.04, while perovskite structures with lower-symmetry distorted versions, such as orthorhombic and rhombohedral symmetries, are observed for 0.75 \(\leqslant\) t \(\leqslant\) 0.90. The ionic radii are related to the CN.

Most ceramics or, more precisely, ionic ceramics are generally insulating materials at room temperature due to the relatively large band gap between the filled valence band and the empty conduction band. Thus, at room temperature, only very few electrons may be excited across the band gap by the available thermal energy, resulting in a very low conductivity. Increasing the temperature will increase the conductivity of oxide materials in general; however, in the case of oxide materials with metallic behavior, the conductivity will decrease with increasing temperature, as shown later in this review. For the ceramic oxide components used in SOFCs, there are different ways to increase the ionic and electronic conductivity by tailoring the defect chemistry.

The electronic conductivity of oxide materials of SOFCs can be either n- or p-type, with p-type materials being commoner. Taking the perovskite lanthanum chromite (LaCrO3) as an example, LaCrO3-based oxides are commonly used as ceramic interconnects in SOFCs. LaCrO3 is a p-type conductor from room temperature to high temperature (> 1 000 °C) and becomes nonstoichiometric through the reaction of oxygen with LaCrO3, resulting in the formation of cation vacancies or defects [38, 39]. This can be written as:

where \({\mathrm{V}}_{\mathrm{La}}^{\mathrm{^{\prime}}\mathrm{^{\prime}}\mathrm{^{\prime}}}\) and \({\mathrm{V}}_{\mathrm{Cr}}^{\mathrm{^{\prime}}\mathrm{^{\prime}}\mathrm{^{\prime}}}\) are La and Cr cation vacancies, respectively, and \({\mathrm{h}}^{\cdot }\) is an electron hole. The negatively charged cation vacancies are electrically compensated by the concomitant appearance of positively charged electron holes. Electronic conduction in LaCrO3 occurs by small polaron hopping via transport of electron holes. However, the electronic conductivity of undoped LaCrO3 is very low. To improve the p-type electronic conductivity, divalent cations such as strontium (Sr) and calcium (Ca) are used as dopants to substitute trivalent La cations. Divalent Sr on a trivalent La site creates a negatively charged point defect, \({\mathrm{Sr}}_{\mathrm{La}}^{\mathrm{^{\prime}}}\). To maintain electroneutrality, a positive electron hole is formed:

\({\mathrm{Cr}}_{\mathrm{Cr}}^{\cdot }\) is Cr4+ on a Cr3+ site and represents an electron hole localized on a Cr site. \({\mathrm{Cr}}_{\mathrm{Cr}}^{\cdot }\) has the same function as \({\text{h}}^{\cdot }\). The introduction of a positively charged electron hole to a cation site will lead to the attraction of anions and the repulsion of cations at the same time. Such polarization of the surroundings of a localized electron hole due to the attraction and repulsion of ions is called a polaron [40]. This is schematically shown in Fig. 3. For small polarons, the polarization is of the size of one unit cell, while for large polarons, the polarized volume is much larger than a unit cell.

Charge compensation of the Sr2+ dopant in a La3+ site by the formation of positively charged electron holes via the Cr3+ → Cr4+ transition in Sr-doped LaCrO3. For simplicity, the arrangement of cations and anions is not to scale. Arrows indicate the attractive and repulsive electrostatic forces between ions

The transport of electron holes (polaron conductivity) can be formulated as charge transfer via a hopping mechanism, in which an electron is transferred from a Cr ion in one oxidation state to a neighboring Cr ion in a higher/lower oxidation state, possibly via an oxygen ion.

Electroneutrality can also be maintained by the formation of oxygen vacancies:

At equilibrium, we have:

where Ko is the equilibrium constant of Eq. (11). This equation does not explicitly include the extrinsic point defect, but the concentration of point defects is involved in the charge neutrality condition:

This means that under reducing conditions, the lattice oxygen transforms into a doubly charged oxygen vacancy, consuming two electron holes simultaneously. Thus, for Sr-doped LaCrO3, La1−xSrxCrO3 should be expressed as La1−xSrxCrO3−δ due to the formation of oxygen vacancies, where the subscript δ is used to represent the oxygen nonstoichiometry. The drop in electronic conductivity with decreasing oxygen partial pressure is a reflection of the reduced electron hole concentration, \([{\text{h}}^{\cdot }]\). Nevertheless, under an oxidizing environment (\({p}_{{\mathrm{O}}_{2}}\)>10−8 atm, 1 atm = 1.013 × 105 Pa), oxygen vacancies are negligible. Therefore, all charge compensation occurs primarily via a Cr3+ → Cr4+ transition, and the neutrality condition can be simply described as:

The p-type (hole) electronic conductivity increases with the concentration of \({\mathrm{Sr}}_{\mathrm{La}}^{\mathrm{^{\prime}}}\) and becomes independent of oxygen partial pressure beyond a pressure threshold. At low oxygen partial pressure, ionic compensation becomes a dominant mechanism through the formation of oxygen vacancies, resulting in a significant drop in the electrical conductivity. Figure 4 gives the conductivity isotherms of Ca-doped LaCrO3 at 1 000 °C [39], showing the electronic compensation mechanism at high \({p}_{{\mathrm{O}}_{2}}\) > 10−10 atm (\([{\mathrm{h}}^{\cdot }]\) is constant) and ionic compensation mechanism at low \({p}_{{\mathrm{O}}_{2}}\)<10−10–10−15 atm (\([{\mathrm{h}}^{\cdot }]\) decreases). Nevertheless, the magnitude of the pressure threshold scales with the doping level.

Conductivity isotherms at 1 000 °C for three different compositions, x = 0.1, 0.2 and 0.3, in La1−xCaxCrO3−δ as a function of oxygen partial pressure. Modified with permission from Ref. [39].

However, LaCrO3-based perovskites are well known to be characterized by a unique densification process and a unique surface/interface structure. The poor sinterability of LaCrO3 can be ascribed to the formation of a thin layer of Cr2O3 condensed at the interparticle neck from CrO3 vaporized from the convex parts of LaCrO3 particles during the initial stage of sintering in air [41]. Sintering in reducing atmospheres and/or doping at the A and/or B sites can prevent the formation of a Cr2O3 layer by decreasing the CrO3 vapor pressure without precipitation of La2O3. Yokokawa et al. showed that Ca doping enhances the LaCrO3 sinterability due to the formation of unique surface/interface structures of Cr2O3, La2O3 and CaO compared to nondoped LaCrO3 [41]. In addition to the sinterability, both experimental and theoretical results reveal that the electronic conductivity of LaCrO3 is significantly increased by partial substitution of La ions in A sites by Ca, Sr, and Ba ions and reaches a maximum value with the Ca dopant [42].

The electronic conductivity through hopping of small polarons is thermally activated and is generally expressed as:

where Ao is the pre-exponential constant and Ea is the activation energy, which can be obtained from the slope of the plots of log(σT) versus 1/T.

