Abstract

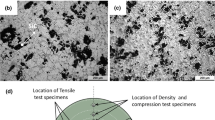

This research aims to study the effect of nickel additive and heat treatment effects on microstructure and mechanical properties of in-situ AA2024-Al3NiCu composite fabricated by the stir casting method. The effects of artificial aging heat treatment, after the homogenization of as-cast composites, were investigated in this study. The results indicated that, after artificial aging, the precipitate-free zone at the inter-dendritic zone disappeared or became smaller. With the addition of nickel up to 3 wt% as well as the aging process, S-Al2CuMg precipitates will be reduced and their size will be smaller. However, after adding 4.5 wt% of nickel and, also, performing aging heat treatment, it is not possible to precipitate the S- Al2CuMg precipitates, and, instead of it, the T-Al6CuMg4 precipitates will be formed. By increasing the nickel amount from 3 to 4.5 wt%, the hardness, ultimate tensile strength, and toughness, after aging treatment, decreases 8, 19, and 28 %, respectively. By adding nickel and performing aging treatment at 200 °C for 120 min, the maximum hardness, ultimate tensile strength, and toughness achieved in the 3 wt% nickel-containing sample as 134.10 ± 4.89 HV, 251.23 ± 3.70 MPa, and 1.96 ± 0.09 MJ.m-3, respectively. The hardness, ultimate tensile strength, and toughness of AA2024-Al3NiCu composite, after aging treatment, increased 11, 49, and 139%, respectively, compared to nickel-free AA2024 aluminum alloy matrix.

Similar content being viewed by others

References

I. Dinaharan, Liquid metallurgy processing of intermetallic matrix composites, in: Intermetallic Matrix Composites, Elsevier, 2018, pp. 167-202.

P. Ajay Kumar, P. Rohatgi, D. Weiss, 50 years of foundry-produced metal matrix composites and future opportunities. Int. J. Metalcast. 14, 291–317 (2020). https://doi.org/10.1007/s40962-019-00375-4.

A. Gnanavelbabu, K.T.S. Surendran, S. Kumar, Process optimization and studies on mechanical characteristics of AA2014/Al2O3 nanocomposites fabricated through ultrasonication assisted stir–squeeze casting. Int. J. Metalcast. (2021). https://doi.org/10.1007/s40962-021-00634-3.

F. Liu, X. Zhu, S. Ji, Effects of Ni on the microstructure, hot tear and mechanical properties of Al–Zn–Mg–Cu alloys under as-cast condition. J. Alloys Compd. 821, 153458 (2020)

R. Ramamoorthi, J.J.M. Hillary, R. Sundaramoorthy, J.D.J. Joseph, K. Kalidas, K. Manickaraj, Influence of stir casting route process parameters in fabrication of aluminium matrix composites–a review. Mater. Today Proc. 45, 6660–6664 (2021)

P. Sahoo, S. Ghosh, Tribological behavior of aluminium metal matrix composites–a review. J. Tribol. Res. 2, 1–14 (2011)

G.F. Aynalem, Processing methods and mechanical properties of aluminium matrix composites, Adv. Mater. Sci. Eng. 2020 (2020).

M.K. Sahu, R.K. Sahu, Fabrication of aluminum matrix composites by stir casting technique and stirring process parameters optimization, in: Advanced Casting Technologies, IntechOpen, 2018.

F. Badia, P. Rohatgi, Dispersion of graphite particles in aluminum castings through injection of the melt (1969).

V.M. Bermudez, Auger and electron energy-loss study of the Al/SiC interface. Appl. Phys. Lett. 42, 70–72 (1983)

V.S. Ayar, M.P. Sutaria, Comparative evaluation of ex situ and in situ method of fabricating aluminum/TiB2 composites. Int. J. Metalcast. 15, 1047–1056 (2021). https://doi.org/10.1007/s40962-020-00539-7.

V.S. Ayar, M.P. Sutaria, Development and characterization of in situ AlSi5Cu3/TiB2 composites. Int. J. Metalcast. 14, 59–68 (2020). https://doi.org/10.1007/s40962-019-00328-x.

M. Zare, A. Maleki, B. Niroumand, In situ Al-SiOC composite fabricated by in situ pyrolysis of a silicone polymer gel in aluminum melt. Int. J. Metalcast. (2021). https://doi.org/10.1007/s40962-021-00658-9.

H. Demirtaş, R. Yildiz, E. Çevik, Mechanical and wear properties of high rate NiAl particle-reinforced Al composites produced by pressure infiltration method. Int. J. Metalcast. (2021). https://doi.org/10.1007/s40962-020-00564-6.

