Abstract

In France, about 450 km of high-speed lines (HSL) are potentially subject to drain scaling problem. A HSL site affected by calcite scaling was continuously monitored for 20 months to follow the phenomenon and also to estimate the monthly calcite precipitation rate. Drain water samples were also monthly analyzed and show high calcium and sulphate concentrations. The high sulphate concentration (~6 mM) highlights the dissolution of gypsum in the drain environment. Based on the material analysis (X-ray diffraction), gypsum is present in the subballast and capping layer. Since the drain system is a multi-environments system, and based on multi-phase reactions, the study is divided into two parts: a physical one (transport of water in the system) and a chemical one (transport of the reactants in the system). The physical processes have an essential impact on the chemical precipitation processes. In the present paper, on the basis of the collected data, the physical behaviour of the experimental site (water circulation) will be presented in the first step and used in the further chemical process study. The monthly calcite precipitation rate and quantities are given as well.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Today, more than 34,000 Km of rail lines have been laid in France, including 6% of high-speed lines (HSL). A safe railway network should be always guaranteed in priority, even facing both the requirements of increasing train speed and of saving annual operation costs. However, the presence of water in the track foundation due to drainage malfunction may lead to a significant loss of its mechanical properties, which will result in rail deformation. The drainage malfunction linked to scaling and clogging is the most common reason of the presence of water inside of the track foundations. In France, up to 450 km of HSL are potentially affected by these phenomena [10].

On one side, the drain maintenance cost is heavy, for example, cleaning one kilometre drain by the high-pressure water jetting requires at least four people working during four nights. This also needs the circulation interruption which leads to a cost more than 30 k€ per kilometre. On the other side, the existing maintenance technologies are partly inefficient. In order to develop new maintenance technologies and strategies as well as to design new drain systems which are more resistant to calcite clogging, the study of the calcite precipitation process and the causes under the railway infrastructure context are necessary and meaningful.

The HSL drain system and the scaling clogging issues

The track foundation (Fig. 1a) was realized according to the construction standard of SNCF (La Société nationale des chemins de fer français). Generally, the ballasted track is realised on a foundation which consists of the two following layers with their own geotechnical roles and properties: the high-compacted subballast layer (28 cm) and the well-compacted capping layer (45 cm). This foundation is based on a lime-treated subgrade layer (upper earthmoving part: 1 m) which is treated by adding 1 or 2% lime to improve the soil mechanical characteristics. This treated layer is the transition between the track foundation and the in situ soil.

The drain system which is generally clogged by the calcite precipitation is shown in Fig. 1a. The underground drain is located along the tracks, at a depth of 1.5 m. The drain is supported by a concrete candle, and the water inlets are covered by clean washed gravel. Water comes through the 2-mm-wide slots which were opened every 10 cm along the drain. The drain collects water eventually present into the track foundation. The calcite usually precipitates around the slots, as well as at the bottom along the drain (see Fig. 1a).

Obviously, the system (Fig. 1b), which is involved in the infrastructural drain calcite clogging, is a multi-environment one which includes the soil and drain, and multi-phase one among the liquids (rain/drain water), solids (soil/deposit) and gas (CO2). The processes can be divided into two sub-processes: the physical processes of the water transport (Q i) through the multi-environments and the chemical processes of transport-reaction which lead to calcite precipitations (C i) among the multi-phases. In a first approach we do not consider the consequences of clogging on the water drainage. As a consequence the physical subsystem dominates the chemical one and this paper is focused on the dynamics of water and its consequences on calcite precipitation.

Many investigations on the drain scaling (deposits of CaCO3, or CaSO4, or CaSiO3, or SiO2 or their mixtures) issues are carried out in the field of agriculture [5] and of tunnels [3, 6]. They are the most similar ones to be compared to the one presented in this paper at the point of either a similar drain type or of the comparable drain environment context. Most of these studies are based on analyses of single sample or series of water and deposits and use an isotopic approach to determine the origin of the reactants. Neither was the seasonal phenomenon evolution studied, nor the small time- and space-scale analysis of the processes in relation, for instance, with the rain events. As a matter of fact, the dynamics of the scaling in relation with the forcing variables could only be superficially discussed in these works.

However, the rainfall-induced runoff and infiltration can play a major role at short time steps [9–11]. For this reason, this paper is focused on (i) the description of a monitoring strategy which enables such a short-term analysis of the physical processes as well as of calcite precipitation (quantities and rates), (ii) the analysis of the data collected and (iii) the development of a conceptual model based on the physical–chemical model of calcite precipitation.

