Abstract

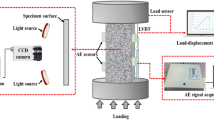

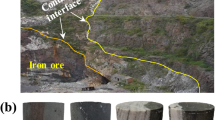

The stability of rock masses in deep underground engineering is always a key issue in geotechnical engineering. However, it is difficult to describe the strength and deformation characteristics of fractured rock masses using the mechanical behavior of intact rocks. The study on the mechanical properties and failure modes of high-temperature jointed rock mass is significant. In this paper, Shandong granite (in China) was taken as the research object. Fracture at different angles were prefabricated at the centre of the rock sample to simulate the echelon joints in rock. the evolution of the strain field and the process of crack initiation, development, and coalescencein the process of uniaxial compression tests were recorded and analysed by digital image correlation (DIC) and acoustic emission (AE) techniques. The results show that the crack starts from the tip of the joint and develops along a certain angle from the top or bottom of the specimen when the echelon jointed granite is subjected to external loads, and the specimen is destroyed when a through-crack is formed. The crack morphology is primarily tensile and shear cracking. When the prefabricated joints are at 30° and 45°, the specimen failure is the result of the joint action of tensile and shear failure. When the prefabricated joint angle is 60°, the tensile failure of the specimen mainly occurs, and the minor shear failure is supplemented.

Article highlights

-

1.

The failure forms of echeloned jointed granite are mainly shear failure and tensile failure.

-

2.

For echelon joint granite, When the angle of joint is 30° and 45°, tensile failure and shear failure act together, and when the angle is 60°, it is mainly tensile failure.

-

3.

The destruction of high-temperature jointed granite is caused by thermal stress and external force.

Similar content being viewed by others

References

Aggelis DG, Soulioti DV, Sapouridis N, Barkoula NM, Paipetis AS, Matikas TE (2011) AE characterization of the fracture process in fibre reinforced concrete. Conster Build Mater 25(11):4126–4131

Aggelis DG, Mpalaskas AC, Matikas TE (2013) Acoustic signature of different fracture modes in marble and cementitious materials under flexural load. Mech Res Commun 47:39–43

Akdag S, Karakus M, Taheri A, Nguyen G, Manchao H (2018) Effects of thermal damage on strain burst mechanism for brittle rocks under true-triaxial loading conditions. Rock Mech Rock Eng 51:1657–1682

Alm O, Jaktlund LL, Shaoquan K (1985) The influence of microcrack density on the elastic and fracture mechanical properties of Stripa granite. Phys Earth Planet In 40(3):161–179

Chen YL, Ni J, Shao W, Azzam R (2012) Experimental study on the influence of temperature on the mechanical properties of granite under uni-axial compression and fatigue loading. Int J Rock Mech Min 56:62–66

Cheng Y, Wong L (2020) A study on mechanical properties and fracturing behavior of carrara marble with the flat-jointed model.Int J Numer Anal Met 44(3)

Ganne P, Vervoort A, Wevers M (2007) Quantification of pre-peak brittle damage: correlation between AE and observed micro-fracturing. Int J Rock Mech Min 44(5):720–729

Ge Z, Sun Q (2021) AE characteristics of gabbro after microwave heating. Int J Rock Mech Min 138:104616

Ge Z, Sun Q, Xue L, Yang T (2021) The influence of microwave treatment on the mode I fracture toughness of granite.Eng Fract Mech.107768

Geng J, Sun Q, Zhang Y, Cao L, Zhang W (2017) Studying the dynamic damage failure of concrete based on acoustic emission. Constr Build Mater 149:9–16

Huang Z, Zhao K, Li X, Zhong W, Wu Y (2021a) Numerical characterization of groundwater flow and fracture-induced water inrush in tunnels. Tunn Undergr Sp Tech 116:104119

Huang Z, Zeng W, Gu Q, Wu Y, Zhong W, Zhao K (2021b) Investigations of variations in physical and mechanical properties of granite, sandstone, and marble after temperature and acid solution treatments. Constr Build Mater 307:124943

Kihara K (2001) Molecular dynamics interpretation of structural changes in quartz. Phys Chem Miner 28(6):365–376

Lee H, Jeon S (2011) An experimental and numerical study of fracture coalescence in pre-cracked specimens under uniaxial compression. Int J Solids Struct 48(6):979–999

Li YP, Wang YH, Chen LZ (2005) Experimental research on pre-cracked marble under compression. Int J Solids Struct 42(9):2505–2516

Liu S, Xu J (2014) Mechanical properties of qinling biotite granite after high temperature treatment. Int J Rock Mech Min 71:188–193

Liu S, Xu J (2015) An experimental study on the physico-mechanical properties of two post-high-temperature rocks. Eng Geol 185:63–70

Menendez B, Dacid C, Darot M (1999) A study of the crack network in thermally and mechanically cracked granite samples using confocal scanning laser microscopy. Phys Chem Earth 24(7):627–632

Miao S, Pan PZ, Zhao X, Shao C, Yu P (2020) Experimental study on damage and fracture characteristics of beishan granite subjected to high-temperature treatment with DIC and AE techniques. Rock Mech Rock Eng (1–3),1–23

Morgan SP, Johnson CA, Einstein HH (2013) Cracking processes in barre granite: fracture process zones and crack coalescence. Int J Fracture 180(2)