D. Yadav, R. Bauri, Nickel particle embedded aluminium matrix composite with high ductility. Mater. Lett. 64, 664–667 (2010)

S. Arul, Effect of nickel reinforcement on micro hardness and wear resistance of aluminium alloy Al7075. Mater. Today: Proc. 24, 1042–1051 (2020)

A. Sytschev, N. Kochetov, S. Vadchenko, D.Y. Kovalev, A. Shchukin, Processing of Ni–Al intermetallic with 2D carbon components. Mater. Chem. Phys. 238, 121898 (2019)

M.T. Hayajneh, A.M. Hassan, Y.M. Jaradat, The effect of nickel addition, solution treatment temperature and time on the precipitation hardening of (Al-Cu) alloys. Acad. Edu 141, 1–5 (2007)

R. Farajollahi, H. Jamshidi Aval, R. Jamaati, Effects of Ni on the microstructure, mechanical and tribological properties of AA2024-Al3NiCu composite fabricated by stir casting process. J. Alloys Compd. 887, 161433 (2021)

A.R. Najarian, R. Emadi, M. Hamzeh, Fabrication of as-cast Al matrix composite reinforced by Al2O3/Al3Ni hybrid particles via in-situ reaction and evaluation of its mechanical properties. Mater. Sci. Eng., B 231, 57–65 (2018)

R. Ramesh, S. Suresh Kumar, S. Gowrishankar, Production and characterization of aluminium metal matrix composite reinforced with Al3Ni by stir and squeeze casting, in: Applied Mechanics and Materials, Trans Tech Publ, 2015, pp. 315–319.

X. Zhang, H. Wang, C. Zou, Z. Wei, The evolution of microstructure and mechanical properties at elevated temperature of cast Al–Li–Cu–Mg alloys with Ni addition. J. Market. Res. 9, 11069–11079 (2020)

M. Raei, M. Panjepour, M. Meratian, Effect of stirring speed and time on microstructure and mechanical properties of Cast Al–Ti–Zr–B 4 C composite produced by stir casting. Russ. J. Non-Ferrous Metals 57, 347–360 (2016)

A. Handbook, Heat treating, vol. 4, ASM International, Materials Park, OH, 860 (1991).

S. Salarieh, S. Nourouzi, H. Jamshidi Aval, An investigation on the microstructure and mechanical properties of Al-Zn-Mg-Cu/Ti composite produced by compocasting. Int. J. Metalcast. (2021). https://doi.org/10.1007/s40962-021-00698-1.

R. Taylor, S. McClain, J. Berry, Uncertainty analysis of metal-casting porosity measurements using Archimedes’ principle. Int. J. Cast Met. Res. 11, 247–257 (1999)

A. Mohamed, F. Samuel, Microstructure, tensile properties and fracture behavior of high temperature Al–Si–Mg–Cu cast alloys. Mater. Sci. Eng., A 577, 64–72 (2013)

M. Liang, L. Chen, G. Zhao, Y. Guo, Effects of solution treatment on the microstructure and mechanical properties of naturally aged EN AW 2024 Al alloy sheet. J. Alloys Compd. 824, 153943 (2020)

S.-B. Yu, M.-S. Kim, Microstructure and high temperature deformation of extruded Al-12Si-3Cu-based alloy. Metals 6, 32 (2016)

J.T. Kim, V. Soprunyuk, N. Chawake, Y.H. Zheng, F. Spieckermann, S.H. Hong, K.B. Kim, J. Eckert, Outstanding strengthening behavior and dynamic mechanical properties of in-situ Al–Al3Ni composites by Cu addition. Composites Part B Engineering 189, 107891 (2020)

C. Chan, Friction Stir Processing of Aluminium-Silicon Alloys, The University of Manchester (United Kingdom), 2011.

L.F. Mondolfo, Aluminum alloys: structure and properties (Elsevier, Amsterdam, 2013)

G. Quan, L. Ren, M. Zhou, 2.13 Solutionizing and age hardening of aluminum alloys, in Comprehensive Materials Finishing. ed. by M.S.J. Hashmi (Elsevier, Oxford, 2017), pp. 372–397

Z. Gxowa-Penxa, P. Daswa, R. Modiba, M. Mathabathe, A. Bolokang, Development and characterization of Al–Al3Ni–Sn metal matrix composite. Mater. Chem. Phys. 259, 124027 (2021)

P. Hernández, H. Dorantes, F. Hernández, R. Esquivel, D. Rivas, V. López, Synthesis and microstructural characterization of Al–Ni3Al composites fabricated by press-sintering and shock-compaction. Adv. Powder Technol. 25, 255–260 (2014)

J.R. Davis, Aluminum and aluminum alloys (ASM International, Almere, 1993)

Y. Yoshida, H. Esaka, K. Shinozuka, Effect of solidified structure on hot tear in Al-Cu alloy, in: IOP Conference Series: Materials Science and Engineering, IOP Publishing, 2015, pp. 012059.

J.-Q. Han, J.-S. Wang, M.-S. Zhang, K.-M. Niu, Relationship between amounts of low-melting-point eutectics and hot tearing susceptibility of ternary Al− Cu− Mg alloys during solidification. Trans. Nonferrous Metals Soc. China 30, 2311–2325 (2020)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Farajollahi, R., Jamshidi Aval, H. & Jamaati, R. Development and Characterization of in-situ AA2024-Al3NiCu Composites. Inter Metalcast 17, 109–123 (2023). https://doi.org/10.1007/s40962-021-00752-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-021-00752-y