The strontium titanate perovskite SrTiO3 provides an example of an n-type conductor. In contrast to LaCrO3, where the Sr2+ cation on a La3+ site creates a negatively charged defect, trivalent La on a divalent Sr site creates a positively charged point defect, \({\mathrm{La}}_{\mathrm{Sr}}^{\cdot }\). The excess positive charge is compensated by the formation of a negatively charged electron:

\({\mathrm{Ti}}_{\mathrm{Ti}}^{\mathrm{^{\prime}}}\) is Ti3+ on a Ti4+ site and represents an electron localized on a Ti site. At low oxygen partial pressure and high temperature, the primary compensation mechanism is the reduction of Ti4+ to Ti3+. Different from the electron holes located in the valence band of Cr in Sr-doped LaCrO3, electrons formed in \({\mathrm{Ti}}_{\mathrm{Ti}}^{\mathrm{^{\prime}}}\) are located in the conduction band formed by the overlap of the Ti 3d orbitals. As expected, the electronic conductivity of doped SrTiO3 increases with decreasing oxygen partial pressure and decreases with temperature, behaving like a metallic conductor.

2.2 Electronic Structure and Defect Chemistry of Perovskite Electrodes

In SOFCs, the cathode is one of the most critical components and becomes a limiting factor for operation at intermediate to low temperatures due to the large energy barrier (i.e., activation energy) of the reaction compared to the ionic conductivity of the electrolyte [43,44,45]. Among the most common and extensively investigated perovskite electrodes are electronic conducting (La, Sr)MnO3 (LSM) and MIEC (La, Sr)(Co, Fe)O3−δ (LSCF) [46, 47]. The electrochemical activity and stability of perovskite electrodes are closely related to their electronic structure and defect chemistry [31].

2.2.1 LSM

LSM is the best known electronic conducting electrode material in SOFCs due to its high electrocatalytic activity for the ORR at high temperatures, high electronic conductivity, high structural stability and chemical compatibility with the YSZ electrolyte [46]. The electrical conductivity of LSM varies significantly with Sr doping and increases with temperature, a typical p-type conductor behavior, as shown in Fig. 5 [48]. The activation energies determined from the slope decrease with the Sr doping level, varying in the range of 24 to 3 kJ mol−1. This suggests the predominant small polaron hopping mechanism for electrical conduction. The maximum conductivity was observed for LSM with a Sr doping level of x = 0.5. However, La1−xSrxMnO3 with x = 0.1–0.2 is commonly used in SOFCs due to its sufficiently high conductivity (~ 200 S cm−1 at 900 °C) and the compatible thermal expansion coefficient (11 × 10−6–12 × 10−6 K−1) with the YSZ electrolyte.

Reproduced with permission from Ref. [48]. Copyright 2000, Elsevier

Arrhenius plots of the electronic conductivity (σ) of La1−xSrxMnO3+δ (0 \(\leqslant\) x \(\leqslant\) 0.7) in pure oxygen (\(p_{{{\text{O}}_{{2}} }}\) = 1 bar, 1 bar = 100 000 Pa).

A detailed density functional theory (DFT) study by Pavone et al. showed that Sr substitution of A-site La leads to the formation of electron holes in the LSM electronic structure [49]. At SOFC operating temperatures, the electron holes are localized onto specific Mn ions, forming Mn4+ ions, \({\mathrm{Mn}}_{\mathrm{Mn}}^{\cdot }\), or electron holes, \({\mathrm{h}}^{\cdot }\), and causing local distortion of the LSM lattice. Due to the high oxygen vacancy formation energy [49,50,51,52], the oxygen vacancy concentration is too low to allow efficient oxygen ion diffusion in LSM. The neutrality condition can be simply described as:

LSM is somewhat unusual compared to most perovskite oxides in that it can have oxygen-excess as well as oxygen-deficient nonstoichiometries. One of the best examples is the oxygen nonstoichiometry of La1−xSrxMnO3±δ as a function of oxygen partial pressure, \({p}_{{\text{O}}_{2}}\), temperature and composition reported by Mizusaki et al.; see Fig. 6 [53]. An oxygen-deficient region and an oxygen-excess region are observed (a typical example is given for La0.9Sr0.1MnO3±δ). The oxygen content depends strongly on the oxygen partial pressure, exhibiting two plateaus: the oxygen-excess (3 + δ) region at high \({p}_{{\mathrm{O}}_{2}}\) and the stoichiometric (δ = 0) region at intermediate \({p}_{{\mathrm{O}}_{2}}\). With decreasing oxygen partial pressure, the oxides become oxygen deficient (3 − δ), and the formation of the positively charged \({\mathrm{V}}_{\mathrm{O}}^{\cdot \cdot}\) is compensated by the reduction of B-site Mn cations.

Oxygen nonstoichiometry of La0.9Sr0.1MnO3±δ as a function of oxygen partial pressure, clearly showing the oxygen-excess and oxygen-deficient regions. Modified with permission from Ref. [53].

Under normal SOFC operating conditions, LSM is in the oxygen-excess region and only becomes oxygen deficient at very low \({p}_{{\mathrm{O}}_{2}}\), e.g., < 10−10 Pa at 900 °C for x = 0.2. In the oxygen-excess region, there are two possibilities for maintaining the electrical neutrality disrupted by the oxidation of B-site Mn cations: formation of cation vacancies or interstitial oxide ions. The close-packed nature of the perovskite lattice implies that the structure cannot accommodate an excess of oxygen as interstitial oxygen ions. Thus, cation vacancies, rather than oxygen interstitials, are responsible for the oxygen-excess nonstoichiometry of LSM [50]. The oxygen-excess nonstoichiometry of LSM-based oxides is probably the most unique and interesting, as it is rarely observed in other perovskite-structured oxides. This is probably the main reason for the dominant electronic conductivity of doped LaMnO3 cathode materials under SOFC operating conditions.

In the oxygen-deficient region, the predominant ionic defect is the oxygen vacancy, and charge compensation occurs by Mn reduction. Since electronic conduction in LSM is a hopping p-type mechanism irrespective of the oxygen content (δ < 0 and δ > 0), disproportion of Mn ions into Mn2+, Mn3+, and Mn4+ occurs [54]. This can be written as:

where \({\mathrm{Mn}}_{\mathrm{Mn}}^{\cdot }\) is Mn4+ on a Mn3+ cation site and \({\mathrm{Mn}}_{\mathrm{Mn}}^{\mathrm{^{\prime}}}\) is Mn2+ on a Mn3+ site. Compared to the electronic conductivity, the ionic conductivity of LSM is much smaller. The oxygen ion conductivity of LSM materials was reported to be approximately 5.9 × 10−8 S cm−1 under \({p}_{{\mathrm{O}}_{2}}\) of 10−1 to 10−3 atm at 800 °C [55].

As the oxygen ion conductivity of LSM is very low, the TPB region is the dominant reaction site for the ORR. In addition to the very low ionic conductivity, the high activation energy of the reaction is also considered to be a limiting factor in the application of LSM-based cathodes for the ORR at reduced operating temperatures. For example, for the ORR on an LSM electrode, RE is 0.4 Ω cm2 at 900 °C and dramatically increases to 56 Ω cm2 at 700 °C [56]. Thus, pristine LSM is not suitable for intermediate temperature (IT) SOFCs.

