Abstract

The beam windows of high-energy beam lines are important, and it is sometimes difficult to design because it is necessary to ensure particle propagation with minimum disturbance and fulfill mechanical requirements at the same time. The upstream decay pipe window of the long baseline neutrino facility at Fermilab has an extremely large diameter (1.8 m), with a thickness of only 1.5 mm to separate the helium atmosphere in the decay pipe and the nitrogen atmosphere on the other side. Furthermore, the center of this dish-shaped window is expected to be a 200-mm-diameter beryllium dish welded to the outside aluminum alloy A6061, and this welded combination must withstand extreme conditions of a 2.4-MW, high-energy proton beam without leakage. These severe conditions make the design of this window an unprecedented challenge. This paper describes the static thermal-structural analyses based on which the structure has been optimized, as well as dynamic analyses for understanding the shockwave effects originating in the beam. After optimization, the maximum von Mises stresses in the window decreased significantly in both normal operation and accident cases, making our design very reasonable.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

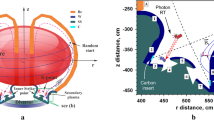

The long baseline neutrino facility (LBNF) is a facility under construction that will provide the accelerator, primary beam, and target infrastructure for the production of a neutrino beam to serve Deep Underground Neutrino Experiment (DUNE) [1, 2]. A high-intensity, high-energy proton beam accelerated in the Fermilab accelerator complex, with an energy of 120 GeV, impinges on a special target, producing high-energy pions and kaons. These unstable secondaries will be focused by magnetic horns and directed through a decay pipe with a length of 194 m toward a hadron absorber. After that, only the neutrinos will survive and continue for 1300 km toward the far end site of the Sanford Underground Research Facility (SURF) [3]. The LBNF is designed for initial operation at a proton beam power of 1.2 MW, with the capability to upgrade to 2.4 MW. The decay pipe has an upstream window and a downstream window at the beginning and end, as shown in Fig. 1.

The upstream and downstream decay pipe windows need to efficiently separate the helium atmosphere inside the decay pipe from the outside, and at the same time withstand the beam power in the long term, which means they should have good strength, heat management ability, and radiation damage resistance. In addition, the upstream window should be transparent enough to minimize the loss of the secondary beam from beam window interactions. For this reason, low-Z materials are preferred.

Mylar and Kevlar composite windows have been used at the Jefferson lab [4], BNL [5], Fermilab [6], and other labs because of their low mass; however, plastic or organic materials tend not to have high resistance to high irradiation doses. Aluminum is another conventional beam window material that has the properties of low density, radiation resistance, and good mechanical strength, and it has been used for proton beam windows at spallation neutron sources such as JSNS [7] and CSNS [8], as well as decay pipe window at NuMI [9].

Beryllium is widely used in X-ray windows for photon sources [10] and drift detectors [11]. With the increasing beam intensities of future multi-mega-watt accelerator facilities, beryllium and AlBeMet (a metal matrix made of 62% beryllium and 38% aluminum by weight) have received increasing attention in the design of the hadron beam window because of their good beam transparency, high thermal conductivity, high strength and thermal stability [12], good resistance against ductility loss from irradiation [13], and good thermal shock resistance [14]. The downstream target window at NuMI was specially constructed using a combination of beryllium and aluminum. The beryllium part is a disk of 1.25 mm in thickness and 135 mm in diameter, electron beam welded to an aluminum ring and an aluminum flange, forming a sandwich structure [15]. AlBeMet, which can be considered alternative to beryllium in some cases, has been adopted as the basic material for the external beam window at PEFP [16]. However, great challenges are also associated with the use of beryllium or AlBeMet, primarily as a result of their toxicity and protection, poor machinability and ductility, and poor weldability [17,18,19], which limit their application as large-dimension beam windows.

Because of the higher energy deposition density (approximately twice that of NuMI), using beryllium or AlBeMet as the material for the upstream decay pipe window at LBNF is attractive. The much larger diameter, uniform thickness requirement, and circular joint shape make it a great challenge, while the superior properties make it a risk-worthy innovation. In pursuit of lower disturbances in particle propagation, beryllium is selected as the base material. In addition, beryllium has higher thermal–mechanical properties and better resistance against ductility loss from irradiation compared with AlBeMet [13]. This paper describes the structure optimization of the window, as well as the thermal–mechanical response induced by beam shock in the case of accidents. Based on the optimization, a window has been designed and will be constructed.

