Abstract

Geomechanical analysis is essential to assess the productivity forecast of cyclic steam simulation (CSS) operations in heavy oil reservoirs. The high-temperature and high-pressure fluid injection, as well as depletion in unconsolidated and poorly cemented porous media during CSS, may generate a relevant stress–strain response at levels that can lead to irreversible changes in reservoir permeability. Therefore, it is fundamental to consider permeability dependence on rock strain to properly analyze the impact of geomechanics, pressure, and temperature on reservoir performance. This paper implements a proposed directional strain-dependent permeability model to assess the productivity and compare it with a conventional volumetric permeability model through numerical simulation, considering the effects of wellbore creation on the stress–strain initial state. An explicit coupling between CMG-STARS and the geomechanics in-house simulator GSIM is carried out to perform the simulations using the proposed model. The results of oil production rates and permeability profiles show competitiveness between dilation and compaction periods that modify the structure of the porous media. There is a significant influence of stress state, strain, and injected energy on the permeability parameter. The approximations of this study might be used for feasibility assessment and optimization of CSS when integrating reservoir flow and geomechanical behavior analysis in productivity forecast.

Highlights

-

Permeability changes near the wellbore are amplified when the open-hole internal condition is implemented in reservoir simulation.

-

A flow capacity and productivity loss due to depletion are expected when CSS is implemented on unconsolidated heavy oil reservoirs.

-

The permeability loss on reservoirs subjected to CSS may be managed by selecting the adequate operating variables.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The main objective of thermal recovery techniques, such as cyclic steam stimulation (CSS), steamflooding, and steam-assisted gravity drainage (SAGD), is to reduce the residual oil saturation in the reservoir by increasing crude oil mobility in the porous medium. This can be achieved by injecting steam into the reservoir at high temperature and high pressure. Thermal recovery techniques such as CSS consist of cycles of three stages, namely, injection, soaking, and production. In the injection stage, a hot steam (200–300 °C) is injected into the reservoir for a few days or weeks and generally at a pressure lower than the fracture pressure. In the soaking stage, the well is shut in to allow the high-temperature fluid to reach the furthest areas within the reservoir. Lastly, in the production stage, the well is opened, allowing a mixture of less viscous crude oil with condensed steam. This stage is extended until the production rate is economically viable. The next injection–soaking–production cycles are repeated until the least achievable feasible rates are achieved (Alvarez and Han 2013; Temizel et al. 2015; Torres-Hernandez 2018).

Injection and production are the most critical stages of CSS, in which significant changes in pressure and temperature occur. These changes generate variations in the stress state and alterations of mechanical and petrophysical properties of the rock (Arias-Buitrago et al. 2021). The scientific literature presents sufficient evidence concerning the effects of pressure and temperature changes during CSS, mainly in terms of stress reorientation, activation of preexisting fractures or the initiation of new ones, reactivation of faults, damage of caprock integrity, and wellbore instability (Shafiei and Dusseault 2013; Temizel et al. 2015, 2016; Uribe-Patiño et al. 2017).

The factors that determine the thermoporoelastic behavior of the rock during CSS include the type of rock (consolidated or unconsolidated), the mechanical properties (elastic moduli and strength parameters), and the level of confining stress to which the rock is subjected (Shunde et al. 2009; Uribe-Patiño et al. 2017; Zhang et al. 2018; Morales-Monsalve et al. 2018).

2 Background

2.1 Experimental evidence approach to permeability changes due to stress–strain response

During the life cycle of any reservoir, absolute permeability evolves in response to local stress–strain changes within the porous system. It is crucial to address the productivity analysis of the reservoir not only in terms of pressure, saturation, and fluid rate but also in terms of stress–strain management, irreversible plasticity, and permeability tensor variations due to complex processes such as compaction and dilation (Crawford et al. 2004; Nguyen et al. 2014; Yale 2002).

A scenario of anisotropic permeability is considered when the permeability tensor reports different permeability values in all analysis directions. This scenario may change when the reservoir is pressurized, heated, or deformed. Consequently, a change in the shape of the porous media can modify the pore size, flow tortuosity, and permeability (Wang and Cheng 2020).

