Abstract

The interaction of underground structures with groundwater is an essential issue for all the phases of the construction and life of an underground work. This issue is essential for its potential effects on the environment, on the excavation technique and on the preservation of the hydraulic resource. A complete analysis of all the problems related to this interaction from the very beginning of the design is of crucial importance for the good execution of the construction and for the minimization of the maintenance cost during the life of the structure. A wrong waterproofing approach or an incorrect installation of the waterproofing system may lead to severe damage to the structure, and to high maintenance and refurbishment costs. In the technical literature, water inflow in tunnels has been recognized as one of the most important sources both of damage to the structures and of claims. Several case histories have highlighted the importance of water preservation and the potential danger of underground excavation for the environment if insufficient controls of underground water are applied. In the paper, a global overview of the techniques used is presented, some relevant case histories are discussed, and a risk analysis procedure is proposed.

Similar content being viewed by others

References

ITA Working Group No. 6 (2001) Study of methods for repair of tunnel linings (1999) Study of methods for repair of tunnel linings. International Tunneling Association

Sandrone F, Labiouse V (2011) Identification and analysis of Swiss National Road tunnels pathologies. Tunn Undergr Sp Technol 26(2):374–390

Moon J, Fernandez G (2010) Effect of excavation-induced groundwater level drawdown on tunnel inflow in a jointed rock mass. Eng Geol 110(3–4):33–42

Piccinini L, Vincenzi V (2010) Impacts of a railway tunnel on the streams baseflow verified by MEAnS of numerical modelling. Aqua Mundi 1:123–134

Nishigaki M (2010) Geotechnical aspects of groundwater control. Soils Found 50(6):893–902

Ohnishi Y, Ohtsu H, Nishioka T, Naka Y, Yasuda T, Takahashi K (2003) Observational method for tunnel construction considering environmental impact to groundwater. In: Kono I, Nishigaki M, Komatsu M (eds) Groundwater engineering—recent advances. A.A. Balkema, Lisse, pp 17–24

Olofsson B (1991) Impact on groundwater conditions by tunnelling—a state of the art report. Department of Land and Water Resources Royal institute of Technology, Stockholm

Howard CAAJ (1991) Report on the damaging effects of water on tunnels during their working life. Tunn Undergr Sp Technol Inc Trenchless 6(1):11–76

Beitness A (2002) Lessons to be learned from long railway tunnels. Norwegian Tunnelling Society Publications No. 12, Sandvika

Karlsrud K (2002) Control of water leakage when tunnelling under urban areas in the Oslo region. Norwegian Tunnelling Society Publications No. 12, Sandvika

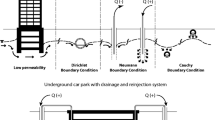

Pujades E, López A, Carrera J, Vázquez-Suñé E, Jurado A (2012) Barrier effect of underground structures on aquifers. Eng Geol 144–145:41–49

Tambara M, Nishigaki M, Hashimoto T, Shinshi Y, Daito K (2003) Basic concept on preservation natural groundwater flows from intercepting by underground structure. In: Kono I, Nishigaki M, Komatsu M (eds) Groundw Eng Recent Adv. A.A. Balkema, Lisse, pp 217–222

Serrano-Juan A, Pujades E, Vázquez-Suñè E, Velasco V, Criollo R, Jurado A (2018) Integration of groundwater by-pass facilities in the bottom slab design for large underground structures. Tunn Undergr Sp Technol 71:231–243

Vik EA et al (2000) Experiences from environmental risk management of chemical grouting agents used during construction of the Romeriksporten Tunnel. Tunn Undergr Sp Technol 15(4):369–378

Wang TT, Wang WL, Lin ML (2004) Harnessing the catastrophic inrush of water into new Yungchuen Tunnel in Taiwan. Tunn Undergr Sp Technol 19(4–5):418

CETU (2015) Guide de l’spection du génie civil des tunnels routiers–Livre 2: Catalogue des désordres

Angel ML, Johnston S, O’Steen K, Brown C, Sando T (2015) Groundwater control issues in transportation engineering: a short review of dewatering methods and lessons learned. J Eng Sci Technol Rev 8(3):8–13

Kalamaras G, Liti M, Avesani F, Pelizza S, Andreis I (2016) The Caltanissetta twin tunnel: segmental lining design and EPBS TBM performance during the construction of the 4 km-long Ø15.08 m tunnel. In: ITA-AITES World tunnel congress, 22–28 April 2016