2.2.2 LSCF

Similar to LSM, LSCF is the best known MIEC ABO3 perovskite electrode in SOFCs, and the most representative composition is La0.6Sr0.4Co0.2Fe0.8O3−δ (or LSCF6428) [47]. LSCF is a typical acceptor-doped (acceptor dopants are cations with a lower oxidation state than the host cation) cobaltite perovskite-type oxide and is characterized by enhanced lattice oxygen vacancy formation, particularly at increased temperatures. For example, La0.8Sr0.2Co0.2Fe0.8O3−δ is stoichiometric (i.e., δ = 0) at room temperature, whereas at 800 °C, δ is 0.02 in air [57] and increases to 0.07 at a low \({p}_{{\mathrm{O}}_{2}}\) of 1.4 × 10−3 atm [58]. The high concentration of oxygen vacancies in conjunction with the relatively high mobility allows LSCF-based oxides to exhibit high oxide ion conductivity. LSCF has a high electrical conductivity and shows metallic conduction behavior at high temperatures.

For acceptor-doped perovskite oxides such as LSCF, charge compensation can occur by both ionic and electronic defects. Thus, the charge compensation due to the dissolution of SrO in the La(Fe, Co)O3 perovskite lattice can be described by a valence change of the B-site cations, e.g., Fe cations:

where \({\mathrm{Fe}}_{\mathrm{Fe}}^{\cdot }\) is the Fe4+ ion in a normal Fe3+ ion lattice site with a positive charge (similar to \({\mathrm{Cr}}_{\mathrm{Cr}}^{\cdot }\), functioning as an electron hole). Electrical neutrality can also be maintained by the formation of positively charged oxygen vacancies:

Since ionic compensation and electronic compensation occur simultaneously and compete with each other, the charge neutrality condition, assuming that only localized electronic charge carriers are present and charge compensation also occurs by the valence change of cobalt ions, can be expressed as:

The oxygen nonstoichiometry (δ) of LSCF is known to vary almost linearly with the logarithm of \({p}_{{\mathrm{O}}_{2}}\), indicating that the predominant defects in LSCF are oxygen vacancies, \({\mathrm{V}}_{\mathrm{O}}^{\cdot \cdot}\), i.e., the charge compensation in LSCF is dominated by Eq. (21) rather than Eq. (20). DFT calculations show that Sr substitution reduces the oxygen vacancy formation energy, \({\Delta G}_{\mathrm{f},\mathrm{vac}}\) [59]. \({\mathrm{Sr}}_{\mathrm{La}}^{\mathrm{^{\prime}}}\) defects produce electron holes that are partially delocalized across the oxygen sublattice, causing the oxygen sublattice to become susceptible to forming \({\mathrm{V}}_{\mathrm{O}}^{\cdot \cdot}\).

The electronic structure of LSCF is considered to be a combination of La1−xSrxCoO3−δ (LSC) and La1−xSrxFeO3−δ (LSF) perovskites. LSC and LSF have very different electronic structures, although their crystal structures are similar. In LSC, the conduction electrons are delocalized, and electrical conduction occurs with more band-like conduction via Co 3d/O 2p hybridization states. This is supported by the metal-like high conductivity of LSC [60]. In LSF, electrons and holes are localized with an adiabatic hopping-type conductivity of small polarons (through Fe3+ and Fe4+ sites) [61]. Thus, the electronic conduction in LSCF is a mixed conduction with band-like conduction by the Co 3d/O 2p hybridized orbital and hopping of small polarons [62]. The electrical conductivity of LSCF depends critically on the composition, as a change in composition changes both the crystal structure and the orbital configuration of valence electrons. The conductivity of LSCF increases with temperature up to a maximum and then decreases (see Fig. 7) [63, 64]. The temperature of the maximum conductivity of LSCF is affected by the Sr and Co contents at the A and B sites of LSCF. The electronic and ionic conductivities of LSCF-based materials critically depend on the defect chemistry of the materials, which is in turn closely related to the Co and Fe contents in the B-site lattice. Ritzmann et al. used DFT plus U (DFT + U) analysis to investigate the effect of Co addition at the B site of LSCF and reported a significant change in the electronic structure of the materials with a mixture of Co and Fe [65]. The electronic conduction changes from the p-type semiconducting behavior of La0.5Sr0.5FeO3 to semimetallic behavior for the Co-containing compounds. The decrease in conductivity at high temperatures can be due to the metal-like conducting behavior, and the increase in oxygen vacancies at high temperatures also reduces the number of p-type electronic carriers.

Electrical conductivity of a La1−xSrxCo0.2Fe0.8O3 and b La0.8Sr0.2Co1−yFeyO3 as a function of temperature in air, showing the change from semiconducting to metallic conducting behavior with the maximum conductivity temperature changing as a function of Sr and Co contents. Lines are added as a guide only. Modified with permission from Ref. [63, 64].

In such a mixed conductivity model, the conductivity of hybridized bands changes with changing oxygen vacancy concentration, while the hopping-type conductivity is more or less constant. Thus, regardless of the temperature, the conductivity decreases with decreasing \({p}_{{\mathrm{O}}_{2}}\) due to the decrease in the number of carrier holes with the increasing number of electrons in the Co 3d/O 2p hybridized orbital [66]. With the decrease in \({p}_{{\mathrm{O}}_{2}}\), Co3+ is preferentially reduced to Co2+, while Fe remains at a higher valence above 3 [67]. This indicates that the formation of oxygen vacancies is the dominant charge compensation mechanism in LSCF.

The oxide ion conductivity depends on the formation of oxygen vacancies. In LSCF, there are three possible oxygen vacancy formation sites, depending on the adjacent Co or Fe ions, \(\mathrm{Co}-{\mathrm{V}}_{\mathrm{O}}^{\cdot \cdot}-\mathrm{Co}\), \(\mathrm{Co}-{\mathrm{V}}_{\mathrm{O}}^{\cdot \cdot}-\mathrm{Fe}\), and \(\mathrm{Fe}-{\mathrm{V}}_{\mathrm{O}}^{\cdot \cdot}-\mathrm{Fe}\). The oxygen vacancy formation reactions can be expressed as:

The preferable position for the formation of oxygen vacancies depends on the formation energy of oxygen vacancies, which is closely related to the local environment. Mastrikov et al. showed that oxygen vacancy formation preferably occurs at oxygen sites between Co ions, \(\mathrm{Co}-{\mathrm{V}}_{\mathrm{O}}^{\cdot \cdot}-\mathrm{Co}\) [68], while Ritzmann et al. indicated that the \({\mathrm{V}}_{\mathrm{O}}^{\cdot \cdot}\) defects prefer to form between one Fe3+ ion and one Co3+ ion, \(\mathrm{Co}-{\mathrm{V}}_{\mathrm{O}}^{\cdot \cdot}-\mathrm{Fe}\), based on a calculation on a supercell with 80 atoms [65]. Nevertheless, oxygen vacancy formation due to the increase in the Co content at the B site of the LSCF perovskite structure also simultaneously leads to increased electron defects. This is consistent with the increase in the electronic conductivity and the reduction in the peak temperature of the metallic conductivity behavior with the Co content (Fig. 7b) [63].

