Abstract

Hot tearing is a common solidification defect in both continuous cast steels and foundry shaped castings, which has a significant impact on the quality of the final products. It is a complex phenomenon that involves both the thermal and mechanical conditions and chemical element segregation that evolves during casting process. Over several decades, much effort has been invested into improving our understanding of the conditions required for the occurrence of hot tearing and to relate these conditions with casting parameters, like casting speed in continuous cast process, alloy composition, cooling conditions, etc. This review summarizes the results from previous investigations that have focused on the hot tearing phenomenon of steels, including criteria for hot tearing, experimental methods, and several validated models for different testing methods. The factors that influence hot tearing sensitivity are also reviewed and discussed in the present work.

Similar content being viewed by others

References

J. Campbell, Casting (Butterworth-Heinemann, Oxford, 1991).

J. Guo, G. Wen, Influence of alloy elements on cracking in the steel ingot during its solidification. Metals 9(8), 836 (2019)

M. Rappaz, J.M. Drezet, M. Gremaud, A new hot-tearing criterion. Metall. Mater. Trans. A 30, 449–455 (1999)

H.F. Bishop, C.G. Ackerlind, W.S. Pellini, AFS Trans. 60, 818–833 (1952)

W. Pellini Foundry, vol. 80, pp. 124–133 and 192–199 (1952)

D.G. Eskin, L. Katgerman, A quest for a new hot tearing criterion. Metall Mater Trans A 38A, 1511–1519 (2007)

M.O. El Bealy, On the formation of macrosegregation and interdendritic cracks during dendritic solidification of continuous casting of steel. Metall Mater Trans B 45B, 988–1017 (2014)

Y.M. Won, T.-J. Yeo, D.J. Seol, K.H. Oh, A new criterion for internal crack formation in continuously cast steels. Metall. Mater. Trans. B 31B, 779–794 (2000)

J.K. Brimacombe, F. Weinberg, E.B. Hawbolt, Formation of longitudinal, midface cracks in continuously-cast slabs. Metall. Trans. B 10, 279–292 (1979)

K. Miyazawa, K. Schwerdtfeger, Macrosegregation in continuously cast steel slabs: preliminary theoretical investigation on the effect of steady state bulging. Steel Res. Int. 52(11), 415–422 (1981)

A. Grill, K. Schwerdtfeger, Finite-element analysis of bulging produced by creep in continuously cast steel slabs. Ironmak. Steelmak. 6, 131–135 (1979)

G. Van Drunen, J.K. Brimacombe, F. Weinberg, Internal cracks in strand-cast billets. Ironmak. Steelmak. 2, 125–133 (1975)

J.K. Brimacombe, K. Sorimachi, Crack formation in the continuous casting of steel. Metall. Trans. B 8, 489–505 (1977)

E.B. Hawbolt, F. Weinberg, J.K. Brimacombe, Influence of hot working on internal cracks in continuously-cast steel billets. Metall. Trans. B 10, 229–236 (1979)

H. K. (2001) On the hot crack formationh during solidification of iron-base alloys, Stockholm, Sweden: PhD thesis, Royal Institute of Technology

D.G. Eskin, L.K. Suyitno, Mechanical properties in the semi-solid state and hot tearing of aluminium alloys. Prog. Mater. Sci. 49, 629–711 (2004)

K. Kim, H.N. Han, T. Yeo, Y. Lee, K.H. Oh, D.N. Lee, Analysis of surface and internal cracks in continuously cast beam blank. Ironmak. Sleelmak. 24(3), 249–256 (1997)

W. Wang, L. Ning, R. Bulte, W. Bleck, Formation of internal cracks in steel billets during soft reduction. J. Univ. Sci. Technol. Beijing 15(2), 114–119 (2008)

T.W. Clyne, M. Wolf, W. Kurz, The effect of melt composition on solidification cracking of steel, with particular reference to continuous casting. Metall. Trans. B 13B, 259–266 (1982)

Y.M. Won, K. Kim, T. Yeo, K.H. Oh, Effect of cooling rate on ZST. LIT and ZDT of carbon steels near melting point. ISIJ Int. 38(10), 1093–1099 (1998)

J.-M. Drezet, M. Gremaud, R. Graf, M. Gäumann, “A New Hot Tearing Criterion for Steel,” in 4th ECCC (Birmingham, UK, 2002).