Several authors have addressed experimental testing that identifies permeability changes due to dilation or compaction effect over rock strain. The general tendency indicates that permeability increases as a result of shear dilation under low confining conditions (Oldakowski 1994; Scott et al. 1994; Touhidi-Baghini 1998; Arias-Buitrago 2015; Correa-Álvarez et al. 2021). Li and Chalaturnik (2006) described the permeability evolution in vertical and horizontal oriented rock samples as a function of volumetric strain, where permeability could increase up to six times the original permeability value. Xu and Yang (2016) identified permeability changes due to creep behavior or prolonged response beyond the elastic limit when the loading and unloading stages are included in laboratory testing. Permeability increased during loading or decreased during unloading.

Louis et al. (2018) stated that higher impacts on permeability occur when the effects of temperature and stress changes simultaneously occur. These effects accumulate and cause thermal expansion, compressibility increment, and fines migration due to changes in pore surface. Certainly, temperature changes induce permeability reductions up to 2.47 × 10− 13 m2 after the heating and cooling processes. This statement agrees with Ferfera et al. (1997), who explained the reservoir permeability reduction in three main scenarios, namely, (a) microfracture closure, (b) elastic reduction of pore throats, and (c) microfracture extension and pore collapse. Lastly, Arias-Buitrago (2015) performed triaxial tests under several temperatures and confining conditions. The author found that permeability tends to decrease at any confining condition when the samples are heated above 100 °C, while permeability is reduced at low confining conditions as the temperature increases.

Hence, this evident dependency of permeability on the mechanical response of the reservoir drives the necessity to include permeability models for production forecast, mainly in processes such as CSS, where considerable changes in pressure and temperature are expected.

2.2 Permeability models

Diverse volumetric and directional models have been proposed to relate permeability to porosity, rock deformation, and effective stress changes. Volumetric models are characterized by an isotropic permeability estimation, while directional models consider permeability heterogeneity according to the fluid flow direction.

Touhidi-Baghini (1998) described an equation relating permeability to porosity and mean particle diameter. Raghavan and Chin (2004) used an empirical exponential permeability model dependent on the mean effective stress to conduct history matching. Tortike used the Kozeny–Carman relationship to develop a model that relates permeability to volumetric strain for isotropic loading, (Li and Chalaturnyk 2006). Lastly, Wang and Cheng (2020) modified an empirical permeability expression to include the effects of mean effective stress and pore compressibility, introducing an exponent for porosity (\(\alpha\)), ranging from 2 to 3.

Wong and Li (2001) proposed a permeability model for shear dilation. This deformation-dependent model is based on a geometric approach that reflects a directional behavior, neglected in conventional semiempirical models such as the Kozeny–Carman. This model was validated through experimental testing, indicating the changes in permeabilities derived from the variation of principal strains in a medium where pore throats were considered as rhombic packages of perfect spheres. Wong (2003) tested an additional directional permeability model expressed in terms of strain tensors based on Hooke’s elasticity theory. The author performed triaxial tests on the oil–sand samples, indicating increments up to four times in vertical and horizontal permeabilities at the largest dilated state. During shear dilation, permeability anisotropy is induced by the grain rearrangement and consequently flow area and tortuosity variations.

Recent permeability models relate reservoir permeability response to principal stresses, such as the one presented by Glowacki and Selvadurai (2016). This empirical model introduces an exponential relationship between permeability and principal stresses, as shown in Eq. (1).

where \(\frac{k({\sigma }_{1},{\sigma }_{3})}{{k}_{0}}\) is the permeability ratio, \({\sigma }_{1}\) and \({\sigma }_{3}\) are the maximum and minimum principal stresses, respectively, \({\sigma }_{T}\) is the mean tensile strength, and \({\lambda }_{1}\)and \({\lambda }_{2}\) are calibration parameters obtained by compressive drained triaxial testing.

