Abstract

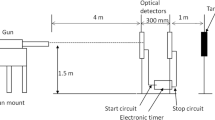

Traditionally, medium-carbon, low-alloy steels with tempered martensitic microstructures are widely used in structural armor applications. There have been continuous attempts to develop alternative structural armor materials that can provide further weight reduction of armored vehicles. In this context, high-nitrogen steel (HNS) plates with austenitic microstructures were studied against a full-scale tungsten heavy alloy penetrator (500 mm in length and 25 mm in diameter), and the results were compared with those of rolled homogeneous armor steels with tempered martensitic microstructures. The ballistic trials on HNS and RHA steel plates were carried out against a WHA penetrator at velocities of 1630 ± 20 m/s (at a 0° angle of attack and a distance of 100 m) to determine the depth of penetration. HNS exhibited higher ballistic performance (i.e., a lower normalized depth of penetration) against WHA long-rod projectiles than RHA steel. The ballistic results were analyzed with the help of the initial mechanical properties and operating failure mechanisms. The better ballistic performance of HNS against tungsten heavy alloy can be primarily attributed to its higher dynamic flow stress. Post-ballistic hardness measurements on crater cross sections indicated that a higher volume of material was involved in energy dissipation in the HNS target than in the RHA steel target. Microstructural analysis showed that adiabatic shear band-induced cracking played an important role in the failure of both steel targets.

Similar content being viewed by others

Data Availability

The data of this present work is part of another ongoing work. Hence data cannot be provided at this point of time.

References

Lach E, Koerber G, Scharf M, Bohanm A (1999) Comparisons of nitrogen alloyed austenitic steels and high strength armour steels impacted at high velocity. Int J Impact Eng 23:509

Lach E, Anderson C, Schirm V, Koerber G (2008) Hypervelocity impact into a high strength and ductile steel alloy. Int J Impact Eng 35:1625–1630

Savage SJ, Skoglund P, Eriksson J, Olsson LG, Persson P (1999). Ballistic and high strain rate properties of high nitrogen steels compared to RHA. In: 16th International symposium on ballistics, San Antonio, TX, 15–19 November, p 1168.

Savage SJ, Hansson H (2002) Modelling of a nitrogen alloyed steel with application to armourpenetration. In: Jones N, Brebbia CA, Rajendran AM (eds) Structures under shock and impact. WIT Press, Ashurst Lodge, pp 467–476

Chen R, Shi J, Dong H, Liu YL, Gu YL, Rong F (2006) Ballistic behaviour of nitrogen alloyed austenitic and martensitic steel plates. Ord Mater Sci Eng 29(2):46–51

Bhav Singh B, Sukumar G, Prakasa Rao P, Siva Kumar K, Madhu V, Arockia Kumar R (2019) Superior ballistic performance of high nitrogen steels against deformable and non-deformable projectiles. Mater Sci Eng A 51:115–127

Bhav Singh B, Siva Kumar Madhu KV, Arockia Kumar R (2017) Effect of hot rolling on mechanical properties and ballistic performance of high nitrogen steels. Procedia Eng 173:926–933

Bhav Singh B, Sivakumar K, Balakrishna Bhat T (2009) Effect of cold rolling on mechanical properties and ballistic performance of nitrogen-alloyed austenitic steels. Int J Impact Eng 36:611–620

Anderson CE, Walker JD, Bless S, Partom Y (1996) On the L/D effect for long rod penetrators. Int J Impact Eng 18:247–264

Anderson CE, Walker JD, Bless S, Sharron TR (1995) On the velocity dependence of the L/D effect for long rod penetrators. Int J Impact Eng 17:13–24

Gray III GT (2003), Classic Split-Hopkinson pressure bar testing. In: Kuhn H (ed) ASM Handbook, ASM International Materials Parks

