Abstract

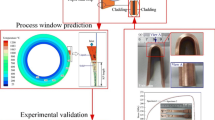

In this study, to improve the interfacial bonding between the inner sleeve and outer layer of a duplex roller sleeve, a model of the uphill casting of a roll sleeve was constructed with a commercially available process modeling software and simulated the temperature fields in the casting process. Furthermore, the effects of the pouring temperature, the preheating temperature of the steel sleeve and the preheating temperature of the sand on the boundary temperature between the casting and 1045 steel sleeve were simulated. The results show that the lower boundary temperature (1268 °C) between the casting and 1045 steel sleeve leads to poor bonding strength because the metallurgical bonding layer does not form. Increasing the pouring temperature (1450–1600 °C), the preheating temperature of the steel sleeve (600–1200 °C) and the preheating temperature of the sand (60–260 °C) can increase the boundary temperature, which favors the formation of a metallurgical bonded layer and enhances the bonding strength between the casting layer and 1045 steel sleeve. Finally, 1550 °C pouring temperature, and the preheating temperature of the inner sheath and casting sand of 1000 and 160 °C, respectively, are adopted in casting a roll sleeve, when other conditions remain unchanged. The results of the samples collected in the middle of the casting suggest that the maximum surface temperature of the inner sheath should be above the solidus temperature and a metallurgical bonded layer will form.

Similar content being viewed by others

References

T. Noguchi, K. Asano, S. Hiratsuka, H. Miyahara, Int. J. Cast Metal. Res. 21(4), 219–225 (2008)

T. Noguchi, N. Horikawa, H. Nagate, T. Nakamura, K. Sato, Int. J. Cast Metal. Res. 18(4), 214–220 (2005)

S. Ghadimi, M. Sedighi, F. Djavanroodi, A. Asgari, Mater. Manuf. Processes 30(10), 1256–1261 (2015)

H.F. Liu, Ph.D. Thesis of Jilin University, 2000, pp. 108–110 (chinese)

J.W. Shi, D.X. Yang, F. Ni, R. Long, Hot Working Technology, 2005, 6, pp 6–8 (chinese)

J. Liu, C. Liu, Mater. Manuf. Processes 30(4), 563–568 (2015)

J. Roucka, M. Kovác, M. Jaroš, O. Šikula, K. Hrbácek, B. Podhorná, Int. J. Metalcast. 10, 71–80 (2010)

Y.X. Yan, Q. Sun, J.J. Chen, H.K. Pan, Mater. Manuf. Processes 30(10), 1174–1178 (2015)

S.L. Lu, F.R. Xiao, S.J. Zhang, W.N. Mao, B. Liao, Appl. Therm. Eng. 73, 512–521 (2014)

N.N. Song, Y.K. Luan, Y.L. Bai, Z.A. Xu, X.H. Kang, D.Z. Li, J. Mater. Sci. Technol. 28, 147–154 (2012)

S. Inthidech, P. Sricharoenchai, Y. Matsubara. Int. J. Metalcast. 25–34 (2012)

Ali Hadji, Khedidja Bouhamla, Hichem Maouche, Int. J. Metalcast. 10(1), 45–55 (2016)

ProCast User Manual Version 2009. 1. ESI group. The virtual try-out space company (2009)

S.L. Lu, F.R. Xiao, Z.H. Guo, L.J. Wang, H.Y. Li, B. Liao, Appl. Therm. Eng. 93, 518–528 (2016)

Acknowledgments

This research is supported by Hebei Science and Technology Support Program (13274202D) and Hebei University of Science and Technology fund (XL201002).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Guo, Zh., Xiao, Fr., Lu, Sl. et al. Optimization of Process Parameters to Improve Combination in Duplex Roller Sleeve. Inter Metalcast 11, 448–455 (2017). https://doi.org/10.1007/s40962-016-0078-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-016-0078-7