Abstract

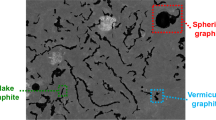

The truck industry has constantly searched to increase the performance of heavy-duty diesel vehicles, either by reducing weight and the size of the engines, or by increasing their power. In this sense, higher strength grades of cast iron have been developed and tested under thermomechanical conditions, and the results have been positive, since life under such conditions has increased significantly. The purpose of this paper was to shed some light on the fracture micromechanisms acting during crack nucleation and growth under thermomechanical loading conditions, in two cast iron types for use in cylinder head manufacturing, namely gray iron grade 300 (GI 300) and compacted graphite iron grade 500 (CGI 500). The results were compared with those from the standard grades GI 250 and CGI 450. In both gray and compacted graphite irons, fractographic examination showed that the crack starts at graphite tips, grows through the graphite skeleton inside a eutectic cell, and progresses by the coalescence of multiple fatigue cracks from one eutectic cell to another, fracturing the matrix at eutectic cell boundaries. In CGI 500, the graphite in eutectic cells ended with a change in the graphite shape, from vermicular to a round shape end. This brings additional difficulties for the crack propagation process, and, together with the rough interface graphite/matrix and with the thick eutectic cell boundaries, it explains the outstanding thermomechanical results with the CGI 500.

Similar content being viewed by others

References

S. Trampert, T.G. Gocmez, S. Pischinger, J. Eng. Gas Turbines Power 130(1), 1–10 (2008)

W. L. Guesser, L.C Guedes. The new generation of engines and the challenges for the foundry industry. AEA SIMEA, São Paulo, Brasil, 2016. http://www.proceedings.blucher.com.br/article-details/the-new-generationof-engines-and-the-challenges-for-the-foundry-industry-23721. Accessed 26 June 2019

A. Bignonnet, E. Charkaluk, Thermomechanical fatigue in the automotive industry. Eur. Struct. Integr. Soc. 29, 319–330 (2002)

D. Löhe, B. Tilmann, K.H. Lang. 5th International Conference on Low Cycle Fatigue. (Berlin, 2003), pp 161–176

T. Seifert, H. Riedel, Int. J. Fatigue 32(8), 1358–1367 (2010)

S. Ghodrat, A.C. Riemslag, L.A.I. Kestens, R.H. Petrov, M. Janssen, J. Sietsma, Metall. Mater. Trans. A 44(5), 2121–2213 (2013)

V.L. Diaconu, T. Sjögren, P. Skoglund, A. Diószegi, Stress relaxation of compacted graphite iron alloyed with molybdenum. Int. J. Cast Met. Res. 26(1), 51–57 (2013)

R.T. Wimber, AFS Trans. 88, 717–726 (1980)

M. H. Ferreira. Análise da vida em fadiga termomecânica de ferros fundidos cinzento e vermicular. Master Thesis, Universidade de São Paulo, São Carlos, 2017. http://www.teses.usp.br/teses/disponiveis/18/18158/tde-05092017-081625/pt-br.php

F. Langmayr, F. Zieher, F.M. Lampic, MTZ 4, 298–304 (2004)

P. Skoglund, J. Elfsberg, N. Ipek, L.V. Diaconu, M. Larsson, P. Schmidt, Mater. Sci. Forum 925, 377–384 (2018)

S. Ghodrat. Thermo-Mechanical Fatigue of Compacted Graphite Iron in Diesel Engine Components. Ph.D. Thesis, Delf University of Technology (2013)

W.L. Guesser, L.C. Guedes, A.L. Müller, V.B. Demetrio, A. Rabelo, Mater. Sci. Forum 925, 296–303 (2018)

V. Norman, P. Skoglund, J. Moverare, Int. J. Cast Met. Res. 29(1–2), 26–33 (2015)

V. Norman, P. Skoglund, D. Leidemark, J. Moverare, Int. J. Fatigue 88, 121–131 (2016)

H. Pirgazi, S. Ghodrat, L.A.I. Kestens, Mater. Charact. 90, 13–20 (2014)

Acknowledgements

This paper is an invited submission to IJMC selected from presentations at the 2nd Carl Loper 2019 Cast Iron Symposium held from September 30 to October 1, 2019, in Bilbao, Spain. The authors would like to thank Tupy Foundry for the financial support and for providing the materials. Two of the authors give thanks to Conselho Nacional de Desenvolvimento Científico e Tecnológico, CNPq, Brasil (Proc. 306388/2017-0 and Proc. 314941/2018-5).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bon, D.G., Ferreira, M.H., Bose Filho, W.W. et al. Fracture Micromechanisms Evaluation of High-Strength Cast Irons Under Thermomechanical Fatigue Conditions. Inter Metalcast 14, 696–705 (2020). https://doi.org/10.1007/s40962-019-00399-w

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-019-00399-w