Gavriljuk VG, Berns H (1999) High nitrogen steels. Springer, Berlin

Mullner P, Solenthaler C, Uggowitzer P, Speidel MO (1993) On the effect of nitrogen on the dislocation structure of austenitic stainless steel. Mater Sci Eng A164:164–169

Karthick B, Veerababu R, Satyanarayana DVV (2016) Effect on aging and oxidation on strain hardening behaviour of nickel free high nitrogen steels. Met Mater Int 22(3):413–423

Sun G, Yu A, Sun S, Ji C, Jiang Z, Lian J (2017) Plastic deformation and fracture behaviour of high-nitrogen nickel free austenitic stainless steel. Mater Sci Tech 1–10

Gavriljuk VG, Tyshchenko AJ, Bliznuk VV, Yakovleva IL, Riedner S, Berns H (2008) Steel Res Int 79(6):413–422

Krauss G, Matlock DK (1995) Effects of strain hardening and fine structure on strength and toughness of tempered martensite in carbon steels. J Phys IV 5:C8-51

Krauss G (2001) Deformation and fracture in martensitic carbon steels tempered at low temperatures. Mater Trans A 32A:861–877

Lach E, Bohmann A, Scharf M, Werner E (2000) Deformation behavior of nitrogen-alloyed stainless steels at high strain rates. Adv Eng Mater 2(11):750–752

Frechard S, Redjaımia A, Lach E, Lichtenberger A (2008) Dynamical behaviour and microstructural evolution of a nitrogen-alloyed austenitic stainless steel. Mater Sci Eng 480:89–95

Tresca H (1878) On the further applications of flow of solids. Proc Inst Mech Eng 30:301–345

Recht RF (1964) Catastropic thermoplastic shear. J Appl Mech 31:189

Culver RS (1973) In: Rohde RW, Butcher BM, Holland JR, Karnes CH (eds). Metallurgical effects at high strain rates. Plenum Press, New York, p 519.

Bai Y (1982) Thermo-plastic instability in simple shear. J Mech Phys Solids 30:195–207

Wright TW (1990) Approximate analysis for the formation of adiabatic shear bands. J Mech Phys Solids 38(4):515–530

Technical Data sheet. CarTech® 15-15HS® Max Stainless steel. Carpenter technology. https://cartech.ides.com/datasheet.aspx?i=102&E=330&c

Holloman JH (1945) Tensile deformation, Trans AIME162 268-29

Timothy SP (1987) The structure of adiabatic shear bands in metals: a critical review. Acta Mater 35:301

Walley SM (2007) Shear localization: a historical overview. Met Trans A 38A:2629

Stelly M, Dormeval R (1986) Metallurgical applications of shock-wave and high-strain-rate phenomena. In: Murr LE, Staudhammer KP, Meyers MA (eds) Marcel-Deksker, New York, pp 607–632

Argon AS (1973) The inhomogeneity of plastic deformation. In: Reed-Hill RE (ed) ASM, Metals Park, pp 161–190

Littlefield DL, Anderson CE, Partom Y, Bless S (1997) The penetration of steel target finite in radial extent. Int J Impact Eng 19(1):49–62

Christman DR, Gehring JW (1996) Analysis of high velocity projectile penetration mechanics. J Appl Phys 37:1579

Rosenberg Z, Dekel E (2012) Terminal ballistics. Springer, Berlin

Crouch I (2016) The science of armour materials. Wood Head Publishing, Amsterdam

Tate A (1967) A theory for the deceleration of long-rods after impact. J Mech Phys Solids 15:87–399

Tate A (1969) Further results in the theory of long-rod penetration. J Mech Phys Solids 17:141–150

Tate A (1986) Long-rod penetration models—Part-II. Extensions to the hydrodynamic theory of penetration. Int J Eng Sci 28(9):599–612

Alekseevskii VP (1966) (1966), Penetration of a rod into a target at high velocity. Combust Explos ShockWaves 2:63–66

