Abstract

Three dimensional (3D) printing technologies, known as the additive manufacturing, have been attracting extensive interests in various fields, including the academic world, industries and even daily life. It has special capabilities that can be used for increasing shape or structure complexity and fabrication efficiency, while reducing the waste materials, capital cost and design cycle for manufacturing. Among these, fabrication of functional components or devices for microelectronic systems with 3D printing technologies is still an emerging field. Recently, a series of 3D printed functional components and devices for electronics have been reported, especially with the widely used direct ink writing 3D printing. This paper will focus on materials and practical applications of 3D printing for electronic units and systems, including microelectrodes, supercapacitances, electronic circuits, batteries and so on. The implementation of 3D printing for electronics with advanced materials will have great advantage in terms of performance, microstructures, product flexibility and tailored shape along with low cost, less waste and high efficiency.

Reproduced with permission from ref [27]. Copyright 2014, Wiley-VCH

Reprinted with permission from ref [47]. Copyright 2004, Elsevier

Reproduced with permission from ref [51]. Copyright 2017, ACS

Reproduced with permission from ref [69]. Copyright 2015, Wiley-VCH

Reproduced with permission from ref [70]. Copyright 2017, Nature

Reprinted with permission from ref [85]. Copyright 2010, RSC

Reproduced with permission from ref [94]. Copyright 2009, Science

Reproduced with permission from ref [102]. Copyright 2014, ACS

Reprinted with permission from ref [103]. Copyright 2017, ACS

Reproduced with permission from ref [104]. Copyright 2016, Elsevier

Reproduces with permission from ref [110]. Copyright 2017, Wiley-VCH

Reproduced with permission from ref [116]. Copyright 2014, ACS

Reproduced with permission from ref [129]. Copyright 2013, Wiley-VCH

Reproduced with permission from ref [128]. Copyright 2016, Wiley-VCH

Reproduced with permission from ref [136]. Copyright 2014, ACS. (Color figure online)

Similar content being viewed by others

References

Ruiz-Morales JC, Tarancón A, Canales-Vázquez J, Méndez-Ramos J, Hernández-Afonso L, Acosta-Mora P, Marín Rueda JR, Fernández-González R (2017) Three dimensional printing of components and functional devices for energy and environmental applications. Energy Environ Sci 10(4):846–859. https://doi.org/10.1039/c6ee03526d

Maeda K, Domen K (2010) Photocatalytic water splitting: recent progress and future challenges. J Phys Chem Lett 1(18):2655–2661. https://doi.org/10.1021/jz1007966

Ruiz-Morales JC, Canales-Vazquez J, Savaniu C, Marrero-Lopez D, Zhou W, Irvine JT (2006) Disruption of extended defects in solid oxide fuel cell anodes for methane oxidation. Nature 439(7076):568–571. https://doi.org/10.1038/nature04438

Luo X, Wang J, Dooner M, Clarke J (2015) Overview of current development in electrical energy storage technologies and the application potential in power system operation. Appl Energy 137:511–536. https://doi.org/10.1016/j.apenergy.2014.09.081

Winter M, Brodd RJ (2004) What are batteries, fuel cells, and supercapacitors? Chem Rev 105(3):4245–4269. https://doi.org/10.1021/cr040110e

Haas O, Cairns EJ (1999) Electrochemical energy storage. Phys Chem 95:163–198. https://doi.org/10.1039/pc095163

Mohammed MG, Kramer R (2017) All-printed flexible and stretchable electronics. Adv Mater. https://doi.org/10.1002/adma.201604965

Liu L, Niu Z, Chen J (2016) Unconventional supercapacitors from nanocarbon-based electrode materials to device configurations. Chem Soc Rev 45(15):4340–4363. https://doi.org/10.1039/c6cs00041j

Aravindan V, Sundaramurthy J, Kumar PS, Shubha N, Ling WC, Ramakrishna S, Madhavi S (2013) A novel strategy to construct high performance lithium-ion cells using one dimensional electrospun nanofibers, electrodes and separators. Nanoscale 5(21):10636–10645. https://doi.org/10.1039/c3nr04486f

Yuan L, Yao B, Hu B, Huo K, Chen W, Zhou J (2013) Polypyrrole-coated paper for flexible solid-state energy storage. Energy Environ Sci. https://doi.org/10.1039/c2ee23977a