M. B. Santillana (2013) Thermo-mechanical properties and cracking during solidification of thin slab cast steel," PhD thesis, Tata Steel Nederland Technology B. V

S. Li, D. Apelian, Hot tearing of aluminum alloys. Inter. Metalcast. 5, 23–40 (2011). https://doi.org/10.1007/BF03355505

S. Li, D. Apelian, K. Sadayappan, Hot tearing in cast Al alloys: mechanisms and process controls. Inter. Metalcast. 6, 51–58 (2012). https://doi.org/10.1007/BF03355533

J. Song, F. Pan, B. Jiang, A. Atrens, M. Zhang, Y. Lu, A review on hot tearing of magnesium alloys. J. Magnes. Alloys 4, 151–172 (2016)

S. K. Trikha, C. E. Bates, Improved method for hot tear testing and methods to reduce hot tears. AFS Trans. 110, 173–180 (2002)

D.S. Bhiogade, S.M. Randiwe, A.M. Kuthe, Failure analysis and hot tearing susceptibility of stainless steel CF3M. Int. J. Metalcast. 13(1), 166–179 (2019). https://doi.org/10.1007/s40962-018-0246-z

D.S. Bhiogade, S.M. Randiwe, A.M. Kuthe et al., Study of hot tearing in stainless steel CF3M during casting using simulation and experimental method. Int. J. Metalcast. 12, 331–342 (2018). https://doi.org/10.1007/s40962-017-0170-7

H. Zhong, X. Li, B. Wang, T. Wu, Y. Zhang, B. Liu, Q. Zhai, Hot tearing of 9Cr3Co3W heat-resistant steel during solidification. Metals 9(1), 25 (2019)

C.H. Dickhaus, L. Ohm, S. Engler, Mechanical properties of solidifying shells of aluminum alloys. AFS Trans. 101, 677–684 (1993)

J. Langlais, J.E. Gruzleski, A novel approach to assessing the hot tearing susceptibility of aluminium alloys. Mater. Sci. Forum 331–337, 167–172 (2000)

D.J. LahaieM, Bouchard, , Physical modeling of the deformation mechanisms of semisolid bodies and a mechanical criterion for hot tearing. Metall. Mater. Trans. B 32(4), 697–705 (2001)

A. Yamanaka, K. Nakajima, K. Okamura, Critical strain for internal crack formation in continuous casting. Ironmak. Steelmak. 22(6), 508–512 (1995)

B. Magnin, L. Maenner, L. Katgerman, S. Engler, Ductility and Rheology of an Al-4.5% Cu Alloy from Room Temperature to Coherency Temperature. Mater. Sci. Forum 217–222, 1209–1214 (1996)

M. Rappaz, J.-M. Drezet, M. Gremaud, A new hot-tearing criterion. Metall. Mater. Trans. A 30A, 449–455 (1999)

T. Senda, F. Matsuda, G. Takano, K. Watanabe, T. Kobayashi, T. Matsuzaka, Fundamental investigations on solidification crack susceptibility for weld metals with trans-varestraint test. Trans. Jap. Weld. Soc. 2, 45–66 (1971)

Suyitno, W.H. Kool, L. Katgrman, Hot tearing criteria evaluation for direct-chill casting of an Al-45 Pct Cu alloy. Metall. Mater. Trans. A 36A, 1537–1546 (2005)