The electrochemical activity of the LSCF electrode for the ORR significantly decreases with decreasing temperature due to its high activation energy for the ORR (e.g., 135–150 kJ mol−1). At temperatures below 600 °C, the reaction is increasingly driven to the electrode/electrolyte interface region due to the substantial decrease in the ionic conductivity of LSCF below 600 °C.

However, replacing La with Ba at the A site of LSCF can substantially enhance its oxygen ion conductivity and thus the electrochemical activity for the ORR at intermediate temperatures. Since the presence of Ba with a large ionic radius (Ba3+—0.16 nm; La3+—0.136 nm for CN = 12 [69]) is beneficial to forming a large lattice spacing for oxide ion movement, a higher Ba content in the perovskite leads to an enhanced ORR rate. Barium strontium cobalt ferrite (BSCF)-based materials are characterized by high oxygen deficiency, i.e., oxygen vacancy concentration, and thus high oxygen mobility due to their low oxygen vacancy formation energy and low oxygen vacancy migration barrier [70, 71]. The best example is Ba0.5Sr0.5Co0.8Fe0.2O3, which has been reported to show a high activity for the ORR and high oxygen exchange kinetics with high oxygen exchange coefficient and surface exchange coefficient [72, 73].

2.3 Oxide Ion Conductivity in Fluorite-Type Oxides

Fluorite-type oxides are the main ionic conductors and are used as electrolyte materials in SOFCs. The fluorite-type structure (CaF2) is a face-centered cubic structure and has the general formula MO2, where M is a large tetravalent cation, e.g., Zr4+, Ce4+, and Th4+, and the anion is an oxygen ion (see Fig. 8). To form the fluorite structure in MO2, the minimum ionic radius ratio (i.e., the ratio of the M ion radius to the O anion radius) is 0.732. This structure is rather open, which is beneficial for rapid ion diffusion.

The oxide ion conductivity is generally related to the lattice defect structure in metal oxides. There are three probable defect models in this case: (i) an oxygen vacancy model with all metal ions fixed at their lattice sites, (ii) a cation interstitial model with all oxygen ions fixed at their lattice sites (Frenkel type), and (iii) a mixed oxygen vacancy and cation interstitial model (the Schottky type). In the case of stabilized ZrO2, the defect structure is the oxygen vacancy model. This also applies for stabilized ceria and other fluorite-type oxide ion conductors.

The best known example is Y2O3-stabilized ZrO2 or YSZ. Dissolution of Y2O3 in ZrO2 results in incorporation of Y3+ on the Zr+4 cation sites with concomitant formation of positively charged oxygen vacancies, \({\mathrm{V}}_{\mathrm{O}}^{\cdot \cdot}\), as charge compensation defects. The defect formation reaction can be written as:

where \({\mathrm{Y}}_{\mathrm{Zr}}^{\mathrm{^{\prime}}}\) is the Y3+ ion in the Zr4+ lattice site with a negative charge and \({\mathrm{O}}_{\mathrm{O}}^{x}\) is a normal oxygen lattice site. The oxygen vacancy concentration is given simply by the electroneutrality condition. In this case, for every two Y3+ occupations of the Zr4+ cation lattice site, one oxygen vacancy is generated.

Thus, oxide ion conduction occurs through oxygen vacancies. The oxide ion conductivity increases with temperature and dopant concentration. The conductivity of YSZ increases with increasing Y2O3 content, reaching a maximum for YSZ with 8 mol% (mol% means the mole percentage) Y2O3 and then decreasing with a further increase in Y2O3 content. A similar dependence of the conductivity on the dopant concentration has been observed for other dopants (see Fig. 9) [74]. The Y2O3 content that corresponds to the maximum conductivity is nearly independent of temperature. The decrease in conductivity is attributed to the formation of dopant-vacancy pairs or defect clusters according to:

Reproduced with permission from Ref. [74]. Copyright 1999, Elsevier

Dependence of the conductivity of (ZrO2)1−x(Ln2O3)x on the dopant concentration, measured at 1 000 °C.

in which the superscript ⋅ indicates the defect cluster with a positive charge and x the neutral defect cluster. These defect clusters trap oxygen vacancies, reducing the defect mobility and thus the conductivity.

The formation of such defect clusters or associates is due to Coulombic and elastic attractive forces between \({\mathrm{Y}}_{\mathrm{Zr}}^{\mathrm{^{\prime}}}\) and \({\mathrm{V}}_{\mathrm{O}}^{\cdot \cdot}\) and is affected by the binding enthalpy, Ea, which is more dominant at low temperatures. Based on Eq. (6), the oxide ion conductivity can be expressed by:

The mobility µ is given by:

where Em is the enthalpy for the motion and B is a constant. The activation energy for oxide ion conduction Ei is also related to the valence of the dopant due to the association effects between dopant cations and their charge compensation defects, and it can be expressed in a more general form as follows [75]:

where n is equal to 1 or 2 for a di- or trivalent dopant, respectively. At higher temperatures, defect clusters tend to dissociate, forming free \({\mathrm{V}}_{\mathrm{O}}^{\cdot \cdot}\), while at lower temperatures, defect clusters or associates prevail, significantly affecting the population of free vacancies. This is reflected by the distinctive curvature of the Arrhenius curves (activation energy plots) of the electrical conductivity of doped ZrO2 systems [74]. YSZ shows a higher activation energy at lower temperatures, and the activation energy at low temperatures increases with dopant concentration, which is characteristic of dopant ions acting as nucleating agents for the formation of dopant-vacancy pairs or defect clusters.

The minimum dopant content necessary to stabilize ZrO2 in the cubic structure is close to the composition that gives the highest conductivity: 8 mol% Y2O3, 10 mol% Sc2O3, 15 mol% Nd2O3, 10 mol% Sm2O3, and 10 mol% Gd2O3. This maximum corresponds to the minimum dopant level required to fully stabilize the high-temperature cubic phase. A further increase in the dopant content results in the formation of oxygen vacancy-dopant clusters, as discussed above. The conductivity and activation energy for oxygen ion conduction depend strongly on the dopant ionic size for the ZrO2-Ln2O3 system (Fig. 10) [74].

Reproduced with permission from Ref. [74]. Copyright 1999, Elsevier

Maximum conductivities, oxygen ion migration enthalpy and association enthalpy of doped ZrO2 for a specific dopant concentration as a function of the dopant ionic radius.

Sc-doped ZrO2 shows the lowest ion migration enthalpy and highest conductivity. ZrO2 doped with 9.0 to 9.3 mol% Sc (ScSZ) has a conductivity of 0.34–0.36 S cm−1 at 1 000 °C [76], higher than that of YSZ. The higher oxide ion conductivity of ScSZ is attributed to the smaller mismatch in size between Zr4+ (0.084 nm) and Sc3+ (0.087 nm) ions compared to that between Zr4+ (0.084 nm) and Y3+ (0.101 9 nm) ions. The ion migration enthalpy increases with increasing dopant ionic radius due to the elastic strain energy induced by the size difference on the cation lattice. This indicates that the diffusion of oxygen ion vacancies is closely related to the elastic strain energy, i.e., the size mismatch between the dopant and host cations.