Wang D-W, Li F, Liu M, Lu GQ, Cheng H-M (2008) 3D aperiodic hierarchical porous graphitic carbon material for high-rate electrochemical capacitive energy storage. Angew Chem 120(2):379–382. https://doi.org/10.1002/ange.200702721

Dhar NK, Johnson DC, Prieto AL, Balaya P, Dutta AK (2013) Three-dimensional lithium-ion batteries with interdigitated electrodes. Paper presented at the energy harvesting and storage: materials, devices, and applications IV, 8728: 872805–872810. https://doi.org/10.1117/12.2016142

Farahani RD, Dube M, Therriault D (2016) Three-dimensional printing of multifunctional nanocomposites: manufacturing techniques and applications. Adv Mater 28(28):5794–5821. https://doi.org/10.1002/adma.201506215

Hassain HSSA (2010) Fabrication of ceramics and ceramic composite microcomponents using soft lithography. PhD thesis, The University of Birmingham, United Kingdom

Brookes KJA (2015) 3D-printing style additive manufacturing for commercial hardmetals. Metal Powder Rep 70(3):137–140. https://doi.org/10.1016/j.mprp.2015.04.011

Leong KF, Cheah CM, Chua CK (2003) Solid freeform fabrication of three-dimensional scaffolds for engineering replacement tissues and organs. Biomaterials 24(13):2363–2378. https://doi.org/10.1016/s0142-9612(03)00030-9

Chua CK, Leong KF (2017) 3D printing and additive manufacturing: principles and applications (the 5th edition of rapid prototyping: principles and applications). World Scientific, Singapore

Highley CB, Rodell CB, Burdick JA (2015) Direct 3D printing of shear-thinning hydrogels into self-healing hydrogels. Adv Mater 27(34):5075–5079. https://doi.org/10.1002/adma.201501234

Billiet T, Vandenhaute M, Schelfhout J, Van Vlierberghe S, Dubruel P (2012) A review of trends and limitations in hydrogel-rapid prototyping for tissue engineering. Biomaterials 33(26):6020–6041. https://doi.org/10.1016/j.biomaterials.2012.04.050

Yazdi AA, Popma A, Wong W, Nguyen T, Pan Y, Xu J (2016) 3D printing: an emerging tool for novel microfluidics and lab-on-a-chip applications. Microfluid Nanofluid. https://doi.org/10.1007/s10404-016-1715-4

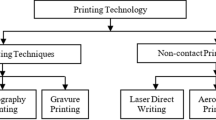

Hon KKB, Li L, Hutchings IM (2008) Direct writing technology—advances and developments. CIRP Ann 57(2):601–620. https://doi.org/10.1016/j.cirp.2008.09.006

Bose S, Vahabzadeh S, Bandyopadhyay A (2013) Bone tissue engineering using 3D printing. Mater Today 16(12):496–504. https://doi.org/10.1016/j.mattod.2013.11.017

Campbell TA, Ivanova OS (2013) 3D printing of multifunctional nanocomposites. Nano Today 8(2):119–120. https://doi.org/10.1016/j.nantod.2012.12.002

Manyika J, Chui M, Bughin J, Dobbs R. Bisson Peter, Marrs A (2013) Disruptive technologies: advances that will transform life, business, and the global economy, MGI

Tian X, Jin J, Yuan S, Chua CK, Tor SB, Zhou K (2017) Emerging 3D-printed electrochemical energy storage devices: a critical review. Adv Energy Mater. https://doi.org/10.1002/aenm.201700127

Tay BY, Evans JRG, Edirisinghe MJ (2013) Solid freeform fabrication of ceramics. Int Mater Rev 48(6):341–370. https://doi.org/10.1179/095066003225010263

Travitzky N, Bonet A, Dermeik B, Fey T, Filbert-Demut I, Schlier L, Schlordt T, Greil P (2014) Additive manufacturing of ceramic-based materials. Adv Eng Mater 16(6):729–754. https://doi.org/10.1002/adem.201400097

Ambrosi A, Pumera M (2016) 3D-printing technologies for electrochemical applications. Chem Soc Rev 45(10):2740–2755. https://doi.org/10.1039/c5cs00714c

Tang Y, Zhang Y, Rui X, Qi D, Luo Y, Leow WR, Chen S, Guo J, Wei J, Li W, Deng J, Lai Y, Ma B, Chen X (2016) Conductive inks based on a lithium titanate nanotube gel for high-rate lithium-ion batteries with customized configuration. Adv Mater 28(8):1567–1576. https://doi.org/10.1002/adma.201505161