L. Katgerman, A mathematical model for hot cracking of aluminum alloys during DC casting. JOM 34(2), 46–49 (1982)

Suyitno, W.H. Kool, L. Katgerman, Integrated approach for prediction of hot tearing. Metall. Mater. Trans. A 40A, 2388–2400 (2009)

M.R. Nasresfahani, B. Niroumand, A new criterion for prediction of hot tearing susceptibility of cast alloys. Metall. Mater. Trans. A 45A, 3699–3702 (2014)

M. Wolf, W. Kurz, The effect of carbon content on solidification of steel in the continuous casting mold. Metall. Trans. B 12B, 85–93 (1981)

C. Bernhard, H. Hiebler, M.M. Wolf, Simulation of shell strength properties by the SSCT test. ISIJ Int. 36, S163–S466 (1996)

C. Bernhard, R. Pierer, A. Tubikanec, C.M. Chimani, “Experimental characterization of crack sensitivity under continuous casting conditions,” in Proceedings of Continuous-Casting Innovation Session, Linz, Austria, June (2004)

M. Suzuki, M. Suzuki, C. Yu, T. Emi, In-situ measurement of fracture strength of solidifying steel shells to predict upper limit of casting speed in continuous caster with oscillating mold. ISIJ Int. 37(4), 375–382 (1997)

A. Yamanaka, K. Nakajima, K. Yasumoto, H. Kawashima, K. Nakai, New evaluation of critical strain for internal crack formation in continuous casting. Rev. Metall. Cah. Inf. Tech 89(7–8), 627–633 (1992)

M. Suzuki, H. Hayashi, H. Shibata, T. Emi, I.-J. Lee, Simulation of transverse crack formation on continuously cast peritectic medium carbon steel slabs. Steel Res. 70(10), 412–419 (1999)

R. Flesch, W. Bleck, Crack susceptibility of medium and high alloyed tool steels under continuous casting conditions. Steel Res. 69(7), 292–299 (1998)

K. Marukawa, M. Kawasaki, T. Kimura, S. Ishikawa, Investigate of the criterion of the internal cracks. Tetsu Hagane 64, S661 (1978)

Y.M. Won, B.G. Thomas, Simple model of microsegregation during solidification of steels. Metall. Mater. Trans. A 32A, 1755–1767 (2001)

B. Bottger, M. Apel, B. Santillana, D.G. Eski, Relationship between solidification microstructure and hot cracking susceptibility for continuous casting of low-carbon and high-strength low-alloyed steels: a phase-field study. Metall. Mater. Trans. A 44A, 3765–3777 (2013)

R. Pierer, C. Bernhard, C. Chimani (2006) A contribution to hot tearing in the continuous casting process. In: Proceedings of the 2006 ATS International Steelmaking Conference. Paris

M.R. Ridolfi, S. Fraschetti, A.D. Vito, L.A. Ferro, Mathematical modeling of hot tearing in the solidification of continuously cast round billets. Metal. Mater. Trans. B 41B, 1293–1309 (2010)

M. Bellet, G. Qiu, J. Carpreau, Comparison of two hot tearing criteria in numerical modelling of arc welding of stainless steel AISI 321. J. Mater. Process. Technol. 230, 143–152 (2016)

Y.M. Won, H.N. Han, T. Yeo, K.H. Oh, Analysis of solidification cracking using the specific crack susceptibility. ISIJ Int. 40(2), 129–136 (2000)

Z. Han, K. Cai, B. Liu, Prediction and analysis on formation of internal cracks in continuously cast slabs by mathematical models. ISIJ Int. 41(12), 1473–1480 (2001)

I.I. Novikov, O.E. Grushko, Hot cracking susceptibility of Al–Cu–Li and Al–Cu–Li–Mn alloys. Mater. Sci. Technol. 11(9), 926–932 (1995)

J. M Drezet, M. Rappaz (1998) Study of hot tearing in aluminum alloys using the ring mold test," in Modeling of Casting, Welding, and Advanced Solidification Process-XIII, San Antonio