Similar to the case of stabilized ZrO2, the conductivity of the doped CeO2 electrolyte increases with the dopant concentration to a maximum and then decreases with a further increase in the dopant concentration [77]. The maximum conductivity with the doping level is also due to the interaction between the dopant and oxygen vacancies, leading to the formation of dopant-vacancy clusters, \({(\mathrm{M}}_{\mathrm{Ce}}^{\mathrm{^{\prime}}\mathrm{^{\prime}}}-{\mathrm{V}}_{\mathrm{O}}^{\cdot \cdot})\mathrm{ or }(2{\mathrm{M}}_{\mathrm{Ce}}^{\mathrm{^{\prime}}}-{\mathrm{V}}_{\mathrm{O}}^{\cdot \cdot})\), where M is a dopant with divalent or trivalent charge.

3 Equipotential Line Distribution and RE Placement

In SOFCs, the position of the RE and its effect on the measurement of the equipotential line have been extensively studied by computational modeling and experimental approaches [78,79,80,81,82,83,84,85,86,87,88,89,90]. This issue is important because it is essentially related to the cell configuration design and reliability of the accurate measurement of the polarization losses and impedances of individual electrode and electrolyte processes. Despite the great effort, there are considerable discrepancies regarding the reliability and suitability of the RE in polarization and impedance measurements in SOFCs. We will examine the issue from idealized cell and experimental aspects of the studies.

3.1 Idealized Cell

Figure 11 shows a thin flat-plate cell with a thin dense oxygen ion conducting electrolyte sandwiched by two active working and counter electrodes (the WE and the CE) and an RE placed on the surface of the inactive region of the electrolyte [91]. The distance between the edge of the active electrodes and the inactive region of the electrolyte is approximately three electrolyte thicknesses [92]. Under these idealized conditions, the cell voltage measured between the WE and the CE (VCell) can be divided into V1 and V2. V1 contains the overpotential of the WE plus some fraction of the cell iR drop, and V2 contains the overpotential of the CE plus the remaining fraction of the cell iR drop (Fig. 11b). Similarly, the cell impedance (ZCell) can be separated into ZCE and ZWE (Fig. 11d). In such ideal cells, the equipotential line will be in the middle of the solid electrolyte.

Reproduced with permission from Ref. [91]. Copyright 2020, Elsevier

Ideal electrolyte cell with an RE in a thin electrolyte. a Cell geometry, b separation of cell potential, c equivalent circuit of the idealized cell, and d separation of cell impedances.

The separation of the polarizations and impedances of electrode reactions in an idealized cell, as shown in Fig. 11, can be validated on symmetric cells in which the WE and CE are identical not only in the electrode/electrolyte contact interfaces but also in their electrochemical behavior (resistance and capacitance). Figure 12 shows an example of symmetric cells with a La0.8Sr0.2MnO3 (LSM) electrode on a YSZ electrolyte measured at 800 °C in air. The polarization performance of the cell can be divided into the polarization losses for the ORR that occurred at the WE and for the O2 evolution reaction (OER) that occurred at the CE (Fig. 12a). For the reaction at 800 °C under open-circuit conditions, i.e., overpotential or dc bias = 0 mV, the impedance responses on the WE and the CE are identical and characterized by a slightly depressed semicircle (Fig. 12b). The polarization resistance for the ORR in the reaction is 3.9 Ω cm2, very close to 3.83 Ω cm2 for the reaction on the CE. The sum of electrode polarization resistances measured for the ORR and OER is 7.73 Ω cm2, which is also close to the value of 8.0 Ω cm2 obtained for the full cell. This indicates the excellent separation of the individual electrode processes at the WE and the CE via the RE due to the fact that in such symmetric cells, the equipotential line is in the middle of the solid electrolyte. This is consistent with the computational calculations that cell configurations with symmetric electrodes and similar electrochemical characteristics introduce little distortion into electrode impedance responses [79, 87]. In fact, symmetric cells are commonly used to investigate the electrode performance, performance degradation, and reaction mechanism and kinetics of the ORR in SOFCs [93,94,95,96,97,98,99,100,101] and the OER in SOECs [102,103,104,105,106,107,108,109].

Caution should be taken in that the reversibility of symmetric cells is a strong function of both the operating conditions (e.g., dc bias and operating temperature) and electrode materials. A recent study on the reversibility of the symmetric cell configuration for Pt, La0.8Sr0.2MnO3 (LSM) and La0.6Sr0.4Co0.2Fe0.8O3 (LSCF) electrodes showed that the reversibility of the ORR at the WE and the OER at the CE strongly depends on the reversibility of the electrode/electrolyte interface in the oxygen incorporation/exsolution process, which in turn is closely related to the oxygen ion conductivity of the electrode and to a lesser extent to the ionic conductivity of the electrolyte [91]. Figure 13 shows a typical example of the impedance responses of a symmetric cell with LSM electrodes, measured at different temperatures and dc biases [91]. The reversibility of the LSM symmetric cells decreases with decreasing temperature and increasing dc bias. In contrast, the LSCF electrode shows a much higher degree of reversibility than LSM, indicating that the MIEC properties of the electrode materials enhance the reversibility. In the case of the Pt electrode, the oxygen reaction is essentially not reversible, consistent with the poor electrocatalytic activity of Pt electrodes for the ORR and OER at high temperatures [91, 110,111,112]. Nevertheless, the symmetric cell configuration is a useful tool for the investigation of oxygen electrodes in solid oxide cells. Tao et al. studied the ORR/OER performance of LSCF/samaria-doped ceria (SDC) composite electrodes on SDC interlayer/YSZ electrolyte cells with a porous LSCF current collector layer [113]. By controlling the SDC content, as well as the thickness and porosity of the LSCF catalyst layer, the gas diffusion rate and the conduction networks for electrons and oxide ions could be optimized, resulting in a marked reduction in the overpotential for the ORR and OER.

Reproduced with permission from Ref. [91]. Copyright 2020, Elsevier

Impedance spectra of the full cell, the WE and the CE for the reaction in an LSM symmetric cell with a YSZ electrolyte, measured under various dc biases at 800 °C, 750 °C and 700 °C.

In reality, achieving perfect alignment is almost impossible, particularly for small and thin electrolyte button cells. In 1998, Winkler et al. [86] theoretically showed that minor misalignment of the WE and the CE can cause significant errors in the measured polarization resistance of the WE, and the major reason for the impedance distortions is the change in the potential distribution inside the electrolyte. Adler used finite element calculations to simulate the half-cell impedance responses and showed that an electrode misalignment of only 11% of the electrolyte thickness can cause a measurable difference in the ohmic resistance and a ~ 10% error in the electrode polarization resistance of half-cells [78].

Cimenti et al. studied in detail the impedance distortions as a function of the position and geometry of the electrodes in solid electrolyte cells [79, 87]. The results indicate that the distortion increases with increasing misalignment, i.e., the differences in the electrode area, as shown in Fig. 14 [87]. With increasing difference in the electrode areas (i.e., r = ACE/AWE), both the size and high frequency intercept of the WE impedance (ZWE) increase, while the cell impedance (ZTOT) decreases, leading to merged ZWE and ZTOT. The overlap of ZTOT and ZWE indicates that ZWE contains a contribution from the CE, leading to overestimation of the WE impedance. At high frequencies (ω → ∝), the equipotential line is shifted toward the CE/electrolyte interface (Fig. 14c). Differences in the two active electrode areas are commonly observed, particularly in the case of anode-supported thin electrolyte cells, in which the area of the anode is much larger than that of the cathode. For example, McIntosh et al. [114] showed that the cathode impedance is very close to the total cell impedance of anode-supported cells, indicating the limitation of the RE in impedance separation for electrode reactions of anode-supported thin electrolyte cells. Similar observations were also reported by others [115, 116].

