Abstract

Waste containment facilities require liners and covers for safe waste disposal, which can be efficiently achieved using robust green technologies. In the present study, a systematic approach was adopted towards the development of reliable expansive soil geopolymers suitable for waste containment application. Various factors that influence geopolymerisation were considered including the precursor type (PT), precursor content, liquid alkali hydroxide type (LT), activator-to-precursor ratio (A/P) and method of preparation. Multiresponse optimisation for permeability, volumetric shrinkage and unconfined compressive strength was executed to achieve soil geopolymers that satisfy the regulatory requirement as hydraulic barrier materials. This was done using a robust experimental design and the utility concept to prescribe a framework for achieving reliable soil geopolymers. The results obtained show that significant interactions between the factors (PT × LT) and (PT × A/P) affected the response characteristics and consequently the soil geopolymer performance. The aptness of the multiresponse optimisation was confirmed at 95% confidence interval, which revealed that the developed soil geopolymers can be used in waste containment facility under certain conditions. Evidence of the geopolymerisation process was clarified using microstructural analyses. Scanning electron microscopy and energy-dispersive spectroscopy supported the formation of N–A–S–H and K–A–S–H gels. Moreover, diffraction patterns for new minerals such as muscovite and crystobalite were formed, with the disappearance of clay minerals. The presence of aluminosilicate gel binding systems was revealed by Fourier transform infrared spectroscopy. The participation of clay minerals in the geopolymerisation distinguishes the developed expansive soil geopolymer from the conventional geopolymers developed for concrete applications.

Similar content being viewed by others

References

Mukherjee K, Mishra AK (2019) Impact of glass fibre on hydromechanical behaviour of compacted sand–bentonite mixture for landfill application. Eur J Environ Civ Eng. https://doi.org/10.1080/19648189.2019.1572541

Naeini AS, Gholampoor N, Jahanfar MA (2017) Effect of leachate’s components on undrained shear strength of clay-bentonite liners. Eur J Environ Civ Eng 23:395–408

Ray S, Mishra AK, Kalamdhad AS (2020) Equilibrum, kinetic and hydraulic study of different Indian bentonites in presence of lead. Eur J Environ Civ Eng. https://doi.org/10.1080/19648189.2020.1754297

Bannour H, Barral C, Touze-Foltz N (2015) Altered geosynthetic clay liners: effect on the hydraulic performance of composite liners. Eur J Environ Civ Eng 19:1155–1176

Benson C, Wang X, Gassner F, Foo D (2008) Hydraulic conductivity of two geosynthetic clay liners permeated with an aluminum residue leachate. GeoAmericas 28:206–218

Benson CH, Oren AH, Gates WP (2010) Hydraulic conductivity of two geosynthetic clay liners permeated with a hyperalkaline solution. Geotext Geomembr 28:206–218

Jo H, Katsumi T, Benson C, Edil T (2001) Hydraulic conductivity and swelling of non-prehydrated GCLs permeated with single species salt solution. J Geotech Geoenviron Eng 127(7):557–567

Jo H, Benson CH, Shackelford CD, Lee J, Edil TB (2005) Long term hydraulic conductivity of a geosynthetic clay liner permeated with inorganic salt solutions. J Geotech Geoenviron Eng 131(4):405–417

Shackelford C, Sevick G, Eykholt G (2010) Hydraulic conductivity of geosynthetic clay liners to tailings impoundment solutions. Geotext Geomembr 28(2):206–218

Amadi AA, Alih CO (2017) Hydraulic conductivity of modified clay treated with CKD. Environ Geotech 6:26–33

Cokca E, Yilmaz Z (2004) Use of rubber and bentonite added fly ash as liner material. Waste Manag 24(2):153–164

Benson CH, Chen JN, Edil TB, Likos WJ (2018) Hydraulic conductivity of compacted soil liners permeated with coal combustion product leachates. J Geotech Geoenviron Eng 144(4):04018011

Daniel DE, Wu YK (1993) Compacted clay liners and covers for arid sites. J Geotech Eng 119:223–237

Federal Register (2015) Hazardous and solid waste management system: disposal of coal combustion residuals from electric utilities; final rules and regulations. Fed Regist 80(74):21302–21501

Gleason MH, Daniel DE, Eykholt GR (1997) Calcium and sodium bentonite for hydraulic containment applications. J Geotech Geoenviron Eng 123(5):438–445

Osinubi KJ (2006) Influence of compactive effort on lime-slag treated tropical black clay. J Mater Civ Eng 18(2):175–181

James AN, Fullerton D, Drake R (1997) Field performance of GCL under ion exchange conditions. J Geotech Geoenviron Eng 123:897–901

Petrov RJ, Rowe RK, Quigley RM (1997) Selected factors influencing GCL hydraulic conductivity. J Geotech Geoenviron Eng 123:683–695

