Abstract

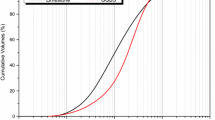

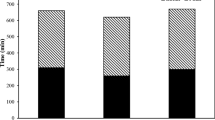

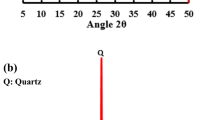

The use of limestone powder (LSP) as a cement replacement is used in abundant applications due to its low cost and wide availability. Adversely, the use of LSP as a part of the precursors of alkali-activated materials (AAMs) is still in the developing stage. This scarcity of studies opened the door and encouraged the researchers for more investigations. Thus, this paper studied the effect of various amounts of LSP on some properties of alkali-activated slag (AAS) pastes activated with NaOH and Na2SiO3 solution. Slag was partially replaced with LSP at ratios of 15–60 wt%. The effects of LSP on mechanical strength, water absorption, chloride penetration permeability, drying shrinkage were studied. Advanced apparatuses were applied to detect the changes in crystalline phases, hydration products and microstructure of the pastes with and without the inclusion of LSP. The results confirmed that 15% LSP was the optimum amount, which is responsible for the highest mechanical strength, lowest water absorption and lowest charge passed. The drying shrinkage was mitigated with the inclusion of LSP. The inclusion of 15% LSP enhanced the 28-day compressive strength and flexural strength by 11.41% and 13.7%, respectively, while the water absorption, charge passed and drying shrinkage were decreased.

Similar content being viewed by others

References

Rashad AM (2015) A brief on high-volume Class F fly ash as cement replacement–A guide for Civil Engineer. Int J Sustain Built Environ 4(2):278–306

Rashad AM (2018) An overview on rheology, mechanical properties and durability of high-volume slag used as a cement replacement in paste, mortar and concrete. Constr Build Mater 187:89–117

Rashad AM (2019) A synopsis manual about recycling steel slag as a cementitious material. J Market Res 8(5):4940–4955

Tomkins C, Throwdown G (2009) Redefining what’s possible for clean energy by 2020, Gigaton Throwdown: San Francisco. CA, USA

Amran YM, Alyousef R, Alabduljabbar H, El-Zeadani M (2020) Clean production and properties of geopolymer concrete. A review, Journal of Cleaner Production 251:119679

Rashad AM (2013) Alkali-activated metakaolin: A short guide for civil Engineer–An overview. Constr Build Mater 41:751–765

Rashad AM (2013) A comprehensive overview about the influence of different additives on the properties of alkali-activated slag–A guide for Civil Engineer. Constr Build Mater 47:29–55

Rashad AM (2014) A comprehensive overview about the influence of different admixtures and additives on the properties of alkali-activated fly ash. Mater Des 53:1005–1025

Rakhimova NR, Rakhimov RZ (2019) Literature review of advances in materials used in development of alkali-activated mortars, concretes, and composites. J Mater Civ Eng 31(11):03119002

Ortega-Zavala DE, Santana-Carrillo JL, Burciaga-Díaz O, Escalante-García JI (2019) An initial study on alkali activated limestone binders. Cem Concr Res 120:267–278

Panesar DK, Zhang R (2020) Performance comparison of cement replacing materials in concrete: Limestone fillers and supplementary cementing materials–A review. Constr Build Mater 251:118866

Wang D, Shi C, Farzadnia N, Shi Z, Jia H, Ou Z (2018) A review on use of limestone powder in cement-based materials: Mechanism, hydration and microstructures. Constr Build Mater 181:659–672

Wang D, Shi C, Farzadnia N, Shi Z, Jia H (2018) A review on effects of limestone powder on the properties of concrete. Constr Build Mater 192:153–166

Choi S-G, Chang I, Lee M, Lee J-H, Han J-T, Kwon T-H (2020) Review on geotechnical engineering properties of sands treated by microbially induced calcium carbonate precipitation (MICP) and biopolymers. Constr Build Mater 246:118415