Although the aforementioned studies approach the dynamic interaction between reservoir permeability and the geomechanical effects, few researchers have published the relationship between permeability and strain in a porous media (Main et al. 2000; Ni et al. 2018; Wang and Cheng 2020). The strain field can affect the pore architecture and petrophysical properties of the reservoir rock. Therefore, this study aims to determine the permeability variation by relating the change of this parameter as a function of deformation and the thermoporoelastic response of a porous rock.

The scope of the present research can be divided into two main steps. In the first step, a strain-dependent permeability model is formulated, and useful data are analyzed to characterize the reservoir properties and parameters of a baseline case subjected to CSS. In the second step, the proposed permeability model is assessed using explicit coupled geomechanical simulation. Three separate reservoir simulations are then run, i.e., the first one with the volumetric permeability approach, the second one implementing the proposed directional strain-dependent permeability model, and the third one with constant permeability to investigate reservoir dynamic performance and analyze the interaction between stress, strain, and permeability during CSS. Finally, the results of a set of explicit coupled geomechanical simulations are used for the sensitivity analysis of operational variables and their influence on reservoir radial permeability.

3 Directional strain-dependent permeability model

Based on the model presented by Glowacki and Selvadurai (2016), a different directional permeability model is proposed in this study, integrating strain and temperature effects on permeability. Equation (2) represents the proposed model.

where \(\frac{k}{{k}_{0}}\) is the permeability ratio, \({\varepsilon }_{ \left|\right|flow \, dir}\) corresponds to the strain parallel to the flow direction, \({\stackrel{-}{{\varepsilon }}}_{\perp \, to \, flow}\) is the average strain in the plane perpendicular to flow, \(\varDelta T\) is the temperature difference considering the initial reservoir temperature as a baseline value, and \({\lambda }_{1}\), \({\lambda }_{2}\), and \({\lambda }_{3}\) are empirical coefficients determined from experimental testing.

Equation (2) is proposed, preserving the exponential structure of the base model and including the strain response to overcome the limitation of considering only principal stresses (Eq. 1). That is, no change in permeability occurs if a material is in a perfect plastic state (i.e., deformation under constant stress state). This proposed model also includes a third exponential term related to the effect of temperature on permeability as a consequence of thermal expansion.

Under laboratory conditions, where flow is oriented in the z-axis, the expression can be written as

where \({k}_{z}\) is the calculated axial permeability, \({k}_{0z}\) is the initial axial permeability, \({\varepsilon }_{ z}\) is the axial strain, and \({\stackrel{-}{{\varepsilon }}}_{r}\) is the average radial strain of the sample.

4 Methodology

It is important to note that the permeability models commonly used in the industry for reservoir modeling consider permeability as a variable that depends on the volumetric deformation level of the porous medium or the stress response. This behavior is not necessarily true or applicable to unconsolidated formations with poorly sorted and rounded grains with an elastoplastic response. This factor may contribute to the inability to assess permeability using stress-dependent or volumetric permeability models, which neglect the reservoir heterogeneity in terms of grain size, sorting, and pore architecture.

Regarding this issue, the main objective of this study is to assess and contrast the oil production variation during a CSS process by implementing a proposed directional permeability model in a poorly consolidated sandstone.

The proposed permeability model (Eq. 2) was initially calibrated. A set of three triaxial tests from Arias-Buitrago (2015) was analyzed in terms of radial and axial strain, temperature variation, and permeability measurements to obtain the empirical model coefficients \({\lambda }_{1} \mathrm{,\,} {\lambda }_{2} \mathrm{,\,and\,} {\lambda }_{3}\). The coefficients were obtained through a curve fitting process, taking the values of 43.8, 143.34, and 0, respectively. These triaxial tests were conducted at different confining levels (4 and 8 MPa) and temperatures up to 230 °C.

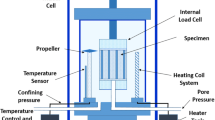

Once the model was calibrated, CMG-STARS was coupled with an in-house geomechanics simulator to execute the required runs. CMG-STARS is a well-known commercial reservoir simulator for multiphase fluid flow, heat transport, and geomechanics developed by the Computer Modeling Group Limited. Nevertheless, it is necessary to perform an explicit update on CMG to evaluate the proposed directional permeability model and include the effects of wellbore creation on the stress–strain response. The explicit update is performed using GSIM, an in-house reservoir simulator designed for rock mechanics, which supports several kinds of stress–strain-dependent permeability models, including the directional strain-dependent permeability model proposed in this study.