2 Mechanical structure and thermal load

The diameter of the upstream window is as large as 1.8 m, and the thickness should be uniform (1.5 mm) within the diameter of 1.5 m because of the beam footprint. A window fabricated entirely of beryllium is an ideal design, but it was not chosen, as beryllium is hardly possible to process because of its poor machinability and potential danger resulting from material brittleness. Therefore, a window with beryllium as the inner part and aluminum alloy A6061 as the outer part has been designed, as shown in Fig. 2. The dish-shaped weldment is composed of an inner part 200 mm in diameter, an outer part 1.5 m in diameter, and a flange ring 1.8 m in diameter and 50 mm in thickness. The uniform thickness (1.5 mm) rather than overlap welding allows for less beam loss and energy deposition at the welding joint, despite the greater difficulty of the welding technique. The thick flange is for the connection to a remotely operated metal seal. The original sphere radius, R1, and two fillet radii, R2 and R3, are set as 5080 mm, 100 mm, and 200 mm, respectively, as parameters to be optimized. The total weight is approximately 75.3 kg, i.e., 0.085 kg for beryllium and the remainder for A6061, respectively. The window will be supported from the bottom to maintain the stability of the structure, and will be removable from the above, consistent with the other target pipe components [1]. The concave side is connected to the decay pipe filled with helium, and the other side faces the target and horns, which are cooled by nitrogen.

The related proton beam parameters are listed in Table 1 [20]. There are two accident modes in addition to normal operation that require special attention. One is the target-destroy accident, which means that the primary beam misses the target but is centered on the upstream decay pipe window. The other is the mis-steered accident, which means that the primary beam is mis-steered off the target and is slightly off-center on the upstream decay pipe window. Figure 3 describes the energy deposition in unit volume on the window at various beam energies and in different operation modes, as simulated by MARS [21]. There is an energy deposition peak at the boundary of the inner part and outer part because the material changes from beryllium to aluminum alloy, as shown in Fig. 3a. The design is based on the upgraded case with 2.4-MW beam power and 120-GeV beam energy because it is the highest deposited energy case, comprising 761 W in total for normal operation, and 13.5 W of which in the inner beryllium part.

3 Optimization studies

During operation, the decay pipe is filled with helium gas. The designed relative pressure on the window is 0.034 MPa, with the assumed atmosphere pressure of 0.1 MPa. Optimization studies of the cooling methods and dimensions have been performed using finite element analysis (FEA) in ANSYS. The energy deposition in unit volume is imported as heat generation in each element. The relative pressure is loaded on the nodes of the concave surfaces. The surfaces sealed with the decay pipe on the flange ring are constrained in the beam and circumferential directions, leaving the radial direction free. The material properties used in the FEA are listed in Table 2.

3.1 Cooling methods

As shown in Fig. 2, the original spherical radius (R1) of the curved dish is set to 5080 mm in terms of the short distance for the beam in the window with a large radius. If no special cooling methods are adopted, the helium and nitrogen sides of the window will have natural convection on the corresponding surfaces. The heat convection coefficients are set to 3.8 W/(m2 °C) and 2.6 W/(m2 °C), respectively. The temperature distribution during normal operation is shown in Fig. 4. It is not symmetrical because the beam has an injection angle with respect to the window. The highest temperature is approximately 145 °C on the flange ring resulting from the high-energy deposition in the thick material, which is too high for the aluminum alloy because the material has the danger of creep [24] and vacuum seal failure. The temperature limit is set as 80 °C, which is approximately 0.4 times the melting point of A6061, at which point the material can be considered free of creep [25]. Therefore, forced-cooling should be used.

Two forced-cooling methods are considered. One is forced air cooling at the air side, and the other is forced water cooling on the flange ring. The FEA results show that both methods are efficient for decreasing the temperature. When using forced air cooling, the cooling surfaces remain the same as natural convection, while the coefficient of heat convection at the air side increases. The highest temperature is 65 °C when the coefficient of heat convection at the air side is set to 10 W/(m2 °C), and it can be decreased further with a stronger convection, as shown in Fig. 5a. The helium in the decay pipe can provide a heat convection coefficient of up to 9 W/(m2 °C) [1], which makes it easier to reach a lower temperature. The location of the highest temperature is also at the flange ring, similar to the distribution under natural convection, but with a lower temperature. When using forced water cooling, a heat convection coefficient of 5000 W/(m2 °C), which can be easily obtained is set at the outermost surface of the flange ring to simulate the cooling channel. The highest temperature decreases to 68.1 °C and its location moves to the window center while the outer ring is cooled down, as shown in Fig. 5b. The temperature distribution is concentric with respect to the beam footprint. Both methods can satisfy the design requirements.