Reproduced with permission from Ref. [87]. Copyright 2007, WILEY‐VCH Verlag GmbH & Co. KGaA, Weinheim

a Asymmetric cell geometry with different WE and CE areas, b ZWE and ZTOT changes with the change in the ratio of the CE to WE area and c equipotential lines probed by the RE in the primary (ω → ∝) and secondary (ω → 0) potential distributions.

Misalignment between two active electrodes can also be caused by the significant differences in the microstructure and electrochemical characteristics of the electrodes. One of the best examples is cells with LSM cathodes and Ni/YSZ cermet anodes. LSM is a dominant electronic conductor with negligible ionic conductivity, and the reaction is restricted mainly to the TPB (where electrode, electrolyte and oxygen gas molecules meet) [46]. In contrast, the Ni/YSZ cermet is a two-phase composite with an electronic conducting Ni phase and an oxygen ion conducting YSZ phase, i.e., an MIEC material. Thus, during the fuel oxidation reaction on Ni/YSZ cermet anodes, the fuel reaction sites will be extended into the electrode bulk due to the presence of an ion-to-ion conducting YSZ network in the cermet and the formation of a TPB of the electronic conducting Ni phase, ionic conducting YSZ phase and fuel reactant [117, 118]. The differences in the electronic and ionic conductivities of the electrode materials will cause significant differences in the location of the TPB, i.e., the electrode/electrolyte interface contacts. Such asymmetries in the interfacial contacts lead to distortion of the potential distribution and a change in the equipotential line, which does not depend on the electrolyte thickness.

In addition to the alignment of active electrodes, the contact between the electrode coating and current collector also affects the equipotential line/surface in a cell [25]. The contact areas affect both the ohmic and polarization resistances of the cell. This will be discussed in detail in the Constriction section.

3.2 Experimental Approaches

Symmetric cells with two identical electrodes on both sides of the electrolyte have the advantage of simplicity in cell configuration without the complications associated with the position of the RE. However, this is an indirect method that allows the measurement of the electrode impedance of only one kind of interface. Symmetric cells also have limitations in the polarization performance under dc bias due to the significant deviation of the cells from reversibility under dc bias or overpotential. As the majority of the cells in SOFCs are unsymmetrical in nature, i.e., cells with different types of anodes and cathodes, three-electrode cells with an additional RE are required to allow the separation of the individual interface impedance and polarization losses. Small-sized cells with diameters of 10–20 mm are commonly used in SOFCs, in which the ring-shaped RE is placed on the electrolyte surface of the CE side or the edge of the electrolyte disc to minimize the effect of changing gas partial pressure of the WE on the RE potential [119,120,121,122]. Other types of RE were also reported. Hashibon et al. suggested a patterned RE very close to the WE with negligible ohmic contribution from the electrolyte [123]; however, in reality, such a patterned RE in thin electrolyte cells is difficult to fabricate, and making good electronic contact with micron-scale electrodes is also difficult. Ostergard et al. presented a Luggin-type RE for thick electrolyte cells [124], which is considered to be analogous to using a Luggin capillary in an aqueous electrolyte. However, this is a complex design, and thick pellets with an internal channel for the Luggin-type RE are not easy to fabricate. The thick electrolyte (~ 20 mm) may also limit the practical and technologically meaningful current density that can be achieved. Figure 15 shows a typical thick electrolyte cell with a Luggin-type RE and a planar cell configuration commonly used in performance measurement and isolation in SOFCs. Small button cells with circular WE and CE with diameters of 10–20 mm or relatively large planar cells with large sizes (e.g., 50 mm × 50 mm) are often used.

Various designs and approaches have been suggested to improve the accuracy and reliability of REs in solid electrolyte cells [80, 123,124,125,126,127]. Barfod et al. presented a method to accurately separate the impedance responses measured on a full cell into the contributions from the anodic hydrogen oxidation and cathodic oxygen reduction reactions [125]. However, this method requires prior knowledge of the frequency domains of the different processes of the anodic and cathodic reactions. A similar subtraction method was also used by Birss et al. to derive the polarization performance of Ni/YSZ anodes deposited using electrophoretic methods on the inner YSZ electrolyte surface of microtubular SOFCs by first performing two-electrode impedance measurements of the symmetric cell [128]. Offer et al. also reported an indirect method using electrochemical impedance spectroscopy to correct for errors in the measurement of the WE overpotential during polarization arising from a shift in the electrolyte current distribution under load [126]. However, from the performance point of view, the most straightforward solution is to design a special cell configuration that has the capability to directly measure and assess the individual electrode processes.

Before the design of such a special cell configuration, we need to examine the equipotential line distribution in an idealized thin, flat-plate cell, as shown in Fig. 11. In this case, the electric field between the cathode and anode is uniform. Therefore, the equipotential line will be present within the electrolyte between the active anode and cathode (see Fig. 16). The requirement of the RE being on an inactive surface of the electrolyte is satisfied for a specific aspect ratio (e.g., > 3), which is defined as the distance between the RE and the edge of the active electrode divided by the electrolyte thickness.

Let us start by examining the resistance distribution and measurement in an SOFC. In a solid electrolyte cell, based on Fig. 16, the total cell resistance, R1, can be obtained by:

where RA1 and RC1 are the anodic and cathodic partitioning resistances of R1 measured by a conventional voltage probe (VP1) against the RE, respectively. RA1 includes the contact resistance between the anode and current collector, anode resistance and part of the electrolyte resistance, and RC1 includes the contact resistance between the cathode and current collector, cathode resistance and remaining electrolyte resistance. The anodic and cathodic partitioning resistances can also be measured through an imaginary voltage that is not in contact with the current collector, VP2. In this case, the measured resistance will mainly be the electrolyte resistance, R2:

As the reference potential samples on average the equipotential line in the cell, the partitioning of the cell resistances can be used to indicate the location/position of the equipotential line. Therefore, the resistance partitioning results measured by VP1 and VP2 should give the same assessment of the equipotential line. Under idealized conditions, the equipotential line lies within the electrolyte, and thus, the cell voltage (VCell) and cell impedance can be separated into two half-cell voltages and impedances.

3.3 Assessment of the Equipotential Line with Special Voltage Probes

Thus, to independently separate the polarization losses and impedances of individual electrode processes, measuring the resistance fraction or partitioning of the associated electrode processes is clearly essential. A conventional voltage probe cannot accurately separate the anodic and cathodic partitioning resistances due to the large contribution of the contact resistance between the electrode and the current collector (CC). To overcome this problem, we designed a special cell configuration in which VP1 is the conventional voltage probe attached to the CC and VP2 is a special voltage probe that is electrically isolated from the CC (Fig. 17) [90, 129]. For the benefit of the readers, the functions of VP1 and VP2 and the corresponding measured resistances are summarized in Table 1 [90].

