Abstract

Currently, more than 360 spray adjuvants are registered in Germany (September 2021). Unlike plant protection products (PPPs), adjuvants are not subjected to regulatory risk assessment. In practice, numerous combinations of PPPs and adjuvants are therefore possible. Thus, tank mixtures containing insecticides that are classified as non-hazardous to bees up to the highest approved application rate or concentration may raise pollinator safety concerns when mixed with efficacy increasing adjuvants and applied in bee-attractive crops. This study analyzes whether selected “PPP–adjuvant” combinations result in increased contact mortality and pose an elevated risk to honey bees. To answer this question, we chose six common spray adjuvants of different classes for laboratory screening. These were then tested in a total of 30 tank mixtures, each with a neonicotinoid (acetamiprid), pyrethroid (lambda-cyhalothrin), diamide (chlorantraniliprole), carbamate (pirimicarb), and butenolide (flupyradifurone) formulation. We adapted an acute contact test (OECD Test Guideline 214) to our needs, e.g., by using a professional spray chamber for more realistic exposures. Our results showed that, in total, 50% of all combinations significantly increased the mortality of caged honey bees in comparison with individual application of insecticides. In contrast, none of the adjuvants alone affected bee mortality (Cox proportional hazard model, p > 0.05). With four of the five insecticide formulations, the organosilicone surfactant Break-Thru® S 301 significantly increased bee mortality within 72 h (for all insecticides except chlorantraniliprole). Furthermore, acetamiprid yielded the highest and second highest mortality increases from a tank mixture with the crop oil surfactant LI 700® (hazard ratio = 28.84, p < 0.05) and the organosilicone Break-Thru® S 301 (hazard ratio = 14.66, p < 0.05), respectively. To assess risk in a more field-realistic setting, field trials should be performed to provide a more realistic exposure scenario under colony conditions.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Multiple factors, such as pathogens, parasites, loss of habitat, malnutrition, and the use of plant protection products (PPPs), are currently suspected to be causes of pollinator decline, which is being discussed globally (vanEngelsdorp and Meixner 2010; Saunders et al. 2020; Montgomery et al. 2020). Scientific evidence suggests that this decline is not the result of an individual but the interaction of many different stressors (vanEngelsdorp and Meixner 2010). Honey bees in particular are relatively resilient, and not just because of their ability as a superorganism to mitigate various stresses by means of social buffering (Straub et al. 2015). Bee colonies are usually cared for by a beekeeper and safeguarded against outside adverse effects. Thus, mostly strong acute or chronic toxic effects of PPPs are visible in bees under field conditions by manifestation of dead bees or brood. Sublethal effects, however, are currently difficult to assess at the colony level. They may remain unnoticed due to social buffering unless they are severe (Odemer et al. 2018).

When investigating these sublethal effects, it became increasingly apparent that adjuvants believed to be “inert” (EPA 2021) can also have potentially toxic effects on bees (Goodwin and McBrydie 2000; Zhu et al. 2014; Chen et al. 2019). Adjuvants can be defined by how they are combined with pesticides in these two ways: Co-formulants are already part of the pesticide product when it is produced by the manufacturer. Agricultural spray adjuvants, on the other hand, are separate products that the user adds to the spray solution to enhance the action of a PPP or the physical properties of the mixture (Hazen 2000; BVL 2021a). Even herbicide products with active ingredients without any insecticidal activity have demonstrated lethal and sublethal effects on honey bees and other bee species (Abraham et al. 2018; Straw et al. 2021; Odemer et al. 2020). Hence, there has recently been an emerging interest not only on the synergistic effects of the tank mixtures of different PPPs but also on their “inert” adjuvants.

Tank mixes can increase total mortality in honey bees in predictable (Pilling and Jepson 1993; Iwasa et al. 2004; Wernecke et al. 2019) and unpredictable ways (Johnson et al. 2013; Zhu et al. 2014; Wade et al. 2019). Despite their relevance under normal field conditions, these aspects of pesticide toxicology are often overlooked (Chmiel et al. 2020). Most emphasis has focused on formulations and their active ingredients rather than on the adjuvants that can be added to the spray solution. However, foragers are evidently confronted with numerous spray adjuvants in the field (Ciarlo et al. 2012; Mullin et al. 2015; reviewed in Iwasaki and Hogendoorn 2021).

By September 2021, over 360 such adjuvants were authorized in Germany (see list of adjuvants, BVL 2021a). They may be added to the spray solution, for example, as wetting agents (reduction of surface tension), as adhesives (deposition and sticking to the target surface), or as water conditioners (e.g., pH adjustment or buffering) (Hazen 2000). This improves the plant coverage, uptake (stomatal infiltration), rainfastening, and other properties to ensure the full efficacy of PPPs even under unfavorable conditions (Stevens 1993). Furthermore, adjuvants are frequently used in bee-attractive crops such as orchards or oilseed rape during flowering (Ratajkiewicz et al. 2009; Durant et al. 2021; Chen et al. 2018). Since they do not contain active ingredients with biological activities, only an application for approval is required for commercialization (dlz agrarmagazin 2006; BVL 2021b; Mullin et al. 2016).

Adjuvants in some EU countries, such as France and Italy, routinely undergo risk assessment for bees (personal communication, N. Kurlemann). In Germany, unlike the assessment of PPPs, no data are generally submitted for adjuvants as a basis for assessing risks for bees and effectiveness in the approval process. Therefore, it is currently unclear whether the environmental impact of adjuvants on pollinators is realistically evaluated or over- or underestimated. In contrast to formulated PPPs, the effects of which on pollinators are being intensively investigated, the level of knowledge about tank mixtures, especially with adjuvants and their possible risks (Fine et al. 2017), and knowledge on the effects on the physiology, behavior, and immune competence of honey bees are low (reviewed in Mullin 2015). The literature provides evidence that the toxicity of formulated products, including adjuvants, can increase the adverse effects of insecticides compared to that of their active ingredient (reviewed in Mullin 2015; Mullin et al. 2016). As an example, some adjuvants are known to increase herbicide activity by a factor of ten, thus reducing effective PPP application rates (Green and Green 1993). Consequently, this could also be the case with other adjuvants/formulation tank mixtures that have not yet been investigated in detail.

Negative effects of adjuvants in combination with insecticides (including lethal and sublethal effects, e.g., on the ability to learn or immune defense) have already been identified in a few scientific studies for adult honey bees (e.g., Ciarlo et al. 2012; Chen et al. 2018; Wernecke et al. 2018) and honey bee larvae (Fine et al. 2017; Zhu et al. 2014). The questions on whether and to what extent tank mixtures from PPPs and adjuvants actually present a realistic risk to honey bees and other non-target organisms have so far been mixed. Their contribution to the decline in biodiversity in agricultural landscapes has not been adequately investigated. Closing these knowledge gaps is therefore a basic requirement for pollinator-friendly, sustainable agriculture to preserve biological diversity and protect pollinators.

This study aimed to address uncertainties for a sound, technically well-founded assessment of adjuvants. Moreover, we wanted to identify the further need for action in the approval of adjuvants by the Federal Office of Consumer Protection and Food Safety (BVL) concerning bee protection. It should be clarified whether and to what extent adjuvants mixed with PPPs cause an increase in bee toxicity and consequently sublethal and lethal effects, with the aim of detection and reducing risks for honey bees.