Crump SS, Stratasys, Inc. (1992) Apparatus and method for creating three-dimensional objects. U.S. Patent 5121329

Yardimci AM, Guceri SI, Danforth SC, Agarwala M, Safari A (1995) Numerical modeling of fused deposition processing. Am Soc Mech Eng 69:1225–1235

Ligon SC, Liska R, Stampfl J, Gurr M, Mulhaupt R (2017) Polymers for 3D printing and customized additive manufacturing. Chem Rev 117(15):10212–10290. https://doi.org/10.1021/acs.chemrev.7b00074

Andre JC, Mehaute AL, De Witte O (1984) Com agn Industrielle des Lasers Cilas Alcatel) Dispositif pour Realiser un Modele de Piece Industrielle. French Patent App. 2567668

Liska R, Schuster M, Inführ R, Turecek C, Fritscher C, Seidl B, Schmidt V, Kuna V, Haase A, Varga F (2007) Photopolymers for rapid prototyping. J Coat Technol Res 4(4):505–510

Fouassier JP, Allonas X, Burget D (2003) Photopolymerization reactions under visible lights: principle, mechanisms and examples of applications. Prog Org Coat 47(1):16–36. https://doi.org/10.1016/s0300-9440(03)00011-0

Gross BC, Erkal JL, Lockwood SY, Chen C, Spence DM (2014) Evaluation of 3D printing and its potential impact on biotechnology and the chemical sciences. Anal Chem 86(7):3240–3253. https://doi.org/10.1021/ac403397r

Noorani R (2006) Rapid prototyping, principles and applications. Wiley, Hoboken, pp 108–155

Karapatis NP, Egger G, Gygax PE, Glardon R (1998) Optimization of powder layer density in selective laser sintering. Proceedings of the SFF Symposium, pp 79–87

Gurr M, Mulhaupt R (2012) Polymer science: a comprehensive reference. In: Matyjaszewski K, Moller M (eds), vol. 8. Elsevier BV, Amsterdam, pp 77–99

Pfister A (2005) Neue Materialsysteme für das Dreidimensionale Drucken und das Selektive Lasersintern. Ph.D. Thesis, Albert-LudwigsUniversitat

Lewis JA, Smay JE, Stuecker J, Cesarano J (2006) Direct ink writing of three-dimensional ceramic structures. J Am Ceram Soc 89(12):3599–3609. https://doi.org/10.1111/j.1551-2916.2006.01382.x

Xu Q, Lv Y, Dong C, Sreeprased TS, Tian A, Zhang H, Tang Y, Yu Z, Li N (2015) Three-dimensional micro/nanoscale architectures: fabrication and applications. Nanoscale 7(25):10883–10895. https://doi.org/10.1039/c5nr02048d

Kalsoom U, Nesterenko PN, Paull B (2016) Recent developments in 3D printable composite materials. RSC Adv 6(65):60355–60371. https://doi.org/10.1039/c6ra11334f

Zhu C, Han TY, Duoss EB, Golobic AM, Kuntz JD, Spadaccini CM, Worsley MA (2015) Highly compressible 3D periodic graphene aerogel microlattices. Nat Commun 6:6962. https://doi.org/10.1038/ncomms7962

Fu K, Wang Y, Yan C, Yao Y, Chen Y, Dai J, Lacey S, Wang Y, Wan J, Li T (2016) Graphene oxide-based electrode inks for 3D-printed Lithium-ion batteries. Adv Mater 28:2587–2594

Lewis JA (2006) Direct ink writing of 3D functional materials. Adv Funct Mater 16:2193–2204

Lewis JA, Gratson GM (2004) Direct writing in three dimensions. Mater Today 7:32–39

Fu K, Yao Y, Dai J, Hu L (2017) Progress in 3D printing of carbon materials for energy-related applications. Adv Mater 29 (9). https://doi.org/10.1002/adma.201603486

Santhiago M, Corrêa CC, Bernardes JS, Pereira MP, Oliveria LJM, Strauss M, Bufon CCB (2017) Flexible and foldable fully-printed carbon black conductive nanostructures on paper for high-performance electronic, electrochemical, and wearable devices. ACS Appl Mater Interfaces. https://doi.org/10.1021/acsami.7b06598

Wang S, Liu N, Tao J, Yang C, Liu W, Shi Y, Wang Y, Su J, Li L, Gao Y (2015) Inkjet printing of conductive patterns and supercapacitors using a multi-walled carbon nanotube/Ag nanoparticle based ink. J Mater Chem A 3:2407–2413