3.2 Von Mises stress optimization based on normal operation mode

The weak points of this specific window design are the beryllium-A6061 (Be–Al) welding joint of the inner part and outer part because of the weakening of the potential strength of beryllium welding, and the fillet location of the outer part and flange ring because of the stress concentration and welding joint. The allowable stress at the Be–Al welding joint for long-term use is assumed to be 77 MPa as an empirical value, which is 70% of the strength of the parent material [26]. The forced coolants can bring the von Mises stress at the welding joint down to approximately 107 MPa by decreasing the temperature gradient, which is still considered risky. Structural optimization has been performed to further decrease the von Mises stress. The sphere radius (R1) and the two fillet radii (R2 and R3) can be optimized for this purpose, as shown in Fig. 2.

The response surfaces have been calculated in ANSYS Workbench by varying the sphere radius and the two fillet radii separately. It is found that the von Mises stress at the risky locations is very sensitive to the sphere radius, as shown in Fig. 6. However, the sphere radius cannot be greatly reduced because a smaller radius means more difficult processing and larger energy deposition. A sphere radius of 2500 mm has been chosen as a compromise. In this case, the required thickness of raw beryllium is 3.5 mm, compared with 2.5 mm for a sphere radius of 5080 mm (100% increase in beryllium processing). The von Mises stress at the risky locations has little change with respect to the variations in the fillet radii, as shown in Fig. 7. Thus, the fillet radii will be determined by the processing technique.

For normal operation, the optimized structure has the highest temperature of 65.1 °C at the flange ring for forced air cooling and 68.3 °C at the window center for forced water cooling, which are within 2% compared with the original structure. The temperature distribution in the window is only slightly affected in the sphere radius optimization. However, the von Mises stresses have significantly decreased for each cooling method, as listed in Table 3. This is mostly due to the proportionality of the Hooke stress and diameter. In the case of forced air cooling, the von Mises stresses decrease by 61% at the window center, 42% at the Be–Al welding joint, and 59% at the fillet, while for the forced water cooling, the decreases are 61%, 37%, and 54%, respectively. Comparing the two cooling methods, the forced air cooling has lower stresses because of the smaller temperature gradient. The von Mises stresses are below the allowable stresses for each cooling method. The results are shown in Fig. 8. Transient thermal analyses have also been performed, showing a temperature fluctuation of approximately 0.2 °C per pulse for the window center, and even lower for the Be–Al welding joint. Thus, there is no need for dynamic analyses with respect to thermal shocks.

Static FEA results for the shape-optimized structure under normal operation. a Temperature distribution in the case of forced air cooling. b Temperature distribution in the case of forced water cooling. c Von Mises stress distribution in the case of forced air cooling. d Von Mises stress distribution in the case of forced water cooling. e Von Mises strain distribution under forced air cooling. f Von Mises strain distribution under forced water cooling (Color figure online)

3.3 Thermal–mechanical response from accidental thermal shock

Two accident modes require special attention, as described in Sect. 2. When the energy deposition changes to ‘accident’ from the normal operation mode, the peak thermal deposition at the beam center increases sharply, as shown in Fig. 3. The location of the maximum von Mises stress moves to the window center because of the sharply increased temperature gradient, which makes the window center also a risky location, particularly in the case of target-destroy modes. At the Be–Al welding joint, the von Mises stress remains almost the same as in the normal operation mode. This is also in accordance with the energy deposition differences of different operation modes, as shown in Fig. 3.

The transient analyses show that the temperature in one pulse at the window center jumps by 64.9 °C in target-destroy accident mode and 32.3 °C in mis-steered accident mode because of beam shock, as listed in Table 4. The dynamic analyses with respect to thermal shock must be considered to evaluate the safety of the window because dynamic thermoelastic stresses can be much higher than static ones.