Y. Wang, Q. Wang, G. Wu, Y. Zhu, W. Ding, Hot-tearing susceptibility of Mg-9Al-xZn alloy. Mater. Lett. 57, 929–934 (2002)

G. Gao, S. Kou, Hot cracking of binary Mg-Al alloy casting. Mater. Sci. Eng. A 417, 230–238 (2006)

S. Li, B. Tang, X. Jin, D. Zeng, An investigation on hot-cracking mechanism of Sr addition into Mg-6Al-0.5Mn alloy. J. Mater. Sci. 47, 2000–2004 (2012)

Q.Y. Sun, D. Liu, L.P. Wang et al., Influences of rod diameter and sand-mould strength on hot tearing in Mg WE43A constrained rod castings. Int. J. Metalcast. 13, 407–416 (2019). https://doi.org/10.1007/s40962-018-0265-9

F.A. Fasoyinu, J.P. Thomson, L. Sullivan, M. Sahoo, Characterization of Microstructures and Mechanical Properties of Aluminum Alloys 206.0 and 535.0 Poured in Metal Molds (AFS Trans, Schaumburg, 2008).

C. Monroe, C. Beckermann (2006) Simulation of hot tearing and distortion during casting of steel: comparsion with experiments. In: 61th SFSA Technical and Operating Conference, Chicago

C. A. Monroe, C. Beckermann, J. Klinkhammer (2009) Simulation of deformation and hot tear formation using a visco-plastic model with damage. In: in Modeling of Casting, Welding, and Advanced Solidification Process - XII

D. Galles and C. Beckermann (2012) Measurement and simulation of distortion of a steel bracket casting. In: Proceedings of the 66th SFSA Technical and Operating Conference, Chicago

F.A. Fasoyinu, J.P. Thomson, M. Sahoo, Permanent Mold Casting of Aluminum Alloys A206.0 and A535.0. AFS Trans. 115, 207–220 (2007)

C. Olivier, C. Yvan, B. Michel, Hot tearing in steels during solidification: experimental characterization and thermomechanical modeling. J. Eng. Mat. Techn. 130, 1–7 (2008)

S. Hadzic, E.S. Kelity, C. Sommitsch, Prediction and validation of hot tearing in permanent mold steel casting using a viscoplastic damage model. Comput. Methods Mater. Sci. 13(1), 36–42 (2013)

D.J. Seol, Y.M. Won, K.H. Oh, Y.C. Shin, C.H. Yim, Mechanical behavior of carbon steels in the temperature range of Mushy zone. ISIJ Int. 40(4), 356–363 (2000)

W. Hu, Y. Zhang, G. Yuan, X. Zhang, and G. Wang, Hot temperature mechanical behavior of high-permeability 6.5 wt% Si electrical steel in a Mushy zone. Steel Res. Int. (2019). https://doi.org/10.1002/srin.201900105

W.T. Lankford, some considerations of strength and ductility in the continuous-casting process. Metallurgical Transactions 3, 1331–1357 (1972)

H. Sato, T. Kitagawa, K. Murakami, K. Kawawa, Effect of the local shrinkage to the internal cracks in strand. Tetsu to Hagane 61, S471 (1975)

K. Miyamura, K. Kanamaru, N. Kaneko, A. Ochi, Effects of the internal cracks. Tetsu Hagane 62, S482 (1976)

K. Narita, T. Mori, K. Ayata, J. Miyazaki, M. Fujimaki, Determination of the temperature distribution in continuous casting process. Tetsu-to-Hagané 64, S152 (1978)

T. Matsumiya, M. Ito, H. Kajioka, S. Yamaguchi, Y. Nakamura, An evaluation of critical strain for internal crack formation in continuously cast slabs. ISIJ Int. 26, 540–546 (1986)