Logarzo A, Stefanizzi S, Grasso P (2014) Dewatering for construction of São Paulo Metro—Line 5 extension: comparison of design predictions with monitored results. In: Tunnels for a better life, Proceedings of the World tunnel congress 2014, Iguazu falls, Brazil

Zingg S, Anagnostou G (2016) An investigation into efficient drainage layouts for the stabilization of tunnel faces in homogeneous ground. Tunn Undergr Sp Technol 58:49–73

Zingg S, Anagnostou G (2018) Effects of the hydraulic capacity of advance drainage boreholes on tunnel face stability. Tunn Undergr Sp Technol 71:518–530

Crespo A, Campo F, Grasso P, Russo G, Pelizza S (1992) Highway tunnel crossing of an old river bed in N. Italy while maintaining the hydrogeological balance. In: International congress on towards new worlds in tunnelling, Acapulco, pp 667–672

Aksoy CO (2008) Chemical injection application at tunnel service shaft to prevent ground settlement induced by groundwater drainage: a case study. Int J Rock Mech Min Sci 45(3):376–383

Chieregato A, Oñate Salazar CG, Todaro C, Martinelli D, Peila D (2014) Laboratory grouting test for waterproofing and consolidation of granular soils by means of innovative materials|Test di laboratorio di iniezione per l’impermeabilizzazione e consolidamento di terreni granulari per mezzo di materiali innovativi. Geoing. Ambient. e Mineraria 141:1

Peila D, Pelizza S (2009) Ground probing and treatments in rock TBM tunnel to overcome limiting conditions. J Min Sci 45:6

AFTES (2016) Recommandations relatives aux traitements d’arrets d’eau dans les ouvrages souterrains. Tunnels ouvrages Souterr

Andersland OB, Ladanyi B (2004) Frozen ground engineering. Wiley, Hoboken

Colombo G, Lunardi P, Cavagna B, Cassani G, Manassero V (2008) The artificial ground freezing technique application for the Naples undergound. In: ITA-AITES World tunnel congress on ‘underground facilities for better environment and safety’, 19–25 September, 2008

Russo G, Corbo A, Cavuoto F, Autuori S (2015) Artificial ground freezing to excavate a tunnel in sandy soil. Measurements and back analysis. Tunn Undergr Sp Technol 50:226–238

Pimentel E, Sres A, Anagnostou G (2012) Large-scale laboratory tests on artificial ground freezing under seepage-flow conditions. Géotechnique, 62(3):227–241

Pimentel E, Papakonstantinou S, Anagnostou G (2012) Numerical interpretation of temperature distributions from three ground freezing applications in urban tunnelling. Tunn Undergr Sp Technol 28(1):57–69

Guglielmetti V, Grasso P, Mahtab A, Xu S (2007) Mechanized tunnelling in urban areas: design methodology and construction control. Taylor & Francis, London

Peila D (2014) Soil conditioning for EPB shield tunnelling. KSCE J Civ Eng 18:3

Thewes M, Budach C (2010) Soil conditioning with foam during EPB tunnelling | Konditionierung von Lockergesteinen bei Erddruckschilden. Geomech. und Tunnelbau 3:3

Budach C, Thewes M (2015) Application ranges of EPB shields in coarse ground based on laboratory research. Tunn Undergr Sp Technol, 50:296–304

Peila D, Borio L, Pelizza S (2011) The behaviour of a two-component backfilling grout used in a tunnel-boring machine. Acta Geotech Slov 8:1

Borio L, Chieregato A, Picchio A, Peila D (2010) Study of the permeability of foam conditioned soils|Studio della permeabilità di terreni condizionati con schiume. Geoing Ambient e Mineraria 130:2

Thewes M, Budach C (2009) Grouting of the annular gap in shield tunnelling. An important factor for minimization of settlements and production performance. In: Proceedings of ITA-AITES World tunnel congress 2009, Budapest, 23–28 May 2009

Peila D et al (2015) Long term behavior of two component back-fill grout mix used in full face mechanized tunneling. Geoing Ambient e Mineraria 144:1

Shah R, Lavasan AA, Peila D, Todaro C, Luciani A, Schanz T (2018) Numerical study on backfilling the tail void using a two-component grout. J Mater Civ Eng 30(3):1–9

Bianchi GW, Piraud J, Robert A, Egal E (2012) Recommendation on the characterisation of geological, hydrogeological and geotechnical uncertainties and risks. Tunnels Espac Souterr 232:315–355

Eskesen SD, Tengbor P, Kampmann J, Veicherts TH (2004) Guidelines for tunnelling risk management: International Tunnelling Association, working group no. 2. Tunn Undergr Sp Technol 19:217–237