Chen B, Jiang Y, Tang X, Pan Y, Hu S (2017) Fully-packaged carbon nanotube supercapacitors by direct ink writing on flexible substrates. ACS Appl Mater Interfaces. https://doi.org/10.1021/acsami.7b06804

Naficy S, Jalili R, Aboutalebi SH, Gorkin Iii RA, Konstantinov K, Innis PC, Spinks GM, Poulin P, Wallace GG (2014) Graphene oxide dispersions: tuning rheology to enable fabrication. Mater Horiz 1(3):326–331. https://doi.org/10.1039/c3mh00144j

Secor EB, Prabhumirashi PL, Puntambekar K, Geier ML, Hersam MC (2013) Inkjet printing of high conductivity, flexible graphene patterns. J Phys Chem Lett 4(8):1347–1351. https://doi.org/10.1021/jz400644c

Yoo EJ, Kim J, Hosono E, Zhou HS, Kudo T, Honma I (2008) Large reversible Li storage of graphene nanosheet families for use in rechargeable lithium ion batteries. Nano Lett 8(8):2277–2282. https://doi.org/10.1021/nl800957b

Wang X, Zhi L, Müllen K (2008) Transparent, conductive graphene electrodes for dye-sensitized solar cells. Nano Lett 8(1):323–327. https://doi.org/10.1021/nl075838r

Goodenough JB (2015) Energy storage materials: a perspective. Energy Storage Mater 1:158–161. https://doi.org/10.1016/j.ensm.2015.07.001

Zhang SW, Lv W, Luo C, You C-H, Zhang J, Pan Z-Z, Kang F-Y, Yang Q-H (2016) Commercial carbon molecular sieves as a high performance anode for sodium-ion batteries. Energy Storage Mater 3:18–23. https://doi.org/10.1016/j.ensm.2015.12.004

Eda G, Chhowalla M (2009) Graphene-based composite thin films for electronics. Nano Lett 9(2):814–818. https://doi.org/10.1021/nl8035367

Eda G, Fanchini G, Chhowalla M (2008) Large-area ultrathin films of reduced graphene oxide as a transparent and flexible electronic material. Nat Nanotechnol 3:270–274

Schedin F, Geim AK, Morozov SV, Hill EW, Blake P, Katsnelson MI, Novoselov KS (2007) Detection of individual gas molecules adsorbed on graphene. Nat Mater 6:652–655

Shao Y, Wang J, Wu H, Liu J, Aksay IA, Lin Y (2010) Graphene based electrochemical sensors and biosensors: a review. Electroanalysis 22:1027–1036

Machado BF, Serp P (2012) Graphene-based materials for catalysis. Catal Sci Technol 2(1):54–75. https://doi.org/10.1039/c1cy00361e

Sutter PW, Flege J-I, Sutter EA (2008) Epitaxial graphene on ruthenium. Nat Mater 7:406–411

Vickery JL, Patil AJ, Mann S (2009) Fabrication of graphene-polymer nanocomposites with higher-order three-dimensional architectures. Adv Mater 21(21):2180–2184. https://doi.org/10.1002/adma.200803606

Ramanathan T, Abdala AA, Stankovich S, Dikin DA, Herrera-Alonso M, Piner RD, Adamson DH, Schniepp HC, Chen X, Ruoff RS, Nguyen ST, Aksay IA, Prud’homme RK, Brinson LC (2008) Functionalized graphene sheets for polymer nanocomposites. Nat Nanotechnol 3:327–331

HadjizadehA DoillonCJ (2010) Directional migration of endothelial cells towards angiogenesis using polymer fibres in a 3D co-culture system. J Tissue Eng Regen Med 4(7):524–531. https://doi.org/10.1002/term.269

Yao Y, Fu K, Yan Y, Dai J, Chen Y, Wang Y, Zhang B, Hitz E, Hu L (2016) Three-dimensional printable high-temperature and high-rate heater. ACS Nano 10:5272–5279

Bao W, Pickel AD, Zhang Q, Chen Y, Yao Y, Wan Y, Fu K, Wang Y, Dai J, Zhu H, Drew D, Fuhrer M, Dames C, Hu L (2016) Flexible, high temperature, planar lighting with large scale printable nanocarbon paper. Adv Mater 28(23):4684–4691. https://doi.org/10.1002/adma.201506116