Park CH, Bobet A (2009) Crack coalescence in specimens with open and closed flaws: a comparison. Int J Rock Mech Min 46(5):819–829

Peng K, Lv H, Zou Q, Wen Z, Zhang Y (2020) Evolutionary characteristics of mode-I fracture toughness and fracture energy in granite from different burial depths under high-temperature effect. Eng Fract Mech 239(2):107306

Shah SG, Kishen J (2010) Fracture behavior of concrete-concrete interface using AE technique. Eng Fract Mech 77(6):908–924

Shao S, Ranjith PG, Wasantha P, Chen BK (2015) Experimental and numerical studies on the mechanical behaviour of australian strathbogie granite at high temperatures: an application to geothermal energy. Geothermics 54:96–108

Sirdesai NN, Mahanta B, Ranjith PG, Singh TN (2017) Effects of thermal treatment on physico-morphological properties of indian fine-grained sandstone. B Eng Geol Environ 78(2):883–897

Tang J, Chen X, Dai F, Wei M (2020) Experimental investigation of fracture damage of notched granite beams under cyclic loading using DIC and AE techniques. Fatigue Fract Eng M (10)

Wong R, Chau KT, Tang CA, Lin P (2001) Analysis of crack coalescence in rock-like materials containing three flaws—part i: experimental approach. Int J Rock Mech Min 38(7):909–924

Wu Y, Li XZ, Huang Z, Xue S (2021) Effect of temperature on physical, mechanical and AE properties of Beishan granite, Gansu Province, China. Nat Hazards 107(2):1577–1592

Yang SQ (2013) Study of strength failure and crack coalescence behavior of sandstone containing three pre-existing fissures. Rock Soil Mech 34(1):31–39

Yang SQ, Jing HW (2011) Strength failure and crack coalescence behavior of brittle sandstone samples containing a single fissure under uniaxial compression. Int J Fracture 168(2):227–250

Yang SQ, Yang DS, Jing HW, Li YH, Wang SY (2012) An experimental study of the fracture coalescence behavior of brittle sandstone specimens containing three fissures. Rock Mech Rock Eng 45(4): 563–582

Yang WM, Geng Y, Zhou ZQ, Li LP, Zhang DS (2020) Dem numerical simulation study on fracture propagation of synchronous fracturing in a double fracture rock mass. Geomech Geophys Geo 6(2)

Yang J, Yang SQ, Liu GJ, Tian WL, Li Y (2021a) Experimental study of crack evolution in prefabricated double-fissure red sandstone based on AE location. Geomech Geophys Geo7 (1)

Yang T, Sun Q, Dong ZH, Ge ZL, Wang SF, Xu CC (2021b) A study on thermal damage mechanism of sandstone based on thermal reaction kinetics. Geomech Geophys Geo 7(3):1–13

Yin Q, Jing HW, Zhu TT (2016) Experimental study on mechanical properties and cracking behavior of pre-cracked sandstone specimens under uniaxial compression. Indian Geotech J 47(3):1–15

Zhang G, Xing Y, Wang L (2018) Comprehensive sandstone fracturing characterization: integration of fiber bragg grating, digital imaging correlation and AE measurements. Eng Geol 246:45–56

Zhang W, Sun Q, Zhang Y (2019) Effects of pre-existing cracks and temperature on failure mode of granite from Eastern China. J Struct Geol 126:330–337

Zhang K, Li N, Liu W, Xie J (2020a) Experimental study of the mechanical, energy conversion and frictional heating characteristics of locking sections. Eng Fract Mech 228:106905

Zhang P, Yu Q, Li L, Xu T, Zhu W (2020b) The radiation energy of AE sources with different tensile angles and implication for the rock failure process. Pure Appl Geophys 177(7)

Zhang H, Sun Q, Jia H, Dong Z, Luo T (2021) Effects of high-temperature thermal treatment on the porosity of red sandstone: an NMR analysis. Acta Geophys 69(1):113–124

Zhao XG, Wang J, Cai M, Cheng C, Ma LK (2014) Influence of unloading rate on the strainburst characteristics of beishan granite under true-triaxial unloading conditions. Rock Mech Rock Eng 47(2):467–483

Zhao F, Sun Q, Pan X (2019) Effects of pre-existing fissures on surface macro-crack characteristics of granite subjected to elevated temperatures. Acta Geodyn Geomater 16(4):441–450

Zhao F, Shi Z, Sun Q (2021) Fracture mechanics behavior of jointed granite exposed to high temperatures. Rock Mech Rock Eng (7–8),1–14

Zhou XP, Lian YJ, Wong L, Berto F (2018) Understanding the fracture behavior of brittle and ductile multi-flawed rocks by uniaxial loading by digital image correlation. Eng Fract Mech 199:438–460

Acknowledgements

This research was supported by the National Natural Science Foundation of China (Grant No. 41972288; No. 4210021463) and China Postdoctoral Science Foundation (No.2020M673443) and the Excellent Doctoral Dissertation Cultivation Program of Xi’an University of Science and Technology.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yang, T., Sun, Q., Zhao, F. et al. Mechanical behaviour and failure modes of high-temperature jointed granite based on DIC and AE Technology. Geomech. Geophys. Geo-energ. Geo-resour. 8, 86 (2022). https://doi.org/10.1007/s40948-022-00402-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40948-022-00402-5