Materials and methods

As widely known, drain scaling is caused by the calcite precipitation (Eq. 1):

The following variables are necessary to analyse the calcite precipitation process: pH, partial air pressure of CO2 (PCO2), dissolved CO2, alkalinity and major ions such as calcium, magnesium, potassium, sodium, nitrate, chlorate and sulphate. They are the state variables of our system, when its forcing variables are related to meteorology like rain (rainfall intensity, duration and nature) and water temperature, the CO2 concentration in atmosphere and the soil condition such as its nature and permeability.

The monitored site (Chauconin) and the drain

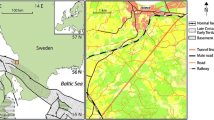

In order to analyse the drain scaling processes caused by the calcite precipitation, an HSL drain where calcite precipitation occurs is investigated and monitored. The monitored site (Chauconin, Fig. 2a) is located on the high-speed line which links Paris to Strasbourg, about 20 km North-East of Paris. The underground drain is located along the circulation tracks (dotted blue line, Fig. 2b) and clogged by calcite. More precisely, the drain is installed between the concrete circulation track which links Strasbourg to Paris and a ballasted train storage track. The drain is 1030 m long (Fig. 3), alternatively passing through soil cutting and backfill line sections. The accessible drain is 800 m long with nine manholes (named from S1 to S9, see Fig. 6) and one outlet (noted S10). The 1-m diameter manholes are located every 80 m at the depth of 1–2 m. The 40-cm-wide drain is made of high-density polyethylene with 2-mm-wide slots.

Geological/hydrogeological context and water table monitoring

Based on the longitudinal profile (Fig. 3, SNCF 2003) of HSL, soil and drain positions, the upper natural soil (first 20 m) consists of two layers: silt and limestone. The upper silt layer thickness varies from 2 to 4 m; and the bottom limestone layer thickness varies from 8 to 15 m. The silt layer generally has a weak permeability. It could sometimes contain a perched water table. The limestone layer is a mixture of marl and limestone and the regional groundwater level which was verified every 50 m along the axe of tracks was always located near the interface of silt and limestone (green triangles in Fig. 3) according to the investigation done in summer of 2003 before line construction. However, the annual records of the regional ground water table observed in limestone layer indicated that it could decline by 3–4 m between winter and summer in 2013/2014 [9]. The high water table observed during summer in 2003 is observed in winter of 2013. After the verification of the rainfall in 2003 and 2013, this shift of the yearly highest water table between summer and winter is linked to the shift of the annual rain season. In 2003, during May, June, July and August, the rain precipitated about 350 mm, nearly half of the annual precipitation. However, this heavy rainfall occurred in winter of 2013.

Compared to the observed seasonal dynamic of the regional water table which is linked to the regional rainfall, the behaviour of the local platform groundwater nearby the drain study section is unknown. Thus, the supplementary piezometers are realized in 2013 at the position of the five boreholes of soil investigation (noted P1 to P5, positions seen in Figs. 3, 4 and 6). The local water tables are followed continuously (every 15 min) by the sensor (min-diver, characteristics noted in Table 1) after the conduction of these 5 boreholes.

Hydrology context and rainfall-flow monitoring

According to drain conception, the regional surface catchment area (estimated by the software “iRIP” developed by SNCF engineering) linked to the drain study section is drawn in Fig. 4a, with a surface area of about 16 km2. Two creeks flow across the target drain section: one is nearby the kilometre point of 19 and the other is nearby 20. These two creeks cut off the surface connection between the local groundwater (around the P1, P2) and the regional groundwater (P5). However, after a local topography investigated in April, 2014 around the target drain, the local catchment area is estimated between the axe of circulation track and the one of the service platform. The surface is about 8600 m2 (Fig. 4b), much smaller. The verification of the local water balance of the rainfall (volume-in) and the drain flow (volume-out) is necessary to confirm the real catchment area around the study drains section. In order to obtain the local water balance, a rain gauge (Ref: SDEC watchdog120, Table 1; Fig. 6) was installed in March 2014 nearby to the outlet to record the rainfall every 5 min. The drain flow has been monitored every 5 min at the drain outlet since June 2014 (Table 1; Fig. 6).

