Abstract

Inoculation can be used to fight many complex iron defects. Five cases will be developed to illustrate in different metallurgical conditions how beneficial some elements can be to solve specific metallurgical issues.

-

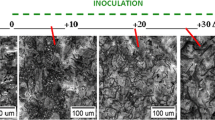

Inoculation solutions to fight chunky graphite in heavy-section castings in SGI: An example of the beneficial use of SB/RE-bearing inoculants associated with 10% Ba-bearing inoculant is given.

-

Inoculation of solid solution-strengthened iron (SSFI): SSFI is well known to be difficult to inoculate, and a correct and consistent graphite shape is not easy to obtain. An efficient “package” has been proposed to a foundry producing SSFI, combining Ba-preconditioning and Bi/RE-bearing inoculation.

-

Inoculation of Ni-resist iron: Ni-resist iron is very sensitive to chunky or degenerated graphite because of the high Ni-amount. Here is shown a case where chunky graphite has been found in a foundry, where the problem has been solved using specific inoculants.

-

Inoculation solutions for vertical centrifugal SG iron: An example of successful association of 10% barium inoculant associated with Bi/RE-bearing inoculation is presented on very-heavy-section rolls. Their effects are beneficial to mechanical properties of the bi-metallic material.

-

Ba-inoculation to modify the slag composition: Slag build-up is a normal phenomenon in the metallurgical process but can, however, be a source of various problems. Here is given an example of use of a high-Ba inoculant facilitating de-slagging operations.

Courtesy: Nathan JANCO “Centrifugal Casting” AFS.

Similar content being viewed by others

References

D.M. Stefanescu, «Le Baryum dans les alliages d’inoculation et de nodulisation au Mg de la fonte», Giesserei, Praxi Nr 20/1975

S. Parent Simonin, Influence des divers oligo-éléments dans les fontes. CTIF, FO 137, Juillet 1980, E 02.100

J. Fourmann, Preconditioning Effect of Barium in Ductile Iron Production, in Proceedings of the AFS Cast Iron Inoculation Conference, 29–30 September 2005

Communication Technique n°7 du Secrétariat International des Fontes, “Influence des impuretés sur la fonte à graphite Sphéroidal”, Hommes et Fonderie, Oct 1973

I. Mihalic Pokupec, P. Mrvar, B. Bauer, Effect of inoculation on the formation of chunky graphite in ductile-iron castings. Mater. Technol. 51(2), 275–281 (2017)

Internal R&D reports, Ferropem

M.J. Gough, J. Morgan, Feeding ductile iron castings—some recent experiments. Trans. Am. Foundry Soc. 84, 351–384 (1976)

P. Larrañaga, I. Asenjo, J. Sertucha, R. Suarez, I. Ferrer, J. Lacaze, Effect of antimony and cerium on the formation of chunky graphite during solidification of heavy-section castings of near-eutectic spheroidal graphite irons. Metall. Mater. Trans. A 40, 654–661 (2009)

BCIRA – Broadsheet N°284

T.C. Xi, J. Fargues, Formation and prevention of chunky graphite in slowly cooled nodular irons, in MRS Proceedings, vol. 34 (1983)

J. Lacaze, Trace elements and graphite shape degeneracy in nodular graphite cast irons. Int. J. Metalcast. 11, 44–51 (2017)

P. Larrañaga, I. Asenjo, J. Sertucha, R. Suarez, I. Ferrer, J. Lacaze, Effect of antimony on the eutectic reaction of heavy section spheroidal graphite castings”. Int. J. Cast Met. Res. 22(1–4), 192–195 (2009)

M. Koch, Chunky graphite, effects and theories on formation and prevention, 2013, in Keith Millis Symposium on Ductile Cast Iron, Nashville, USA (2013)

Norm EN 1563: 2012 «Founding. Spheroidal graphite cast irons»

«Werkstofff und Fertigungstechnische Grundlagen der Herstellung une Anwendung von hoch siliciumhaltigem Gusseisen mit Kugelgraphit», Giesserei 100, 2013, N°7 – S30-47

Gilles Regheere, «Fontes GS à matrice ferritique à durcissement structural», Fonderie Magazine, N°28, Oct 2012

K. Challier, «Les fontes GS++», Fonderie Magazine N°39, Nov 2013

Dr. Klaus Röhrig, “Austenitische Gusseisen”, Konstruieren+Giessen 29 (2004), N°2

D. Sheng, J. Liu, Cast Irons Containing Rare Earths (Tsinghua University Academic Treatise, Beijing, 2000)

Ellingham Diagrams, DoITPoMS, University of Cambridge

“Slag Atlas”, 2nd edn., edited by Verein Deutscher Eisenhüttenleute (VDEh), Verlag Stahleisen GmbH

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Fay, A., Pinel, P. Inoculation Solutions Against Metallurgical Problems. Inter Metalcast 14, 1123–1135 (2020). https://doi.org/10.1007/s40962-020-00431-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-020-00431-4