Abstract

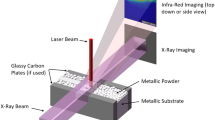

As unprecedented design freedom is realized through additive manufacturing and simultaneously as the diversity of materials improves to include high-performance metals, aerospace and biomedical applications demand improved quality control measures. In the context of additive manufacturing, new opportunities for in situ monitoring are now possible with a qualify-as-you-go layer-by-layer methodology. In this study, a pair of low-cost, high-speed cameras recording the selective laser melting of maraging steel was synchronized to measure stereoscopic features of the resulting spatter. Through epipolar geometry, accurate measurements were calculated of the age, speed and direction of thousands of spatter events. Statistical analysis was performed focusing on spatter velocity with the driving hypothesis that velocity can be correlated to the weld quality and eventually leveraged in real-time process control. Opportunities, future work, and challenges are discussed.

Similar content being viewed by others

References

Berumen S, Bechmann F, Lindner S, Kruth J-P, Craeghs T (2010) Quality control of laser- and powder bed-based additive manufacturing (AM) technologies. Phys Procedia 5:617–622

Liu Y, Yang Y, Mai S, Wang D, Song C (2015) Investigation into spatter behavior during selective laser melting of AISI 316L stainless steel powder. Mater Des 87:797–806

Gunenthiram V, Peyre P, Schneider M, Dal M, Coste F, Koutiri I, Fabbro R (2018) Experimental analysis of spatter generation and melt-pool behavior during the powder bed laser beam melting process. J Mater Process Technol 251:376–386

Bidare P, Bitharas I, Ward RM, Attallah MM, Moore AJ (2018) Fluid and particle dynamics in laser powder bed fusion. Acta Mater 142:107–120

Repossini G, Laguzza V, Grasso M, Colosimo BM (2017) On the use of spatter signature for in situ monitoring of laser powder bed fusion. Addit Manuf 16:35–48

Tang M, Pistorius PC, Beuth JL (2017) Prediction of lack-of-fusion porosity for powder bed fusion. Addit Manuf 14:39–48

Criales LE, Arısoy YM, Lane B, Moylan S, Donmez A, Özel T (2017) Laser powder bed fusion of nickel alloy 625: experimental investigations of effects of process parameters on melt pool size and shape with spatter analysis. Int J Mach Tools Manuf 121:22–36

King WE, Barth HD, Castillo VM, Gallegos GF, Gibbs JW, Hahn DE, Kamath C, Rubenchik AM (2014) Observation of keyhole-mode laser melting in laser powder-bed fusion additive manufacturing. J Mater Process Technol 214:2915–2925

Cunningham R, Narra SP, Montgomery C, Beuth J, Rollett AD (2017) Synchrotron-based X-ray microtomography characterization of the effect of processing variables on porosity formation in laser power-bed additive manufacturing of Ti–6Al–4 V. JOM 69:479–484

Khairallah SA, Anderson AT, Rubenchik A, King WE (2016) Laser powder-bed fusion additive manufacturing: physics of complex melt flow and formation mechanisms of pores, spatter, and denudation zones. Acta Mater 108:36–45

Foster BK, Reutzel EW, Nassar AR, Hall BT, Brown SW, Dickman CJ (2015) Optical, layerwise monitoring of powder bed fusion. In: Proceedings of solid freeform fabrication symposium. pp 295–307. sffsymposium.engr.utexas.edu

Everton SK, Hirsch M, Stravroulakis P, Leach RK, Clare AT (2016) Review of in situ process monitoring and in situ metrology for metal additive manufacturing. Mater Des 95:431–445

Barrett C, Walker J, Enriquez Gutierrez R, MacDonald E, Conner B (2018) A low cost, high-speed optical monitoring system for tracking spatter during laser powder bed fusion. In: TMS 2018. Phoenix

Kneen TJ (2016) Characterizing the high strain rate mechanical behavior of stainless steel 316L processed by selective laser melting. Youngstown State University

Mumtaz K, Hopkinson N (2009) Top surface and side roughness of Inconel 625 parts processed using selective laser melting. Rapid Prototyp J 15:96–103

Ladewig A, Schlick G, Fisser M, Schulze V, Glatzel U (2016) Influence of the shielding gas flow on the removal of process by-products in the selective laser melting process. Addit Manuf 10:1–9

Taheri Andani M, Dehghani R, Karamooz-Ravari MR, Mirzaeifar R, Ni J (2018) A study on the effect of energy input on spatter particles creation during selective laser melting process. Addit Manuf 20:33–43

