Abstract

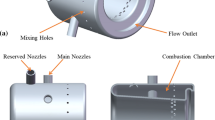

In the present study, the performance of an open cycle magneto hydrodynamics (MHD)-gas turbine (GT) combined plant has been analysed by considering the combustion products of MHD in partially ionized state and through the application of exergy. The combustor in the MHD system uses preheated air and coal mix and potassium carbonate as seed material to release the combustion products as partially ionized gases together with the undissociated product gases. The GT unit burns a mixture of methane and preheated air. Both MHD and the GT components have been modelled for computing energy rates and exergy destruction rates and the combined power generated. The ionization fraction is taken as 0.4 which is significant only up to the MHD generator due to temperature reduction below ionization beyond the generator. The exergy model of the GT plant is validated with a known model and the overall efficiency of the combined plant is determined. The exergy analysis which is partly based upon the effect of gas ionization shows the MHD combustor to have maximum exergy destruction followed by the process heater. Using partial ionization during combustion process in MHD, a more realistic attempt has been made to measure the power output and efficiency of the plant.

Similar content being viewed by others

Abbreviations

- AC:

-

Air compressor

- HHV:

-

Higher heating value, (MJ kg−1)

- SRU:

-

Seed recovery unit

- CC:

-

Combustion chamber

- DSU:

-

Desulphurization unit

- PH:

-

Process heater

- DAF:

-

Dry ash-free

- F :

-

Fuel

- A :

-

Air

- H:

-

Enthalpy of reaction

- \(R_{u}\) :

-

Universal gas constant, (kJ kg−1 K−1)

- \(\overline{h}\) :

-

Specific molar enthalpy, (kJ kmol−1)

- \(\overline{s}\) :

-

Specific molar entropy, (kJ kmol−1 K−1)

- \(\overline{c}_{p}\) :

-

Molar specific heat, (kJ kmol−1 K−1)

- \(\overline{e}\) :

-

Molar specific exergy

- l:

-

Liquid

- Re:

-

Reynold’s number

- \(\dot{m}\) :

-

Mass flow rate, (kg s−1)

- n :

-

No. of moles

- T :

-

Temperature (K)

- p :

-

Pressure (bar)

- \(\dot{\xi }\) :

-

Exergy rate (MW)

- \(\zeta\) :

-

Exergy efficiency (%)

- \({\Sigma }\) :

-

Summation

- Δ:

-

Change

- D :

-

Destruction

- 0:

-

Reference state

- in:

-

Inlet

- out:

-

Outlet

- f :

-

Formation

- sys:

-

System

- tot:

-

Total

References

Aithal SM (2009) Characteristics of optimum power extraction in a MHD generator with subsonic and supersonic inlets. Energy Conv&mgmt 50:765–771

Alboussière T (2008) Fundamentals of MHD. Les Houches 88:1–44

Al-Habahbeh OM, Al-Saqqa M, Safi M, Abo KT (2016) Review of magnetohydrodynamic pump applications. Alex Eng J 55:1347–1358. https://doi.org/10.1016/j.aej.2016.03.0011110-0168Ó2016

Assad M, El H (2015) Thermodynamic analysis of MHD power cycle. Mechanical Systems Engineering 1:1–3

Ayeleso AO, Kahn Md TE (2018) Modelling of a combustible ionised gas in thermal power plants using MHD conversion system in South Africa. King Saud University-Science 30:367–374

Baruah PK, Baruah MK (1996) Sulphur in Assam coal. Fuel Process Technol 46:83–97

Bejan A (2002) Fundamentals of exergy analysis, entropy generation minimization, and the generation of flow architecture. Energy Research 26:545–565

Bejan A, Tsatsaronis G, Moran M (1996) Thermal design and Optimization. John Wiley & Sons Inc, USA

Bowman CT, Hanson RK, Davidson DF, Gardiner WC, Lissianski V Jr, Smith, D.M. Golden GP, Frenklach M, Goldenberg M (1995) http://www.me.berkley.edu/gri_mech/

Channiwala SA, Parikh PP (2002) A unified correlation for estimating HHV of solid, liquid and gaseous fuels. Fuel 81:1051–1063

Chen L, Gong J, Sun F, Wu C (2002) Heat transfer effect on the performance of MHD power plant. Energy Convers Manage 43(15):2085–2095

Chernyshev V (1978) International co-operation in MHD electrical power generation. IAEA Bull 20:42–53

Cicconardi PS, PernaA, (2014) Performance analysis of integrated systems based on MHD generators. Energy Procedia 45:1305–1314

Davidson PA (2001) An Introduction to Magnetohydrodynamics. Cambridge University Press, UK

Demutskii VP, Polovin RV (1990) Fundamentals of Magnetohydrodynamics. Springer-Verlag, US

Dincer I, Rosen MA (2013) Exergy, energy, environment and sustainable development, 2nd edn. Elsevier Science, UK

Eiserman W, Johnson P, Conger WL (1980) Estimating thermodynamic properties of coal, char, tar and ash. Fuel Process Technol 3:39–53

Farrokhi H, Otuya DO, Khimchenko A, Dong J (2019) Magnetohydrodynamics in biomedical applications. Ferro hydrodynamics and Magneto hydrodynamics. Intechopen. https://doi.org/10.5772/intechopen.87109

Fitzsimons L, Corcoran B, Young P, Foley G, Regan F (2012) Modelling the activity of seawater and implications for desalination exergy analyses. In 9th International conference on heat transfer, fluid mechanics and thermodynamics, pp 1–11