Secor EB, Ahn BY, Gao TZ, Lewis JA, Hersam MC (2015) Rapid and versatile photonic annealing of graphene inks for flexible printed electronics. Adv Mater 27(42):6683–6688. https://doi.org/10.1002/adma.201502866

Park JS, Kim T, Kim WS (2017) Conductive cellulose composites with low percolation threshold for 3D printed electronics. Sci Rep 7(1):3246. https://doi.org/10.1038/s41598-017-03365-w

Xu W et al (2015) Electrically conductive silver nanowires-filed methylcellulose composite transparent films with high mechanical properties. Mater Lett 152:173–176

White SI et al (2010) Electrical percolation behavior in silver nanowire-polystyrene composites: simulation and experiment. Adv Funct Mater 20:2709–2716

Inui T et al. (2014) High-dielectric paper composite consisting of cellulose nanofier and silver nanowire. 14th IEEE International Conference on Nanotechnology. https://doi.org/10.1109/nano.2014.6967965

Sun Y, Mayers B, Herricks T, Xia Y (2003) Polyol synthesis of uniform silver nanowires: a plausible growth mechanism and the supporting evidence. Nano Lett 3:955–960

Hu N et al (2008) Tunneling effect in a polymer/carbon nanotube nanocomposite strain sensor. Acta Mater 56:2929–2936

Lonjon A, Demont P, Dantras E, Lacabanne C (2012) Low filed conductive P(VDF-TrFE) composites: influence of silver particles aspect ratio on percolation threshold from spheres to nanowires. J Non-Cryst Solids 358:3074–3078

Hawkins DMS (1999) Thesis Dissertation (Dept. of Chem., Rochester Institute of Technology: Rochester, NY)

Edali M, Esmail MN, Vatistas GH (2001) Rheological properties of high concentrations of carboxymethyl cellulose solutions. J Appl Polym Sci 79:1787–1801

Benchabane A, Bekkour K (2008) Rheological properties of carboxymethyl cellulose (CMC) solutions. Colloid Polym Sci 286:1173–1180

Jeong S et al (2012) Natural cellulose as binder for lithium battery electrodes. J Power Sources 199:331–335

Buqa H et al (2006) Study of styrene butadiene rubber and sodium methyl cellulose as binder for negative electrodes in lithium-ion batteries. J Power Sources 161:617–622

Kim G et al (2011) Use of natural binders and ionic liquid electrolytes for greener and safer lithium-ion batteries. J Power Sources 196:2187–2194

Zhang D, Chi B, Li B, Gao Z, Du Y, Guo J, Wei J (2016) Fabrication of highly conductive graphene flexible circuits by 3D printing. Synth Met 217:79–86. https://doi.org/10.1016/j.synthmet.2016.03.014

Banks CE, Compton RG (2005) Exploring the electrocatalytic sites of carbon nanotubes for NADH detection: an edge plane pyrolytic graphite electrode study. Analyst 130:1232–1239

Ahn BY, Lorang DJ, Duoss EB, Lewis JA (2010) Direct-write assembly of microperiodic planar and spanning ITO microelectrodes. Chem Commun 46(38):7118–7120. https://doi.org/10.1039/c0cc01691h

Sirringhaus H, Kawase T, Friend RH, Shhimoda T, Inbasekaran M (2000) High-resolution inkjet printing of all-polymer transistor circuits. Science 290(5499):2123–2128

Forrest SR (2004) The path to ubiquitous and low-costorganic electronic appliances on plastic. Nature 428(6986):911–918

Sun Y, Rogers JA (2007) Inorganic semiconductors for flexible electronics. Adv Mater 19:1897–1916

Menard E, Meitl MA, Sun YG (2007) Micro- and nanopatterning techniques for organic electronic and optoelectronic systems. Chem Rev 107:1117–1160

LeMieux MC (2008) Self-sorted, aligned nanotube networks for thin-film transistors. Science 321:101–104

Cao Q, Kim SH, Pimparkar N, Kulkarni P, Wang C, Shim M, Roy K, Alam MA, Rogers JA (2008) Medium-scale carbon nanotube thin-film integrated circuits on flexible plastic substrates. Nature 454(7203):495–500. https://doi.org/10.1038/nature07110

Foster CW, Down MP, Zhang Y, Ji X, Rowley-Neale SJ, Simth GC, Kelly PJ, Banks CE (2017) 3D printed graphene based energy storage devices. Sci Rep 7:42233. https://doi.org/10.1038/srep42233