Drain status before/after the high-pressure water cleaning

All before the drain monitoring, in January 2014, 8 years after line construction, a high-pressure water cleaning operation which aims for unclogging the drain’s inlet was realized. After removing the cumulated calcite, it is assumed that water circulation is not modified by chemically induced obstacles and is dominant since water chemistry depends on water dynamics. More specifically, in the absence of clogging at the water inlets, reactant transport depends strongly on water transport. Monitoring the whole calcite precipitation processes from the beginning becomes feasible thanks to this drain cleaning. A video inspector passed all along the drain to check the clogging–unclogging status of the drain water inlet before and after the drain cleaning. Photos are shown in Fig. 5. The thickness of the calcite accumulated at the bottom of the drain in each manhole (S1 to S9, Fig. 6) was measured. It varies from 5 to 25 cm. This heterogeneous calcite thickness throughout the drain highlights the potential drain inside forcing variables, such as the micro barrage due to the drain joints [7].

Drain flow and water chemistry monitoring

After the drain was cleaned, the camera inspection confirmed the absence of obstacles to water circulation near the drain water inlets. Then, the drain flow and water chemistry were monitored by progressively installing four physical–chemical sensors on the test site between March and June, 2014. Those four sensors record mainly the following five parameters: pH, temperature (T °C), conductivity (σ), PCO2 and dissolved CO2. Their positions are shown in Fig. 6. The drain flow is monitored at the drain outlet (S10, Fig. 6). All the chemical sensors are monitored in the last manhole (S9, Fig. 6) where the water height is enough to cover the detectors. The main characteristics of the sensors such as the measured frequency and duration are listed in Table 1. Based on seasonal site visits, the water height at the drain outlet is usually lower than 1 cm compared to its large diameter of 50 cm. On considering that there is not enough water to immerge the flowmeter, the system of v-notch weir (45°) combined to an ultrasonic sensor (Ref: Nivus-NMI00310000000H, Table 1) is used. This v-notch system measures the discharged water height (H dis) over the weir. The continuous H dis data are transformed to the flow by using the KINDSVATER V-Notch Weir Equation every 5 min. This equation is largely recommended for the rectangular channel flow study by the International Organization for Standardization (ISO 1438-1) [8]. However, for this case study, since the drain cross section is circular, the equation was corrected by the in situ calibration.

Geotechnical context

During the five boreholes operation, drain environment soil and construction materials were sampled and analysed at the laboratory. Their mineral compositions are analysed by X-ray diffraction (Bruke—AXS D8 Advance XRD). The carbonates fractions are tested by the acid titration. According to the analysis results listed in Table 2, the clean washed gravel is mainly calcite with 10% (mass) of quartz. It showed a high permeability of 10−4 m/s compared to the compacted platform materials of 10−7 m/s (Internal documents of SNCF, 2003). The sub-ballast layer and capping layer have the same composition. They are rich in carbonates (80% of calcite and dolomite on mass). Meanwhile, gypsum (<20%) was also detected in those materials. The 2% lime-treated silt layer contains only 10% carbonate fraction. It is mainly a mixture of clay fraction and quartz. This layer is considered as an impermeable layer since its permeability is around 10−10 m/s (Table 2; Fig. 7). The natural soil of silt shows similar compositions compared to the treated silt layer, but slightly less carbonated (8%). However, the natural limestone layer is rich in carbonates (45%). It is a mixture of clay, quartz and carbonates fractions.

Site experiment

The monthly calcite precipitation rate was estimated by hanging the thin glass slices (H × W × L = 0.1 × 2.6 × 7.6 cm) into the drain water. The total surface that could be used for the calcite precipitation is 41.56 cm2. The photo in Fig. 8 shows the calcite precipitated on one glass slice after immerging into the drain water for one month. The monthly water and deposits were sampled in manhole S9 (Fig. 6). They were analysed at the laboratory to follow the evolution of water compositions and its thermodynamic status which could be used to predict the quantities and rate of calcite precipitations. The deposit composition was also identified by X-ray diffraction (Bruker – AXS D8 Advance XRD), while the carbonates’ fraction was tested by acid titration. The water major compositions were analysed by quantifying the alkalinity (sum of alkaline) and the concentration of major ions such as calcium, magnesium, sodium, potassium, chloride, nitrate and sulphate. The alkalinity was tested using acid titration (METTLER TOLEDO T50), while the concentrations of major ions were analysed by ionic chromatography (Metrohm 761 Compact IC).

