Abstract

This work reports the optimization of engine parameters (including compression ratio and load) and the fuel additive blend (concentration of plastic oil and ethanol) of a single cylinder 4-stroke direct injection (DI) variable compression ratio (VCR) diesel engine with an objective to identify suitable engine conditions for better thermal efficiency and exhaust emission. For this the engine performance and emission parameters are experimentally evaluated at 1500 rpm constant engine speed, varying loads and compression ratios. The break thermal efficiency and emission quality is found improved by increasing load and compression ratio and by the addition of waste plastic oil (WPO) and ethanol with diesel. The best possible engine condition of load, compression ratio and fuel blend, for better performance and lesser emission have been optimized using Taguchi technique using the S/N ratio, ANOVA, and multivariate analyses results. The study revealed that higher compression ratio (18.1) and higher load (100%) give maximum brake thermal efficiency and lesser emissions for 20%WPO and 20% ethanol blended diesel. The optimized condition obtained in this study would provide a way to use the waste plastic oil as a sustainable alternate fuel in a diesel engine.

Similar content being viewed by others

References

Agarwal AK, Sharma N, Singh AP, Kumar V, Satsangi DP, Patel C (2019) Adaptation of methanol–dodecanol–diesel blend in diesel genset engine. Journal of Energy Resources Technology 141(10)

Anand R, Kannan G, Reddy R, Velmathi KR (2009) The performance and emissions of a variable compression ratio diesel engine fuelled with bio-diesel from cotton seed oil. ARPN Journal of Engineering and Applied Sciences 4:72–87

Arjanggi RD, Kansedo J (2019) Recent advancement and prospective of waste plastics as biodiesel additives: a review. J Energy Inst

Attri V, Sharma K, Singh SK, Saraswat M (2015) Effect of compression ratio on performance and emissions of diesel on a single cylinder four stroke VCR engine. Inter J Emerging Technol Adv Eng 5:94–102

Bridjesh P, Periyasamy P, Krishna Chaitanya AV, Geetha NK (2018) MEA and DEEas additives on diesel engine using waste plastic oil diesel blends. Sustainable Environment Research doi 28:142–147. https://doi.org/10.1016/j.serj.2018.01.001

Channapattana SV, Kantharaj C, Shinde VS, Pawar AA, Kamble PG (2015) Emissions and performance evaluation of DI CI-VCR engine fuelled with honne oil methyl ester/diesel blends. Energy Proc 74:281–288. https://doi.org/10.1016/j.egypro.2015.07.606

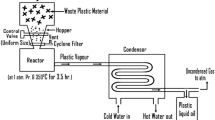

Damodharan D, Sathiyagnanam AP, Rana D, Rajesh Kumar B, Saravanan S (2016) Extraction and characterization of waste plastic oil (WPO) with the effect of n-butanol addition on the performance and emissions of a DI diesel engine fueled with WPO/diesel blends. Energy Convers Manag 2016(10):076

Damyanov A, Hofmann P (2019) Operation of a diesel engine with intake manifold alcohol injection. Automot Engine Technol 4:17–28. https://doi.org/10.1007/s41104-019-00040-2

Das AK, Hansdah D, Mohapatra AK, Panda AK (2020) Energy, exergy and emission analysis on a DI single cylinder diesel engine using pyrolytic waste plastic oil diesel blend. Journal of Energy Institute 93:1624–1633

Dhanasekaran R, Krishnamoorthy V, Rana D, Saravanan S, Nagendran A, Kumar BR (2017) A sustainable and eco-friendly fueling approach for direct-injection diesel engines using restaurant yellow grease and n-pentanol in blends with diesel fuel. Fuel 193:419–431

Duraisamy MK, Balusamy T, Senthilkumar T (2012) Effect of compression ratio on CI engine fueled with methyl ester of thevetia peruviana seed oil. ARPN Journal of Engineering and Applied Sciences 7:229–232

Elkassaby M, Nemit allah MA (2013) Studying the effect of compression ratio on an engine fueled with waste oil produced biodiesel/diesel fuel. Alexandria Engineering Journal 52:1–11. https://doi.org/10.1016/j.aej.2012.11.007

Gavade NK, Vangire A, Boda MA (2019) A comparative study on performance of diesel engine using Jatropha biodiesel as fuel, international journal of trend in scientific Research and Development (ijtsrd). 4(1):695–698

Joshi MP, Kulkarni AV (2012) Variable compression ratio (VCR) engine-a review of future power plant for automobile. International journal of mechanical engineering Research and Development (IJMERD) 2

Kaimal VK, Vijayabalan P (2016) An investigation on the effects of using DEE additive in a DI diesel engine fuelled with waste plastic oil. Fuel 180:90–96

Kalargaris I, Tian G, Gu S (2017) Combustion, performance and emission analysis of a DI diesel engine using plastic pyrolysis oil. Fuel Process Technol 157:108–115. https://doi.org/10.1016/j.fuproc.2016.11.016

Kidoguchi Y, Yang C, Kato R, Miwa K (2000) Effects of fuel cetane number and aromatics on combustion process and emissions of a direct injection diesel engine. JSAE Rev 21:469–475