Ruhl J, Daniel DE (1997) Geosynthetic clay liners permeated with chemical solutions and leachates. J Geotech Geoenviron Eng 123:369–381

Shan HY, Lai YJ (2002) Effect of hydrating liquid on the hydraulic properties of geosynthetic clay liners. Geotext Geomembr 20:19–38

Bonaparte R, Daniel D, Koerner R (2002) Assessment and recommendation for improving the performance of containment systems. Office of Research and Development, US Environmental Protection Agency, Washington, DC

Bouazza A (2002) Geosynthetic clay liners. Geotext Geomembr 20:3–17

Hewitt R, Daniel D (1997) Hydraulic conductivity of geosynthetic clay liners after freeze-thaw. J Geotech Geoenviron Eng 123(4):305–313

Daniel DE, Koerner R, Bonaparte R, Landreth R, Carson D, Scranton H (1998) Slope stability of geosynthetic clay liner test plots. J Geotech Geoenviron Eng 124(7):628–632

Kraus J, Benson CH, Erickson A, Chamberlain E (1997) Freeze-thaw and hydraulic conductivity of bentonite barriers. J Geotech Geoenviron Eng 123(3):229–238

Kashir M, Yanful E (2001) Hydraulic conductivity of bentonite permeated with acid mine drainage. Can Geotech J 38:1034–1048

Lange K, Rowe RK, Jamieson H (2007) Metal retention in geosynthetic clay liners following permeation by different minning solutions. Geosynth Int 14(3):178–187

Ackroyd L, Husain R (1986) Residual and lacustrine black cotton cotton soils of north-east Nigeria. Geotechnique 36(1):113–118

Ikeagwuani CC, Nwonu DC (2019) Emerging trends in expansive soil stabilisation: a review. J Rock Mech Geotech Eng 11:423–440

Nelson JD, Miller DJ (1992) Expansive soil: problems and practice in foundation and pavement engineering. Wiley, New York

Osinubi KJ, Nwaiwu CM (2006) Design of compacted lateritic soil liners and covers. J Geotech Geoenviron Eng 132:203–213

Oriola FO, Moses G (2011) Compacted black cotton soil treated with cement kiln dust as hydraulic barrier material. Am J Sci Ind Res 2(4):521–530

Amnadnua K, Tangchirapat W, Jaturapitakkul C (2013) Strength, water permeability, and heat evolution of high strength concrete made from the mixture of calcium carbide residue and fly ash. Mater Des 51:894–901

Arulrajah A, Kua TA, Phetchuay C, Horpibulsuk S, Mahghoolpilehrood F, Disfani MM (2016) Spent coffee grounds-flyash geopolymer used as an embankment structural fill material. J Mater Civ Eng 28(5):04015197

Bagheri A, Nazari A (2014) Compressive strength of high strength class C fly ash-based geopolymers with reactive granulated blast furnace slag aggregates designed by taguchi method. Mater Des 54:483–490

Cheng TW, Chiu JP (2003) Fire-resistant geopolymer produced by granulated blast furnace slag. Mater Eng 16(3):205–210

Duxson P, Provis JL, Lukey GC, Deventer JS (2007) The role of inorganic polymer technology in the development of “green concrete.” Cem Concr Res 37(12):1590–1597

El Idrissi AC (2019) The development of a global mix design and analysis approach for alkali activated soil reinforcement grouts. Eur J Environ Civ Eng 23(5):645–656

Hoy M, Rachan R, Horpibulsuk S, Arulrajah A, Mirzababaei M (2017) Effect of wetting–drying cycles on compressive strength and microstructure of recycled asphalt pavement–fly ash geopolymer. Constr Build Mater 144:624–634

Lee WK, Van Deventer JS (2002) The effects of inorganic salt contamination on the strength and durability of geopolymers. Colloids Surf A Physicochem Eng Asp 211:115–126

Sarkar PK, Kelly S, Yao Z (2014) Effect of fire exposure on cracking, spalling and residual strength of fly ash geopolymer concrete. Mater Des 63:584–592

Sukmak P, De Silva P, Horpibulsuk S, Chindaprasirt P (2015) Sulfate resistance of clay-portland cement and clay high-calcium fly ash geopolymer. J Mater Civ Eng 27(5):04014158

Sharma K, Kumar A (2020) Utilization of industrial waste-based geopolymers as a soil stabilizer-a review. Innov Infrastruct Solut 5:1–20

Rios S, Ramos C, da Fonseca AV, Cruz N, Rodrigues C (2017) Mechanical and durability properties of a soil stabilised with an alkali-activated cement. Eur J Environ Civ Eng 23(4):1–23

Murmu AL, Dhole N, Patel A (2018) Stabilisation of black cotton soil for subgrade application using fly ash geopolymer. Road Mater Pavement Des 21:867–885