Adjuvants can be added to many different PPPs, including herbicides, fungicides, and insecticides. In our screening, we focused on insecticide formulations because a potential increase in efficacy there is likely to pose a higher risk to non-target organisms such as bees compared to other PPP groups due to their mode of action. In addition, when selecting the products, we made sure that they were all registered for use in flowering crops. In the laboratory, we then simulated realistic mixtures of insecticides and adjuvants for field use. Based on the evidence provided by other studies, we suspect that when applied as a tank mixture, spray adjuvants may increase the toxicity of insecticidal formulations.

To investigate the scale of this increase and determine the class with the highest and lowest effects for both the insecticide formulation and the spray adjuvants, we investigated these issues with a series of acute laboratory contact tests in 2019 and 2020. This involved testing selected insecticide formulations (Coragen®, Karate® Zeon, Mospilan® SG, Pirimor® Granulat, Sivanto® Prime) and spray adjuvants (Acxcess®, Break-Thru® SP 133, Break-Thru® S 301, Hasten® TM, Kantor®, LI 700®) alone and in combination. All formulated insecticides in our trials are classified as not dangerous to bees when used up to their maximum application rate or concentration when applied separately. Conventional application rates were used based on the methods and guidelines established in the regulatory risk assessment. The products tested in the screening were systematically combined into a total of 30 different mixtures. All resulting combinations are theoretically allowed in practice and thus represent realistic exposure.

Materials and methods

Honey bees

A total of four honey bee colonies (Apis mellifera L.), healthy and queen-right, from the institute’s beekeeping in Braunschweig (Germany), were used. The queens were sisters from a breeding line reared in the same year at the test facility. For the trials in the spray chamber, two colonies each were selected, and adult workers were sampled near the brood nest to standardize the age of the bees. The last treatment of the colonies against Varroa destructor was at least six weeks previous. No clinical symptoms of adult bee or brood diseases were visible during inspection.

Experimental design

The experiment consisted of five individual trials conducted between November 2019 and August 2020 (trials A–E, see supplementary information). For the laboratory studies, worker bees were taken near the brood chamber of each of the two colonies and subjected to CO2 treatment for approximately 30 s. Anesthetized bees were then counted in standard stainless steel experimental cages (10 cm × 8.5 cm × 5.5 cm) with filter paper inserts at ten bees per cage and randomly placed in a climate chamber (24 °C ± 1 °C, 60% RH ± 10%, no light, and overnight acclimation). Six replicates per treatment and control group were used in each experiment, yielding a total number of 60 bees per treatment. Feeding was ad libitum with 50% sugar solutions (w/v) via a 5-ml disposable syringe with the tip removed. The syringes were replaced daily for sanitary reasons. For all experiments, a pre-examination was performed on the application day to ensure that 100% of the experimental bees were vital and undamaged. Bees were visually inspected for injury during handling, and their behavior was assessed after physical stimulation by blowing on them. If necessary, the cages were replaced with spare cages. To minimize separation of the spray solution, exposure was started as soon as possible after preparation.

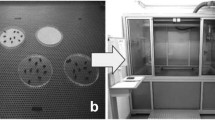

The acute contact tests were conducted using a similar study design as described in Test Guideline 214 (OECD 1998) with certain adaptations. To simulate a more realistic field contact exposure, the usual application of a single droplet to the thorax of the bees was omitted. Instead, whole-body exposure was performed in a professional spray chamber (custom-built by Christan Schachtner Gerätetechnik, Ludwigsburg, Germany) following the method of Wernecke et al. (2019) with minor modifications. The aim was to simulate the contact exposure of bees foraging at the time of spraying.

Briefly, bees were immobilized at 4 °C prior to application for approximately two hours, transferred cagewise to Petri dishes, and sprayed in the chamber at room temperature with the respective spray solution (spray speed: 2.5 km/h; nozzle pressure: 2.9 bar; system pressure 7–8 bar; spray height: 42 cm; setting 300 l water/ha). The spray chamber was equipped with commercially available application nozzles allowing for the bees to be evenly covered with a fine spray mist (flat spray nozzle Teejet 9503 EVS) like in the field. The bees were then retransferred in cages and brought back to the climate chamber. The mortality effects of each mixture were evaluated by visual inspection of bees after 2-, 4-, 24-, 48-, and 72-h intervals directly in the climate chamber.

Chemical treatment

All test substances used for this study were approved in Germany at the start of the trial. To achieve systematic screening with a broad spectrum, insecticides were selected on the basis of active ingredient classes. Therefore, one representative formulation from each of the classes of neonicotinoids (Mospilan® SG), diamides (Coragen®), pyrethroids (Karate® Zeon), butenolides (Sivanto® Prime), and carbamates (Pirimor® Granulat) was selected. In the course of the product authorization and based on higher tier semi-field and field studies under field-realistic conditions, these insecticides were evaluated as non-harmful to bees (classified as B4 in Germany) when used up to the maximum recommended application rate or concentration and when applied separately.

Six representative, best-selling spray adjuvants were also tested (Table 1). All were approved for mixing with insecticides. They can be broadly classified into different categories (e.g., superspreaders, penetration agents, or multifunctional agents) depending on their properties. However, there is no clear classification definition, so some adjuvants may serve multiple purposes.

In the contact test, all adjuvants were applied at the maximum application rate permitted in Germany. The application rate of the insecticides was determined independently of the crop, i.e., irrespective of bee attractiveness and BBCH stage and the specified water application rate. For Karate Zeon and Pirimor Granulat, we decided to reduce the maximum application rate to a maximum of 50%, because we found almost all the bees in the cages dead within the first few hours of application in preliminary trials. Otherwise, we would not have been able to detect an increase in mortality in combination with the spray adjuvants due to the high background mortality of the insecticide alone.

To determine the dose of active substance per bee, six bulk samples of ten live bees each were weighed before and after spraying with water and the weights were averaged (laboratory analytical balance Denver Instrument, type SI-234). It was determined that there was an average application quantity of 1.545 mg of water per bee. The formula for calculating the nominal amount of active ingredient per bee is as follows (1):

Honey bees were acutely exposed to the test substances. The use of a toxic reference substance was omitted in favor of increasing the number of replicates. Further details on the test substances are given in Table 1.