Anderson CE, Walker JD (1991) An examination of long-rod penetration. Int J Impact Eng 11:481–501

Anderson CE, Walker JD, Hauver GE (1996) Target resistance for-long-rods penetration into semi-infinite targets. Nucl Eng Des 138:93–104

Tate A (1986) long-rod penetration models.-Part-I. A flow field model for high speed long-rod penetration. Int J Mech Sci 28:535–548

Rosenberg Z, Dekel E (2001) More on the secondary penetration of long-rods. Int J Impact Eng 26:639–649

Erlich DC, Seaman L, Curran DR, Shockey DA, Caligiuri RD, Burback R (1987) Computation model for armor penetration. Second Annual Report, , SRI international, Menlo Park, pp 1–202

Farrand TG (1991) Various target failure mechanisms observed for the ballistic penetrations. Technical report. BRL-TR-3255. U.S. Army Ballistic Research Laboratory. Aberdeen Proving Ground, pp 21005–5066

Berns H, Riedner S, Gavriljuk V, Petrov Y, Weihrauch A (2011) Microstructural changes in high interstitial stainless austenitic steels due to ballistic impact. Mater Sci Eng A528:4669–4675

Zener C, Hollomon JH (1944) Effect of strain rate upon plastic flow of steel. J Appl Phys 15:22–32

Rittel D, Landau P, Venkert A (2008) Dynamic recrystallization as a potential cause for adiabatic shear failure. Phys Rev Lett 101:16550

Rittel D, Zhang LH, Osovski S (2017) Mechanical characterization of impact-induced dynamically recrystallized nanophase. Phys Rev Appl 7:044012

Rogers HC (1979) Adiabatic plastic deformation. Annu Rev Mater Sci 9:238–311

Odeshi AG, Bassim MN, Al-Ameeri S (2006) Effect of heat treatment on adiabatic shear bands in a high-strength low alloy steel. Mater Sci Eng A 419:69–75

Glenn RC, Leslie WC (1971) The nature of ‘‘white Streaks’’ in impacted armor steel plate. Metall Trans 2:2945–2947

Wittman CL, Meyers MA, Pak HR (1990) Observation of an adiabatic shear band in AISI 4340 steel by high voltage transmission electron microscopy. Metall Mater Trans A 21A:707–716

Derep JL (1987) Microstructure transformation induced by adiabatic shearing in armored steel. Acta Metall 35(6):1245–1249

Zurek AK (1994) The study of adiabatic shear bands instability in a pearlitic 4340 steel using a dynamic punch test. Metall Mater Trans 25A:2483–2489

Mgbokwere CO, Nutt SR, Duffy J (1994) Shear band formation in 4340 steel: a TEM study. Mech Mater 17:97–110

Xue Q, Gray GT III (2006) Development of adiabatic shear bands in annealed 316L stainless steel: part II. TEM studies of the evolution of microstructure during deformation localization. Metall Mater Trans 37:2447–2458

Kad BK, Gebert JM, Perez-Prado MT, Kassner ME, Meyers MA (2006) Ultrafine-grain-sized zirconium by dynamic deformation. Acta Mater 54:4111–4127

Meyers MA, Xu YB, Xue Q, Perez-prada MT, Mcnelly TR (2003) Microstructural evolution in adiabatic shear localization in stainless steel. Acta Mater 51:1307–1325

Andrade U, Meyers MA, Vecchio KS, Chokshi AH (1994) Dynamic recrystallization in high-strain, high-strain-rate plastic deformation of copper. Acta Metall Mater 42:3183–3195

Hines JA, Vecchio KS (1997) Recrystallization kinetics within adiabatic shear bands. Acta Mater 45:635–649

Meyers MA, Subhash G, Kad BK, Prasad L (1994) Evolution of microstructure and shear-band formation in α-hcp titanium. Mech Mater 17:175–193

Armstrong RW, Coffey CS, Elban WL (1982) Adiabatic heating at a dislocation pile-up avalanche. Acta Metallu 30:2111–2116