CMG and GSIM are executed with the same grid geometry and linked through external data files, allowing the data transfer and synchronization between both software. GSIM transfers stress–strain and permeability according to the constitutive model and permeability configuration to CMG. CMG updates the permeability response and transfers pressures and temperature in an iterative way until reaching a desired convergence tolerance. Figure 1 shows a schematic of CMG and GSIM coupling. The CMG to GSIM link takes the pressure (\(P\)) and temperature (\(T\)) response of every node grid at a specific time step. The data that transferred to GSIM allows the update of the geomechanical model, resulting in the calculations of the strain response parallel to the flow direction \({\varepsilon }_{ \left|\right|}\), the average strain in the plane perpendicular to flow \({\stackrel{-}{{\varepsilon }}}_{\perp }\), and the permeability tensors using the resulting permeability ratios (\({k/k}_{0}\)) from the proposed directional permeability model (\({k}_{model}\)). The permeability data estimated by GSIM using the chosen permeability model are then transferred to CMG to execute a new time step simulation.

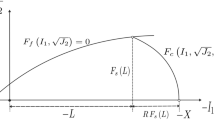

The CMG-GSIM coupling is used to simulate the study case and discuss the following key aspects in numeral simulation. The first aspect includes the implications of considering the effect of the stress–strain redistribution due to the wellbore creation. This effect is assessed based on the reservoir permeability response and the reservoir productivity. The second aspect is the comparison between the permeability response when implementing the proposed directional permeability model and the simulation results using a volumetric permeability approach. To compare the permeability response from the directional and the equivalent volumetric approach, it is necessary to run a simulation, in which CMG is executed using the set of permeability multipliers, as shown in Fig. 2. This set of multipliers is obtained by simulations in GSIM, where axial, radial, and tangential strains are compiled in the volumetric deformation term, and permeability calculations are internally done using the proposed directional strain-dependent permeability model (Eq. 2). The resulting permeability multipliers indicate an increase in permeability when reporting negative volumetric strain (tensile strains) induced due to pore size expansion or rock dilation. On the contrary, a higher volumetric strain (positive values) is translated into higher deformability and possible compaction of the pore structure or closure of pore throats.

4.1 Case study

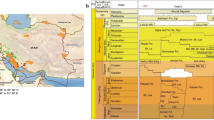

Modeling and numerical simulations are performed for a single well model based on data from a Colombian heavy oil field located in the Middle Magdalena Valley Basin where CSS has been implemented. The initial reservoir pressure was 5516 kPa at a depth of 413 m and the reservoir temperature of 40 °C. Table 1 summarizes the reservoir oil and petrophysical properties. Table 2 lists the mechanical and thermal properties of the rock.

The radial reservoir model includes a non-flow condition for the lateral, top, and bottom reservoir boundaries. A zero-displacement condition is assigned to the reservoir bottom, and an open-hole condition is set for the inner boundary when evaluating the proposed directional permeability model. The reservoir top is free to move vertically (constant vertical stress condition). Regarding the reservoir in situ stress state, the model includes a horizontal stress isotropy with a horizontal effective stress gradient and a vertical effective stress gradient of 8.8 kPa/m and 12.4 kPa/m, respectively.

The numerical simulation baseline uses a representative radial model, and the reservoir interval that opened for injection and production is 9 m. Eight CSS cycles are simulated. The injection stages have a duration of 15 days, in which steam is injected at 296 °C at a constant rate of 80 m3/day and quality of 75%. The soaking stage duration is set to 5 days. Regarding the production constraints, the well is operated under a constant bottom hole pressure of 2068.5 kPa. Moreover, a new CSS cycle is started when the oil production rate drops to an oil limit rate of 2.4 m3/day.

