Abstract

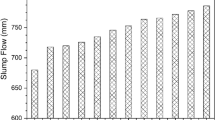

This study will investigate the viability of SCC constructed using fine aggregates derived from waste copper slag (WCS). WCS replacement ranged from 0 to 70% (10% increments) with sand at constant W/C ratio of 0.43; eight SCC mixtures were prepared. The cement content was substituted with 17.85% fly ash (FA), and a consistent amount of superplasticizer was utilized for the experiment. Tests on SCC mixes included mechanical properties like compressive strength at 28, and 56 days, pull-out tests after 28 days of curing, and durability tests, including rapid chloride permeability test (RCPT), and water absorption, and sorptivity after 28 days of curing were tested. Results showed that maximum compressive strength was noticed for 40% WCS. In the pull-out test, the maximum pull-out load and bond stress are recorded at 40% and 50% WCS is 44.35kN, 44.3kN and 11.76 MPa, 11.54 MPa compared to the control concrete mix (WCS0%). In terms of longevity, there is a strong link between CMS and several other performance metrics. Scanning electron microscopy, XRD analysis, and energy dispersive spectroscopy were used to analyze the microstructure of concrete. WCS may be used as a substitute for fine aggregates in concrete up to 70% which can benefit the building industry. By using this method, copper slag may be safely disposed of without damaging the environment or requiring land management.

Similar content being viewed by others

Code availability

Not applicable.

References

Rajasekar A, Arunachalam K, Kottaisamy M (2019) Assessment of strength and durability characteristics of copper slag incorporated ultra-high strength concrete. J Clean Prod 208:402–414

Dey S, Kumar VVP, Goud KR et al (2021) State of art review on self-compacting concrete using mineral admixtures. J Build Rehabil 6:18. https://doi.org/10.1007/s41024-021-00110-9

Hooton R, Al-Jabri K, Taha R, Al-Ghassani M (2002) Use of copper slag and cement by-pass dust as cementitious materials. Cement Concr Aggreg 24(1):7

Samabangi A, Eluru A (2022) Industrial copper waste as a sustainable material in high strength SCC. Clean Eng Technol 6:100403

Chaitanya BK, Sivakumar I (2022) Flow-behaviour, microstructure, and strength properties of self-compacting concrete using waste copper slag as fine aggregate. Innov Infrastruct Solut 7:181. https://doi.org/10.1007/s41062-022-00766-3

Chaitanya BK, Kumar IS (2022) Effect of waste copper slag as a substitute in cement and concrete—a review. IOP Conf Ser Earth Environ Sci 982(1):012029. https://doi.org/10.1088/1755-1315/982/1/012029

Krishna Chaitanya B, Sivakumar I (2021) Influence of waste copper slag on flexural strength properties of self-compacting concrete. Mater Today Proc 42:671–676

Sharma R, Khan RA (2018) Influence of copper slag and metakaolin on the durability of self-compacting concrete. J Clean Prod 171:1171–1186

Gupta N, Siddique R (2020) Durability characteristics of self-compacting concrete made with copper slag. Constr Build Mater 247:118580. https://doi.org/10.1016/j.conbuildmat.2020.118580

Sharma R, Khan RA (2017) Durability assessment of self compacting concrete incorporating copper slag as fine aggregates. Constr Build Mater 155:617–629. https://doi.org/10.1016/j.conbuildmat.2017.08.074

Najimi M, Sobhani J, Pourkhorshidi A (2011) Durability of copper slag contained concrete exposed to sulfate attack. Constr Build Mater 25(4):1895–1905. https://doi.org/10.1016/j.conbuildmat.2010.11.067

Mithun BM, Narasimhan MC (2016) Performance of alkali activated slag concrete mixes incorporating copper slag as fine aggregate. J Clean Prod 112(1):837–844. https://doi.org/10.1016/j.jclepro.2015.06.026

Brindha D, Nagan S (2011) Durability studies on copper clag admixed concrete. Asian J Civ Eng (Build Hous) 12(5):563–578

Chithra S, Senthil Kumar S, Chinnaraju K (2016) The effect of colloidal nano-silica on workability, mechanical and durability properties of high-performance concrete with copper slag as partial fine aggregate. Constr Build Mater 113:794–804

Sandra N, Kawaai K, Ujike I (2020) Influence of copper slag on corrosion behavior of horizontal steel bars in reinforced concrete column specimen due to chloride-induced corrosion. Constr Build Mater 255:119265

IS:269:2015 (2015) Ordinary portland cement—specification (sixth revision). Bureau of Indian Standard, New Delhi

IS 9103: 1999 (1999) Concrete admixtures-specification (first revision). Bureau of Indian Standard, New Delhi

IS 383-2016 (2016) Specification for coarse and fine aggregates from natural sources for concrete. Bureau Of Indian Standard, New Delhi

IS:2386 (Part-3) (1963) Indian Standard methods of test for aggregates for concrete. Bureau of Indian Standard, New Delhi

EFNARC (2002) Specification and guidelines for self-compacting concrete

EFNARC (2005) The European guidelines for self-compacting concrete. Specification, Production and Use