Symed MD et al (2012) Integrated 3D-printed reactionware for chemical synthesis and analysis. Nat Chem 4:349–354

Ahn BY, Duoss EB, Motala MJ, Guo X, Park S, Xiong J, Yoon J, Nuzzo RG, Rogers JA, Lewis JA (2009) Omnidirectional printing of flexible, stretchable, and spanning silver microelectrodes. Science 323:1950–1953. https://doi.org/10.1126/science.1168375

Beidaghi M, Wang C (2012) Micro-supercapacitors based on interdigital electrodes of reduced graphene oxide and carbon nanotube composites with ultrahigh power handling performance. Adv Funct Mater 22(21):4501–4510. https://doi.org/10.1002/adfm.201201292

Simon P, Gogotsi Y (2008) Graphene-based supercapacitor with an ultrahigh energy density. Nat Mater 7:845–854

El-Kady MF, Kaner RB (2013) Scalable fabrication of high-power graphene micro-supercapacitors for flexible and on-chip energy storage. Nat Commun 4:1475. https://doi.org/10.1038/ncomms2446

Salanne M, Rotenberg B, Naoi K, Kaneko K, Taberna PL, Grey CP, Dunn B, Simon P (2016) Efficient storage mechanisms for building better supercapacitors. Nat Energy. https://doi.org/10.1038/nenergy.2016.70

Zhong C, Deng Y, Hu W, Qiao J, Zhang L, Zhang J (2015) A review of electrolyte materials and compositions for electrochemical supercapacitors. Chem Soc Rev 44(21):7484–7539. https://doi.org/10.1039/c5cs00303b

Shen C, Wang X, Zhang W, Kang F (2011) A high-performance three-dimensional micro supercapacitor based on self-supporting composite materials. J Power Sources 196(23):10465–10471

Nystrom G, Marais A, Karabulut E, Wagberg L, Cui Y, Hamedi MM (2015) Self-assembled three-dimensional and compressible interdigitated thin-film supercapacitors and batteries. Nat Commun 6:7259. https://doi.org/10.1038/ncomms8259

Zhu C, Liu T, Qian F, Han TY, Duoss EB, Kuntz JD, Spadaccini CM, Worsley MA, Li Y (2016) Supercapacitors based on three-dimensional hierarchical graphene aerogels with periodic macropores. Nano Lett 16(6):3448–3456. https://doi.org/10.1021/acs.nanolett.5b04965

Yu W, Zhou H, Li BQ, Ding S (2017) 3D printing of carbon nanotubes-based microsupercapacitors. ACS Appl Mater Interfaces 9(5):4597–4604. https://doi.org/10.1021/acsami.6b13904

Yang Y, Chen Z, Song X, Zhu B, Hsiai T, Wu P-I, Xiong R, Shi J, Chen Y, Zhou Q, Shung KK (2016) Three dimensional printing of high dielectric capacitor using projection based stereolithography method. Nano Energy 22:414–421. https://doi.org/10.1016/j.nanoen.2016.02.045

Secor EB, Hersam MC (2015) Emerging carbon and post-carbon nanomaterial inks for printed electronics. J Phys Chem Lett 6(4):620–626. https://doi.org/10.1021/jz502431r

Torrisi F, Hasan T, Wu WP, Sun ZP, Lombardo A, Kulmala TS, Hsieh GW, Jung S, Bonaccorso F, Paul PJ (2012) Inkjet-printed graphene electronics. ACS Nano 6:2992–3006

Kamyshny A, Magdassi S (2014) Conductive nanomaterials for printed electronics. Small 10(17):3515–3535. https://doi.org/10.1002/smll.201303000

Garcia-Tunon E, Barg S, Franco J, Bell R, Eslava S, D’Elia E, Maher RC, Guitian F, Saiz E (2015) Printing in three dimensions with graphene. Adv Mater 27(10):1688–1693. https://doi.org/10.1002/adma.201405046

Zhang Q, Zhang F, Medarametla SP, Li H, Zhou C, Lin D (2016) 3D printing of graphene aerogels. Small 12(13):1702–1708. https://doi.org/10.1002/smll.201503524

Valentine AD, Busbee TA, Boley JW, Raney JR, Chortos A, Kotikian A, Berrigan JD, Durstock MF, Lewis JA (2017) Hybrid 3D printing of soft electronics. Adv Mater 29(40):1703817. https://doi.org/10.1002/adma.201703817