In the case of rapid temperature rise and stress waves with large amplitudes, understanding and predicting the resulting stress waves resulting from rapid energy deposition is considered crucial for robust design and safe operation. Many factors should be carefully considered, including design parameters such as geometry and energy deposition profile, as well as FEA parameters such as the element size (\({ES}\)) and time step (\({TS}\)). For the dynamic analyses, the element size at the window center and time step can be defined as [14]

where \(\delta\) is the half length of the temperature transition, \(E\) is the Young’s modulus, and \(\rho\) is the density of the material. In this study, \(\delta\) is approximately 6 mm, according to the results of the thermal transient analyses. Thus, \({ES}\) is set to 0.5 mm, and \({TS}\) is set to 0.02 µs. Compared with the static or transient analyses discussed above, the element sizes of dynamic analyses become much smaller, and the beam center in the case of the mis-steered accident mode shifts slightly. The sub-modeling method has been used for re-meshing and temperature mapping which is edited in the ANSYS parametric design language (APDL) code.

The window is supposed to withstand the thermal shock induced by a one-pulse accident event. In this study, two pulses have been calculated under the severe thermal shock of the two accident modes separately. The steady-state temperature of the normal operation is set as the initial condition, and the velocity of the window at the initial time is assumed to be zero.

Three nodes at the axis of symmetry of the window are recorded, as shown in Fig. 9. Points A, B, and C are at the helium, medium, and air sides, respectively. Table 5 lists the highest von Mises stresses before and after the optimization. The optimized window can bring about a 40% decrease in the von Mises stress at the Be–Al welding joint for the two accidents, either forced cooled by air or water. The highest von Mises stresses decrease by approximately 35% at the window center for mis-steered accidents, while they increase slightly (approximately 5%) for the target-destroy accident. The optimized structure has great advantages in stress conditions caused by thermal shock, especially at the Be–Al welding joint. The highest stresses at the window center exceed the allowable stress listed in Table 2 for the target-destroy accident, but they are below the yield strength. We consider this acceptable because the accident modes are as short as one-pulse event. The results demonstrate that the target-destroy accident mode in the case of forced water cooling is the most dangerous case, and the thermal–mechanical response is shown in Fig. 10. At the window center, the von Mises stress increases to a maximum value of 174.3 MPa at 10 µs because of thermoelastic stress resonance, and after the beam pulse, it converges to approximately 30 MPa. The frequency of the von Mises stress vibration is approximately 6 MHz. However, this vibration only lasts approximately 10 µs, which is in accordance with the spill time. The displacement of the window center is approximately 1.92 mm and does not change significantly during a thermal pulse. Despite the large temperature jump at the window center, the temperature remains almost the same at the Be–Al welding joint, so do the von Mises stress and deformation. The dynamic results in the case of forced air cooling show nearly the same tendency at the window center and Be–Al welding joint.

Dynamic analyses of the window in target-destroy operation mode in the case of forced water cooling. a Temperature at window center in two pulses; b Temperature at the Be–Al welding joint in two pulses; c Von Mises stress at window center in a spill pulse; d Von Mises stress at window center in two pulses; e Deformation at window center in a spill pulse; f Deformation at window center in two pulses (Color figure online)

The FEA results show that the forced air cooling method demonstrates better efficiency for decreasing the temperature and von Mises stress of the window in normal operation, as well as the two considered accident modes, based on which it is selected as the cooling baseline. However, the temperature at the flange ring is relatively high and non-uniform, which is considered an adverse factor. It may be necessary to add water cooling to the outer ring as auxiliary cooling to improve safety.

4 Prototype design

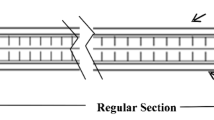

A prototype was designed to study the fabrication technique. Three main welding joints were designed for the prototype, as shown in Fig. 11. The beryllium inner part is welded with an aluminum ring (outer part I) first, composing sub-assembly I, taking advantage of the convenience of smaller dimensions. The main body of the outer part (outer part II) and the flange ring compose sub-assembly II, which is attached via vacuum electron beam welding. Finally, the two sub-assemblies are welded together by vacuum electron beam welding to form the prototype.