Statistical analysis

All statistical analyses were performed using the software “R” version 4.0.4 (R Core Team 2021) and a significance level α of 0.05. Plots were generated using the package “tidyverse” version 1.3.0 (Wickham et al. 2019) and the package “survminer” version 0.4.9 (Kassambara et al. 2021). Cox proportional hazards models from the package “survival” version 3.2.7 (Therneau 2020) were used for mortality analysis. Parameter estimates and 95% confidence intervals are reported. To examine the effects of all test substances (including their combinations) with the control as a reference, the following model was fitted: (survival ~ treatment + replicate). There was no correlation between variables. To measure the magnitude of the impact of the spray adjuvants on the insecticide, the control was omitted, and the insecticide was used as a reference. Consequently, the final model was (survival ~ treatment + replicate), with only one insecticide of the five tested at a time with all combinations of spray adjuvants. The proportional hazards were checked for each experiment to validate the Cox proportional hazards assumption. The Cox proportional hazards model yields a type of hazard ratio (HR). Its simplified interpretation is as follows: HR = 1 means equal or no effect of treatment (T) vs. control/reference (C). If the treatment was worse than the control, then HR was > 1 and vice versa. We chose to use HR as a relative measure versus median survival and time point estimate (absolute measure) because it summarizes the treatment effect over the entire study period (72 h) and uses all the information in the entire Kaplan–Meier (KM) curve. Assuming HR (T vs. C) = 1.25, this can be either interpreted as an average of approximately 25% higher risk of death (25% as 1–1.25 = − 0.25) or an average of approximately 20% decrease in survival time (20% as 1/1.25 = 0.8) from any point in the trial (Barraclough et al. 2011). Thus, unlike comparing survival curves for treatment and control, e.g., by a log-rank test, which gives only binary discrimination, an HR tells the magnitude and direction of this difference (Emmert-Streib and Dehmer 2019).

Results

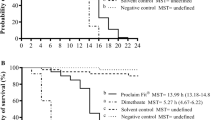

Bee mortality of the six tested adjuvants alone was not significantly different from that of the control group (Fig. 1, Figs. S1–S5). Most insecticides such as Coragen, Mospilan SG, and Sivanto Prime also did not cause higher bee mortality compared to the control group. However, Pirimor Granulat caused significantly higher mortality in one out of two trials and Karate Zeon caused significantly higher bee mortality in two out of two trials.

Hazard ratios (HRs) for all insecticides and spray adjuvants (adjuvants indicated with * after the name) applied as a single substance and plotted against the control shown for a 72-h period. A total of 60 (n) bees per treatment were used. The dots represent the mean, and the horizontal lines represent the lower and upper limits of the 95% confidence interval (CI) of the estimates. Data to the left of the vertical dividing line (no-effect line) indicate a higher risk of mortality for the reference (water control); data to the right of the vertical dividing line indicate a higher risk of mortality for the treatment (individual insecticide or adjuvant). If the confidence interval crosses the no-effect line, there is no statistically significant difference between the treatment (insecticide or adjuvant) and reference (water control), represented by hollow dots. Overall, no increased risk of death was observed for any of the single adjuvants (p > 0.05) but for both Karate Zeon and one Pirimor Granulat treatment (Cox proportional hazard model, p < 0.05)

Subsequently, the five selected insecticides (Figs. 2, 3, 4, 5, 6) were used as a reference in each case instead of the controls to measure the magnitude of mortality increase associated with the spray adjuvant (see section Statistical analysis). The overall results of all five trials (A–E) in reference to the control and raw mortality data are included in supplementary information (Figs. S1–S5; Tables S1–S5).

Hazard ratios (HRs) for the six spray adjuvants mixed with Mospilan SG (Mos) relative to the single insecticide are shown for a 72-h period. Overall, an increased risk of death was observed for the adjuvants Kantor, LI 700, and Break-Thru S 301 in mixture with Mospilan SG (Cox proportional hazard model, p < 0.05)

Hazard ratios (HRs) for the six spray adjuvants mixed with Pirimor Granulat (Pir) relative to the single insecticide are shown for a 72-h period. Overall, an increased risk of death was observed for the adjuvants Acxcess, Hasten TM, Break-Thru SP 133, and Break-Thru S 301 mixed with Pirimor Granulat (Cox proportional hazard model, p < 0.05)

Hazard ratios (HRs) for the six spray adjuvants mixed with Sivanto Prime (Siv) relative to the single insecticide are shown for a 72-h period. Overall, an increased risk of death was observed for the adjuvants Break-Thru SP 133 and Break-Thru S 301 in a mixture with Sivanto Prime (Cox proportional hazard model, p < 0.05)

Of all tested insecticide-spray adjuvant combinations, Break-Thru S 301 significantly increased bee mortality in four out of the five trials (for all insecticides except Coragen). The second Break-Thru adjuvant SP 133 increased bee mortality in three of the five trials. The spray adjuvants Acxcess, LI 700, Hasten TM, and Kantor each increased mortality in two of five trials (Figs. 2, 3, 4, 5, 6). Of all 30 combinations of spray adjuvants and insecticides evaluated, 15 significantly increased bee mortality.

Control versus single substances

Except for Karate Zeon and Pirimor Granulat, all other single insecticides did not significantly increase bee mortality over a 72-h period. Furthermore, no single adjuvant increased bee mortality either (Fig. 1, Cox proportional hazard model, p > 0.05). Absolute and control-corrected mortality is found in supplementary information (Tables S1–S5).

Coragen (chlorantraniliprole)

Bee mortality of the insecticide Coragen did not increase significantly over a 72-h period with any of the spray adjuvants tested (Fig. 2, Cox proportional hazard model, p > 0.05).

The control-corrected mortality for the Coragen–adjuvant combinations after 72 h was: Coragen + Acxcess: 0.0%; Coragen + Break-Thru SP 133: 1.7%; Coragen + Break-Thru S 301: 1.7%; Coragen + Hasten TM: 1.7%; Coragen + Kantor: 3.3%; Coragen + LI 700: 0.0% (Tables S1–S3).

Karate Zeon (lambda-cyhalothrin)

The pyrethroid Karate Zeon, on the other hand, showed a significantly higher risk of death between 67% and 142% and a significant decrease in survival time between 40.1% and 58.7% for all adjuvants tested within 72 h. Bees treated with Karate Zeon + Acxcess had a 67% higher risk of death and a 40.1% decrease in survival time. Treatment group Karate Zeon + Hasten TM had a 73% higher risk of death and a 42.2% decrease in survival time, similar to the combination Karate Zeon + Kantor with 142% and 58.7% and the mixture of Karate Zeon + LI 700 with 116% and 53.7%, respectively. Groups Karate Zeon + Break-Thru SP 133 and Karate Zeon + Break-Thru S 301 had a likewise higher risk of death, with 94% and 91% or a decrease in survival time of 48.5% and 47.6%, respectively (Fig. 3, Cox proportional hazard model, p < 0.05).

The control-corrected mortality for the Karate Zeon–adjuvant combinations after 72 h was: Karate Zeon + Acxcess: 100.0%; Karate Zeon + Break-Thru SP 133: 96.7%; Karate Zeon + Break-Thru S 301: 100.0%; Karate Zeon + Hasten TM: 91.7%; Karate Zeon + Kantor: 96.7%; Karate Zeon + LI 700: 98.3% (Tables S2–S3).

Mospilan SG (acetamiprid)

Half of the Mospilan SG–adjuvant tank mixtures resulted in statistically significant efficacy increases relative to the single insecticide application. Mospilan SG showed a 741% significant increase in the risk of death and a significant 88.1% decrease in 72-h survival time in the Mospilan SG + Kantor combination. Mospilan SG + LI 700 showed the highest increase in the risk of death by 2784% and the largest reduction in survival time by 96.5% of all trials. The Mospilan SG + Break-Thru S 301 combination had a 1366% higher risk of death and a 93.2% decrease in survival time and was the second highest increase of all trials (Cox proportional hazard model, p < 0.05). All other tested combinations with Mospilan SG did not significantly increase bee mortality over a 72-h period (Fig. 4, p > 0.05).