Cell configuration and arrangement of conventional and special voltage probes (VP1 and VP2) with REs. A and C represent the anode and cathode sides, respectively, and the cell typically has an area of 5 cm × 5 cm. An optical image of a Pt woven mesh CC is shown in the figure. Modified with permission from Ref. [129].

Figure 18 shows an example of polarization curves measured on a YSZ electrolyte cell with a Pt anode and a Pt cathode by a galvanostatic current interruption (GCI) technique at 900 °C [90]. The total cell resistance measured by VP1, R1, is 1.23 Ω cm2, which is much higher than the electrolyte resistance measured by VP2, R2 = 0.61 Ω cm2, indicating the existence of significant contact resistance between the electrode and the electrolyte. The GCI curves measured between VPs on the same electrode sides primarily consist of iR losses, which are characteristics of the contact resistance [129]. From the curves, the electrode/CC contact resistances of the anode and cathode sides (RA/C and RC/C) are 0.34 and 0.29 Ω cm2, respectively. The very high polarization losses, ~ 230 mV at 25 mA cm−2, measured between voltage probes are actually due to the fact that Pt is a very poor electrode for both the HOR and ORR at high temperatures. The cathodic resistance measured between CVP1 and Aref is very small, RC1 = 0.08 Ω cm2. In contrast, the anodic resistance measured between AVP1 and Cref, RA1, is 1.17 Ω cm2. The most interesting observation is the GCI curves measured between CVP2 and Aref on the Pt cathode side, showing an unusual and depressed GCI curve. However, from the instantaneous potential drop immediately after the current interruption, the resistance between CVP2 and Aref can be measured, and RC2 is 0.24 Ω cm2. In contrast, a normal GCI curve is observed between AVP2 and Cref, giving RA2 = 0.82 Ω cm2.

GCI curves measured between various VPs and REs on a cell with a Pt anode and a Pt cathode at 25 mA cm−2 and 900 °C. The thickness of the 3 mol% Y2O3-doped ZrO2 (3YSZ) electrolyte plate is approximately (108 ± 4) μm. The circle indicates the depressed polarization decay. Modified with permission from Ref. [90].

Let us briefly discuss the physical significance of resistance components R1, R2, RA/C and RC/C. R1 is the total cell resistance, as shown by the arrangement of VP1, while R2 is dominantly the electrolyte resistance because VP2 is isolated from the current collect with no current passing through the probe. RA/C and RC/C are physically the contact resistances between the electrode and CC, as they are measured from VPs on the same electrode side.

With respect to the resistances, we can also identify the positions of various VPs. For example, AVP2 would be positioned between RA/C and R2, and CVP2 would be positioned between RC/C and R2. Similarly, AVP1 and CVP1 would be positioned outside RA/C and RC/C, respectively. The equipotential line can be estimated based on the anodic and cathodic partitioning resistances of the cell, RA1 and RC1. Based on the resistance values, the resistance distribution in the cell with a Pt anode and a Pt cathode along with the estimated equipotential line location can be obtained, as shown in Fig. 19.

Resistance distribution and partitioning of the cell resistances in a YSZ electrolyte cell with a Pt cathode and a Pt anode at 900 °C, showing the equipotential line location (the dotted line) within the Pt cathode. The scanning electron microscopy (SEM) micrographs show asymmetric contacts at the electrode/electrolyte interface, showing that the Pt anode/electrolyte interface contact is much smaller than that at the Pt cathode/electrolyte interface. The unit for R is Ω cm-2. Modified with permission from Ref. [90].

From the resistance partitioning, the total resistance in a solid electrolyte cell consists of three components:

For the cell with a Pt anode and a Pt cathode, the measured anodic partitioning resistance, RA1, is 1.17 Ω cm2, very close to the cell resistance, R1 = 1.23 Ω cm2. Additionally, the cathodic partitioning resistance, RC1, is 0.08 Ω cm2, which is much smaller than the cathode contact resistance, RC/C = 0.29 Ω cm2. This indicates that the partitioning of the electrolyte resistances cannot be within the electrolyte bulk and that the equipotential line is located inside the Pt cathode in the vicinity of the Pt cathode/YSZ electrolyte interface region. This may be the reason for the depressed GCI responses observed for CVP2 against the RE. This in turn indicates that the cathodic resistance fraction, RC2, measured between CVP2 and ARef. becomes negative, as it is outside the electrolyte. By the definition of Eq. (34), we have:

This is very close to the measured value of 0.61 Ω cm2. The shift of the equipotential line for the cell with Pt electrodes is consistent with the microstructure of the cell, showing a highly porous Pt anode in comparison with the Pt cathode. Thus, the contact areas at the Pt anode/YSZ electrolyte interface would be much smaller than the contact area between the Pt cathode and the YSZ electrolyte. This will push the equal potential line toward the Pt cathode side, as shown in Fig. 19.

The same tests were also carried out for a thin YSZ electrolyte cell with a Ni/YSZ cermet anode and a La0.8Sr0.2MnO3 (LSM) cathode, and based on the results, the resistance distribution with estimation of the equipotential line location was observed, as shown in Fig. 20 [90]. Similar to the cell with Pt electrodes, RC1 and RA1 are also far from equal, but RC1 is much higher than RA1 and is close to the total cell resistance, R1. The results indicate that the location of the equipotential line is inside the Ni/YSZ cermet anode rather than inside the LSM cathode. This is consistent with the much higher interface contact area between the Ni/YSZ cermet anode and the YSZ electrolyte due to the existence of an ionic conducting YSZ-to-YSZ network in the cermet. In the case of the LSM cathode, the interface contact is restricted to the cathode/YSZ electrolyte interface. The resistance values measured on both cells are given in Table 2. However, different from the cell with a Pt cathode and a Pt anode, the anodic resistance fraction, RA2, measured between AVP2 and Cref becomes negative, as it is outside the electrolyte. By the definition of Eq. (34), we also have:

Resistance distribution and partitioning of the cell resistances in a YSZ electrolyte cell with an LSM cathode and a Ni/YSZ cermet anode at 800 °C, showing the equipotential line location (the dotted line) within the Ni/YSZ cermet anode. The SEM micrographs show asymmetric contacts at the electrode/electrolyte interface, showing that the Ni/YSZ cermet anode/electrolyte interface contact area is much higher than that at the LSM cathode/electrolyte interface due to the presence of YSZ-to-YSZ networks in the cermet. The Ni phase in the Ni/YSZ cermet was removed by acid treatment. The unit for R is Ω cm-2. Modified with permission from Ref. [90].

This is very close to the measured electrolyte resistance of 0.77 Ω cm2.