Fridman A (2008) Plasma chemistry, 1st edn. Cambridge University Press, New York

Ganesan V (2017) Gas Turbines. McGraw Hill Education, India

Haloi P, Gogoi T K (2020) Performance analysis of a coal-fired open cycle MHD plant at constant subsonic inlet nozzle Mach number with variation in nozzle-area ratio. In: Biswal BB et al (ed) Advances in Mechanical Engineering. Springer Nature Pte Ltd, Singapore pp 709–716

Haloi P, Gogoi T K (2020) Exergy modelling of a coal-fired MHD power plant. In: Voruganti HK et al (ed). Advances in applied mechanical engineering. Singapore Springer Nature Pte Ltd, Singapore, pp 81–89

Haloi P, Gogoi TK (2019) Energy analysis of a coal-fired MHD power plant. Int J Recent Tech and Engg 8:281–285

Horn G, Sharp GA, Hryniszak WR (1967) Air heaters and seed recovery for M.H.D. plant. Philos Trans R Soc Lond Ser A Math Phys Sci 261(1123):514–554

Kamali R, Mousavi SM, Binesh AR, Abolfazli-Esfahani J (2017) Large eddy simulation of the flameless oxidation in the IFRF furnace with varying inlet conditions. Int J Spray Combust Dyn 9(2):102–115

Kayukawa N (2004) Open-cycle magnetohydrodynamic electrical power generation: a review and future perspectives. Progress in Egy&CombnSc 30(1):33–60

Kotas TJ (2012) TheExergy Method of Thermal Plant Analysis. Exergon Publishing Company UK Ltd, UK

Krishnan RA, Jinshah BS (2013) Magnetohydrodynamics power generation. International J Scfand Resr Pubs 3:1–11

Malghan VR (1996) History of MHD power plant development. Energy Convers Manage 37(5):569–590

Mori Y, Ohtake K, Yamamoto M, Imani K (1968) Thermodynamic and electrical properties of combustion gas and its plasma. Bulletin of JSME, NII Library Service 11(44):241–252

Mousavi SM, Abolfazli-Esfahani J (2014) Numerical investigation of the flameless oxidation of natural gas in the IFRF furnace using large eddy simulation. International Journal of Spray and Combustion Dynamics 6(4):387–410

Mousavi SM, Abolfazli-Esfahani J, Yazdi-Mamaghani M (2014) Numerical study of entropy generation in the flameless oxidation using large eddy simulation model and Open FOAM Software. Int J Thermodyn 17(4):202–208

Mousavi SM, Kamali R, Sotoudeh F, Karimi N, Jeung IS (2020) Numerical investigation of the effects of swirling hot co-flow on MILD combustion of a hydrogen–methane blend. J Energy Res Technol 142(11):112301–112313

Mousavi SM, Kamali R, Sotoudeh F, Karimi N, Khojasteh D (2021b) Large eddy simulation of pseudo shock structure in a convergent–long divergent duct. Comput Math Appl 81:823–837

Mousavi SM, Kamali R, Sotoudeh F, Karimi N, Lee BJ (2021) Numerical investigation of the plasma-assisted MILD combustion of a CH4/H2 fuel blend under various working conditions. J Energy Res Technol 143(6):062302–1–12

Murakami T, Nakata Y, Okuno Y, Yamasaki H (2003) An analytical study of the plasma conditions and performance of an MHD generator. Electrical Engineering in Japan 144(2):9–15

Pattanayak L (2015) Thermodynamic modeling and exergy analysis of gas turbine cycle for different boundary conditions. Power Electronics and Drive System 6(2):205–215

Poonthamil RS, Prakash S, Varma AK (2016) Enhancement of power generation in thermal power plant using MHD system. IOSR J Mech&CivEngg 13(5):142–146

Rosa RJ, Krueger CH, Shioda S (1991) Plasma in MHD power generation. IEEE Trans Plasma Sci 19:1180–1190

Sahin B, Ali K, Hasbi Y (1996) A performance analysis for MHD power cycles operating at maximum power density. J Phys D Appl Phys 29:1473–1475

Seetharaman MK, Patwa N, Saravanan GY (2019) Breaking barriers in deployment of renewable energy. Heliyon 5(1):1–23. https://doi.org/10.1016/j.heliyon.2019.e01166

Sheth AC, Johnson TR (1978) Evaluation of Available MHD Seed-Regeneration Processes on the Basis of Energy Considerations.U.S. Department of Energy/Fossil Energy MHD Division, Argonne National Laboratory, Arsonne, Illinois

Shuler K, Fenn J (1963) Ionization in high temperature gases. Progress in Astronautic & Aeronautics 12:5–65

Sohret Y, Acikkalp E, Hepbasli A, Karakoc TH (2015) Advanced exergy analysis of an aircraft gas turbine: Splitting exergy destruction into parts. Energy 90:1219–1228

Sustainable Development Goals. Affordable and clean energy. http://www.un.org/sustainable

Szargut J (1988) Energy and exergy analysis of the preheating of combustion reactants. Energy Research 12(1):45–58

Szargut J (1989) Chemical exergies of the elements. Journal of Applied Energy 32:269–286

Tsatsaronis G, Morosuk T, Koch D, Sorgenfrei M (2013) Understanding the Thermodynamic inefficiencies in combustion processes. Energy 62:3–11

Turns SR (2012) An Introduction to Combustion Concepts and Applications, 3rd edn. McGraw Hill Education Private Ltd, India

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Haloi, P., Gogoi, T.K. Effects of Partially Ionized Combustion Products on the Performance of a Magneto-Hydrodynamics (MHD)-Gas Turbine (GT) Combined Power Plant, Part 1: Exergy Analysis. Iran J Sci Technol Trans Mech Eng 46, 481–495 (2022). https://doi.org/10.1007/s40997-021-00456-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40997-021-00456-y