The control-corrected mortality for the Mospilan SG–adjuvant combinations after 72 h was: Mospilan SG + Acxcess: 5.0%; Mospilan SG + Break-Thru SP 133: 11.7%; Mospilan SG + Break-Thru S 301: 21.7%; Mospilan SG + Hasten TM: 11.7%; Mospilan SG + Kantor: 25.0%; Mospilan SG + LI 700: 38.3% (Tables S1–S3).

Pirimor Granulat (pirimicarb)

Pirimor Granulat showed an overall increase in efficacy with four of the six adjuvants. The Pirimor Granulat + Acxcess combination had a 278% increased risk of death and a 73.5% shortened survival time. Pirimor Granulat + Hasten TM increased the risk of death by 369% and shortened survival by 78.7%. Pirimor Granulat + Break-Thru SP 133 and Pirimor Granulat + Break-Thru S 301 unevenly increased the risk of death by 248% and 601% and shortened survival by 71.3% and 85.7%, respectively (Cox proportional hazard model, p < 0.05). The combination of Pirimor Granulat + Kantor and Pirimor Granulat + LI 700 showed no statistically significant increase in bee mortality (Fig. 5, p > 0.05).

The control-corrected mortality for the Pirimor Granulat–adjuvant combinations after 72 h was: Pirimor Granulat + Acxcess: 39.7%; Pirimor Granulat + Break-Thru SP 133: 37.9%; Pirimor Granulat + Break-Thru S 301: 63.8%; Pirimor Granulat + Hasten TM: 48.3%; Pirimor Granulat + Kantor: 23.7%; Pirimor Granulat + LI 700: 32.2% (Tables S4–S5).

Sivanto Prime (flupyradifurone)

Sivanto Prime showed a significant increase in effect only for the combinations Sivanto Prime + Break-Thru SP 133 and Sivanto Prime + Break-Thru S 301. Here, the risk of death was 1097% and 1003% higher, respectively, and the survival time was 91.6% and 90.9% shorter when compared to the single insecticide (Fig. 6, Cox proportional hazard model, p < 0.05).

The control-corrected mortality for the Sivanto Prime–adjuvant combinations after 72 h was: Sivanto Prime + Acxcess: 0.0%; Sivanto Prime + Break-Thru SP 133: 13.8%; Sivanto Prime + Break-Thru S 301: 15.5%; Sivanto Prime + Hasten TM: 3.4%; Sivanto Prime + Kantor: 3.4%; Sivanto Prime + LI 700: 8.5% (Tables S4–S5).

Discussion

Agricultural spray adjuvants improve the ability of PPPs to spread or better adhere to the leaves of the crop or the surface of the target insect. These adjuvants are currently not regulated in the U.S., Canada and most European countries (PMRA 1993; personal communication, N. Kurlemann; Durant et al. 2021). That is, they can be mixed with any insecticide class without prior risk assessment. Therefore, especially in agricultural practice, we find situations where bees may be exposed to a mixture of insecticides classified as non-hazardous to bees (B4-rated) and these specific adjuvants, which may enhance the toxicity of the insecticides (reviewed in Mullin et al. 2016).

In this study, we mixed five representative insecticides of different classes, all B4-rated, with six different spray adjuvants and investigated bee longevity. To systematically screen as many combinations as possible, this experiment was conducted in the laboratory in a professional spray chamber. We found that in 50% of the different combinations, there was an effect of increasing mortality. The adjuvant Break-Thru S 301, an organosilicone surfactant (OSS), showed this increase in four out of five insecticide classes—the highest ratio in the trial.

The highest and second highest mortality increases totaled in this study were for Mospilan SG in a tank mixture with LI 700 and Mospilan SG mixed with Break-Thru S 301 (HR = 28.84 and 14.66, respectively). In addition, there is a third mortality-increasing combination, Mospilan SG and Kantor (HR = 8.41). All these high increases can be attributed to the class of neonicotinoids, which were similarly reported by Chen et al. (2019). Here, three laboratory-tested adjuvants (N-methyl-2-pyrrolidone (NMP), Silwet L-77, Triton X-100) in combination with acetamiprid resulted in significantly higher acute contact toxicity to honey bees than with the insecticide alone.

Previous studies have already pointed out the effect-increasing property of OSSs (Mullin et al. 2016; Chen et al. 2019), but it was also highlighted that OSSs are toxic even when applied alone (Goodwin and McBrydie 2000; Mullin 2015). All tested spray adjuvants, including organosilicones, nonionic adjuvants, and crop oil concentrates alone, did not affect honey bees in their mortality in our trials. However, the effect-increasing property could be confirmed for pyrethroids, neonicotinoids, butenolides, and carbamates, but not for diamides.

OSSs cause a larger reduction in surface tension than other nonionic surfactants and crop oil concentrates. This makes them extreme surfactants and superpenetrants that can lead to impaired olfactory learning in adult bees (Stevens 1993; Hazen 2000; Ciarlo et al. 2012). Such potent surfactant activity can allow the uptake of even bacteria-sized mineral particles through the stomata of leaves (Kaiser 2014). May et al. (2015) consequently suggest that OSSs may be more likely to penetrate the cuticle of honey bees (and other non-target arthropods) to increase uptake of the insecticide and support delivery of active ingredients into bee tissue. This would explain why all of the tested adjuvants alone did not cause mortality in our experiments, as they did not contain any active ingredients.

Our result is consistent with that of Donovan and Elliot (2001), who also did not observe any mortality effects with topical application of four different adjuvants (including LI 700, which was also used in our study) at field-realistic application rates (OSS trisiloxane, crop oil concentrate, synthetic latex + alcohol ethoxylate, and OSS + synthetic latex) and orally. Even when fed to nurse bees and transferred by royal jelly to queen larvae, OSSs did not affect the survival or development of honey bee queens (Johnson and Percel 2013). This, however, contrasts to the findings of Goodwin and McBrydie (2000). They assessed negative effects on survival when bees were sprayed with a nonionic wetting agent (ethoxylated octylphenol), a surfactant (polyethoxylated tallow amines), and two OSSs (one siloxane and one trisiloxane). These varying results indicate that the mode of action of the various adjuvants on bees, as well as the methods used to evaluate them, needs to be studied in more detail to understand why there are differences and where they come from.

A recent study by Straw et al. (2021) suggests that co-formulants have lethal effects that are directly related to formulation. The authors tested glyphosate, which is nontoxic to bees, as three commercial formulations for toxicity to sprayed bumblebees (Bombus terrestris audax). It was found that two of the formulations increased the mortality of the bees and one did not. From this, the authors conclude that it is not the active ingredient but the co-formulants that must be responsible for the increased mortality. The hairs of the bees matted and perhaps the respiratory openings were covered. The narrow sections in the respiratory system may have also been blocked by the coating of the surface, which could be associated with the suffocation of the bees. In addition, Stevens (1993) noted that insect stigmas to be similar in size to plant stomata. He pointed out that the surfactants could allow water to enter the tracheal system, which in turn could lead to the drowning of the sprayed animal. However, these are still hypothetical conclusions that need to be further substantiated by experiments.