Azzaroni O, Fonticelli MH, Benítez G, Schilardi PL, Gago R, Caretti I, Vázquez L, Salvarezza RC (2004) Direct nanopatterning of metal surfaces using self-assembled molecular films. Adv Mater 16(5):405–409. https://doi.org/10.1002/adma.200306190

Wang X, Hu H, Shen Y, Zhou X, Zheng Z (2011) Stretchable conductors with ultrahigh tensile strain and stable metallic conductance enabled by prestrained polyelectrolyte nanoplatforms. Adv Mater 23(27):3090–3094. https://doi.org/10.1002/adma.201101120

Wang X, Zhang T, Kobe B, Lau WM, Yang J (2013) Grafting of polyelectrolytes onto hydrocarbon surfaces by high-energy hydrogen induced cross-linking for making metallized polymer films. Chem Commun 49(41):4658–4660. https://doi.org/10.1039/c3cc41644e

Liu X, Zhou X, Li Y, Zheng Z (2012) Surface-grafted polymer-assisted electroless deposition of metals for flexible and stretchable electronics. Chem Asian J 7(5):862–870. https://doi.org/10.1002/asia.201100946

Guo R, Yu Y, Xie Z, Liu X, Zhou X, Gao Y, Liu Z, Zhou F, Yang Y, Zheng Z (2013) Matrix-assisted catalytic printing for the fabrication of multiscale, flexible, foldable, and stretchable metal conductors. Adv Mater 25(24):3343–3350. https://doi.org/10.1002/adma.201301184

Wang X, Guo Q, Cai X, Zhou S, Kobe B, Yang J (2014) Initiator-integrated 3D printing enables the formation of complex metallic architectures. ACS Appl Mater Interfaces 6(4):2583–2587. https://doi.org/10.1021/am4050822

Ye Q, Wang X, Hu H, Wang D, Li S, Zhou F (2009) Polyelectrolyte brush templated multiple loading of Pd nanoparticles onto TiO2 nanowires via regenerative counterion exchange-reduction. J Phys Chem C 113:7677–7683

Azzaroni O, Zheng Z, Yang Z, Huck WTS (2006) Polyelectrolyte brushes as efficient ultrathin platforms for site-selective copper electroless deposition. Langmuir 22:6730–6733

Liu Z, Hu H, Yu B, Chen M, Zheng Z, Zhou F (2009) Binary oppositely charged polyelectrolyte brushes for highly selective electroless deposition of bimetallic patterns. Electrochem Commun 11(2):492–495. https://doi.org/10.1016/j.elecom.2008.12.033

Scrosati B, Garche J (2010) Lithium batteries: status, prospects and future. J Power Sources 195:2419–2430. https://doi.org/10.1016/j.jpowsour.2009.11.048

Armand M, Tarascon JM (2008) Building better batteries. Nature 451(7179):652–657

Ye J, Baumgaertel AC, Wang YM, Biener J, Biener MM (2015) Structural optimization of 3D porous electrodes for high-rate performance lithium ion batteries. ACS Nano 15:2194–2202

Zhang H, Yu X, Braun PV (2011) Three-dimensional bicontinuous ultrafast-charge and -discharge bulk battery electrodes. Nat Nanotechnol 6(5):277–281. https://doi.org/10.1038/nnano.2011.38

Liu J, Li N, Goodman MD, Zhang HG, Epstein ES, Huang B, Pan Z, Kim J, Choi JH, Huang X, Liu J, Hsia KJ, Dillon SJ, Braun PV (2015) Mechanically and chemically robust sandwich-structured C@Si@C nanotube array Li-ion battery anodes. ACS Nano 9(2):1985–1994. https://doi.org/10.1021/nn507003z

Pikul JH, Gang ZH, Cho J, Braun PV, King WP (2013) High-power lithium ion microbatteries from interdigitated three-dimensional bicontinuous nanoporous electrodes. Nat Commun 4:1732. https://doi.org/10.1038/ncomms2747

Liu J, Zhang HG, Wang J, Cho J, Pikul JH, Epstein ES, Huang X, Liu J, King WP, Braun PV (2014) Hydrothermal fabrication of three-dimensional secondary battery anodes. Adv Mater 26(41):7096–7101. https://doi.org/10.1002/adma.201402552

Liu J, Chen X, Kim J, Zheng Q, Ning H, Sun P, Huang X, Liu J, Niu J, Braun PV (2016) High volumetric capacity three-dimensionally sphere-caged secondary battery anodes. Nano Lett 16(7):4501–4508. https://doi.org/10.1021/acs.nanolett.6b01711