ITIG (2012) A code of practice for risk management of tunnel works. Tunnels Espac Souterr 232, 315–355

Wang X, zhongsheng Tan M, Wang M, Zhang, Ming H (2008) Theoretical and experimental study of external water pressure on tunnel lining in controlled drainage under high water level. Tunn Undergr Sp Technol 23(5):552–560

Shin JH, Kim KH, Kim DR (2014) Smart control of hydraulic actions in tunnels and underwater structures. In: Tunnels for a better life, Proceedings of the World tunnel congress 2014. Iguazu falls, Brazil

Perello P, Venturini G, Delle L, Piane, Dematteis A (2007) Ground water inflows in tunnels excavated in faulted rock mass. A case history from the Italian Western ALps. Felsbau 25:28–34

Banzato C, Civita M, Fiorucci A, Vigna B, Papale S (2011) Hydrogeological prognosis with regard to realisation of the new Colle di Tenda road tunnel. Am J Environ Sci 7:1–14

Pelizza S (1999) Federico Sacco e le gallerie. Quad della casa di Stud ‘Fondazione Federico Sacco’ 14:69

Flüeler PH, Farshad M, Löwe C, Kramer H, Böhni H, Zwicky P (2003) New evaluation procedure of the waterproofing systems for the Swiss Alpine base tunnels. In: Proceedings of the ITA World Tunnelling Congress 2003’(Re)Claiming the Underground Space', 12–17 April 2003, Amsterdam, The Netherlands. Saveur, A.A. Balkema Publishers, pp 441–448

Bonomi T (1999) Groundwater level evolution in the Milan area: natural and human issues. In: Impacts of urban growth on surface water and groundwater quality, Proceedings of the IUGG 99 symposium

Dammyr Ø, Nilsen B, Thuro K, Grøndal J (2014) Possible concepts for waterproofing of norwegian TBM railway tunnels. Rock Mech. Rock Eng 47(3):985–1002

Mahuet JL (2013) Dévelopement en France de l’utilisation des géosynthetiques de drainage dans les ouvrages souterrains. Rencontres Gèosynthetiques, 9–11 April

Yoo C (2015) The use of geosynthetics in underground works. In: 13th International congress of rock mechanics, 10–13 May 2015

AFTES (2000) Recomandations sur l’étanchéité et le drainage des ouvrages souterrains, Tunnels ouvrages Souterr 2:41–59

SIA (2009) SIA 272 Abdichtungen und Entwasserungen von Bauten unter Terrain und im Untertagbau

Österreichische Bautechnik Vereinigung (2015) Guideline: tunnel waterproofing. Austrian Society for Construction Technology

AFTES (2005) Racommandations relatives à l’utilisation et la mise en oeuvre d’un compartimentage associé à un dispositif d’étanchéité par géomembrane synthétique. Tunnels ouvrages Souterr 2:11–17

Ministère, de l’Equipement (2014) Fascicule 67—III du Cachier des Clauses Techniques Générales (CCTG)—Etanchéité des ouvrages souterrains

Mahuet JL (1984) Prolongement de la ligne B de part-dieu à jean macé du métro de Lyon. Tunnels ouvrages Souterr 62:59–69

Mahuet JL (2011) Bilan et évolution de la mise en œuvre des GSB dans les ouvrages souterrains. 8 Rencotres Géosynthétiques, 22–24 March 2011

Dal Negro E, Leotta M, Pavese E (2016) Advanced waterproofing at Farringdon Station. Tunn J April/May:30–35

Zotti IM, Cunegatti M (2014) Waterproofing in underground structures with syntetics membranes: the vacuum system, testable and reparable. In: Tunnels for a better life, Proceedings of the World tunnel congress 2014. Iguazu falls, Brazil

ITA-AITES, ITAtech (2013) Design guidance for spray applied waterproofing membranes (ISBN: 978-2-9700858-1-2)

Holter KG, Foord R (2015) Testing of properties and constructability considerations of EVA-based sprayed membranes for waterproofing of tunnels. SEE tunnel: promoting tunneling in SEE region, ITA WTC 2015 congress and 41st general assembly, 22–28 May 2015

Holter KG, Nilsen B, Langas C, Tandberg MK (2014) Testing of sprayed waterproofing membranes for single shell sprayed concrete tunnel linings in hard rock. In: Tunnels for a better life, Proceedings of the World tunnel congress 2014. Iguazu falls, Brazil

