Abstract

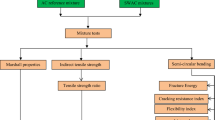

This paper presents the results of an experimental investigation carried out on warm mix asphalt (WMA) incorporated with copper slag (CS) and reclaimed asphalt pavement (RAP) material. Both CS and RAP are considered as waste materials and cause a lot of environmental problems. Their use in asphalt pavements will solve the landfill problems associated with them. Also, to save energy and reduce carbon emissions, WMA technology was adopted in this study. A total of nine combinations of warm mixes were prepared with varying proportions of CS (0–15%) and RAP (0–30%). The use of CS improved Marshall stability, indirect tensile strength, and tensile strength ratio. The introduction of CS and RAP produced a balanced mix as CS improved mechanical properties due to high angularity, density, and lime content. In contrast, RAP decreased these properties except the Marshall quotient and resilient modulus. All the RAP–CS WMA mixes satisfied the minimum value of stability (9 kN) as required for dense bituminous macadam. Furthermore, it was concluded that the mechanical properties of RAP–CS WMA mixes decreased with each freeze–thaw (F–T) cycle. The CS-incorporated mixes showed better resistance against F–T cycles.

Similar content being viewed by others

References

Fadhil T, Jasim S, Aziz K, Ahmed A (2013) Influence of using white cement kiln dust as a mineral filler on hot asphalt concrete mixture properties. Int J Civ Eng Technol 4:87–96

Karlheinz S, John T (2008) Mining and the environment: from ore to metal. CRC Press, Boca Raton

Al-Jabri KS, Taha RA, Al-Hashmi A, Al-Harthy AS (2006) Effect of copper slag and cement by-pass dust addition on mechanical properties of concrete. Constr Build Mater 20:322–331. https://doi.org/10.1016/j.conbuildmat.2005.01.020

Ziari H, Moniri A, Imaninasab R, Nakhaei M (2017) Effect of copper slag on performance of warm mix asphalt. Int J Pavement Eng 8436:1–7. https://doi.org/10.1080/10298436.2017.1339884

Ameri M, Hesami S, Goli H (2013) Laboratory evaluation of warm mix asphalt mixtures containing electric arc furnace (EAF) steel slag. Constr Build Mater 49:611–617. https://doi.org/10.1016/j.conbuildmat.2013.08.034

Celauro C, Bernardo C, Gabriele B (2010) Production of innovative, recycled and high-performance asphalt for road pavements. Resour Conserv Recycl 54:337–347. https://doi.org/10.1016/j.resconrec.2009.08.009

Kumar B (2013) Properties of pavement quality concrete and dry lean concrete with copper slag as fine aggregate. Int J Pavement Eng 14:746–751. https://doi.org/10.1080/10298436.2012.729059

Havanagi VG, Sinha AK, Ranjan A (2016) Fine copper slag as an alternative marginal material for road construction. Transp Res Board 44:25–33

Khanzadi M, Behnood A (2009) Mechanical properties of high-strength concrete incorporating copper slag as coarse aggregate. Constr Build Mater 23:2183–2188. https://doi.org/10.1016/j.conbuildmat.2008.12.005

Hassan HF, Al-jabri K (2011) Laboratory evaluation of hot-mix asphalt concrete containing copper slag aggregate. J Mater Civ Eng 23:879–885. https://doi.org/10.1061/(ASCE)MT.1943-5533.0000246

Recycled Materials Resource Centre (2008) User guidelines for by-products and secondary use of materials in pavement construction. Available at: http://rmrc.wisc.edu/ug-mat-nonferrous-slags/

Shi C, Meyer C, Behnood A (2008) Utilization of copper slag in cement and concrete. Resour Conserv Recycl 52:1115–1120. https://doi.org/10.1016/j.resconrec.2008.06.008

Mirhosseini SR, Fadaee M, Tabatabaei R, Fadaee MJ (2017) Mechanical properties of concrete with Sarcheshmeh mineral complex copper slag as a part of cementitious materials. Constr Build Mater 134:44–49. https://doi.org/10.1016/j.conbuildmat.2016.12.024

Gorai B, Jana RK, PREMCHAND (2003) Characteristics and utilisation of copper slag: a review. Resour Conserv Recycl 39:299–313. https://doi.org/10.1016/S0921-3449(02)00171-4

Mohi ud Din I, Mir MS (2019) Study of warm mix asphalt using reclaimed asphalt pavement and copper slag: a review. Can J Civ Eng. https://doi.org/10.1139/cjce-2019-0093

Farooq MA, Mir MS, Sharma A (2018) Laboratory study on use of RAP in WMA pavements using rejuvenator. Constr Build Mater 168:61–72. https://doi.org/10.1016/j.conbuildmat.2018.02.079