Lastly, a set of experiments is designed using the surface response methodology (RSM) to assess the relevance of the four operational parameters over the permeability behavior. The parameters of interest include the minimum oil production rate, steam quality, injection rate, and the number of CSS cycles, as presented in Table 3. This particular study is conducted over three points radially distributed along the reservoir, i.e., near the wellbore, at 9 m from the wellbore, and at the lateral external boundary (Fig. 3).

5 Results and discussion

5.1 Initial permeability distribution

During wellbore drilling, a stress redistribution is generated around the well due to the rock extraction and its circular shape. Consequently, the first modeling step of the GSIM simulator seeks to determine the stresses and strains caused by the drilling of the well and determine the effects of this mechanical response on the reservoir permeability.

Applying the open-hole initial condition in GSIM, the wellbore creation induces the stress–strain redistribution, as shown in Fig. 4, where the radial stress decreases to match the reservoir pressure at the borehole wall. These results are translated into negative or tensile radial strains, leading to an increase of 8% in radial and vertical permeability near the wellbore (see Fig. 5) when the proposed directional permeability is applied. In Eq. (2), \({\varepsilon }_{ \left|\right|flow \, dir}\) is taken as the radial strain, while \({\stackrel{-}{{\varepsilon }}}_{\perp \, to \, flow}\) is taken as the vertical strain to study the effect of subsidence on the permeability response. Note that the proposed model predicts vertical permeability changes even though the vertical strain remains constant.

During the injection and production stages, greater changes in permeability are expected when the open-hole condition is applied due to the stress redistributions near the wellbore.

5.2 Strain–permeability behavior during CSS

The difference in permeability response during several CSS cycles between the volumetric and directional permeability models can be observed in Fig. 6, near the wellbore, where the largest pressure and temperature changes are expected in the reservoir. A permeability enhancement is observed compared to the baseline case from both the directional and volumetric approaches. However, the directional model predicts permeability values up to 39% greater than the volumetric model. The reported permeability enhancement is related to rock dilation induced by the high-temperature–pressure steam injection.

In the first cycle, the permeability increases from 1.38 × 10− 12 m2 (Kr_Base case) to 2.41 × 10− 12 m2. Once soaking starts and a pressure drop occurs, the effective stresses increase, and radial/axial strains try to be restored to the original values, causing a permeability drop. In the region near the wellbore, temperature and permeability at the end of the production stage tend to increase along with the increase in the number of CSS cycles.

The permeability disparity between the directional and volumetric permeability approaches shown in Fig. 6 is attributed to wellbore creation, increasing the tensile radial strain due to the stress redistribution as seen in the strain profiles from Fig. 7. The strain profiles are plotted at the end of the first injection stage. The profiles for the radial and tangential strains overlap and indicate rock expansion in both directions when the volumetric approach is used. In contrast to the previous behavior, the strain profiles computed using the directional approach diverge in the region near the wellbore. The tangential strain and the radial strain indicate rock compaction and rock expansion, respectively. Regarding the vertical strain, both profiles indicate a vertical displacement of the top of the reservoir (negative strain) due to the steam injection.

Since the volumetric permeability approach takes the volumetric strain (i.e., the sum of radial, tangential, and vertical strains) and the tangential strain results as negative values, while the radial strain is positive (Fig. 8), the expected volumetric and, consequently, permeability values are lower than those computed with the directional permeability model, as shown in Fig. 6. The vertical strain has a similar pattern for both study cases, which means it is not considered in the observed permeability disparities.

The radial and tangential strain variations between the directional permeability model (DM) and the volumetric model (VM) identified in Fig. 8 are due to the effect of the permeability and flow rate of each case, which modifies the pressure and stress–strain response of the porous media.

5.3 Reservoir productivity and permeability

Despite the generous permeability increment near the wellbore in the injection stage shown in Fig. 5 and the strain tendencies shown in Fig. 8, which should indicate a permeability enhancement along the eight CSS cycles, an oil production loss is reported when compared with the base case. Figure 9 shows the oil rate and cumulative produced oil (Np) for the directional permeability approach and the baseline case, in which permeability is set constant. Approximately 7% loss of oil production occurs at the end of the eight cycles, indicating a reservoir flow capacity reduction that is attributed to a permeability loss on a particular region of the reservoir due to depletion. On the contrary, the base case reports an overestimation of the permeability response due to the implementation of a constant permeability approach, neglecting the directional plasticity effect on the reservoir permeability and falsely indicating some permeability enhancement with higher oil production.