Adjuvants are advertised to increase the efficacy of PPPs (Alzchem 2021; Adama 2021), and combined effects that increase the overall effectiveness are therefore to be expected from the manufacturer. As already suggested, they can be partly explained by their physicochemical properties. For example, adhesion agents not only improve the adhesion of the spray solution to the plant (Stevens 1993) but may also increase the adhesion of the active ingredients to the bee. Wetting agents, on the other hand, lower the surface tension of the spray solution so that the PPP is distributed evenly on the leaf, which prevents spillage and increases wetting and active ingredient uptake (Miller and Westra 1998; Stevens 1993; reviewed in Jibrin et al. 2021).

Goodwin and McBrydie (2000) described such observations in their studies of contact exposure of A. mellifera to adjuvants. While single droplets formed on the hair coat of bees when water was applied alone, bees that died as a result of adjuvant application were completely soaked or matted, which supports the drowning hypothesis. In addition, adjuvants can increase leaf surface permeability (reviewed in Jibrin et al. 2021). This occurs particularly with lipophilic adjuvants such as crop oil concentrates such as Hasten TM (Dubovik et al. 2020). In combination, such increased penetration of insecticides through the cuticle can lead to higher toxicity of the active ingredient (quasi-synergism) (Sun and Johnson 1972). This could explain the large toxicity increase for the Mospilan SG + LI 700. Furthermore, Sims and Appel (2007) found an increased binding ability of surfactants with small HLB (hydrophilic–lipophilic balance), which penetrate the fatty wax coating of cockroaches and thus enter the body via the epicuticle, corroborating the earlier hypothesis for the OSS mode of action (May et al. 2015). In addition, there is evidence that cytochrome P450 monooxygenases are involved in the metabolism of adjuvants (e.g., ethoxylated alcohol surfactants) (Sims and Appel 2007). Thus, the increased toxicity of tank mixtures may also be explained by competition for access to the same P450 enzyme.

Co-formulants that can influence the toxicity of PPPs are evidenced by a variety of formulations. For identical active ingredients, some formulations are thousands of times more toxic than the active ingredient (Mullin 2015). This has been demonstrated for herbicides as well as fungicides and insecticides (Mesnage et al. 2014). It is thus clear that it is not only the dose of a particular active ingredient alone that makes the poison but also the formulation composition, i.e., the co-formulants contained therein (Mullin 2015; Mullin et al. 2015; Straw et al. 2021). Here is probably also a link to the spraying adjuvants, which may act similarly when present in a tank mixture.

The present experiment shows that the efficacy-enhancing potential of adjuvants can vary considerably and that the observed effects are mostly invariably dependent on the combined insecticide. Sims and Appel (2007) describe a relationship between the observed effects and the molecular characteristics of adjuvants. For example, alkyl chain length, HLB (hydrophilic–lipophilic balance), degree of ethoxylation (Sims and Appel 2007), and molecular weight (Verge et al. 2001) can modify the toxicity of adjuvants.

The effect of all adjuvants in combination with the diamide Coragen (chlorantraniliprole) was absent, which can be attributed to the low contact toxicity in adult bees. Interestingly, Demkovich et al. (2018) showed that the tank mixture of Altacor® (chlorantraniliprole) + Dyne-Amic® (OSS siloxane) increased the mortality of sprayed adult navel orange worms, Amyelois transitella (approximately 41%), compared to that of Altacor alone (approximately 24%). However, the results were inconsistent in eggs and larvae when high and low concentrations of the OSS adjuvant were used. The low-concentration mixture resulted in more killed eggs, and the high-concentration mixture resulted in more dead larvae. Conversely, however, no significant effects were measurable compared to Altacor.

The same adjuvant (Dyne-Amic) was fed to bee larvae by Kordecki (2019) in the laboratory and provided reduced hatching rates. However, the tank mixture of Altacor + Dyne-Amic, similar to Demkovich et al. (2018), did not increase efficacy. This suggests that mortality was induced by OSS rather than insecticide in bee brood. Moreover, Zhu et al. (2014) showed that the commonly used solvent N-methyl-2-pyrrolidone (NMP), which is utilized in PPP formulations, is highly toxic to honey bee larvae upon chronic oral exposure. Thus, bee brood seems to appear significantly more sensitive to certain adjuvants and co-formulants, such as NMP, than adult bees (Zhu et al. 2014; Mullin et al. 2015; Chen et al. 2018). Moreover, chlorantraniliprole (Coragen) is considered a highly selective insecticide (de Sousa Pereira et al. 2019) and, similar to Sivanto Prime, has a very high LD50 in contact exposure (Table 1). This may explain the lower activity of the two insecticides in combination with the adjuvants in our study.

Another finding we were able to demonstrate was that both formulations, Karate Zeon and Pirimor Granulat, showed clear bee toxicity under laboratory conditions. Karate Zeon also showed an increased effect with all adjuvants, and Pirimor Granulat showed an increased effect with four of the six adjuvants. In this context, Barnett et al. (2007) indicate that lambda-cyhalothrin (Karate Zeon) and other pyrethroid compounds are acutely toxic to bees under laboratory conditions. However, they are not considered a poisoning risk for honey bee colonies when applied to bee-attractive crops at their maximum authorized application rate in the field. The authors suggest that this could be due to a repellent effect, leading to a reduction in exposure. This obvious difference between laboratory and field studies shows that honey bees can be quite resilient to environmental stressors at the colony level and that their responses to pesticide exposure can be contextual (reviewed in Harwood and Dolezal 2020). Simply put, the colony might buffer the effects that individuals in cages display. However, it is not yet clear whether and to what extent adjuvants may increase the toxicity of insecticides in the field. It is known that tank mixtures with fungicides that inhibit ergosterol biosynthesis alter the repellent properties of pyrethroids. As a result, the risk of bee pollinators being harmed increases when this mixture is applied to flowering crops due to higher exposure (Thompson and Wilkins 2003). Similar effects of adjuvants in tank mixtures with insecticides may be possible and should therefore be further evaluated under field conditions.

Lastly, unlike Coragen and Sivanto Prime, both Karate Zeon and Pirimor Granulat have a rather low LD50, with Karate Zeon having the lowest LD50 of all insecticides tested in this study (Table 1). This suggests that the acute toxicity of the active ingredient also largely determines the effect enhancement by the adjuvant. Consequently, the toxicities of adjuvants are highly dependent not only on the particular target organism or PPP (class) combination but also on how they were administered (i.e., route of exposure) and what developmental stage they reach (i.e., egg, larva, adult) (Demkovich et al. 2018; Li et al. 2019; de Sousa Pereira et al. 2019). Whether the adjuvants examined in this study can have negative effects on honey bees after oral administration or under field conditions must be answered in further experiments.

This study was conducted with bees in an artificial laboratory environment using hoarding cages, which is a limitation. The actual concentrations to which bees are exposed during foraging may depend on weather, temperature, time of day, and the time difference between application and foraging. These factors are all field dependent, and future studies are needed to further translate what is known in the laboratory to field exposure studies. In addition, pesticide exposure is exacerbated by the transfer of nectar within the colony as foragers return to the hive and pass the collected food to the hive bees. The freshly collected nectar is then first ripened and possibly later fed to larvae. Therefore, future studies should investigate whether bioaccumulation of the active ingredients or adjuvants occurs during trophallaxis and ripening (Kordecki 2019).