Taheri Andani M, Dehghani R, Karamooz-Ravari MR, Mirzaeifar R, Ni J (2017) Spatter formation in selective laser melting process using multi-laser technology. Mater Des 131:460–469

Simonelli M, Tuck C, Aboulkhair NT, Maskery I, Ashcroft I, Wildman RD, Hague R (2015) A study on the laser spatter and the oxidation reactions during selective laser melting of 316L stainless steel, Al–Si10–Mg, and Ti–6Al–4V. Metall Mater Trans A 46:3842–3851

Craeghs T, Bechmann F, Berumen S, Kruth J-P (2010) Feedback control of layerwise laser melting using optical sensors. Phys Procedia 5(Part B):505–514

Clijsters S, Craeghs T, Buls S, Kempen K, Kruth J-P (2014) In situ quality control of the selective laser melting process using a high-speed, real-time melt pool monitoring system. Int J Adv Manuf Technol 75:1089–1101

Lott P, Schleifenbaum H, Meiners W, Wissenbach K, Hinke C, Bültmann J (2011) Design of an optical system for the in situ process monitoring of selective laser melting (SLM). Phys Procedia 12(Part A):683–690

Yadroitsev I, Krakhmalev P, Yadroitsava I (2014) Selective laser melting of Ti6Al4V alloy for biomedical applications: temperature monitoring and microstructural evolution. J Alloys Compd 583:404–409

Doubenskaia M, Pavlov M, Grigoriev S, Tikhonova E, Smurov I (2012) Comprehensive optical monitoring of selective laser melting. J Laser Micro Nanoeng 7:236–243

Kanko JA, Sibley AP, Fraser JM (2016/5) In situ morphology-based defect detection of selective laser melting through inline coherent imaging. J Mater Process Technol. 231: 488–500

Krauss H, Eschey C, Zaeh M (2012) Thermography for monitoring the selective laser melting process. In: Proceedings of the solid freeform fabrication symposium

Lane B, Moylan S, Whitenton E, Ma L (2016) Thermographic measurements of the commercial laser powder bed fusion process at NIST. Rapid Prototyp J 22:778–787

Bayle F, Doubenskaia M (2008) Selective laser melting process monitoring with high speed infra-red camera and pyrometer. In: Fundamentals of laser assisted micro- and nanotechnologies. International Society for Optics and Photonics, pp 698505–698508

Grasso M, Laguzza V, Semeraro Q, Colosimo BM (2017) In-process monitoring of selective laser melting: spatial detection of defects via image data analysis. J Manuf Sci Eng 139:051001

You D, Gao X, Katayama S (2014) Monitoring of high-power laser welding using high-speed photographing and image processing. Mech Syst Signal Process 49:39–52

Ly S, Rubenchik AM, Khairallah SA, Guss G, Matthews MJ (2017) Metal vapor micro-jet controls material redistribution in laser powder bed fusion additive manufacturing. Sci Rep 7:4085

Guo Q, Zhao C, Escano LI, Young Z, Xiong L, Fezzaa K, Everhart W, Brown B, Sun T, Chen L (2018) Transient dynamics of powder spattering in laser powder bed fusion additive manufacturing process revealed by in situ high-speed high-energy X-ray imaging. Acta Mater 151:169–180

Zhao C, Fezzaa K, Cunningham RW, Wen H, De Carlo F, Chen L, Rollett AD, Sun T (2017) Real-time monitoring of laser powder bed fusion process using high-speed X-ray imaging and diffraction. Sci Rep 7:3602

Barrett C, Carradero-Santiago C, Harris E, Mc Knight J, Walker J, MacDonald E, Conner B (2018) Low cost, high speed stereovision for spatter tracking in laser powder bed fusion. In: Solid freeform fabrication symposium

Acknowledgements

We would like to thank the Friedman Endowment for Manufacturing at Youngstown State University. This effort was performed in part through the National Center for Defense Manufacturing and Machining under the America Makes Program entitled “Maturation of Advanced Manufacturing for Low Cost Sustainment (MAMLS)” and is based on research sponsored by Air Force Research Laboratory under agreement number FA8650-16-2-5700. The U.S. Government is authorized to reproduce and distribute reprints for Governmental purposes notwithstanding any copyright notation thereon.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Barrett, C., Carradero, C., Harris, E. et al. Statistical analysis of spatter velocity with high-speed stereovision in laser powder bed fusion. Prog Addit Manuf 4, 423–430 (2019). https://doi.org/10.1007/s40964-019-00094-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40964-019-00094-6