Abstract

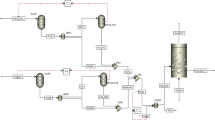

This paper presents the thermodynamic modeling and validation of a 210-MW subcritical coal-fired power plant situated in North India. In the era of high computing facilities available, modeling and simulation have become a very pertinent tool for design and development. As such, the objective of the present work is not to enhance the thermal conversion efficiency, but to represent the thermal system in a simplistic yet functional manner. The thermal performance module consists of the following main sections such as steam boiler, economizer, superheater, reheater, steam turbine, condensate extraction pump, boiler feed pump, feedwater heaters and condenser. Thus, a semi-empirical module has been developed to predict thermal performance of coal-fired power plant. It includes the mass balance, energy balance, thermodynamic property relations for working substance followed by empirical correlations for steam bled pressure and thermodynamics of a steam power cycle. By using the MATLAB calculation tool, a process-based computer program of the coal-fired power plant has been successfully validated for thermal efficiency, steam flow rate and coal consumption rate at wide plant load range. The predictions were compared with operating data of 210-MW thermal power plant at different power output levels. The predicted results agree with plant operating data.

Similar content being viewed by others

Abbreviations

- BF:

-

Boiler feed pump

- CEP:

-

Condensate extraction pump

- CM, GM:

-

Gland steam leakage collector

- COND:

-

Condenser

- C pw :

-

Specific heat capacity of working substance

- Cina:

-

Carbon content in ash

- DR:

-

Deaerator

- DC:

-

Drain cooler

- ECO:

-

Economizer

- EJE:

-

Ejector

- ETD:

-

Entry temperature difference

- FW:

-

Feedwater

- GSC:

-

Gland steam condenser

- GCVcoal :

-

Gross calorific value of coal (kJ kg−1)

- HPT:

-

High-pressure turbine

- HPH:

-

High-pressure feedwater heater

- h :

-

Enthalpy (kJ kg−1)

- h s(i) :

-

Enthalpy of superheated steam (kJ kg−1)

- h f(i) :

-

Enthalpy of feedwater at exit (kJ kg−1)

- h f(i+1) :

-

Enthalpy of feedwater at entry (kJ kg−1)

- h c(i) :

-

Enthalpy of condensate (kJ kg−1)

- IPT:

-

Intermediate pressure turbine

- IPH:

-

Intermediate pressure feedwater heater

- LPT:

-

Low-pressure turbine

- LPH:

-

Low-pressure feedwater heater

- m coal :

-

Coal consumption rate (ton h−1)

- m uw :

-

Unit mass flow rate of water (ton h−1)

- MWe:

-

Net power output

- MW:

-

Plant capacity

- NCVcoal :

-

Net calorific value of coal (kJ kg−1)

- P :

-

Pressure in bar

- P i :

-

Pressure of bled steam at various locations from turbine

- P op :

-

Power output of turbine

- Q i :

-

‘ith’ loss in boiler

- RH:

-

Reheater

- SH:

-

Superheater

- T f :

-

Temperature of flue gas at air preheater outlet

- T a :

-

Forced draft fan inlet temperature

- TTD:

-

Terminal temperature difference

- W t :

-

Work done by turbine

- x i :

-

Fractional mass flow rate of steam at ‘ith’ state

- η plant :

-

Overall thermal efficiency of the plant

- η boiler :

-

Boiler efficiency

References

Aljundi IH (2009) Energy and exergy analysis of a steam power plant in Jordan. Appl Therm Eng 29(2–3):324–328

Ameri M, Ahmadi P, Hamidi A (2009) Energy, exergy and exergoeconomic analysis of a steam power plant-a case study. Int J Energy Res 33(5):499–512

Angelino G, Invernizzi C, Moltenti G (1999) The potential role of organic bottoming Rankine cycles in steam power stations. Proc Inst Mech Eng Part A J Power Energy 213(2):75–81

Cengel YA, Boles MA (2006) Thermodynamics: an engineering approach. McGraw-Hill, New York

Gill AB (1984) Power plant performance. Butterworths-Heinemann, London

Haywood RW (1949) A generalized analysis of the regenerative steam cycle for a finite number of heaters. Proc Inst Mech Eng Part A J Power Energy 161(1):157–164

Horlock JH (1996) Simplified analysis of some vapor power cycles. Part A J Power Energy 210(3):191–204

Kapooria RK, Kumar S, Kasana KS (2008) An analysis of a thermal power plant working on a Rankine cycle: a theoretical investigation. J Energy South Afr 19(1):77–83

Kostyuk A, Frolov V (1985) Steam and gas turbines. Mir, Moscow

Kumar R, Sharma AK, Tewari PC (2014) Thermal performance and economic analysis of 210 MWe coal-fired power plant. J Thermodyn, Article ID 520183, 1–10

Luo X, Zhang B, Chen Y, Mo S (2011) Modeling and optimization of a utility system containing multiple extractions steam turbines. Energy 36(5):3501–3512

Lv T, Yu L, Song J (2012) A research of simplified method in boiler efficiency test. Energy Proc 17:1007–1013

Murugan RS (2009) Study of alternative bottoming cycles for modern rankine cycle power plants, Ph. D dissertation, Indian Institute of Technology

Nag PK (2001) Power plant engineering. Tata McGraw-Hill, New Delhi

Ortiz FJG (2011) Modeling of fire-tube boilers. Appl Therm Eng 31(16):3463–3478

Reddy VS, Tyagi SK (2011) Energy and exergy analysis of thermal power plants: a review. Renew Sustain Energy Rev 15(4):1857–1872

Reddy VS, Kaushik SC, Tyagi SK, Panwar NL (2010) An approach to analyze energy and exergy analysis of thermal power plants: a review. Smart Grid Renew Energy 1:143–152

Seikan IN (1999) Steam power engineering-thermal and hydraulic design principles. Cambridge University Press, Cambridge

Tzolakis G, Papanikoaou P, Kolokotronis D, Samaras A (2012) Simulation of a coal-fired power plant using mathematical programming algorithms in order to optimize its efficiency. Appl Therm Eng 48:256–267

Wang M, Oko E (2014) Dynamic modelling, validation and analysis of coal-fired subcritical power plant. Fuel 135:292–300

Weir CD (1960) Optimization of heater enthalpy rises in feed-heating trains. Proc Inst Mech Eng Part A J Power Energy 174(1):769–796

Author information

Authors and Affiliations

Corresponding author

Appendix: Properties Modeling of Working Substance

Appendix: Properties Modeling of Working Substance

The thermodynamic properties of water in unsaturated, saturated and superheated conditions have been obtained from a curve fit to the thermodynamic data originally by Keenan and Keyes Steam Tables.

The enthalpy of saturated water is obtained in the following form

The graphical presentation is given in Fig. 11.

The empirical fit of entropy in terms of pressure of saturated water is graphically presented in Fig. 12.

Enthalpy of water vapor in superheated conditions is obtained from a curve fit to the thermodynamic data originally by Keenan and Keyes Steam Tables in the following form

The values of constants are listed in Table 4.

Equation 36 is valid in the pressure range of 0.1–175 bar and entropy in the range of 5–11.6 (kJ kg K) with coefficient of determination of 0.9198 and with percentage error (average) of 3.0258 and RMS error of 0.1888.

Rights and permissions

About this article

Cite this article

Kumar, R. Thermodynamic Modeling and Validation of a 210-MW Capacity Coal-Fired Power Plant. Iran J Sci Technol Trans Mech Eng 40, 233–242 (2016). https://doi.org/10.1007/s40997-016-0025-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40997-016-0025-5