To perform the experiments, we used two different colonies with sister queens in each trial. In trials C and E (Figs. S3 and S5), we found that the origin of the bees (replicate) was a significant covariate that may have influenced the respective reported HR. However, this may have been a minimal influence, as we did not have this difference in trials A, B, and D with the same colonies used. In addition, the test substances in question were replicated at least once in the other trials mentioned, which confirmed their negative or neutral effects compared to the control. Nevertheless, in future studies, care should be taken to randomize or mix the bees of both colonies before placing them in the cages. A third colony could also be added to increase the variance between replicates to avoid bias from the genetic background of the bees.

As previously discussed, it is now immensely important to understand the mode of action of adjuvants only, as well as that of co-formulants in PPP formulations (Straw et al. 2021). However, the ingredients of many formulations are legally protected, and their composition is usually not accessible to the user or the scientific community (EC 2009; Cox and Surgan 2006). This makes it difficult to understand the mode of action of these substances and hinders the ecotoxicological testing of potentially hazardous substances. Straw et al. (2021) urges that all components should be disclosed in the product’s safety data sheet to allow for individual testing. For most adjuvants, this is already possible, but co-formulations are legally considered a trade secret and therefore not accessible.

Mullin et al. (2015) critically pointed out that co-formulants are released into the environment in large quantities, but residues remain largely unmonitored. While they found 100% of the co-formulants analyzed in hive samples, only 70% of the pesticide active ingredients they were screening for were detected. Documentation of the formulation and adjuvants used would make it easier to trace potential bee poisoning to a specific active ingredient or co-formulants. This knowledge would help to better protect pollinators from pesticide hazards (Mullin et al. 2015).

To maintain the health of bee pollinators, May et al. (2015) suggested that labeling requirements should be changed to include sublethal and synergistic bee-toxic agrochemicals. In addition, ecotoxicological risk assessments should include adjuvants such as pesticides (Mesnage and Antoniou 2018) that require larval and chronic toxicity testing as part of this registration (May et al. 2015).

The results of the present study confirm the toxicity-increasing potential of adjuvants in combination with several different insecticide classes under laboratory conditions. We were able to show that the tested adjuvants in combination with B4-rated products, which are declared non-hazardous to bees, in the laboratory led to significantly increased mortality of sprayed bees. Among these, organosilicon surfactants (OSS) showed particularly prevalent and particularly strong effects. In light of our and other work, the classification of adjuvants as “inactive” or “inert” should be reconsidered, since adverse effects on bees in practice cannot be ruled out at the current state of research. Because data are insufficient to realistically assess the risk of adjuvants to pollinators without over- or underestimating environmental effects at present, further work, especially under field conditions, is essential. Until then, it has been doubtful that current data requirements in risk assessment and regulatory practices for adjuvants can prevent adverse effects on bees. Another important step is the declaration and labeling of ingredients and adjuvants, which is not required at the moment for adjuvant formulations, unlike PPPs. Addressing this problem and regulatory gaps is crucial for pollinator-friendly and more sustainable agriculture to maintain biodiversity and protect pollinators.

Availability of data and material

The data that support the findings of this study are available in the “Open Science Framework” under https://doi.org/10.17605/OSF.IO/NUX9G. Supplementary information to this article can be found online.

Code availability

Not applicable.

References

Abraham J, Benhotons GS, Krampah I et al (2018) Commercially formulated glyphosate can kill non-target pollinator bees under laboratory conditions. Entomol Exp Appl 166:695–702. https://doi.org/10.1111/eea.12694

Adama (2021) Hasten®. https://www.adama-produkte.com/de/produkt/hasten. Accessed 08 Oct 2019

Alzchem (2021) Break-Thru® S 301—richtige Anwendung der Schlüssel zum Erfolg. https://www.alzchem.com/de/landwirtschaft/break-thru-s-301. Accessed 21 Apr 2021

Barraclough H, Simms L, Govindan R (2011) Biostatistics primer: what a clinician ought to know: hazard ratios. J Thorac Oncol 6:978–982. https://doi.org/10.1097/JTO.0b013e31821b10ab

Barnett EA, Charlton AJ, Fletcher MR (2007) Incidents of bee poisoning with pesticides in the United Kingdom, 1994–2003. Pest Manag Sci 63:1051–1057. https://doi.org/10.1002/ps.1444

BVL [Federal Office of Consumer Protection and Food Safety] (2021a) Information on approved and listed adjuvants. https://www.bvl.bund.de/EN/Tasks/04_Plant_protection_products/01_ppp_tasks/05_ppp_Adjuvants/ppp_Adjuvants_node.html. Accessed 10 Sept 2021

BVL [Federal Office of Consumer Protection and Food Safety] (2021b) The approval procedure for adjuvants. https://www.bvl.bund.de/EN/Tasks/04_Plant_protection_products/03_Applicants/12_ApprovalAdjuvants/ppp_ApprovalProcedure_adjuvants_node.html. Accessed 08 June 2021

Chen J, Fine JD, Mullin CA (2018) Are organosilicon surfactants safe for bees or humans? Sci Total Environ 612:415–421. https://doi.org/10.1016/j.scitotenv.2017.08.175

Chen L, Yan Q, Zhang J, Yuan S, Liu X (2019) Joint toxicity of acetamiprid and co-applied pesticide adjuvants on honeybees under semifield and laboratory conditions. Environ Toxicol Chem 38:1940–1946. https://doi.org/10.1002/etc.4515

Chmiel JA, Daisley BA, Pitek AP, Thompson GJ, Reid G (2020) Understanding the effects of sublethal pesticide exposure on honey bees: a role for probiotics as mediators of environmental stress. Front Ecol Evol 8:22. https://doi.org/10.3389/fevo.2020.00022

Ciarlo TJ, Mullin CA, Frazier JL, Schmehl DR (2012) Learning impairment in honey bees caused by agricultural spray adjuvants. PLoS ONE 7:e40848. https://doi.org/10.1371/journal.pone.0040848

Cox C, Surgan M (2006) Unidentified inert ingredients in pesticides: implications for human and environmental health. Environ Health Perspect 114:1803–1806. https://doi.org/10.1289/ehp.9374

de Sousa PK, Chediak M, Zanuncio JC, Guedes RNC (2019) Chlorantraniliprole impact on survival and progeny quality of the pupa of the parasitoid Palmistichus elaeisis (Hymenoptera: Eulophidae). Can Entomol 151:94–100. https://doi.org/10.4039/tce.2018.49

Demkovich MR, Siegel JP, Walse SS, Berenbaum MR (2018) Impact of agricultural adjuvants on the toxicity of the diamide insecticides chlorantraniliprole and flubendiamide on different life stages of the navel orangeworm (Amyelois transitella). J Pest Sci 91:1127–1136. https://doi.org/10.1007/s10340-018-0959-z

dlz agrarmagazin (2006) Der Turbo für den Pflanzenschutz. Deutscher Landwirtschaftsverlag München. https://www.agrarheute.com/heftarchive/dlz/download/1093+&cd=1&hl=de&ct=clnk&gl=de&client=firefox-b-d. Accessed 08 Oct 2019