Tao M, Mallick R (2009) Effects of warm-mix asphalt additives on workability and mechanical properties of reclaimed asphalt pavement material. Transp Res Rec J Transp Res Board 2126:151–160. https://doi.org/10.3141/2126-18

Al-Qadi IL, Elseifi M, Carpenter SH (2007) Reclaimed asphalt pavement: a literature review. Civ Eng Stud 7:23

Alvarez C, Bonneau D, Dupriet S et al (2008) Very high recycling rate (> 50%) in hot mix and warm mix asphalts for sustainable road construction. In: Proceedings of the 4th Eurasphalt and Eurobitume congress held 2008, Copenhagen, Denmark

Miliutenko S, Björklund A, Carlsson A (2013) Opportunities for environmentally improved asphalt recycling: the example of Sweden. J Clean Prod 43:156–165. https://doi.org/10.1016/j.jclepro.2012.12.040

Zaumanis M (2010) Warm mix asphalt investigation. Master of Science thesis

Solaimanian M, Tahmoressi M (1996) Variability analysis of hot-mix asphalt concrete containing high percentage of reclaimed asphalt pavement. Transp Res Rec 1543:89–96. https://doi.org/10.3141/1543-11

Chiu CT, Hsu TH, Yang WF (2008) Life cycle assessment on using recycled materials for rehabilitating asphalt pavements. Resour Conserv Recycl 52:545–556. https://doi.org/10.1016/j.resconrec.2007.07.001

Hesami S, Roshani H, Hamedi GH, Azarhoosh A (2013) Evaluate the mechanism of the effect of hydrated lime on moisture damage of warm mix asphalt. Constr Build Mater 47:935–941. https://doi.org/10.1016/j.conbuildmat.2013.05.079

Gandhi TS, Amirkhanian SN (2007) Laboratory investigation of warm asphalt binder properties: a preliminary analysis. In: Fifth international conference on maintenance and rehabilitation of pavements and technological control (MAIREPAV5)

Hamzah MO, Jamshidi A, Kanitpong K, Aman MY (2012) Parameters to characterise the effects of Sasobit® content on the rheological properties of unaged and aged asphalt binders. Road Mater Pavement Des 13:368–375. https://doi.org/10.1080/14680629.2012.668836

Jamshidi A, Hamzah MO, You Z (2013) Performance of warm mix asphalt containing Sasobit®: state-of-the-art. Constr Build Mater 38:530–553. https://doi.org/10.1016/j.conbuildmat.2012.08.015

Topal A, Sengoz B, Kok BV et al (2014) Evaluation of mixture characteristics of warm mix asphalt involving natural and synthetic zeolite additives. Constr Build Mater 57:38–44. https://doi.org/10.1016/j.conbuildmat.2014.01.093

Ziari H, Moniri A, Ayazi MJ, Nakhaei M (2016) Investigation of rutting performance of WMA mixtures containing copper slag. Int J Transp Eng 3:227–235

ASTM D2172 (2017) Standard test methods for quantitative extraction of asphalt binder from asphalt mixtures

IS: 1206 Part-II & III (1978) Indian Standard methods for testing tar and bituminous materials: determination of viscosity

Capitão SD, Picado-Santos LG, Martinho F (2012) Pavement engineering materials: review on the use of warm-mix asphalt. Constr Build Mater 36:1016–1024. https://doi.org/10.1016/j.conbuildmat.2012.06.038

Tan YQ, Zhang L, Gong WQ, Guo M (2012) Investigation of the effects of wax additive on the properties of asphalt binder. Constr Build Mater 36:578–584. https://doi.org/10.1016/j.conbuildmat.2012.06.024

Shaw J (2007) TWG: warm mix asphalt, Hunt Val. MD Sasol Res. New Front

MORTH (2013) Specifications for road and bridge works. Indian Roads Congress

IRC:SP:101 (2014) Interim guidelines for warm mix asphalt. Indian Roads Congress

AASHTO T 245 (2015) Standard method of test for resistance to plastic flow of bituminous mixtures using Marshall apparatus

AASHTO T 283 (2014) Standard method of test for resistance of compacted asphalt mixtures to moisture-induced damage

Lavin P (2003) Asphalt pavements: a practical guide to design, production and maintenance for engineers and architects

AASHTO T 195 (2017) Standard method of test for determining degree of particle coating of asphalt mixtures

Hwang CL, Laiw JC (1989) Properties of concrete using copper slag as a substitute for fine aggregate. Spec Publ. https://doi.org/10.14359/1986

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mohi Ud Din, I., Mir, M.S. Laboratory study on the use of copper slag and RAP in WMA pavements. Innov. Infrastruct. Solut. 5, 35 (2020). https://doi.org/10.1007/s41062-020-0285-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41062-020-0285-1