It is important to note that cycle shifting in both cases in Fig. 9 is controlled by a preestablished minimum oil rate. Therefore, differences are expected between the DM and the constant permeability base case as the latter reaches the minimum oil rate later than the former.

At the end of the injection stage, the area with the greatest permeability changes matches the thermal front limit, as shown in Fig. 10. The radial permeability profiles for three cycles (curves Kr-I1, Kr-I4, and Kr-I8) along the whole reservoir report permeability values greater than the initial reservoir permeability (Kr_Base) in the region affected by the thermal front.

While the CSS number of cycles increases, the thermal front extends, as seen in the temperature profiles for the three selected cycles (T_I1, T_I4, T_I8). The extension of the thermal front increases permeability in a larger reservoir area. However, the permeability profiles at the fourth (Kr-I4) and eighth (Kr-I8) cycles are similar. The permeability values are less than the first injection stage (Kr-I1) profile, indicating that the permeability values for the affected region not only decrease but stabilize over time.

Figure 11 shows the permeability profiles at the end of production stages in the first, fourth, and eighth cycles (curves: Kr-P1, Kr-P4, and Kr-P8). The results indicate an overall flow capacity loss except the region near the wellbore for later cycles (curves: Kr-P4 and Kr-P8); nevertheless, the areas affected by the thermal front (around 10 m from the wellbore) increase its permeability as the number of cycles increase, indicating a heat accumulation in this region. In contrast to this behavior, the pressure profiles (curves: Kr-P1, Kr-P4, and Kr-P8) show the growth of the depletion front over time, inducing a permeability reduction in a larger area, especially where the thermal front has not arrived.

As observed in Fig. 12, the pressurization and depletion of the reservoir along with the CSS cycles cause compressive vertical strains. The vertical strain profiles at the end of injection stages (curves: I1, I4, and I8) indicate a decreasing reservoir vertical displacement over time, matching the decreasing permeability behavior presented in Fig. 10. The profiles at the end of the production stages (curves: P1, P4, and P8) indicate a progressive rock expansion over time in the region affected by the thermal front, while reservoir compaction is reported for the area where the temperature has not increased.

The described overall permeability reduction eventually leads to a loss in oil production, which is manifested to a greater extent in later cycles when the reservoir matrix unloads and enters a depletion state (Teklu et al. 2012; Nguyen et al. 2014).

5.4 CSS operating variables and permeability

The previously discussed interaction between temperature and pressure over rock permeability suggests the possibility of managing the reservoir mechanical behavior under CSS to maintain or enhance the reservoir flow capacity.

Based on the Sobol graph in Fig. 13, operational variables significantly influence the radial permeability behavior at the end of the CSS cycles. Variables such as injection rate and steam quality have the most significant impact on near-wellbore permeability. These parameters control the temperature and the amount of energy injected into the reservoir, affecting volumetric strain and consequently the permeability.

On the other hand, at the lateral reservoir boundary where no temperature changes occur, the production parameters, such as the number of cycles and the minimum oil rate for cycle switching, are more critical because they control the depletion state of the reservoir, as shown in Fig. 13.

6 Conclusions and recommendations

-

The proposed directional strain-dependent permeability model assumes that each component in the strain tensor has its own effects on the changes in permeability in each direction due to the thermoporoelastic response of the porous media, implying complex mechanisms between the permeability, rock elasticity and plasticity, grain size, shape, and sorting.

-

A significant difference in near-wellbore permeability response is identified when comparing the volumetric and directional permeability approaches. The differences are attributed to the open-hole condition and the nature of the radial and tangential strains.