Donovan BJ, Elliott G (2001) Honey bee response to high concentrations of some new spray adjuvants. NZPP 54:51–55. https://doi.org/10.30843/nzpp.2001.54.3739

Dubovik V, Dalinova A, Berestetskiy A (2020) Effect of adjuvants on herbicidal activity and selectivity of three phytotoxins produced by the fungus, Stagonospora Cirsii. Plants 9(11):1621. https://doi.org/10.3390/plants9111621

Durant JL, Goodrich BK, Chang KT, Yoshimoto E (2021) Growers follow the label: an analysis of bee-toxic pesticide use in almond orchards during bloom. Calif Agric. https://doi.org/10.3733/ca.2020a0030

EC [European Commission] (2009) Regulation (EU) No 1107/2009. Official Journal of the European Union, 309, 1–50

Emmert-Streib F, Dehmer M (2019) Introduction to survival analysis in practice. MAKE 1:1013–1038. https://doi.org/10.3390/make1030058

EPA [United States Environmental Protection Agency] (2021) Basic Information about Pesticide Ingredients. https://www.epa.gov/ingredients-used-pesticide-products/basic-information-about-pesticide-ingredients. Accessed 21 June 2021

Fine JD, Cox-Foster DL, Mullin CA (2017) An inert pesticide adjuvant synergizes viral pathogenicity and mortality in honey bee larvae. Sci Rep 7:40499. https://doi.org/10.1038/srep40499

Gehring K (2003) Zusatzstoffe zu Herbiziden—Wundermittel oder Placebos? Top Agrar 78–84. https://www.topagrar.com/acker/aus-dem-heft/wundermittel-oder-placebos-9790541.html. Accessed 21 Apr 2021

Goodwin RM, McBrydie HM (2000) Effect of surfactants on honey bees. N Z Plant Prot 53:230–234. https://doi.org/10.30843/nzpp.2000.53.3694

Green JM, Green JH (1993) Surfactant structure and concentration strongly affect rimsulfuron activity. Weed Technol 7:633–640. https://doi.org/10.1017/S0890037X00037465

Harwood GP, Dolezal AG (2020) Pesticide-virus interactions in honey bees: challenges and opportunities for understanding drivers of bee declines. Viruses 12:566. https://doi.org/10.3390/v12050566

Hazen JL (2000) Adjuvants—terminology, classification, and chemistry. Weed Technol 14(4):773–784. https://doi.org/10.1614/0890-037X(2000)014[0773:ATCAC]2.0.CO;2

Iwasa T, Motoyama N, Ambrose JT, Roe RM (2004) Mechanism for the differential toxicity of neonicotinoid insecticides in the honey bee, Apis mellifera. Crop Prot 23:371–378. https://doi.org/10.1016/j.cropro.2003.08.018

Iwasaki JM, Hogendoorn K (2021) Non-insecticide pesticide impacts on bees: a review of methods and reported outcomes. Agr Ecosyst Environ 314:107423. https://doi.org/10.1016/j.agee.2021.107423

Jibrin MO, Liu Q, Jones JB, Zhang S (2021) Surfactants in plant disease management: a brief review and case studies. Plant Pathol 70:495–510. https://doi.org/10.1111/ppa.13318

Johnson RM, Dahlgren L, Siegfried BD, Ellis MD (2013) Acaricide, fungicide and drug interactions in honey bees (Apis mellifera). PLoS ONE 8:e54092. https://doi.org/10.1371/journal.pone.0054092

Johnson RM, Percel EG (2013) Effect of a fungicide and spray adjuvant on queen-rearing success in honey bees (Hymenoptera: Apidae). J Econ Entom 106:1952–1957. https://doi.org/10.1603/EC13199

Kaiser H (2014) Stomatal uptake of mineral particles from a sprayed suspension containing an organosilicone surfactant. J Plant Nutr Soil Sci 177:869–874. https://doi.org/10.1002/jpln.201300607

Kassambara A, Kosinski M, Biecek P (2021) Survminer: Drawing Survival Curves using 'ggplot2'. R package version 0.4.9. https://CRAN.R-project.org/package=survminer. Accessed 25 May 2021

Kordecki H (2019) Effects of Insecticides, Fungicides, and Adjuvant Combinations on Honey Bee Brood Development. The Ohio State University

Li B, Liu Y, Zhang P, Li XX, Pang XY, Zhao YH, Li H, Liu F, Lin J, Mu W (2019) Selection of organosilicone surfactants for tank-mixed pesticides considering the balance between synergistic effects on pests and environmental risks. Chemosphere 217:591–598. https://doi.org/10.1016/j.chemosphere.2018.11.061

May E, Wilson J, Isaacs R (2015) Minimizing pesticide risk to bees In: Fruit Crops. Department of Entomology, Michigan State University—E3245, 1–16.

Mesnage R, Antoniou MN (2018) Ignoring Adjuvant Toxicity Falsifies the Safety Profile of Commercial Pesticides. Front Public Health 5:361. https://doi.org/10.3389/fpubh.2017.00361

Mesnage R, Defarge N, Spiroux de Vendômois J, Séralini GE (2014) Major pesticides are more toxic to human cells than their declared active principles. Biomed Res Int 2014:1–8. https://doi.org/10.1155/2014/179691

Miller P, Westra P (1998) How Surfactants Work. Colorado State University, Cooperative Extension. 11/98.

Montgomery GA, Dunn RR, Fox R et al (2020) Is the insect apocalypse upon us? How to find out. Biol Conserv 241:108327. https://doi.org/10.1016/j.biocon.2019.108327

Mullin CA (2015) Effects of ‘inactive’ ingredients on bees. Curr Opin Insect Sci 10:194–200. https://doi.org/10.1016/j.cois.2015.05.006

Mullin CA, Chen J, Fine JD, Frazier MT, Frazier JL (2015) The formulation makes the honey bee poison. Pestic Biochem Physiol 120:27–35. https://doi.org/10.1016/j.pestbp.2014.12.026

Mullin CA, Fine JD, Reynolds RD, Frazier MT (2016) Toxicological risks of agrochemical spray adjuvants: organosilicone surfactants may not be safe. Front Public Health. https://doi.org/10.3389/fpubh.2016.00092

Odemer R, Alkassab AT, Bischoff G, Frommberger M, Wernecke A, Wirtz I, Pistorius J, Odemer F (2020) Chronic high glyphosate exposure delays individual worker bee (Apis mellifera L.) development under field conditions. Insects 11:664. https://doi.org/10.3390/insects11100664

Odemer R, Nilles L, Linder N, Rosenkranz P (2018) Sublethal effects of clothianidin and Nosema spp. on the longevity and foraging activity of free flying honey bees. Ecotoxicology 27:527–538. https://doi.org/10.1007/s10646-018-1925-5

OECD [Organisation for Economic Cooperation and Development] (1998) Guideline for the Testing of Chemicals, No. 214: Honeybees: acute contact toxicity test. Organisation for Economic Cooperation and Development, Paris

Pilling ED, Jepson PC (1993) Synergism between EBI fungicides and a pyrethroid insecticide in the honeybee (Apis mellifera). Pestic Sci 39:293–297. https://doi.org/10.1002/ps.2780390407

