Abstract

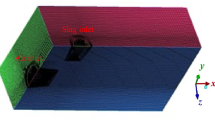

In the heat recovery technology of molten slag granulation, gas quenching is one of the most promising and crucial technologies for high-quality resource utilization. This study performed numerical investigations on the slag granulation process through the realizable k-epsilon model and volume of fluid methodology and gained deep insight into the breakup mechanism and influence of the gas Weber number (We) and liquid Reynolds number (Re). Results indicated that the shear action between gas and slag leads to the generation of the KH (Kelvin–Helmholtz) wave, which dominates the surface liquid film fragmentation. The pressure gradient between the gas and slag interfaces leads to the generation of RT (Rayleigh–Taylor) waves and, finally, to the liquid film fragmentation of spherical pores. The crushing effect of slag is mainly determined by the We, Re, and local momentum ratio between gas and slag (RLM). The variation of the dimensionless number has a significant effect on the fragmentation effect of the slag. When the We ranges from 621 to 932 and the Re from 336 to 605, an increase in the dimensionless number reduces the surface wavelength and the mean particle size of the slag. The surface wavelength decreases from about 12 to about 5 mm, and the mean particle size of the slag decreases from about 2.65 to 2.3 mm. The length and height of the break also decrease with increasing We and Re. Finally, an empirical formula for the size of the slag particle is obtained. According to the empirical formula, the particle size of the slag decreases with increasing airflow velocity and slag flow rate, and increases with increasing slag surface tension and viscosity.

Similar content being viewed by others

References

Aharonov E, Rothman DH (2013) Non‐Newtonian flow (through porous media): A lattice‐Boltzmann method[J]. Geophysical Research Letters 20(8):679–682

Ando J, Onoue H, Nakahara T et al (1985) Development of slag blast granulation plant characterized by innovation of the slag treatment method, heat recovery, and recovery of slag as resources. Mitsubishi Heavy Ind Tech Rev 22(2):136–142

Chang H (2014) Simulation experiment and solidification heat release analysis of blast furnace slag granulation. Dissertation, Shandong Jianzhu University, Jinan, China

Chang JL, He LJ, Chen LH, Shen ZF, Chuah LF, Bokhari A, Klemes JJ, Han N (2022a) Numerical simulation of liquid jet atomization in subsonic crossflow. Energy 257:124676

Chang JL, Chen LH, He LJ, Zhou Y (2022b) Numerical simulation of primary atomization process of liquid jet in subsonic crossflow. Energy Rep 8:1–15

Delouei AA, Nazari M, Kayhani M, Kang S, Succi S (2016) Non-Newtonian particulate flow simulation: a direct-forcing immersed boundary–lattice Boltzmann approach. Phys A 447:1–20

Du C, Gao X, Kitamura S (2019) Measures to decrease and utilize steelmaking slag. J Sustain Metall 5:141–153

Duan YC, Xing HW, Sun RJ, Kang Y, Shao C (2022) Status and prospect of high-value resource utilization of blast furnace slag. World Nonferrous Met 17:7–9

Gao J, Feng YH, Feng DL et al (2021) Centrifugal granulation of liquid slag under air quenching. J Eng Thermophys 42(05):1288–1292

Jalali A, Delouei AA, Khorashadizadeh M, Golmohammadi AM, Karimnejad S (2019) Mesoscopic simulation of forced convective heat transfer of Carreau–Yasuda fluid flow over an inclined square: temperature-dependent viscosity. J Appl Comput Mech 6(2):307–319

Kang Y, Liu C, Zhang YZ, Jiang MF (2019) Properties of glass beads prepared by gas quenching of blast furnace slag. J Northeast Univ (Nat Sci) 40:202–206

Kang Y, Liu C, Zhang YZ, Jiang MF (2020) Experimental study on granulation of blast furnace slag by gas quenching. J Northeast Univ (Nat Sci) 41:212–216

Lateb M, Masson C, Stathopoulos T, Bedard C (2013) Comparison of various types of k–ε models for pollutant emissions around a two-building configuration. J Wind Eng Ind Aerodyn 115(4):9–21

Li P (2017) Thermodynamic analysis of waste heat recovery of molten blast furnace slag. Int J Hydrogen Energy 42(15):9688–9695

Li C, Shen CB, Li QL et al (2019) Primary break-up process of liquid jet in supersonic crossflow. J Natl Univ Defense Technol 41(04):73–78

Liu N (2015) Experimental and large eddy simulation of primary atomization of liquid transverse jet in supersonic flow. Dissertation, National University of Defense Technology, Changsha, China

Liu XH, Wen Z, Du YH, Lou GF (2022) Study on liquid film breaking process of gas quenched granulated slag. J Cent South Univ (Nat Sci) 53(8):2851–2860

Rasul M, Amin AD, Amin J, Mohsen I, Abdulmajeed AM (2019) Pore-scale simulation of non-Newtonian power-law fluid flow and forced convection in partially porous media: Thermal lattice Boltzmann method. Phys A 525:642–656

Sasmal C, Chhabra R (2012) Effect of aspect ratio on natural convection in power-law liquids from a heated horizontal elliptic cylinder. Int J Heat Mass Tran 55(17–18):4886–4899

Wang LL, Zhang YZ, Ke HB, Long Y (2020a) Experimental investigation on granulation characteristics and waste heat recovery of molten slag in gas quenching dry granulation technique. Appl Therm Eng 184:116295

Wang LL, Zhang YZ, Ke HB, Long Y (2020b) Simulation of primary breakup of molten slag in the gas quenching dry granulation process. Appl Therm Eng 181:115850

Wang L, Fang B, Wang GC (2021a) Process of pressure swirl nozzle atomization based on large eddy simulation. J Propul Power 42(8):1855–1864

Wang LL, Zhang YZ, Long Y (2021b) Numerical investigation of breakup process of molten blast furnace slag through air quenching dry granulation technique. J Iron Steel Res 28(1):10–18

Wei H, Chang JC, Fu HF (2016) Application of dimensional analysis in granulation degree of steel slag by gas quenching. J North China Univ Sci Technol (Natl Sci Ed) 38:14–19

Zhang B, Cheng P, Li QL et al (2021) Breaking process of liquid transverse jet under the action of gas film. Acta Physica Sinica 70(05):230–241

Zhang Y, Xu J, Chang Q, Ge W (2022) Bi-layer coarse-grained DPM of gas-solid systems with mesoscale heterogeneity resolved. Chem Eng Sci 263(12):118058

Acknowledgements

This research was supported by Fundamental Research Funds for the Central Universities (FRF-TP-22-077A1) and Key R&D Projects in Hebei Province (22373805D).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing interests to influence the work reported in this paper.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liu, X., Wen, Z., Du, Y. et al. Numerical Simulation of the Slag Granulation Process in Gas Quenching Under Multi-influencing Factors. Iran J Sci Technol Trans Mech Eng 47, 1733–1745 (2023). https://doi.org/10.1007/s40997-023-00640-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40997-023-00640-2