Results and discussion

Calibration of catchment surface and the platform run-off coefficient

Before modelling the precise flow path inside of the drainage system, the input data reliability should be verified first, especially the surface of local catchment and the platform runoff coefficient. The monthly recorded rainfall (Q in) and the outlet flow (Q out) data from July 1st, 2014 to March 31st, 2016 are listed in Table 3. In this table, the raw data of monthly cumulated rainfall (mm) are given in column 1. The raw ratio of monthly cumulated volume (m3) of drain water and the theoretical local catchment surface (8600 m2) is listed in column 2. The used unit is millimetre. The ratio of monthly cumulated drain flow and cumulated rainfall is given in column 3. Their units are measured in metres during the division. Since few plants are around the drain, the evapotranspiration could be considered negligible during the winter.

As a result, the average ratio of flow and rainfall throughout December, January and February could give us the real local catchment surface. This value is estimated at 6937 m2 compared to the topographic one of 8600 m2. The platform runoff coefficient obtained by the topographic surface is 0.63 (699/1107 in Table 3). After the calibration of local catchment surface, this runoff coefficient is up to 0.78, still smaller than the one (0.85) indicated in the SNCF internal guide of railway platform construction. This in situ low runoff coefficient highlights the platform infiltration.

Considering the structure of target drainage system, this platform runoff will all go through the highly calcareous permeable clean washed gravel, so the runoff coefficient estimated (0.78) equals the wash gravel infiltration coefficient. This value (0.78) is approached to the one observed in a general limestone aquifer (0.8), but much higher than the one detected in a gypsum–dolomite–limestone aquifer (0.5) [4]. This consistency of infiltration coefficient through the calcareous system both in literature and in situ estimation insures the rainfall- flow data reliability. Obviously, the drain flow is highly correlated to the rainfall since the correlation coefficient is as high as 0.83 during 20 months of data recording. This high correlation coefficient highlights the contribution of runoff (rapid flow) to the total drain flow.

Site observations and a process-conception model

Facing a daily rainfall of 15 mm, the drainage system recovers its initial total flow in 2–3 days based on the soil initial water status, while reverting to the initial chemical status around 12–30 h. Considering the different environment permeability in the drainage system, there are two passages of flux: the first is the rapid one (the platform runoff) through the permeable clean washed gravel; the second is the slow flux infiltrating the compacted platform. The gap between initial platform runoff coefficient according to the construction code and today’s in situ measured one (0.85 vs. 0.78) illustrates this slow infiltration indirectly. Since the wash gravel is mainly calcite (CaCO3), the pH which strongly depends on dissolved carbonates can be an indicator to verify the duration of the quick flux. Based on the 20 months’ pH recording, this quick flux lasts 6–12 h and depends on rain episode. However, the less permeable platform which contains carbonates, minerals and gypsum (Table 2) shows less effect on pH due to their slow dynamic facing to the rainfall. However, this slow platform infiltration can strongly modify the electric conductivity via the gypsum dissolution. As a result, the conductivity can serve as an indicator to verify the duration of the slow platform duration. The continuous recording of drain water conductivity indicates that the evacuation of the slow platform infiltration could last 1–3 days after the rain episode during summer. However, during winter this evacuation could last for weeks.

On the basis of these observations, the water residence time inside of different materials varies dramatically. The difference of residence time causes differences in the reactants concentrations. Thus the precise flow path inside of different environmental materials should be assessed for the further chemical process study. Based on the materials characteristics (Table 1) and the previous observation of time scale of the drainage system facing to different rain episode, the main flow path in the drain environment is defined into two parts and their observed chemical affections is given in the following:

-

A rapid flow inside (Q r) the clean washed gravel (10−4 m/s, finish mainly in 6–12 h);

-

A slow flow (Q l) in the compacted platform materials (10−7 m/s, finish mainly in 1–3 days);

-

The rapid flow charged in calcium and carbonates which varies the water pH between 8 and 11;

-

The slow flow through the sub-ballast and capping layer charged in calcium and sulphate which increases the water hardness and was illustrated by a largely increasing water electronic conductivity after the quick flow;

-

The 2%-lime treated layer (50 cm thickness) supposed to be impermeable (<10−8 m/s), and no more rainfall infiltration in this deeper soil layer was considered. It cuts off the connection between the local ground water and the rainfall.

This primary observation of flow-path is used to develop a conceptual model which is used to model the reaction affection during the flow-path. The repartition of rapid and slow flow in the system will be modelled by an empiric hydrologic model (GR4) [1] which is modified on hourly time scale to adapt to the monitored site’s conditions.