Aboulayt A, Riahi M, Touhami MO, Hannache H, Gomina M, Moussa R (2017) Properties of metakaolin based geopolymer incorporating calcium carbonate. Adv Powder Technol 28(9):2393–2401

Qian J, Song M (2015) Study on influence of limestone powder on the fresh and hardened properties of early age metakaolin based geopolymer. Springer, Calcined Clays for Sustainable Concrete, pp 253–259

Perez-Cortes P, Escalante-Garcia JI (2020) Design and optimization of alkaline binders of limestone-metakaolin–A comparison of strength, microstructure and sustainability with portland cement and geopolymers. J Clean Prod 273:123118

A. Aboulayt, A. Gounni, M. El Alami, R. Hakkou, H. Hannache, M. Gomina, R. Moussa, Thermo-physical characterization of a metakaolin-based geopolymer incorporating calcium carbonate: A case study, Materials Chemistry and Physics (2020) 123266.

Rashad AM (2015) Influence of different additives on the properties of sodium sulfate activated slag. Constr Build Mater 79:379–389

Lemougna PN, Wang K-T, Tang Q, Kamseu E, Billong N, Melo UC, Cui X-M (2017) Effect of slag and calcium carbonate addition on the development of geopolymer from indurated laterite. Appl Clay Sci 148:109–117

Gao X, Yu Q, Brouwers H (2015) Properties of alkali activated slag–fly ash blends with limestone addition. Cement Concr Compos 59:119–128

Xiang J, Liu L, Cui X, He Y, Zheng G, Shi C (2018) Effect of limestone on rheological, shrinkage and mechanical properties of alkali–Activated slag/fly ash grouting materials. Constr Build Mater 191:1285–1292

Kalinkin AM, Gurevich BI, Myshenkov MS, Chislov MV, Kalinkina EV, Zvereva IA, Cherkezova-Zheleva Z, Paneva D, Petkova V (2020) Synthesis of Fly Ash-Based Geopolymers: Effect of Calcite Addition and Mechanical Activation. Minerals 10(9):827

Topark-Ngarm P, Tho-In T, Sata V, Chindaprasirt P, Cao T (2019) Influence of Glass and Limestone Powders in High Calcium Fly Ash Geopolymer Paste on Compressive Strength and Microstructure. Trans Tech Publ, Key Engineering Materials, pp 397–403

M. Elchalakani, M. Dong, A. Karrech, G. Li, M. Mohamed Ali, T. Xie, B. Yang, Development of fly ash-and slag-based geopolymer concrete with calcium carbonate or microsilica, Journal of Materials in Civil Engineering 30(12) (2018) 04018325.

Yip CK, Provis JL, Lukey GC, van Deventer JS (2008) Carbonate mineral addition to metakaolin-based geopolymers. Cement Concr Compos 30(10):979–985

Bayiha BN, Billong N, Yamb E, Kaze RC, Nzengwa R (2019) Effect of limestone dosages on some properties of geopolymer from thermally activated halloysite. Constr Build Mater 217:28–35

Yuan B, Yu Q, Dainese E, Brouwers H (2017) Autogenous and drying shrinkage of sodium carbonate activated slag altered by limestone powder incorporation. Constr Build Mater 153:459–468

Perez-Cortes P, Escalante-Garcia JI (2020) Alkali activated metakaolin with high limestone contents–Statistical modeling of strength and environmental and cost analyses. Cement Concr Compos 106:103450

Moseson AJ, Moseson DE, Barsoum MW (2012) High volume limestone alkali-activated cement developed by design of experiment. Cement Concr Compos 34(3):328–336

Fernández-Jiménez A, Palomo A (2005) Composition and microstructure of alkali activated fly ash binder: Effect of the activator. Cem Concr Res 35(10):1984–1992

A.M. Rashad, G.M. Essa, Effect of ceramic waste powder on alkali-activated slag pastes cured in hot weather after exposure to elevated temperature, Cement and Concrete Composites (2020) 103617.