In the process of the window prototype, the most challenging technique is the Be–Al welding of sub-assembly I because of the extremely poor weldability of beryllium. There have been some previous reports on the brazing of beryllium and copper [17], friction stir welding of Be–Al powder metallurgy alloy [18], argon-shielded arc welding in chambers with a controlled atmosphere, and electron beam welding of beryllium [26]. However, there have been few reports on the existing application of Be–Al circular butt welding. The two materials differ significantly in terms of their melting points and are insoluble [19], which makes welding very difficult. Other than ordinary butt welding, the circular welding joint increases the difficulty because of the large difference in the coefficients of thermal expansion, which causes it to break easily when the temperature changes. Moreover, the uniform thickness further limits the welding technique. The leak rate requirement of the window itself (sealing at the flange ring excluded) is assumed to be less than 1 × 10− 3 Pa m3/s to fulfill the total leak rate requirement of the decay pipe of approximately 10 cm3 of helium per minute [1]. The leak rates of the two Al–Al welding joints should be much smaller than the requirement, less than 1 × 10− 11 Pa m3/s, from experience, so the leak rate of the Be–Al welding joint should be less than 1 × 10− 3 Pa m3/s. An order of magnitude smaller is expected in consideration of the safety margin.

Two different welding scenarios to solve this challenging technique. One is butt welding directly by laser welding or electron beam welding, taking advantage of concentrated energy and small heat-affected zones. The other is overlap welding by vacuum brazing or hot isostatic pressing after the processing of complementary steps, taking advantage of the larger overlap area, as shown in Fig. 12. Many welding factors should be carefully considered, such as tolerance, oxidation resistance, and welding power density. In addition, special attention must be paid to the toxic protection. The welding technique will be focused on in future work.

5 Conclusion

The structure design and optimization of the upstream decay pipe window of the LBNF has been carried out. It is a very large and thin dish-shaped window that combines beryllium as the inner part and aluminum alloy as the outer part. Forced air cooling has been chosen from the thermal analyses, and forced water cooling could be added in the future if needed. A sphere radius of 2500 mm has been adopted based on von Mises stress optimization. The dynamic performance with respect to the thermal shock has been analyzed for each of the two accident modes. The von Mises stresses in the normal operation mode as well as the two accident modes have been markedly decreased with a slight temperature increase, which demonstrates that the optimization is effective. It seems that there is no potential static or fatigue failure hazard if the window is successfully developed. A window prototype has been designed, and challenging weld technique studies are under way, which will be the focus of future research. This work tackles one of the key problems to be solved for the LBNF and provides a reference for other similar projects.

References

Long-Baseline Neutrino Facility (LBNF)/DUNE Conceptual Design Report. September 29, (2017)

V. Papadimitriou, K. Ammigan, J. Anderson Jr. et al., Design of the LBNF beamline. Fermilab-Conf-16-163-AD (2017). arXiv:1704.04471

J. Heise, The Sanford Underground Research Facility at Homestake. J. Phys. Conf. Ser. 606, 012015 (2015). https://doi.org/10.1088/1742-6596/606/1/012015

S.M. Matthews, H. Crannell, J.T. O’Brien et al., A composite thin vacuum window for the CLAS photon tagger at Jefferson lab. Nucl. Instrum. Meth. A 421, 23–30 (1999). https://doi.org/10.1016/S0168-9002(98)00910-3

M. Mapes, W.J. Leonhardt, Design of large aperture low mass vacuum windows. J. Vac. Sci. Technol. A 11(4), 1587–1592 (1993). https://doi.org/10.1116/1.578509

E.D. Zimmerman, Use of the KL→3π0 decay as a tagged photon source to measure material thickness in a neutral kaon beam. Nucl. Instrum. Meth. A 426, 229–237 (1999). https://doi.org/10.1016/S0168-9002(98)01424-7

M. Harada, N. Watanabe, C. Konno et al., DPA calculation for Japanese spallation neutron source. J. Nucl. Mater. 343, 197–204 (2005). https://doi.org/10.1016/j.jnucmat.2005.01.023

H.J. Wang, W.B. Liu, H.M. Qu et al., Thermal analysis and optimization of proton beam window for the CSNS. Chinese Phys. C 37(7), 077001 (2013). https://doi.org/10.1088/1674-1137/37/7/077001

Y. He, FEA of NuMI megawatt decay pipe US window and beam absorber. Report on TSD Topical Meeting, December 19, (2019) https://indico.fnal.gov/event/22729.