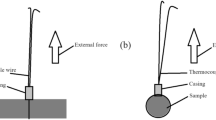

M. Bellet, O. Cerri, M. Bobadilla, Y. Chastel, Modeling hot tearing during solidification of steels: assessment and improvement of macroscopic criteria through the analysis of two experimental tests. Metall. Mater. Trans. A 40A, 2705–2717 (2009)

C. Olivier, C. Yvan, B. Michel, Hot tearing in steels during solidification: experimental characterization and thermomechanical modeling. J. Eng. Mater. Technol. 130(2), 021018 (2008)

T. Koshikawa, M. Bellet, C.-A. Gandin, H. Yamamura, M. Bobadilla, Experimental study and two-phase numerical modeling of macrosegregation induced by solid deformation during punch pressing of solidifying steel ingots. Acta Mater. 124, 513–527 (2017)

T. Koshikawa, M. Bellet, C.-A. Gandin, H. Yamamura, M. Bobadilla (2013) Study of hot tearing through ingot bending test: thermomechanical and solute transport analysis. In: Czech metallurgical Society, Ostrava

T. Koshikawa, M. Bellet, C.-A. Gandin, H. Yamamura, M. Bobadilla (2015) Study of hot tearing and macrosegregation through ingot bending test and its numerical simulation. IOP Conf. Ser.: Mater. Sci. Eng. https://doi.org/10.1088/1757-899X/84/1/012096

T. Koshikawa, M. Bellet, C.-A. Gandin, H. Yamamura, M. Bobadilla, Study of hot tearing during steel solidification through ingot punching test and its numerical simulation. Metall. Mater. Trans. A 47, 4053–4067 (2016)

P. Ackermann, W. Kurz, W. Heinemann, In situ tensile testing of solidifying aluminium and Al-Mg shells. Mater. Sci. Eng. 75(1–2), 79–86 (1985)

H. Hiebler, C. Bernhard, Mechanical properties and crack susceptibility of steel during solidification. Steel research 70(8–9), 349–355 (1999)

X. Ruan, P. Robert, C. Shi, F. Mei, Experimental research on hot-tearing crack sensitivity. Baosteel Tech. Res. 6(3), 18–23 (2012)

J. Reiter, R. Pierer (2005) Thermo-mechanical simulation of a laboratory test to determine mechanical properties of steel near the solidus temperature," in COMSOL, Burlington

M. Rowan, B.G. Thomas, R. Pierer, C. Bernhard, Measuring mechanical behavior of steel during solidification: modeling the SSCC test. Metall. Mater. Trans. B 42B, 837–851 (2011)

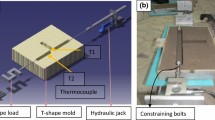

Y. Lu, L. Bartlett, R. O'Malley, S. Lekakh, M. Buchely (2020) New experimental apparatus to investigate hot tearing behavior in steel. In: Proceedings of AISTech

G. Sigworth (2002) Hot tearing of metals," in AFS Library Copy

K. Kim, T. Yeo, K.H. Oh, D.N. Lee, Effect of carbon and sulfur in continuously cast strand on longitudinal surface cracks. ISIJ Int. 36(3), 284–289 (1996)

K. Wunnenberg, R. Flender, Investigation of internal-crack formation in continuous casting, using a hot model. Ironmak. Steelmak. 12(1), 22–29 (1985)

S.N. Singh, K.E. Blazek, Heat transfer and skin formation in a continuous-casting mold as a function of steel carbon content. JOM 26(10), 17–27 (1974)

D.R. Poirier, G.H. Geiger, Transport Phenomena in Materials Processing (Springer International Publishers, Switzerland, 2006).