Murmu AL, Jain A, Patel A (2019) Mechanical properties of alkali activated fly ash geopolymer stabilized expansive clay. KSCE J Civ Eng 23(9):3875–3888

Kumar P, Devendra S (2019) Effect of molarity of geopolymer on cement kiln dust and unground cement clinker admixed black cotton soil. In: Geo-congress 2019 GSP 309

Parhi PS, Garanayak L, Mahamaya M, Das SK (2018) Stabilization of an expansive soil using alkali activated fly ash based geopolymer. In: Hoyos LR, McCartney J (eds) Advances in characterization and analysis of expansive soils and rocks, Sustainable civil infrastructures. Springer, Berlin, pp 36–50

Phetchuay C, Horpibulsuk S, Arulrajah A, Suksirirpattanapong C, Udomchai A (2016) Strength development in soft marine clay stabilized by fly ash and calcium carbide residue based geopolymer. Appl Clay Sci 127–128:134–142

Sukmak P, Sukmak G, Horpibulsuk S, Setkit M, Kassawat S, Arulrajah A (2019) Palm oil fuel ash–soft soil geopolymer for subgrade applications: strength and microstructural evaluation. Road Mater Pavement Des 20(1):110–131

Yaghoubi M, Arulrajah A, Disfani MM, Horpibulsuk S, Bo WM, Darmawan S (2018) Effects of industrial by-product based geopolymers on the strength developemnt of a soft soil. Soils Found 58:716–728

Yaghoubi M, Arulrajah A, Disfani MM, Horpibulsuk S, Darmawan S, Wang J (2019) Impact of field conditions on the strength development of a geopolymer stabilized marine clay. Appl Clay Sci 167:33–42

Yao J, Qui H, He H, Chen X, Hao G (2020) Experimental research and application of geopolymer in soft soil foundation treatment. In: Tatsouka F, Guler E, Shehata H, Giroud JP (eds) Innovative infrastructure solutions using geosynthetics. Springer, Cham, pp 82–94

Du YJ, Yu BW, Liu K, Jiang NJ, Liu MD (2017) Physical, hydraulic and mechanical properties of clayey soil stabilized by lightweight alkali-activated slag geopolymer. J Mater Civ Eng 29(2):04016217

Nazari A, Khanmohammadi H, Amini M, Hajiallahyari H, Rahimi A (2012) Production geopolymers by portland cement: designing the main parameters’ effects on compressive strength by Taguchi method. Mater Des 41:43–49

Olivia M, Nikraz H (2012) Properties of fly ash geopolymer concrete designed by Taguchi method. Mater Des 36:191–198

Riahi S, Nazari A (2012) The effects of nanoparticles on early age compressive strength of ash-based geopolymers. Ceram Int 38:4467–4476

Derek WB (1982) Analysis for optimal decisions. Wiley, New York

Bosser JL (1991) Quality function deployment—a practioner approach. Marcel Dekker, New Delhi

BS 1377 (1990) Method of testing soils for civil engineering purposes. British Standard Institution, London

Diop MB, Grutzeck MW, Molez L (2011) Comparing the performances of brick made with natural clay and clay activated by calcination and addition of sodium silicate. Appl Clay Sci 54(2):172–178

Teerawattanasuk C, Voottipruex P (2018) Comparison between cement and fly ash geopolymer for stabilized marginal lateritic soil as road material. Int J Pavement Eng 20:1–11

Nwonu DC (2020) Development and application of expansive soil geopolymer binders. Unpublished MEng. Thesis, University of Nigeria Nsukka, Nsukka

Leong HY, Ong DL, Sanjayan JG, Nazari A (2018) Strength development of soil–fly ash geopolymer: assessment of soil, flyash, alkali activators, and water. J Mater Civ Eng 30(8):04018171

Roy RK (1990) A primer on Taguchi method. Van Nostrand Reinhold, New York

Roy RK (2001) Design of experiments using the Taguchi approach; 16 steps to product and process improvement. Wiley, New York

Head KH (1994) Manual of soil laboratory testing, vol 2. Pentech, London

Amadi AA, Eberemu AO (2012) Delineation of compaction criteria for acceptable hydraulic conductivity of lateritic soil–bentonite mixtures designed as landfill liners. Environ Earth Sci 67(4):999–1006

Phadke MS (1989) Quality engineering using robust design. P T R Prentice-Hall Inc, New Jersey

Kumar P, Barua PB, Gaindhar JL (2000) Quality optimization (multi-characteristics) through Taguchi’s technique and utility concept. Qual Reliab Eng Int 16:475–485

Walia RS, Shan SH, Kumar P (2006) Multi-response optimization of CFAAFM process through Taguchi method and utility concept. Mater Manuf Process 21(8):907–914