A. Snigirev, I. Snigireva, V.G. Kohn et al., On the requirements to the instrumentation for the new generation of the synchrotron radiation sources. Beryllium windows. Nucl. Instrum. Meth. A 370, 634–640 (1996). https://doi.org/10.1016/0168-9002(95)00849-7

Y. Xu, M. Xu, G.F. Wang et al., Beam charge integration in external beam PIXE–PIGE analysis utilizing proton backscattering with an extraction window. Nucl. Sci. Tech. 27, 137 (2016). https://doi.org/10.1007/s41365-016-0131-5

M.A. Boland, Beryllium—important for national defense: U.S. Geological Survey Fact Sheet 2012–3056, 2 p, https://pubs.usgs.gov/fs/2012/3056/. Accessed 21 July 2021

N. Simos, H. Ludewig, H. Kirk et al., Multi-MW accelerator target material properties under proton irradiation at Brookhaven National Laboratory linear isotope producer. Phys. Rev. Accel. Beams 21, 053001 (2018). https://doi.org/10.1103/PhysRevAccelBeams.21.053001

K. Ammigan, S. Bidhar, P. Hurh et al., Thermal shock experiment of beryllium exposed to intense high energy proton beam pulses. Phys. Rev. Accel. Beams 22, 044501 (2019). https://doi.org/10.1103/PhysRevAccelBeams.22.044501

Y. He, NOvA target downstream be window. Report on tsd topical meeting, January 11, 2018. https://indico.fnal.gov/event/16159/contributions/35944/. Accessed 21 July 2021

B.-S. Park, Y.-S. Cho, M.-S. Moon, Mechanical properties of the external beam window for the PEFP. J. Korean Phys. Soc. 54, 1961–1965 (2009). https://doi.org/10.3938/jkps.54.1961

B.C. Odegard, B.A. Kalin, A review of joining techniques for plasma facing components in fusion reactors. J. Nucl. Mater. 233–237, 44–50 (1996). https://doi.org/10.1016/S0022-3115(96)00303-0

F. Contreras, E. Trillo, A. Murr, Friction-stir welding of a beryllium–aluminum powder metallurgy alloy. J. Mater. Sci. 37, 89–99 (2002). https://doi.org/10.1023/A:1013193708743

Z. Lin, J.P. Lin, Y.L. Wang et al., Analysis of condensation structure in a YAG laser welded Be/Al alloy. J. Univ. Sci. Technol. Beijing 25, 433–435 (2003). (in Chinese)

V. Papadimitriou, Design of the LBNF Beamline, Report on 38th International Conference on High Energy Physics, Chicago (2016). https://indico.fnal.gov/event/12571/contributions/14797/. Accessed 21 July 2021

S.D. Reitzner, Energy Deposition results in the upstream decay pipe window. https://docs.dunescience.org/cgi-bin/ShowDocument?docid=8552. Accessed 6 July 2018

ASME Boiler and Pressure Vessel Committee on Materials, 2013 ASME Boiler and Pressure Vessel Code II, Materials, Part D, Properties, Two Park Avenue, (New York, 2013)

http://www.matweb.com/. Accessed 21 July 2021

H. J. Wang, L. Kang, H. Qu et al., Material test of proton beam window for CSNS. Paper Presented at the 6th International Particle Accelerator Conference (Richmond, VA, USA, 2015)

N. Ahmad, Creep of Metals. http://ocw.utm.my/file.php/160/edited_creep_part_1.pdf. Accessed 21 July 2021

M.A. Komarov, L.S. Guitarsky, Welding of beryllium. Weld. Int. 29, 561–566 (2014). https://doi.org/10.1080/09507116.2014.9524

Acknowledgements

The authors would like to thank the other fellows of the project, especially Dave Pushka, S.D. Reitzner, Ang Lee, and Vaia Papadimitriou at Fermilab for their collaboration in pushing forward this work.

Author information

Authors and Affiliations

Contributions

Material preparation was performed by Hai-Jing Wang, Ye Yuan, Quan Ji, Ji-Lei Sun, Shao-Hong Wei. Data collection was performed by Hai-Jing Wang, Ye Yuan, Jing-Yu Tang. Analysis was performed by Hai-Jing Wang, Ye Yuan, Jing-Yu Tang, Ling Kang, Chang-Jun Ning. The first draft of the manuscript was written by Hai-Jing Wang and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding authors

Additional information

This work was supported by the National Key Research and Development Program of China (No. 2017YFE0106100).

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Wang, HJ., Yuan, Y., Tang, JY. et al. Design of the upstream decay pipe window of the long baseline neutrino facility. NUCL SCI TECH 32, 129 (2021). https://doi.org/10.1007/s41365-021-00960-5

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41365-021-00960-5