PMRA [Pest Management Regulatory Agency] (1993) Registration requirements for adjuvant products, regulatory directive, Gov. of Canada 93–15. https://www.canada.ca/content/dam/hc-sc/migration/hc-sc/cps-spc/alt_formats/pacrb-dgapcr/pdf/pubs/pest/pol-guide/dir/dir9315-eng.pdf

PPDB [Pesticide Properties DataBase] (2021) A to Z list of pesticide active ingredients. http://sitem.herts.ac.uk/aeru/ppdb/en/atoz.htm. Accessed 25 May 2021

R Core Team (2021) R: A language and environment for statistical computing. R Foundation for Statistical Computing, Vienna, Austria. https://www.R-project.org/. Accessed 25 May 2021

Ratajkiewicz H, Kierzek R, Karolewski Z, Wachowiak M (2009) The effect of adjuvants, spray volume and nozzle type on azoxystrobin efficacy against Leptosphaeria maculans and L. biglobosa on winter oilseed rape. J. Plant Prot Res 49(4):440–445. https://doi.org/10.2478/v10045-009-0070-9

Saunders ME, Janes JK, O’Hanlon JC (2020) Moving on from the insect apocalypse narrative: engaging with evidence-based insect conservation. Bioscience 70:80–89. https://doi.org/10.1093/biosci/biz143

Schneider-Orelli O (1947) Entomologisches Praktikum: Einführung in die land-und forstwirtschaftliche Insektenkunde. Aarau: Sauerländer, p 149

Sims SR, Appel AG (2007) Linear Alcohol Ethoxylates: Insecticidal and Synergistic Effects on German Cockroaches (Blattodea: Blattellidae) and Other Insects. J Econ Entomol 100(3):871–879. https://doi.org/10.1093/jee/100.3.871

Stevens PJG (1993) Organosilicone surfactants as adjuvants for agrochemicals. Pestic Sci 38:103–122. https://doi.org/10.1002/ps.2780380206

Straw EA, Carpentier EN, Brown MJF, Kaplan I (2021) Roundup causes high levels of mortality following contact exposure in bumble bees. J Appl Ecol 1365–2664:13867. https://doi.org/10.1111/1365-2664.13867

Straub L, Williams GR, Pettis J, Fries I, Neumann P (2015) Superorganism resilience: Eusociality and susceptibility of ecosystem service providing insects to stressors. Curr Opin Insect Sci 12:109–112. https://doi.org/10.1016/j.cois.2015.10.010

Sun Y-P, Johnson ER (1972) Quasi-Synergism and Penetration of Insecticides. J Econ Entomol 65:349–353. https://doi.org/10.1093/jee/65.2.349

Therneau T (2020) A package for survival analysis in R_. R package version 3.2–7. https://CRAN.R-project.org/package=survival. Accessed 25 May 2021

Thompson H, Wilkins S (2003) Assessment of the synergy and repellency of pyrethroid/fungicide mixtures. Bull Insectol 56(1):131–134

vanEngelsdorp D, Meixner MD (2010) A historical review of managed honey bee populations in Europe and the United States and the factors that may affect them. J Invertebr Pathol 103:80–95. https://doi.org/10.1016/j.jip.2009.06.011

Verge C, Moreno A, Bravo J, Berna JL (2001) Influence of water hardness on the bioavailability and toxicity of linear alkylbenzene sulphonate (LAS). Chemosphere 44:1749–1757. https://doi.org/10.1016/S0045-6535(00)00574-9

Wade A, Lin CH, Kurkul C, Regan ER, Johnson RM (2019) Combined toxicity of insecticides and fungicides applied to California almond orchards to honey bee larvae and adults. Insects 10(1):20. https://doi.org/10.3390/insects10010020

Wernecke A, Frommberger M, Pistorius J (2018) Auswirkungen von Tankmischungen auf Honigbienen. In: JKI (Hrsg.): 61. Deutsche Pflanzenschutztagung: Herausforderung Pflanzenschutz - Wege in die Zukunft; 11. - 14. September 2018, Universität Hohenheim -Kurzfassungen der Vorträge und Poster- (Julius-Kühn-Archiv 461), Braunschweig, 399. https://www.julius-kuehn.de/ex_anwendung/downloadFatPdf.php?file=2018_0917.pdf. Accessed 21 Apr 2021

Wernecke A, Frommberger M, Forster R, Pistorius J (2019) Lethal effects of various tank mixtures including insecticides, fungicides and fertilizers on honey bees under laboratory, semi-field and field conditions. J Consum Prot Food Saf 14:239–249. https://doi.org/10.1007/s00003-019-01233-5

Wernecke A, Eckert JH, Forster R, Kulemann N, Odemer R (2021) Data: Inert agricultural spray adjuvants may increase the adverse effects of selected insecticides on honey bees (Apis mellifera L.) under laboratory conditions. https://doi.org/10.17605/OSF.IO/NUX9G

Wickham H, Averick M, Bryan J, Chang W, McGowan LDA, François R, Grolemund G, Hayes A, Henry L, Hester J, Kuhn M, Pedersen TL, Miller E, Bache SM, Müller K, Ooms J, Robinson D, Seidel DP, Spinu V, Takahashi K, Vaughan D, Wilke C, Woo K, Yutani H (2019) Welcome to the Tidyverse. JOSS 4:1686

Zhu W, Schmehl DR, Mullin CA, Frazier JL (2014) Four common pesticides, their mixtures and a formulation solvent in the hive environment have high oral toxicity to honey Bee Larvae. PLoS ONE 9:e77547. https://doi.org/10.1371/journal.pone.0077547

Acknowledgements

We would like to thank Anke Ehlers, Saskia Toleikis, Sebastian Müller, and Jan Fritsch for their experimental assistance. Furthermore, we thank Maria Kalimeri for the support and implementation of the graphical visualization of the forest plots using the R package “ggforestplot.” We would also like to thank the reviewers for their thoughtful comments and efforts towards improving our manuscript.

Funding

Open Access funding enabled and organized by Projekt DEAL. This research study was supported in part by the Federal Office of Consumer Protection and Food Safety.

Author information

Authors and Affiliations

Contributions

A.W., J.H.E., R.F., and N.K. were involved in conceptualization; A.W. and R.O. were involved in data curation and formal analysis; R.F. was involved in funding acquisition; A.W. and J.H.E. were involved in investigation and methodology; A.W. was involved in project administration; R.O. was involved in software; A.W. and R.O. were involved in visualization and writing—original draft; J.H.E., R.F., and N.K. were involved in writing—review and editing. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare that no competing interests exist.

Ethics approval

All applicable international, national, and/or institutional guidelines for the careful handling and use of animals were followed. In the context of the article, none of the authors conducted studies with human subjects.

Consent to participate

Not applicable.

Consent for publication

The authors declare the agreement of publication including appropriate statements.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Wernecke, A., Eckert, J.H., Forster, R. et al. Inert agricultural spray adjuvants may increase the adverse effects of selected insecticides on honey bees (Apis mellifera L.) under laboratory conditions. J Plant Dis Prot 129, 93–105 (2022). https://doi.org/10.1007/s41348-021-00541-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41348-021-00541-z