T. Nakagawa, T. Umeda, J. Murata, Y. Kamimur, N. Niwa, Detormation behavior during solidification of steels. ISIJ Int. 35(6), 723–729 (1995)

A. Chojecki, I. TeleJko, T. Bogacz, Influence of chemical composition on the hot tearing formation of cast steel. Theoret. Appl. Fract. Mech. 27, 99–105 (1997)

W. Wang, S. Luo, Z. Cai, M. Zhu (2013) The effect of phosphorus and sulfur on the crack susceptibility of continuous casting steel. TMS, pp. 89–98

G.A. de Toledo, O. Campo, E. Lainez, Influence of Sulfur and Mn/S ratio on the hot ductility of steels during continuous casting. Steel Res. 64(4), 292–299 (1993)

L.K. Bigelow, M.C. Flemings, Sulfide inclusions in steel. Metall. Trans. B 6B, 275–283 (1975)

N. Bandyopadhyay, C.L. Briant, The effect of phosphorus on intergranular caustic cracking of NiCr steel. Nat Ass Corros. Eng. 38(3), 125–129 (1982)

E.D. Hondros, M.P. Seah, Segregation to interfaces. Int. Metals Rev. 22(1), 262–301 (1977)

F. Weinberg, The ductility of continuously-cast steel near the melting point-hot tearing. Metall. Trans. B 10B, 219–227 (1979)

J.C. Hamaker, W.P. Wood, Influence of phosphorus on hot tear resistance of plain and alloy gray iron. AFS Trans. 60, 501–510 (1952)

Y. Li, Q.L. Bai, J.C. Liu, H.X. Li, Q. Du, J.S. Zhang, L.Z. Zhuang, The influences of grain size and morphology on the hot tearing susceptibility, contraction, and load behaviors of aa7050 alloy inoculated with Al-5ti-1B master alloy. Metall. Mater. Trans. A 74A, 4024–4037 (2016)

H. Fujii, T. Ohashi, T. Hiromoto, On the formation of internal cracks in continuously cast slabs. Trans. ISIJ 18, 510–518 (1978)

K. Shinozaki, P. Wen, M. Yamamoto, K. Kadoi, Y. Kohno, T. Komori, Effect of grain size on solidification cracking susceptibility of type 347 stainless steel during laser welding. Trans. JWRI 39(2), 136–138 (2010)

Y. Yoshida, H. Esaka, K. Shinozuka, Effect of solidified structure on hot tear in Al-Cu alloy. IOP Conf. Ser. Mater. Sci. Eng. 84, 012059 (2015)

F. Matsuda, H. Nakata, Y. Shimokusu, K. Tsukamoto, K. Arai, Effect of additional element on weld solidification crack susceptibility of Al-Zn-Mg alloy. Trans. JWRI 12(1), 81–87 (1983)

J.E. Kelly, K.R. Michalek, T.G. O’connor, B.G. Thomas, J.A. Dantzig, Initial development of thermal and stress fields in continuously cast steel billets. Metall. Trans. A 19A, 2589–2602 (1988)

J. Lee, H.N. Han, K.H. Oh, J. Yoon, A fully coupled analysis of fluid flow, heat transfer and stress in continuous round billet casting. ISIJ Int. 39(5), 435–444 (1999)

C.H. Yu, M. Suzukl, H. Shibata, T. Em, Simulation of crack formation on solidifying steel shell in continuous casting mold. ISIJ Int. 36, S159–S162 (1996)

H.G. Suzuki, S. Nishimura, S. Yamaguchi, Characteristics of hot ductility in steels subjected to the melting and solidification. Trans. ISIJ 22, 48–56 (1982)

Acknowledgement

The authors would like to thank Dr. Simon N. Lekakh for his technical advice and contribution within this manuscript. The present work is supported by Peaslee Steel Manufacturing Research Center (PSMRC) at Missouri University of Science and Technology (Missouri S&T). All the faculty and industry mentoring committee of the PSMRC are greatly acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lu, Y., Bartlett, L.N. & O’Malley, R.J. A Review on Hot Tearing of Steels. Inter Metalcast 16, 45–61 (2022). https://doi.org/10.1007/s40962-021-00599-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-021-00599-3