Rashad AM, Zeedan SR, Hassan AA (2016) Influence of the activator concentration of sodium silicate on the thermal properties of alkali-activated slag pastes. Constr Build Mater 102:811–820

Burciaga-Díaz O, Gómez-Zamorano LY, Escalante-García JI (2016) Influence of the long term curing temperature on the hydration of alkaline binders of blast furnace slag-metakaolin. Constr Build Mater 113:917–926

Chi M (2012) Effects of dosage of alkali-activated solution and curing conditions on the properties and durability of alkali-activated slag concrete. Constr Build Mater 35:240–245

Bilim C, Karahan O, Atiş CD, Ilkentapar S (2013) Influence of admixtures on the properties of alkali-activated slag mortars subjected to different curing conditions. Mater Des 44:540–547

Nasir M, Johari MAM, Maslehuddin M, Yusuf MO, Al-Harthi MA (2020) Influence of heat curing period and temperature on the strength of silico-manganese fume-blast furnace slag-based alkali-activated mortar. Constr Build Mater 251:118961

Yuan B, Yu Q, Brouwers H (2017) Assessing the chemical involvement of limestone powder in sodium carbonate activated slag. Mater Struct 50(2):136

Zhang L, Suleiman A, Nehdi M (2020) Self-healing in fiber-reinforced alkali-activated slag composites incorporating different additives. Constr Build Mater 262:120059

Rakhimova NR, Rakhimov RZ, Naumkina NI, Khuzin AF, Osin YN (2016) Influence of limestone content, fineness, and composition on the properties and microstructure of alkali-activated slag cement. Cement Concr Compos 72:268–274

Yum WS, Jeong Y, Song H, Oh JE (2018) Recycling of limestone fines using Ca (OH) 2-and Ba (OH) 2-activated slag systems for eco-friendly concrete brick production. Constr Build Mater 185:275–284

Cwirzen A, Provis JL, Penttala V, Habermehl-Cwirzen K (2014) The effect of limestone on sodium hydroxide-activated metakaolin-based geopolymers. Constr Build Mater 66:53–62

Avila-López U, Almanza-Robles J, Escalante-García J (2015) Investigation of novel waste glass and limestone binders using statistical methods. Constr Build Mater 82:296–303

Hu X, Shi C, Shi Z, Zhang L (2019) Compressive strength, pore structure and chloride transport properties of alkali-activated slag/fly ash mortars. Cement Concr Compos 104:103392

Tsivilis S, Chaniotakis E, Batis G, Meletiou C, Kasselouri V, Kakali G, Sakellariou A, Pavlakis G, Psimadas C (1999) The effect of clinker and limestone quality on the gas permeability, water absorption and pore structure of limestone cement concrete. Cement Concr Compos 21(2):139–146

Mehta A, Siddique R, Ozbakkaloglu T, Shaikh FUA, Belarbi R (2020) Fly ash and ground granulated blast furnace slag-based alkali-activated concrete: Mechanical, transport and microstructural properties. Constr Build Mater 257:119548

Lee W-H, Wang J-H, Ding Y-C, Cheng T-W (2019) A study on the characteristics and microstructures of GGBS/FA based geopolymer paste and concrete. Constr Build Mater 211:807–813

Behfarnia K, Rostami M (2017) Effects of micro and nanoparticles of SiO2 on the permeability of alkali activated slag concrete. Constr Build Mater 131:205–213

Bernal SA, de Gutiérrez RM, Provis JL (2012) Engineering and durability properties of concretes based on alkali-activated granulated blast furnace slag/metakaolin blends. Constr Build Mater 33:99–108

Ravikumar D, Neithalath N (2013) Electrically induced chloride ion transport in alkali activated slag concretes and the influence of microstructure. Cem Concr Res 47:31–42

Najimi M, Ghafoori N, Sharbaf M (2018) Alkali-activated natural pozzolan/slag mortars: A parametric study. Constr Build Mater 164:625–643

Yoon H, Park SM, Lee H-K (2018) Effect of MgO on chloride penetration resistance of alkali-activated binder. Constr Build Mater 178:584–592