Ciucci et al. studied the distribution of the electrochemical equipotential and transport interaction, i.e., the flux of both ionic and electronic species, through a mixed ionic and electronic conductor (e.g., SDC in this case) with an electrochemically active surface in a uniform gas environment (H2-H2O-Ar) using an adaptive finite element method [130]. SDC serves as both the active electrocatalyst for the reaction and the electrolyte through which ions are transported. In addition to the ionic flux that flows through the SDC electrolyte, there are two currents: a cross-plane (CP) current that flows in a general direction as the ionic current and an in-plane (IP) current that flows between the redox-active SDC surface and the metal CCs, as shown in Fig. 21 for a typical set of conditions. The ionic (i.e., oxygen vacancy) equipotential and flux lines bend gently around the metal/SDC interface but are linear through the bulk of the cell. In contrast, the equipotential and flux lines for electrons are not linear even at some distance from the termination of SDC. In addition to the flow of an electronic current between metal electrodes, an electronic current flows laterally between the metal electrode and the SDC redox-active surface (i.e., the IP current). The termination of the ionic current at the metal electrode/SDC electrolyte interface is based on the assumption that the metal/MIEC interface blocks the ionic species. However, if the electrode is MIEC or ionic conductivity develops in the vicinity of an electronically dominant electrode such as LSM under polarization conditions in SOFCs [131, 132], then the ionic current could propagate into the electrode bulk, i.e., ionic equipotential and flux lines will be within the electrode bulk of solid electrolyte cells. This is experimentally demonstrated by the measurement of the presence of ionic equipotential lines within the cathode in the case of the cell with Pt cathode and anode and within the anode for the cell with an LSM cathode and a Ni/YSZ cermet anode, as shown in Figs. 19 and 20.

Reproduced with permission from Ref. [130]. Copyright 2011, Royal Society of Chemistry

Electronic and ionic electrochemical equipotential lines (thin) and corresponding current flux lines (thick) computed for a typical set of conditions (T = 650 °C, \({p}_{{\mathrm{O}}_{2}}\) = 4.1 × 10−26 atm, at which the electronic transfer number is 0.86) for three representative reaction rate constants: a, b k0 = 3 × 10−7 Ω−1 cm−2 atm−1/4, c, d k0 = 6 × 10−7 Ω−1 cm−2 atm−1/4, and e, f k0 = 3 × 10−5 Ω−1 cm−2 atm−1/4. Only the region close to the interface is shown; the potentials and fluxes are essentially linear beyond the plotted region. The hatched area in (a) is the surface-influence zone.

Due to the StS contact at the electrode/electrolyte interface, the electric field is not uniform. Charge transfer can occur at the physical interface between the electrode and the electrolyte as well as within the solid electrode, depending on the migration of charge carriers such as ions and electrons. This is particularly the case for MIEC materials and composite electrodes [133,134,135]. Considering the experimental results of Fig. 20, the contact at the LSM/YSZ interface is not continuous and is primarily restricted to the physical boundary between LSM and YSZ due to the electronically dominant LSM electrode materials. In contrast, the Ni/YSZ cermet is a two-phase system with an electronic conducting Ni phase and an ionic conducting YSZ phase. In Ni/YSZ cermet anodes, the established electron-to-electron and ion-to-ion conducting networks are responsible for the high structural stability and high electrochemical activity of the HOR [136, 137]. Therefore, electrode reactions occur beyond the physical boundary of the solid electrode and solid electrolyte interface [131, 133, 138]. This is very different from the uniform distribution of the electric field in the aqueous electrolyte and restriction of the charge transfer to the physical solid electrode and liquid electrolyte interface in the case of aqueous electrochemical systems. Consequently, the reactive areas on the Ni/YSZ cermet anode/YSZ side will be significantly larger than those on the LSM cathode/YSZ electrolyte side. This implies that the electrochemical contacts at the anode/YSZ electrolyte are larger than those at the LSM/YSZ electrolyte, resulting in a nonuniform distribution of the electric field (i.e., ionic and electronic flux lines) within the solid electrolyte between the two electrodes. Such asymmetric contact in terms of electrochemical reaction areas would push the equipotential line to the anode side close to the YSZ electrolyte, as shown experimentally in Fig. 20. Therefore, the equipotential lines being located within the Ni/YSZ cermet anode are theoretically possible due to the continuous YSZ phase in the anode arising from the YSZ-to-YSZ ionic conducting network within the cermet.

3.4 Equipotential Line Distribution vs. Electrolyte Thickness

Theoretical calculations on the effect of the solid electrolyte thickness on changes in the equipotential line have not yet been performed. However, experimentally, the effect of the solid electrolyte thickness on changes in the equipotential line can be assessed. In a carefully designed experiment, planar cells with a large WE area of 10.88 cm2 were used with a model LSM cathode and a Ni/YSZ cermet anode, and the anodic and cathodic fraction or partitioning resistances, RA1 and RC1, of the cell were measured by using conventional VP1 (see Fig. 22) [83]. The YSZ electrolyte thickness varied between 65 and 247 µm, the same Pt mesh CCs were used on both sides of the cells to ensure equal contact resistance, and large cells were used to increase the accuracy. As shown above [90], the relative change in the RA1 and RC1 values can be used as an indication of the change in the position of the equipotential line. The relative electrode resistance partitioning strongly depends on the electrolyte thickness. For example, for thin electrolyte cells with electrolyte thicknesses in the range of 65 to 75 µm, the relative percentage of RC1 with respect to the cell resistance is 90%–95%, indicating a significant distortion of the electrochemical potential distribution in the cell. In this case, the equipotential line is most likely shifted to the cathode/electrolyte interface side. This indicates that for thin electrolyte cells, the use of an RE is no longer reliable. This is consistent with the observed distortion of the polarization measurements in anode-supported thin electrolyte cells [114,115,116, 128]. However, the difference between RC1 and RA1 decreases as the electrolyte thickness increases. This implies a shift of the equipotential line to the middle region of the electrolyte with increasing electrolyte thickness. This in turn indicates that increasing the electrolyte thickness effectively diminishes the distortion effect of asymmetric contact at the interface on the electrochemical polarization measurements of solid electrolyte cells. For cells with electrolyte thicknesses larger than ~ 125 μm, the anodic and cathodic partitioning resistances, RC1 and RA1, fall within the range of 20%–80%. In this case, the anodic and cathodic polarization losses can be accurately separated under the conditions of this study [83].

Resistance partitioning/fraction measured based on the relative anodic and cathodic fraction resistances of the cell. Cell—50 mm × 50 mm; cathode—LSM; anode—Ni/YSZ; YSZ electrolyte—65–247 µm in thickness. Lines are a guide only. Symbols: (•) RA1 at 1 000 °C, (ο) RC1 at 1 000 °C, (closed triangle) RA1 at 900 °C, and (open triangle) RC1 at 900 °C. The shaded area indicates the validity of the RE in the separation of anodic and cathodic polarization resistances based on the resistance partition ratio. Modified with permission from Ref. [83].

The shift of the equipotential line away from the electrolyte bulk will lead to significant errors in and distortion of the polarization and impedance measurements in thin electrolyte cells, as shown in the literature. Clearly, the uniformity of the electric field within the solid electrolyte improves with increasing thickness of the solid electrolyte, resulting in a shift of the equipotential line. Thus, the equipotential line shifts toward the solid electrolyte with increasing electrolyte thickness, as shown schematically in Fig. 23. Numerous studies have demonstrated that in thick electrolyte cells, the polarization and impedance responses of individual electrode reactions at the electrode/electrolyte interface can be accurately separated and measured with a properly positioned RE [114, 119, 122, 139,140,141,142,143,144]. Nevertheless, the location of the equipotential line is not necessary in the middle of the solid electrolyte.