Affection of rainfall (rapid/slow flow) on the calcite precipitation rate

Based on 14-month test of the calcite precipitation rate by the glass slices, the monthly rate compared to the cumulated drain water quantity and the total monthly rainfall is given in Fig. 9a; the monthly rate compared to rapid flow water volume (Q r) and slow flow water volume (Q l) is given in Fig. 9b. Based on the monthly deposits analysis, the scales sampled in the drain on the site of Chauconin are mainly calcite (more than 90%). The drain water is rich in calcium (about 6 mmol/l) and sulphate (about 5.5 mmol/l), less rich in carbonates (0.2–0.6 mmol/l). The monthly calcite precipitation rate did not show a strong correlation either with the total volume of the rainfall or with the total volume of the drain water. However, it showed a similar tendency to the slow infiltration. This consistency highlights the affection of the platform in the calcite precipitation processes, especially its local higher permeability produces a slow infiltration which could bring in the calcium and sulphate due to gypsum dissolution. Considering the high water sulphate concentration and the gypsum detected in platform materials, this correlation between calcite precipitation rate and platform infiltration water volume is quite reasonable and explicable. These observations are important for the study, especially to define the proper nature of platform materials or a proper permeability which can slow down or prevent totally the calcite clogging problem.

The rates observed in the drain manholes are between 10−8 and 10−10 mmol/cm2/s at different calcite saturation degrees (Ω): 10 and 1 respectively. In literature, for Ω < 1, calcite is dissolved. For Ω = 1, dissolution and precipitation equilibrate. For Ω > 1, calcite occurs. The maximum observed calcite precipitation rate on the glass surface is similar to that on the PVC surface which varies from 10−8 to 10−7 mmol/cm2/s during different Ω test done by different authors at laboratory [2, 14, 15, 16]. They are also quite similar to those observed in the stagnant water poor at the downstream of the Huanglong ravine in China [12, 17]. This substrate surface precipitation rate is also similar to the crystal growth rate in the bulk water [13] tested in laboratory with a Ω which varies between 1 and 4. Base on this rate, the yearly calcite precipitated in the drain of Chauconin is estimated to be between 100 (one quarter of drain intern surface contacted to water) to 200 kg (one-third of drain intern surface contacted to water). That quantity equals about 1.2 mm thickness of calcite which forms at the bottom of 1 km drain. This annual quantity estimation of calcite precipitation is meaningful for optimising the drain maintenance frequency.

Conclusions and perspectives

Based on the precedent results, the drain environment can be considered as a two-reservoir water transport system: a rapid one through the clean washed gravel and a slow one inside of the platform. However, the chemical indicators such as the pH and the conductivity show a prompt dynamics (half to one day) compared to the hydraulic one (days to weeks). It is estimated that 22% of the total rainfall infiltrates in the platform and contributes to the slow infiltration. The corresponding water is highly calcium concentrated (>6 mmol/l) which results in the calcite precipitation inside the drain with a quantity of up to 200 kg per year. The light rain event (<2 mm during 3 h) shows less contribution to the slow platform infiltration. Those above observations illustrate that the rainfall, the permeability and nature of platform materials are the key factors for the test site calcite clogging phenomenon. The calcite precipitation rate is comparable to the ones in literature at a similar calcite saturation degree and could be used to optimize the actual strategies of drain cleaning such as frequency. An adapted version of the rainfall-flow model GR4 will be used in this case study to assess quantitatively the catchment behaviour on an hourly time scale. Finally, this flow quantified simulation will be used later in the chemical water reactants’ transport simulation. The later hydro-geochemical simulation could help us answer our final objective of studying the drain clogging process linked to the calcite precipitation in general railway infrastructural context, for more case studies. The chemical modelling part will be presented in the other paper.

References

Perrin C, Michel C (2003) Improvement of a parsimonious model for streamflow simulation. J Hydrol 279(1–4):275–289. doi:10.1016/S0022-1694(03)00225-7

Chibowski E, Hołysz L, Szcześ A (2003) Adhesion of in situ precipitated calcium carbonate in the presence and absence of magnetic field in quiescent conditions on different solid surfaces. Water Res 37(19):4685–4692. doi:10.1016/j.watres.2003.07.001

Dietzel M, Rinder T, Leis A, Reichl P, Sellner P, Draschitz C, Plank G, Klammer D, Schöfer H (2008) Koralm tunnel as a case study for sinter formation in drainage systems–precipitation mechanisms and retaliatory action. Geomechanik Und Tunnelbau 1(4):271–278. doi:10.1002/geot.200800024

