Abstract

In the present study, the behavior of saturated clays while they are mechanically loaded under constant temperatures has been investigated by simulating thermal triaxial test. A critical state-based thermo-mechanical constitutive model has been added to the ABAQUS finite element (FE) software through a user subroutine to define the stress–strain, volume change and pore pressure behavior of saturated clays. In order to have better predictions by the numerical implemented model, it has been changed by defining a new plastic potential function similar to its yield surface. The model has been integrated via an explicit integration scheme. Verification of the discretized axisymmetric numerical model has been carried out by three different series of triaxial tests for both drained and undrained conditions, and the experimental results were compared with numerical simulations. According to these comparisons, the adopted numerical model is able to predict the results of thermal triaxial tests on saturated normally consolidated and overconsolidated clays in a good manner. The presented methodology is general and can be used for application of any other critical state-based thermal constitutive model in a FE program. Based on the results, it can be suggested to be implemented in similar thermal boundary value problems of geotechnical engineering.

Similar content being viewed by others

References

Venkateshan SP, Swaminathan P (2014) Computational methods in engineering, 1st edn. Elsevier, Amsterdam

Puzrin AM (2012) Constitutive modelling in geomechanics, 2nd edn. Springer, Berlin

Campanella RG, Mitchell JK (1968) Influence of temperature variations on soil behavior. J Soil Mech Found Div 94(3):709–734

Hueckel T, Borsetto M, Peano A (1987) Modelling of coupled thermos, elastoplastic, hydraulic response of clays subjected to nuclear waste heat. In: Lewis W, Hinton E, Bettess P, Schrefler BA (eds) Proceedings of numerical methods in transient and coupled problems. Wiley, Chichester, pp 213–235

Baldi G, Hueckel T, Pellegrini R (1988) Thermal volume changes of mineral-water system in low-porosity clay soils. Can Geotech J 25(4):807–825

Hueckel T, Borsetto M (1990) Thermoplasticity of saturated soils and shales: constitutive equations. J Geotech Eng 116:1765–1777

Hueckel T, Pellegrini R (1992) Thermo-plastic modelling of untrained failure of saturated clay due to heating. Soils Found 31:1–16

Roscoe K, Burland J (1968) On the generalized stress-strain behaviour of wet clay. In: Heyman J, Leckie FA (eds) Engineering Plasticity. Cambridge University Press, Cambridge, pp 535–609

Yao YP, Zhou AN (2013) Non-isothermal unified hardening model: a thermo-elasto plastic model for clays. Géotechnique 63(15):1328–1345

Hong PY, Pereira JM, Cui YJ, Tang AM (2015) A two-surface thermomechanical model for saturated clays. Int J Numer Anal Methods Geomech 40(7):1059–1080

Wang LZ, Wang KJ, Hong Y (2016) Modeling temperature-dependent behavior of soft clay. J Eng Mech 142(8):1. https://doi.org/10.1061/(ASCE)EM.1943-7889.0001108

Abuel-Naga HM, Bergado DT, Bouazza A, Pender M (2009) Thermomechanical model for saturated clays. Géotechnique 59:273–278

Hamidi A, Khazaei C (2010) A thermo-mechanical constitutive model for saturated clays. Int J Geotech Eng 4(4):445–459

Hamidi A, Tourchi S, Khazaei C (2015) Thermomechanical constitutive model for saturated clays based on critical state theory. Int J Geomech 15(1):1. https://doi.org/10.1061/(ASCE)GM.1943-5622.0000402

Hamidi A, Tourchi S, Kardooni F (2017) A critical state based thermo-elasto-plastic constitutive model for structured clays. J Rock Mech Geotech Eng 9(6):1094–1103

Golchin A, Vardon PJ, Hicks MA (2019) A thermodynamically based thermo-mechanical model for fine-grained soils. In: XVII European conference on soil mechanics and geotechnical engineering (ECSMGE-2019), Reykjavik, Iceland

Xiong Y, Yang Q, Sang Q, Zhu Y, Zhang S, Zheng R (2019) A unified thermal-hardening and thermal-softening constitutive model of soils. Appl Math Model 74:73–84

Tourchi S, Hamidi A (2015) Thermo-mechanical constitutive modeling of unsaturated clays based on the critical state concepts. J Rock Mech Geotech Eng 7(2):193–198

Hamidi A, Tourchi S (2018) A thermomechanical constitutive model for unsaturated clays. Int J Geotech Eng 12(2):185–199

Bellia Z, Ghembaza MS, Belal T (2015) A thermo-hydro-mechanical model of unsaturated soils based on bounding surface plasticity. Comp Geotech 69:58–69

Kurz D, Sharma J, Alfaro M, Graham J (2016) Semi-empirical elastic-thermoviscoplastic model for clay. Can Geotech J 53:1583–1599

Wang K, Wang L, Hong Y (2020) Modelling thermo-elastic–viscoplastic behavior of marine clay. Acta Geotech. https://doi.org/10.1007/s11440-020-00917-9