Gupta V, Murthy PN (1982) An introduction to engineering design methods. Tata McGraw-IEII, New Delhi

Kumar Y, Singh H (2014) Multi-response optimization in dry turning process using Taguchi’s approach and utility concept. Proceedia Mater Sci 5:2142–2151

Ikeagwuani CC, Nwonu DC (2020) Model performance assessment in resilient modulus modelling: a multimodel approach. Road Mater Pavement Des. https://doi.org/10.1080/14680629.2020.1753100

Rawlings JO, Pantula SG, Dickey DA (1998) Applied regression analysis: a research tool. Springer, New York

Cioffi R, Maffucci L, Santoro L (2003) Optimization of geopolymer synthesis by calcination and polycondensation of a kaolinitic residue. Resour Conserv Recycl 40:27–38

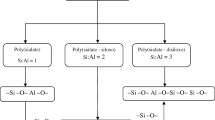

Davidovits J (1991) Geopolymers. J Therm Anal 37(8):1633–1656

Duxson P, Provis JL, Lukey GC, Mallicoat SW, Kriven WM, Van Deventer JS (2005) Understanding the relationship between geopolymer composition, microstructure and mechanical properties. Colloids Surf A Physicochem Eng Asp 269(1–3):47–58

Kriven WM, Bell JL (2004) Effect of alkali choice on geopolymer properties. Ceram Eng Sci Proc 25(4):99–104

Xu H, Van Deventer J (2000) The geopolymerisation of alumino-silicate minerals. Int J Miner Process 59:247–266

Nwonu DC, Ikeagwuani CC (2019) Evaluating the effect of agro-based admixture on lime-treated expansive soil for subgrade material. Int J Pavement Eng. https://doi.org/10.1080/10298436.2019.1703979

Nwonu DC, Ikeagwuani CC (2020) Microdust effect on the physical condition and microstructure of tropical black clay. Int J Pavement Res Technol. https://doi.org/10.1007/s42947-020-0004-5

Sukprasert S, Hoy M, Horpibulsuk S, Arulrajah A, Rashid AS, Nazir R (2019) Fly ash based geopolymer stabilisation of silty clay/blast furnace slag for subgrade applications. Road Mater Pavement Des. https://doi.org/10.1080/14680629.2019.1621190

Bakharev T (2005) Geopolymeric materials prepared using Class F fly ash and elevated temperature curing. Cem Concr Res 35:1224–1232

Davidovits J (1982) Mineral polymers and methods of making them. USA Patent 4, 349 and 386

Antohi-Trandafir O, Timar-Gabor A, Vulpoi A, Balc R, Longman J, Veres D, Simon S (2018) Luminiscence properties of natural muscovite relevant to optical dating of contaminated quartz samples. Radiat Measur 109:1–7

Gutierrez-Castorena MC (2018) Pedogenic siliceous features. In: Stoops G, Marcelino V, Mees F (eds) Interpretation of micromorphological features of soils and regoliths. Elsevier, Amsterdam, pp 127–155

Zhang Z, Wang H, Provis JL (2012) Quantitative study of the reactivity of fly ash in geopolymerization by FTIR. J Sustain Cem Based Mater 1(4):154–166

Criado M, Palomo A, Fernandez-Jimenez A (2005) Alkai activation of fly ashes. Part 1: effect of curing conditions on the carbonation of the reaction products. Fuel 84:2048–2054

Sharma LK, Sirdesai NN, Sharma KM, Singh TN (2017) Experimental study to examine the independent roles of lime and cement on the stabilization of a mountain soil. Appl Clay Sci 152:183–195

Etim KR, Attah IC, Yohanna P (2020) Experimental study on potential of oyster shell ash in structural strength improvement of lateritic soil for road construction. Int J Pavement Res Technol 13:341–351

Guo X, Wu Y (2017) Characterizing molecular structure of water adsorbed by cellulose nanofiber film using in situ micro-FTIR spectroscopy. J Wood Chem Technol 37:383–392

Nenadovic SS, Kljajevic LM, Nesic MA, Petkivic MZ, Trivunac KV, Pavlovic VB (2017) Structure analysis of geopolymers synthesized from clay originated from Serbia. Environ Earth Sci 76:79

Pourakbar S, Asadi A, Huat BK, Cristelo N, Fasihnikoutalab MH (2016) Application of alkai-activated agro-waste reinforced with Wallastonite fibers in soil stabilization. J Mater Civ Eng 29(2):04016206

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest related to this research.

Rights and permissions

About this article

Cite this article

Agunwamba, J.C., Onyia, M.E. & Nwonu, D.C. Development of expansive soil geopolymer binders for use in waste containment facility. Innov. Infrastruct. Solut. 6, 32 (2021). https://doi.org/10.1007/s41062-020-00400-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41062-020-00400-0