Giorgio G, Carletti A, Pittalis D (2014). Runoff coefficient and average yearly natural aquifer recharge assessment by physiography-based indirect methods for the island of Sardinia (Italy) and its NW Area (Nurra). J Hydrol 519, Part B (November): 1779–1791. doi:10.1016/j.jhydrol.2014.09.054

Ghobadi Nia M, Rahimi H, Sohrabi T, Naseri A, Tofighi H (2010) Potential risk of calcium carbonate precipitation in agricultural drain envelopes in arid and semi-arid areas. Agric Water Manag 97(10):1602–1608. doi:10.1016/j.agwat.2010.05.014

Girmscheid G, Gamisch T, Meinlschmidt A (2003) Scale sintering in tunnel drainages-recommendations for maintenance of tunnels. Bauingenieur 78:562–570

Hammer Ø, Dysthe DK, Lelu B, Lund H, Meakin P, Jamtveit B (2008) Calcite precipitation instability under laminar, open-channel flow. Geochimica et Cosmochimica Acta 72(20):5009–5021. doi:10.1016/j.gca.2008.07.028

ISO 1438-1 (1980). Water flow measurement in open channels using weirs and venturi flumes—Part 1: Thin-Plate Weirs. Distributed through American National Standards Institute, ASIN: B000Y2UBXK

Jia N, Tassin B, Deneele D, Prévot F, Nivon D, Koscielny M, Calon N (2014) Clogging of drainage devices in railway infrastructures: survey and assessment. In: GEORAIL 2014, 2:601–10. ISSN: 168-4704; ISBN: 978-2-7208-2621-4

Jia N, Tassin B, Koscielny M, Prevot F, Calon N, Deneele D (2016) Clogging of drainage devices in railway infrastructure: site study and geotechnical materials impact. J Pombo (Railways2016). doi:10.4203/ccp.110.27

Jia N, Tassin B, Koscielny M, Prevot F, Calon N, Deneele D (2016) Clogging of drainage devices in railway infrastructure: site instrumentation and water system. GeoChina 2016 (ID 1058 – section E5), Shan dong, China

Liu ZH, Svensson U, Dreybrodt W, Yuan DX, Buhmann D (1995) Hydrodynamic control of inorganic calcite precipitation in Huanglong Ravine, China: field measurements and theoretical prediction of deposition rates. Geochim Cosmochim Acta 59(15):3087–3097. doi:10.1016/0016-7037(95)00198-9

Teng HH, Dove PM, De Yoreo JJ (2000) Kinetics of calcite growth: surface processes and relationships to macroscopic rate laws. Geochim Cosmochim Acta 64(13):2255–2266. doi:10.1016/S0016-7037(00)00341-0

Yee E, Lee JW, Lim DS, Chun BS (2012) Magnetic water treatment to inhibit calcium carbonate scale deposition in the drainage system of an old tunnel in Seoul, South Korea. Adv Mater Res 594–597:2045–2055. doi:10.4028/www.scientific.net/AMR.594-597.2045

Yee E, Zhang Y, Chun B (2015) Substrate modification and magnetic water treatment on the maintenance of tunnel drainage systems. I: feasibility tests. J Perform Constr Facil 29(3):04014076. doi:10.1061/(ASCE)CF.1943-5509.0000572

Yee E (2015) Substrate modification and magnetic water treatment on the maintenance of tunnel drainage systems. II: field tests. J Perform Constr Facil 29(3):04014077. doi:10.1061/(ASCE)CF.1943-5509.0000575

Zhang JL, Wang HJ, Liu ZH, An DJ, Dreybrodt W (2012) Spatial–temporal variations of travertine deposition rates and their controlling factors in Huanglong Ravine, China—a world’s heritage site. Appl Geochem 27(1):211–222. doi:10.1016/j.apgeochem.2011.10.005

Acknowledgements

The authors appreciate the support of the authors (C. Perrin and A. Ficchi, IRSTEA) of the hourly time step version of GR4 model. They are especially acknowledged for the R version of the model (“airGR” package).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made.

The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

To view a copy of this licence, visit https://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Jia, N., Tassin, B., Calon, N. et al. Scaling in railway infrastructural drainage devices: site study. Innov. Infrastruct. Solut. 1, 42 (2016). https://doi.org/10.1007/s41062-016-0042-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41062-016-0042-7