Knothe G, Van Gerpen J (2005) The biodiesel handbook, American oil chemists society press: Champaign. Illinois 2005. https://doi.org/10.1201/9781439822357

Lazic ZR (2004) Design of experiments in chemical engineering. Weinheim, WILEYVCH

Lynos T, Kenworthy J, Austin P (1986) The development of a driving cycle for fuel consumption and emissions evaluation. Transportation Research, Part A: General 20:447–462. https://doi.org/10.1016/0191-2607(86)90081-6

Mani M, Nagarajan G, Sampath S (2011) Characterization and effect of using waste plastic oil and diesel fuel blends in compression ignition engine. Energy 36(1):212–219. https://doi.org/10.1016/j.energy.2010.10.049

Mendenhall W, Sincich T (1989) Statistics for the engineering and computer sciences, second edn. Maxwell Macmillan, Singapore

Milojević S, Pešić R (2018) Determination of combustion process model parameters in diesel engine with variable compression ratio. Journal of combustion:1–11. https://doi.org/10.1155/2018/5292837

Muralidharan K, Vasudevan D, Sheeba KN (2011) Performance, emission and combustion characteristics of biodiesel fuelled variable compression ratio engine. Energy 36(8):5385–5539

Murugan S, Ramaswamy MC, Nagarajan G (2008) Performance, emission and combustion studies of a DI diesel engine using distilled tyre pyrolysis oil-diesel blends. Fuel Process Technol 89:152–159

Nagarajan G, Rao AN, Renganarayanan S (2002) Emission and performance characteristics of neat ethanol fuelled Dl diesel engine. International journal of ambient energy 23(3):149–158

Ozcanli M (2015) Castor-oil methyl ester/butanol/diesel fuel blend as an alternative for compression ignition engines. J Biotechnol 208:32. https://doi.org/10.1016/j.jbiotec.2015.06.089

Pakiya Pradeep A, Gowthaman S (2019) Combustion and emission characteristics of diesel engine fuelled with waste plastic oil–a review. International Journal of Ambient Energy:1–19

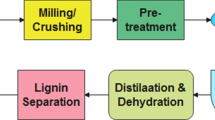

Panda AK, Singh RK (2011) Catalytic performances of kaolin and silica alumina in the thermal degradation of polypropylene. J Fuel Chem Technol 39:198–202

Panda AK, Singh R (2013) Optimization of process parameters by Taguchi method: catalytic degradation of polypropylene to liquid fuel. Int J Multidiscip Curr Res 4:50–54

Panda AK, Murugan S, Singh RK (2016) Performance and emission characteristics of diesel fuel produced from waste plastic oil obtained by catalytic pyrolysis of waste polypropylene. Energy Sources, Part A: Recovery, Utilization, and Environmental Effects 38(4):568–576. https://doi.org/10.1080/15567036.2013.800924

Patel SN, Kirar R (2012) An experimental analysis of diesel engine using biofuel at varying compression ratio. International Journal of Emerging Technology and Advanced Engineering 2:385–391

Rao SR, Padmanabhan G (2012) Application of Taguchi methods and ANOVA in optimization of process parameters for metal removal rate in electrochemical machining of Al/5% SiC composites. International Journal of Engineering Research and Applications (IJERA) 2:192–197

Serin H, Yildizhan Ş (2017) Influence of the compression ratio on the performance and emission characteristics of a vcr diesel engine fuelled with alcohol blended fuels. European Mechanical Science 1:39–46. https://doi.org/10.26701/ems.320255

Shaik, A., Moorthi, N.S.V., Rudramoorthy, R. et al.,2017 “Variable compression ratio engine: a future power plant for automobiles - an overview,” Journal of Automobile Engineering 221(9):1159–1168, 2007, doi:https://doi.org/10.1243/09544070JAUTO573

Srinivas K, B BN , R KK (2016) Performance and emission characteristics of VCR CI engine fueled with methyl ester of palm kernel oil and eucalyptus oil blends. Perspectives in Science 8:195–197.https://doi.org/10.1016/j.pisc.2016.04.030

Vasudeva M, Sharma S, Mohapatra SK, Kundu K (2016) Performance and exhaust emission characteristics of variable compression ratio diesel engine fuelled with esters of crude rice bran oil. Springer Plus 5:293. https://doi.org/10.1186/s40064-016-1945-7

Yildizhan Ş, Uludamar E, Çalık A, Dede G, Özcanlı M(2017) Fuel properties, performance and emission characterization of waste cooking oil (WCO) in a variable compression ratio VCR) diesel engine. European mechanical science 1: 56-62. Doi: https://doi.org/10.26701/ems.321789

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Das, A.K., Padhi, M.R., Hansdah, D. et al. Optimization of Engine Parameters and Ethanol Fuel Additive of a Diesel Engine Fuelled with Waste Plastic Oil Blended Diesel. Process Integr Optim Sustain 4, 465–479 (2020). https://doi.org/10.1007/s41660-020-00134-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41660-020-00134-7