Armstrong RW, Zerilli FJ (1994) Dislocation mechanics aspects of plastic instability and shear banding. Mech Mater 17:319–327

Furuhara T, Kobayashi K, Maki T (2004) Control of cementite precipitation in lath martensite by rapid heating and tempering. ISIJ Int 44:1937–1944

Meyers MA (1994) Dynamic failure: mechanical and microstructural aspects. J Phys III 6:C8-597-621

Erlich DC, Curran DR, Seaman L (1980) Further development of a shear band model. Final Report to the Army Materials and Mechanics Research Center, Report AMMRC TR 80-3, SRI Int., Menlo Park, p 51

Odeshi AG, Al-ameeri S, Mirfakhraei S, Yazdani F, Bassim MN (2006) Deformation and failure mechanism in AISI 4340 steel under ballistic impact. Theoret Appl Fract Mech 45:18–24

Odeshi AG, Bassim MN, Al-Ameeri S, Li Q (2005) Dynamic shear band propagation and failure in AISI 4340 steel. J Mater Process Technol 169:150–155

Bassim MN, Odeshi AG (2008) Shear strain localisation and fracture in high strength structural materials. Arch Mater Sci Eng 3:69–74

Kassner ME, Hayes TA (2003) Creep cavitation in metals. Int J Plast 19:1715–1748

Gao ZY, Han FS, Wu J, Wang QZ (2006) Mechanism of void formation in grain interior of ODS alloys. J Alloy Compd 419:126–132

Odeshi AG, Bassim MN (2009) High strain-rate fracture and failure of a high strength low alloy steel in compression. Mater Sci Eng A 525:96–101

Ghomi HM, Odeshi AG (2012) The effects of microstructure, strain rates and geometry on dynamic impact response of a carbon–manganese steel. Mater Sci Eng A 532:308

Dieter GE (1976) Mechanical metallurgy (SI metric edition). Mcgraw-Hill Book Company, New York, p 498

Anderson CE, Hohler V, Walker JD, Stlip AJ (1995) Time resolved penetration of long rods into steel targets. Int J Impact Eng 16:1–18

Johnson GR, Cook WH (1985) Fracture characteristics of three metals subjected to various strains, strain rates, temperatures and pressure. Eng Fract Mech 21(1):31–48

Rosenberg Z, Dekel E (1998) A computational study of the relations between material properties of long rod penetrators and their ballistic performance. Int J Impact Eng 21(4):283–296

Acknowledgements

The authors would like to thank Director, DMRL for giving permission to publish this paper. The authors thank DRDO, Govt of India for funding this work. The authors thank MBG, EMG and high strain rate testing team of ADDD for their support in the experimental work. The authors thank PXE, Balasore for their support in long-rod penetrator firing trials. The authors BBS and G.S would like to thank Mr. P. Ponguru Senthil for fruitful discussions.

Funding

The authors acknowledge funding from DRDO,Govt of India for this work.

Author information

Authors and Affiliations

Contributions

BBS: Planning, Experiments, Data Analysis, Manuscript Preparation. G.Sukumar-Experiments, Data Analysis, constitutive modelling. AP: Constitutive modelling, Numerical Simulation. GB: Experiments. KSK: Supervising and Guidance. VM: Overall Planning, Analysis of Data, Guidance. RAK: Supervising, Analysis of Data and Guidance.

Corresponding author

Ethics declarations

Conflict of interest

All authors declare that there are no conflicts of interest in this work.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Singh, B.B., Sukumar, G., Paman, A. et al. A Comparative Study on the Ballistic Performance and Failure Mechanisms of High-Nitrogen Steel and RHA Steel Against Tungsten Heavy Alloy Penetrators. J. dynamic behavior mater. 7, 60–80 (2021). https://doi.org/10.1007/s40870-020-00270-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40870-020-00270-8