Hamidi A (2020) A novel elasto-thermo-viscoplastic model for the isotropic compression of structured clays. J Hazard Tox Radioact Waste 24(4):1. https://doi.org/10.1061/(ASCE)HZ.2153-5515.0000528

Olivella S, Gens A, Carrera J, Alonso EE (1996) Numerical formulation for a simulator (CODE_BRIGHT) for the coupled analysis of saline media. Eng Comput 13(7):87–112

Sánchez M, Gens A (2014) Modelling and interpretation of the FEBEX mock up test and of the long-term THM tests. EU project: Long-term performance of engineered barrier systems PEBS: Deliverable D3.3-3, European Commission

Cui W, Potts DM, Zdravković L, Gawecka KA, Taborda DMG (2018) An alternative coupled thermo-hydro-mechanical finite element formulation for fully saturated soils. Comp Geotech 94:22–30

Abaqus 6.13 (2013) CAE User’s guide. SIMULIA, Providence

Helwany S (2007) Applied soil mechanics: with ABAQUS applications, 1st edn. Wiley, Hoboken

Ottosen NS, Ristinmaa M (2005) The mechanics of constitutive modeling. Elsevier, Amsterdam

Tian H (2013) Development of a thermo-mechanical model for rocks exposed to high temperatures during underground coal gasification. PhD Thesis, RWTH Aachen University, Aachen, Germany

Saggu R, Chakraborty T (2016) Thermomechanical response of geothermal energy pile groups in sand. Int J Geomech 16(4):1. https://doi.org/10.1061/(ASCE)GM.1943-5622.0000567

Wood DM (1990) Soil behavior and critical state soil mechanics. Cambridge University Press, New York

Liu EL, Xing HL (2009) A double hardening thermo-mechanical constitutive model for overconsolidated clays. Acta Geotech 4:1–6

Dunne F, Petrinic N (2005) Introduction to computational plasticity. Oxford University Press, New York

Hashiguchi K (2014) Elastoplasticity Theory, 2nd edn. Springer, Berlin

Ghahremannejad B (2003) Thermo-mechanical behavior of two reconstituted clays. PhD Thesis, University of Sydney, Sydney, Australia

Cekerevac C, Laloui L (2004) Experimental study of thermal effects on the mechanical behavior of a clay. Int J Numer Anal Methods Geomech 28:209–228

Uchaipichat A, Khalili N (2009) Experimental investigation of thermo-hydro-mechanical behavior of an unsaturated silt. Géotechnique 59(4):339–353

Borja RI, Tamagnini C, Amorosi A (1997) Coupling plasticity and energy-conserving elasticity models for clays. J Geotech Geoenv Eng 123(10):948–957

Lashkari A, Mahboubi M (2015) Use of hyper-elasticity in anisotropic clay plasticity models. Scientia Iranica 22(5):1643–1660

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

Constitutive model parameters

As it was pointed out in the text, additional parameters of the model are discussed here. The slopes of NCL and URL are represented by λ and κ, respectively. Also, C shows how κ is affected by temperature variations and is calculated through Eq. (18).

The slope of critical state line in q-\(p^{\prime}\) space (\({\rm M}_{T}\)) is possible to be considered as temperature dependent or independent based on the following group of equations according to ξ values.

The shear modulus \(G_{T}\) is considered temperature-dependent by applying D, which is the slope of linear regression line given by Eq. (20).

Modification of the void ratio in relation to temperature changes is taken into account by \(\chi\) which is introduced by Eq. (21).

Derivation of the model equations

The elastic stiffness matrix \(\left[ {D^{el} } \right]\) is considered based on Eq. (22).

The hardening parameter in the yield surface is a function of plastic volumetric strain. Utilizing the chain rule, derivation of the yield surface with respect to volumetric strain is in the form of Eqs. (23)–(26).

In Eq. (26), \(\psi\) can be defined as the ratio of plastic volumetric strain (\(d\varepsilon_{v}^{p}\)) to the plastic shear strain (\(d\varepsilon_{s}^{p}\)) or \(\psi = {{d\varepsilon_{v}^{p} } \mathord{\left/ {\vphantom {{d\varepsilon_{v}^{p} } {d\varepsilon_{s}^{p} }}} \right. \kern-0pt} {d\varepsilon_{s}^{p} }}\). Variations of hardening parameter with respect to plastic volumetric strain can be determined based on Eq. (10).

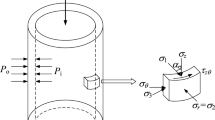

The mean effective stress (\(p^{\prime}\)) and deviatoric stress (\(q\)) are defined based on Eqs. (28) and (29), respectively.

Deviations of the yield and plastic potential surfaces with respect to principal stresses can be determined based on Eqs. (30)–(41).

Rights and permissions

About this article

Cite this article

Ashrafi, M.S., Hamidi, A. Application of a thermo-elastoplastic constitutive model for numerical modeling of thermal triaxial tests on saturated clays. Innov. Infrastruct. Solut. 5, 81 (2020). https://doi.org/10.1007/s41062-020-00330-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41062-020-00330-x