Abstract

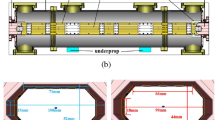

To the transverse beam collimation system in a rapid cycling synchrotron, an important component is the primary collimator, which improves emittance of the beam halo particles such that the particles outside the predefined trajectory can be absorbed by the secondary collimators. Given the material properties and power deposition distribution, the beam scraper of the primary collimator is a 0.17 mm tungsten foil on a double face-wedged copper block of 121.5 mm × 20 mm. The heat is transferred to the outside by a ϕ34 mm copper rod. In this paper, for minimizing brazing thermal stress, we report our theoretical analysis and tests on brazing the tungsten and copper materials which differ greatly in size. We show that the thermal stress effect can be controlled effectively by creating stress relief grooves on the copper block and inserting a tungsten transition layer into the copper block. This innovation contributes to the successful R&D of the primary collimator. And this study may be of help for working out a brazing plan of similar structures.

Similar content being viewed by others

References

S. Wang, S.X. Fang, S.N. Fu et al., Introduction to the overall physics design of CSNS accelerators. Chin. Phys. C 33(2), 1–3 (2009). doi:10.1088/1674-1137/33/S2/001

T. Wei, Q. Qin, Design of the two-stage collimation system for CSNS/RCS. Nucl. Instrum. Methods A 566(2), 212–217 (2006). doi:10.1016/j.nima.2006.06.069

T. Wei, Q.B. Wu, W.Q. Li, Beam collimation for CSNS/RCS. Chin. Phys. C 34(4), 506–511 (2010). doi:10.1088/1674-1137/34/4/018

Y.Q. Zou, L. Kang, H.M. Qu et al., Design and research of primary collimator for CSNS/RCS. High Power Laser Part. Beams 25(3), 741–745 (2013). doi:10.3788/HPLPB20132503.0741

Y.Q. Zou, N. Wang, L. Kang et al., Thermal analysis and cooling structure design of the primary collimator in CSNS/RCS. Chin. Phys. C 37(5), 05704 (2013). doi:10.1088/1674-1137/37/5/057004

C.P. Liang, J.L. Fan, H.R. Gong et al., Interface structure and work function of W–Cu interfaces. Appl. Phys. Lett. 103(21), 211604 (2013). doi:10.1063/1.4833249

C.H. Chen, X.J. Liu, Z.B. Wang, The effects of joining methods on the resistivity of W-Cu alloy and Cu joint. Phys. Proc. 25, 68–72 (2012). doi:10.1016/j.phpro.2013.03.051

Y.Q. Zou, L. Kang, J.B. Yu et al., Experiments and analysis of thin tungsten slice and W/Cu brazing for primary collimator scraper in CSNS/RCS. Sci. China Ser. G 57(4), 1–4 (2014). doi:10.1007/s11433-013-5386-9

Y.J. Li, J. Wang, P. Liu, Welding of Dissimilar Hard-to-Weld Materials and Its Application (Chemical Industry Press, Beijing, 2004), pp. 36–38

W.B. Lee, B.D. Kwon, S.B. Jung, Effect of bonding time on joint properties of vacuum brazed WC_Co hard metal/carbon steel using stacked Cu and Ni alloy as insert metal. Mater. Sci. Technol. Ser. 20(11), 1474–1478 (2004). doi:10.1179/026708304X4312

K. Suganuma, T. Okamoto, Y. Miyamoto et al., Joining Si3N4 to type 405 steel with soft metal interlayers. Mater. Sci. Technol. Ser. 2(11), 1156–1161 (1986). doi:10.1179/mst.1986.2.11.1156

K. Loki, M. Nayama, S. Tsujimura et al., Development and heat load experiments of graphite brazed to stainless steel for the first wall structure of Fer. Fusion Eng. Des. 9, 283–287 (1989). doi:10.1016/S0920-3796(89)80047-X

R.U. Vaidya, P. Rangaswamy, M.A.M. Bourke et al., Measurement of bulk residual stresses in molybdenum disilicide/stainless steel joints using neutron scattering. Acta Mater. 46(6), 2047–2061 (1998). doi:10.1016/S1359-6454(97)00429-1

Q.S. Cai, W.S. Liu, Y.Z. Ma et al., Diffusion brazing of tungsten and steel using Ti–Ni liquid phase forming interlayer. Fusion Eng. Des. 91(2), 67–72 (2015). doi:10.1016/j.fusengdes.2014.12.029

T. Zaharinie, R. Moshwan, F. Yusof et al., Vacuum brazing of sapphire with Inconel 600 using Cu/Ni porous composite interlayer for gas pressure sensor application. Mater Des. 54, 375–381 (2014). doi:10.1016/j.matdes.2013.08.046

A.P. Xian, Z.Y. Si, Interlayer design for joining pressureless sintered sialon ceramic and 40Cr steel brazing with Ag 57 Cu 38 Ti 5 filler metal. J. Mater. Sci. 27(6), 1560–1566 (1992). doi:10.1007/BF00542918

A. Elrefaey, W. Tillmann, Brazing of titanium to steel with different filler metals: analysis and comparison. J. Mater. Sci. 45(16), 4332–4338 (2010). doi:10.1007/s10853-010-4357-z

Q. Han, Q.S. Wu, J.W. Chen et al., Analysis of fixation method of fuel assembly for lead-alloy cooled reactor. J. Nucl. Sci. Technol. 26(5), 050601 (2015). doi:10.13538/j.1001-8042/nst.26.050601

L. Zhao, X.H. Li, J.B. Hou et al., Bonding of Cf/SiC composite to Invar alloy using an active cement, Ag–Cu eutectic and Cu interlayer. Appl. Surf. Sci. 258(24), 10053–10057 (2012). doi:10.1016/j.apsusc.2012.06.073

X.G. Song, J. Cao, H.J. Chen et al., Contact reactive brazing of Ti53311S alloy using Cu foil as interlayer: interlayer microstructure and joining properties. Mater. Des. 46, 895–901 (2013). doi:10.1016/j.matdes.2012.11.044

W.Q. Yang, T.S. Lin, P. He et al., Microstructural evolution and growth behavior of in situ TiB whisker array in ZrB 2—SiC/Ti6Al4V brazing joints. J. Am. Ceram. Soc. 96(12), 3712–3719 (2013). doi:10.1111/jace.12629

H.G. Dong, Z.L. Yang, Z.R. Wang et al., Vacuum brazing TC4 titanium alloy to 304 stainless steel with Cu–Ti–Ni–Zr–V amorphous alloy foil. J. Mater. Eng. Perform. 23(10), 3770–3777 (2014). doi:10.1007/s11665-014-1145-y

Author information

Authors and Affiliations

Corresponding author

Additional information

This work was supported by the National Natural Science Foundation of China (No.11375217).

Rights and permissions

About this article

Cite this article

Yu, JB., Chen, JX., Kang, L. et al. Thermal analysis and tests of W/Cu brazing for primary collimator scraper in CSNS/RCS. NUCL SCI TECH 28, 46 (2017). https://doi.org/10.1007/s41365-017-0208-9

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41365-017-0208-9