Lemke S (2014) Critical review of spray-applied membranes in the field of tunnelling in comparison to sheet membranes: advantages, disadvantages and open questions. In: Tunnels for a better life, proceedings of the World tunnel congress 2014. Iguazu falls, Brazil

Makhlouf R, Holter KG (2008) Rehabilitation of concrete lined tunnels using a composite sprayed liner with sprayed concrete and sprayable waterproofing membrane; the Chekka road tunnel, Lebanon. In: World tunneling congress 2008—underground facility better environment safety—India, pp 1175–1182

Clement F, Saraiva E, Garcia M (2014) Sprayable waterproofing membranes: possibilities and limitations. In: Tunnels for a better life, Proceedings of the World tunnel congress 2014. Iguazu falls, Brazil

Su J, Bloodworth A (2016) Interface parameters of composite sprayed concrete linings in soft ground with spray-applied waterproofing. Tunn Undergr Sp Technol 59:170–182

Thomas AH, Dimmock RH (2017) The design philosophy for permanent sprayed concrete linings. In Proceedings of the World tunnel congress 2017—surface challenges—underground solutions, vol 5

Pillai A, Jung H, Clement F, Wilson C, Traldi D (2017) Sprayed concrete composite tunnel lining—load sharing between the primary and secondary lining, and its benefit in reducing the structural thickness of the lining. In Proceedings of the World tunnel congress 2017–surface challenges–underground solutions

Traldi D, Levanto P (2010) Rivestimenti definitivi di gallerie con l’utilizzo di guaine impermeabili spruzzabili. Geoingeneria Ambient e Mineraria 129:81–86

Bomben G, Bringiotti M (2013) Innovazione e sperimentazione per le guarnizioni di Sparvo e di Scilla. Gallerie e spazio sotterraneo nello sviluppo dell’Europa, 17–19 Oct 2013, pp 758–769

Schurch M (2006) Small but important—gaskets for tunnel segments. In: International symposium on underground excavation and tunnelling, Bangkok, Thailand, Feb 2006 pp. 239–248

Taillebois A, Fauvel MM, Mahuet JL, Meyniel P (2005) AFTES recommendations on segmental gaskets. Tunnels et ouvrages souterrains 1:243–245

STUVA (2005) STUVA recommendations for testing and application of sealing gaskets in segmental linings. Tunnel 8:8–21

ISO 11346 (2014) Rubber, vulcanized or thermoplastic—estimation of life-time and maximum temperature of use

Shi C, Cao C, Lei M, Peng L, Shen J (2015) Time-dependent performance and constitutive model of EPDM rubber gasket used for tunnel segment joints. Tunn Undergr Sp Technol 50:490–498

AFTES (2005) Hydrophilic swelling gaskets for tunnel lining segments gasket assessment and quality control procedures. Tunnels ouvrages Souterr

Shirlaw JN, Wen D, Ong JCW (2016) The importance of the choice of gasket type and grout mix in segmental tunnel linings. In: International conference and exhibition on tunnelling and trenchless technology, 7–9 March 2016

ITA-AITES, ITAtech (2014) Guidelines on best practices for segment backfilling (ISBN: 978-2-9700858-5-0)

Youn BY, Breitenbücher R (2014) Influencing parameters of the grout mix on the properties of annular gap grouts in mechanized tunneling. Tunn Undergr Sp Technol 43:290–299

Pellegrini L, Perruzza P (2009) Sao Paulo Metro Project—control of settlements in variable soil conditions through EPB pressure and bicomponent backfill grout. RETC, 14–17 June 2009

Paglini PF, Antonelli A, Pelizza S, Boschi PF, Lo Faro V (2016) Esperienze di scavo con E.P.B.S. di grande diametro in terreni geologicamente complessi, il caso della costruzione del tunnel a doppia canna “Caltanissetta” sulla Strada di Grande Comunicazione 640 in Sicilia. Le sfide per la realizzazione di grandi opere in sotterraneo: progettazione, costruzione e gestione di opere complesse e sfidanti, 20–21 Oct 2016

Acknowledgements

The authors have equally contributed to the paper. The authors thank M. Leotta and E. Pavese for having generously shared their opinions and ideas during the paper development. The financial support of this research has been provided by MAPEI and by Politecnico di Torino Research Founds.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Luciani, A., Peila, D. Tunnel Waterproofing: Available Technologies and Evaluation Through Risk Analysis. Int J Civ Eng 17, 45–59 (2019). https://doi.org/10.1007/s40999-018-0328-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40999-018-0328-6