Fu K, Wang Y, Yan C, Yao Y, Chen Y, Dai J, Lacey S, Wang Y, Wan J, Li T, Wang Z, Xu Y, Hu L (2016) Graphene oxide-based electrode inks for 3D-printed lithium-ion batteries. Adv Mater 28(13):2587–2594. https://doi.org/10.1002/adma.201505391

Sun K, Wei TS, Ahn BY, Seo JY, Dillon SJ, Lewis JA (2013) 3D printing of interdigitated Li-ion microbattery architectures. Adv Mater 25(33):4539–4543. https://doi.org/10.1002/adma.201301036

Shaijumon MM, Perre E, Daffos B, Taberna PL, Tarascon JM, Simon P (2010) Nanoarchitectured 3D cathodes for Li-ion microbatteries. Adv Mater 22(44):4978–4981. https://doi.org/10.1002/adma.201001922

Notten PHL, Roozeboom F, Niessen RAH, Baggetto L (2007) 3-D integrated all-solid-state rechargeable batteries. Adv Mater 19:4564–4567

Long JW, Dunn B, Rolison DR, White HS (2004) Three-dimensional battery architecture. Chem Rev 104(10):4463. https://doi.org/10.1002/chin.200451264

Anikeeva PO, Halpert JE, Bawendi MG, Bulovic V (2007) Electroluminescence from a mixed red–green–blue colloidal quantum dot monolayer. Nano Lett 7(8):2196–2200. https://doi.org/10.1021/nl0703424

Chen O, Zhao J, Chauhan VP, Cui J, Wong C, Harris DK, Wei H, Han HS, Fukumura D, Jain RK, Bawendi MG (2013) Compact high-quality CdSe–CdS core–shell nanocrystals with narrow emission linewidths and suppressed blinking. Nat Mater 12:445–451

Kim TH, Jun S, Cho KS, Choi BL, Jang E (2013) Bright and stable quantum dots and their applications in full-color displays. MRS Bull 38(9):712–720. https://doi.org/10.1557/mrs.2013.184

Kong YL, Tamargo IA, Kim H, Johnson BN, Gupta MK, Koh TW, Chin HA, Sreingart DA, Rand BP, McAlpine MC (2014) 3D printed quantum dot light-emitting diodes. Nano Lett 14:7017–7023. https://doi.org/10.1021/nl5033292

Qian L, Zheng Y, Xue JG, Holloway PH (2011) Stable and efficient quantum-dot light-emitting diodes based on solution-processed multilayer structures. Nat Photonics 5(9):543–548. https://doi.org/10.1038/nphoton.2011.171

Lipomi DJ, Tee BC, Vosgueritchian M, Bao Z (2011) Stretchable organic solar cells. Adv Mater 23(15):1771–1775. https://doi.org/10.1002/adma.201004426

Haverinen HM, Myllyla RA, Jabbour GE (2010) Inkjet printed RGB quantum dot-hybrid LED. J Disp Technol 6(3):87–89. https://doi.org/10.1109/JDT.2009.2039019

Haverinen HM, Myllyla RA, Jabbour GE (2009) Inkjet printing of light emitting quantum dots. Appl Phys Lett 94(7):073108. https://doi.org/10.1063/1.3085771

Zhu T, Shanmugasundaram K, Price SC, Ruzyllo J, Zhang F, Xu J, Mohney SE, Zhang Q, Wang AY (2008) Mist fabrication of light emitting diodes with colloidal nanocrystal quantum dots. Appl Phys Lett. https://doi.org/10.1063/1.2834734

Shirasaki Y, Supran GJ, Bawendi MG, Bulovic V (2013) Emergence of colloidal quantum-dot light-emitting technologies. Nat Photonics 7(1):13–23

Acknowledgements

The authors are grateful for the financial supports from the National Natural Science Foundation of China (51775538), Gansu province science and technology plan (17JR5RA318, 1606RJZA051 and 17YF1FA139), and the West Light Program of CAS.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declared that there is no conflict of interest.

Rights and permissions

About this article

Cite this article

Jiang, P., Ji, Z., Zhang, X. et al. Recent advances in direct ink writing of electronic components and functional devices. Prog Addit Manuf 3, 65–86 (2018). https://doi.org/10.1007/s40964-017-0035-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40964-017-0035-x