-

To estimate the calibration parameters \({\lambda }_{1} \mathrm{,\,} {\lambda }_{2} \mathrm{,\,and\,} {\lambda }_{3}\) of the proposed directional strain permeability model, it is necessary to properly design a set of triaxial testing experiments with proper permeability measurements to calibrate and isolate strain and thermal effects when addressing permeability changes.

-

Despite the overall permeability increase during injection stages, the production loss due to permeability variation is more evident in the later CSS cycles due to reservoir depletion and compressive strain accumulation. A certain competitiveness is observed between dilation and compaction processes during CSS.

-

Injection variables, such as injection rate and steam quality, report a greater effect on near-wellbore permeability. In contrast, production parameters such as the number of cycles and minimum oil rate impact the permeability value outward the thermal front. Hence, it may be possible to strategically modify operational parameters during the injection and production stages to mitigate and assess the risk of any permeability loss triggered by the thermal effects and reservoir depletion.

-

For further research, it is suggested to assess the degree of irreversible permeability and strain variations to which the reservoir may be subjected in elastic/plastic regimes as a means to determine the potential permeability that can be restored through an adequate reservoir exploitation strategy. The anisotropic initial stress state should also be a sensitive scenario to analyze in thermal operations.

References

Alvarez J, Han S (2013) Current overview of cyclic steam injection process. J Pet Sci Res 2:116–127

Arias-Buitrago JA (2015) Efecto de la temperatura en las propiedades mecánicas de formaciones de crudo pesado. Master´s Thesis. Universidad Nacional de Colombia. Medellin, Colombia

Arias-Buitrago JA, Alzate-Espinosa GA, Arbeláez-Londoño A, Zambrano-Narvaez G, Chalaturnyk R (2021) Experimental study on the effect of temperature on the mechanical properties of unconsolidated silty sandstones. Energies 14:7007

Correa-Álvarez JC, Alzate-Espinosa GA, Araujo-Guerrero EF (2021) Porosity and Permeability behavior at different stress path and drainage condition in an uncemented and reconstituted porous medium. In: Paper presented at the ISRM 9th international symposium on geomechanics, virtual, 2021

Crawford BR, Gooch MJ, Webb DW (2004) Textural controls on constitutive behavior in unconsolidated sands: micromechanics and cap plasticity. In: Gulf Rocks 2004, the 6th North America Rock mechanics symposium (NARMS), 2004. Houston, USA

Ferfera FMR, Sarda JP, Bourteca M, Vincke O (1997) Experimental study of monophasic permeability changes under various stress paths. Int J Rock Mech Min Sci Geomech Abstr 34:1–12

Glowacki A, Selvadurai APS (2016) Stress-induced permeability changes in Indiana limestone. Eng Geol 2015:122–130

Li P, Chalaturnyk RJ (2006) Permeability variations associated with shearing and isotropic unloading during the SAGD process. J Can Pet Technol 45:54–61

Louis L, Henck S, Honarpour M, Araujo E, Bryant D (2018) Experimental study on the hydromechanical behavior of a Gulf of Mexico reservoir sand analogue at in situ conditions of pressure and temperature. In 52nd U.S. rock mechanics/geomechanics symposium, 2018, Seattle, USA

Morales-Monsalve CB, Lara-Restrepo IF, Araujo-Guerrero EF, Alzate-Espinosa GA, Arbeláez-Londoño A, Naranjo-Agudelo A (2018) Effect of temperature on the strength parameters at the plastic domain for unconsolidated sandstones. Geotech Geol Eng 36:3537–3549

Main IG, Kwon O, Ngwenya BT, Elphick SC (2000) Fault sealing during deformation-band growth in porous sandstone. Geology 28:1131–1134

Nguyen VH, Gland N, Dautriat J, David C, Wassermann J, Guélard J (2014) Compaction, permeability evolution and stress path effects in unconsolidated sand and weakly consolidated sandstone. Int J Rock Mech Min Sci 67:226–239

Ni X, Chen Z, Wang P, Wu J, Wu Y, Gong P (2018) Experimental investigation of the influence of differential stress, confining pressure and strain on aquifer sandstone permeability. Eur J Environ Civil Eng. https://doi.org/10.1080/19648189.2018.1429319.