IS 10262:2019, Concrete mix, proportioning guidelines (first revision). Bureau of Indian Standard, New Delhi

ACI-237R-07 (2007) Self-consolidating concrete. ACI Committee 237, USA

IS 516:2015 (2015) Methods of tests for strength of concrete. Bureau of Indian Standard, New Delhi

IS 2770 (Part I)—1967 (Reaffirmed 2007) (2007) Indian Standard methods of testing bond in reinforced concrete (part 1): pull-out test

BIS, IS 1124-1974 (1974) Specification for water absorption for concrete. Bureau of Indian Standards, New Delhi

ASTM C1202-07 (2007) Standard test method for electrical indication of concrete’s ability to resist chloride ion penetration. ASTM International, West Conshohocken

ASTM C1585-13 (2013) Standard test method for measurement of rate of absorption of water by hydraulic-cement concretes. ASTM International, West Conshohocken

Arel HS, Aydin E (2018) Use of industrial and agricultural wastes in construction concrete. ACI Mater J. https://doi.org/10.14359/51700991

Aydin E, Arel HŞ (2017) Characterization of high-volume fly-ash cement pastes for sustainable construction applications. Constr Build Mater 157:96–107 (ISSN 0950-0618)

Jalal M, Mansouri E, Sharifipour M, Pouladkhan AR (2012) Mechanical, rheological, durability and microstructural properties of high-performance self-compacting concrete containing SiO2 micro and nanoparticles. Mater Des 34:389–400

Adak D, Sarkar M, Mandal S (2014) Effect of nano-silica on strength and durability of fly ash based geopolymer mortar. Constr Build Mater 70:453–459

Dey S, Kumar VVP, Manoj AV (2022) An experimental study on strength and durability characteristics of self-curing self-compacting concrete. Struct Concr. https://doi.org/10.1002/suco.202100446

Mavroulidou M (2017) Mechanical properties and durability of concrete with water-cooled copper slag aggregate. Waste Biomass Valoriz 8(5):1841–1854

Sharifi Y, Afshoon I, Asad-Abadi S, Aslani F (2020) Environmental protection by using waste copper slag as a coarse aggregate in self-compacting concrete. J Environ Manag 271:111013

Swathi V, Asadi SS (2022) An experimental investigation on mechanical, durability and microstructural properties of high-volume fly ash-based concrete. J Build Pathol Rehabil. https://doi.org/10.1007/s41024-022-00172-3

Venkatesh C, Ruben N, Madduru SR (2020) Role of red mud as a cementing material in concrete: a comprehensive study on durability behavior. Innov Infrastruct Solut 6:13. https://doi.org/10.1007/s41062-020-00371-2

Gupta N, Siddique R (2019) Strength and micro-structural properties of self-compacting concrete incorporating copper slag. Constr Build Mater 224:894–908

Fadaee M, Mirhosseini RT, Tabatabaei R, Fadaee M (2015) Investigation on using copper slag as part of cementitious materials in self compacting concrete. Asian J Civ Eng (BHRC) 16(3):368–381

Nurwidayati R, Ekaputri J, Triwulan T, Suprobo P (2019) Bond behaviour between reinforcing bars and geopolymer concrete by using pull-out test. MATEC Web Conf 280:04008. https://doi.org/10.1051/matecconf/201928004008

Baena M, Torres L, Turon A, Barris C (2009) Experimental study of bond behaviour between concrete and FRP bars using a pull-out test. Compos Part B Eng 40(8):784–797

de Almeida Filho FM, El Debs MK, El Debs ALHC (2008) Bond-slip behavior of self-compacting concrete and vibrated concrete using pull-out and beam tests. Mater Struct 41:1073–1089. https://doi.org/10.1617/s11527-007-9307-0

Ponmalar P (2018) Bond behaviour of self-compacting concrete. Sel Sci Pap J Civ Eng 13:95–105. https://doi.org/10.1515/sspjce-2018-0009

Cunha VMCF, Barros JAO, Sena-Cruz JM (2010) Pull-out behavior of steel fibers in self-compacting concrete. J Mater Civ Eng 22(1):1–9. https://doi.org/10.1061/ASCE_MT.1943-5533.0000001

IS 456:2000 (2000) Indian standard plain and reinforced concrete code of practice, (fourth revision). Bureau of Indian Standard, New Delhi

Bellum RR, Al Khazaleh M, Pilla RK et al (2022) Effect of slag on strength, durability and microstructural characteristics of fly ash-based geopolymer concrete. J Build Rehabil 7:25. https://doi.org/10.1007/s41024-022-00163-4

Khotbehsara MM, Mohseni E, Ozbakkaloglu T, Ranjbar MM (2017) Durability characteristics of self-compacting concrete incorporating pumice and metakaolin. J Mater Civ Eng 29(11):04017218

Funding

No.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author declared there is no conflict of interest on behalf of all authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chaitanya, B.K., Sivakumar, I. Experimental investigation on bond behaviour, durability and microstructural analysis of self-compacting concrete using waste copper slag. J Build Rehabil 7, 85 (2022). https://doi.org/10.1007/s41024-022-00224-8

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41024-022-00224-8