Kumar V, Kumar A, Prasad B (2019) Mechanical behavior of non-silicate based alkali-activated ground granulated blast furnace slag. Constr Build Mater 198:494–500

Manjunath R, Narasimhan MC, Umesha K (2019) Studies on high performance alkali activated slag concrete mixes subjected to aggressive environments and sustained elevated temperatures. Constr Build Mater 229:116887

Rostami M, Behfarnia K (2017) The effect of silica fume on durability of alkali activated slag concrete. Constr Build Mater 134:262–268

Khan MNN, Sarker PK (2020) Effect of waste glass fine aggregate on the strength, durability and high temperature resistance of alkali-activated fly ash and GGBFS blended mortar. Constr Build Mater 263:120177

Ravikumar D, Neithalath N (2013) An electrical impedance investigation into the chloride ion transport resistance of alkali silicate powder activated slag concretes. Cement Concr Compos 44:58–68

Balcikanli M, Ozbay E (2016) Optimum design of alkali activated slag concretes for the low oxygen/chloride ion permeability and thermal conductivity. Compos B Eng 91:243–256

Ghafoori N, Spitek R, Najimi M (2016) Influence of limestone size and content on transport properties of self-consolidating concrete. Constr Build Mater 127:588–595

H. Du, S. Dai Pang, High-performance concrete incorporating calcined kaolin clay and limestone as cement substitute, Construction and Building Materials 264 (2020) 120152.

Sun J, Chen Z (2018) Influences of limestone powder on the resistance of concretes to the chloride ion penetration and sulfate attack. Powder Technol 338:725–733

Collins F, Sanjayan JG (1999) Workability and mechanical properties of alkali activated slag concrete. Cem Concr Res 29(3):455–458

Atiş CD, Bilim C, Çelik Ö, Karahan O (2009) Influence of activator on the strength and drying shrinkage of alkali-activated slag mortar. Constr Build Mater 23(1):548–555

Abdollahnejad Z, Mastali M, Woof B, Illikainen M (2020) High strength fiber reinforced one-part alkali activated slag/fly ash binders with ceramic aggregates: Microscopic analysis, mechanical properties, drying shrinkage, and freeze-thaw resistance. Constr Build Mater 241:118129

Neto AAM, Cincotto MA, Repette W (2008) Drying and autogenous shrinkage of pastes and mortars with activated slag cement. Cem Concr Res 38(4):565–574

Ye H, Radlińska A (2016) Shrinkage mechanisms of alkali-activated slag. Cem Concr Res 88:126–135

Ye H, Cartwright C, Rajabipour F, Radlińska A (2017) Understanding the drying shrinkage performance of alkali-activated slag mortars. Cement Concr Compos 76:13–24

Meddah MS, Lmbachiya MC, Dhir RK (2014) Potential use of binary and composite limestone cements in concrete production. Constr Build Mater 58:193–205

Tongaroonsri S, Tangtermsirikul S (2009) Effect of mineral admixtures and curing periods on shrinkage and cracking age under restrained condition. Constr Build Mater 23(2):1050–1056

Li P, Brouwers H, Chen W, Yu Q (2020) Optimization and characterization of high-volume limestone powder in sustainable Ultra-high Performance Concrete. Constr Build Mater 242:118112

Rakhimova NR, Rakhimov RZ, Morozov VP, Gaifullin AR, Potapova LI, Gubaidullina AM, Osin YN (2018) Marl-based geopolymers incorporated with limestone: A feasibility study. J Non-Cryst Solids 492:1–10

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no conflict of interest.

Rights and permissions

About this article

Cite this article

Rashad, A.M., Morsi, W.M. & Khafaga, S.A. Effect of limestone powder on mechanical strength, durability and drying shrinkage of alkali-activated slag pastes. Innov. Infrastruct. Solut. 6, 127 (2021). https://doi.org/10.1007/s41062-021-00496-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41062-021-00496-y