Oldakowski K (1994) Stress induced permeability changes of Athabasca oil sands. Master’s Thesis. University of Alberta, Edmonton, Canada

Raghavan R, Chin LY (2004) Productivity changes in reservoirs with stress-dependent permeability. SPE Reserv Evaluat Eng 7:308–315

Scott JD, Proskin SA, Adhikary DP (1994) Volume and permeability changes associated with steam stimulation in an oil sands reservoir. J Can Pet Technol 33:44–52

Shafiei A, Dusseault M (2013) Geomechanics of thermal viscous oil production in sandstones. J Petrol Sci Eng 103:121–139

Shunde Y, Towler B, Dusseault M, Rothenburg L (2009) Numerical experiments on oil sands shear dilation and permeability enhancement in a multiphase thermoporoelastoplasticity framework. J Pet Sci Eng 69:219–226

Teklu T, Alameri W, Graves R, Tutuncu A, Kazemi H, Alsumaiti A (2012) Geomechanics considerations in enhanced oil recovery. In: SPE Canadian unconventional resources conference, Calgary, Canada

Temizel C, Gorucu S, Erdogan S, Tiwari A (2015) Optimization of cyclic steam stimulation (CSS) under geomechanics-dependent permeability. In: SPE Russian Petroleum technology conference, 2015. Moscow, Russia

Temizel C, Tiwari A, Aktas S, Tuna T, Gok I, Putra D (2016) Integrated workflow for robust reservoir management through production optimization in reservoirs with geomechanics-dependent permeability. In: Offshore Technology Conference Asia, Kuala Lumpur, Malaysia

Torres-Hernandez C (2018) Modelamiento del perfil de temperatura dentro del yacimiento durante procesos recobro térmico con inyección de vapor en yacimientos de crudo pesado. Master´s Thesis. Universidad Nacional de Colombia. Medellin, Colombia

Touhidi-Baghini A (1998) Absolute permeability of McMurray formation oil sands at low confining stresses. Ph.D Dissertation. University of Alberta. Edmonton, Canada

Uribe-Patiño J, Alzate-Espinosa GA, Arbeláez-Londoño A (2017) Geomechanical aspects of reservoir thermal alteration: a literature review. J Pet Sci Eng 152:250–266

Wang F, Cheng H (2020) Effect of tortuosity on the stress-dependent permeability of tight sandstones: analytical modelling and experimentation. Mar Pet Geol 120

Wong R (2003) A model for strain-induced permeability anisotropy in deformable granular media. Can Geotech J 40:95–106

Wong R, Li Y (2001) A deformation-dependent model for permeability changes in oil sand due to shear dilation. J Can Pet Technol 40:37–44

Xu P, Yang SQ (2016) Permeability evolution of sandstone under short-term and long-term triaxial compression. Int J Rock Mech Min Sci 85:152–164

Yale DP (2002) Coupled geomechanics-fluid flow modeling: effects of plasticity and permeability alteration. In: SPE/ISRM rock mechanics conference, Irving, USA

Zhang Z, He S, Gu D, Gai S, Li G (2018) Effects of stress-dependent permeability on well performance of ultra-low permeability oil reservoir in China. J Pet Explor Prod Technol 8:565–575

Acknowledgements

The authors acknowledge the Ministerio de Ciencia, Tecnología e Innovación from Colombia (MINCIENCIAS) and the Agencia Nacional de Hidrocarburos (ANH) for funding this research under the project no. FP80740-801-2019, as well as CMG for providing STARS licenses at Universidad Nacional de Colombia.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

Beyond what was mentioned above about the research funding, all authors certify that they have no affiliations with or involvement in any organization or entity with any financial interest or nonfinancial interest in the subject matter or materials discussed in this manuscript.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Alzate-Espinosa, G.A., Araujo-Guerrero, E.F., Torres-Hernandez, C.A. et al. Impact assessment of strain-dependent permeability on reservoir productivity in CSS. Geomech. Geophys. Geo-energ. Geo-resour. 9, 67 (2023). https://doi.org/10.1007/s40948-023-00538-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40948-023-00538-y