Abstract

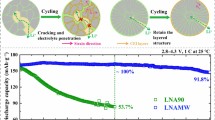

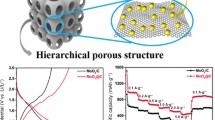

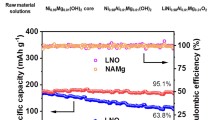

An Ostwald ripening-based route is proposed to prepare Ni-rich layered cathodes with Co-rich surface for lithium-ion batteries (LIBs). Commercially available Ni0.8Co0.1 Mn0.1(OH)2 and spray pyrolysis derived porous Co3O4 are used as mixed precursors. During the lithiation reaction process under high-temperature, the porous Co3O4 microspheres scatter primary particles and spontaneously redeposit on the surface of Ni-rich spheres according to Ostwald ripening mechanism, forming the Ni-rich materials with Co-rich outer layers. When evaluated as cathode for LIBs, the resultant material shows ability to inhibit the cation disorder, relieves the phase transition from H2 to H3 and diminishes side reactions between the electrolyte and Ni-rich cathode material. As a result, the obtained material with Co-rich outer layers exhibits much more improved cycle and rate performance than the material without Co-rich outer layers. Particularly, NCM-Co-1 (molar ratio of Ni0.8Co0.1Mn0.1(OH)2/Co3O4 is 60:1) delivers a reversible capacity of 159.2 mA h g−1 with 90.5% capacity retention after 200 cycles at 1 C. This strategy provides a general and efficient way to produce gradient substances and to address the surface problems of Ni-rich cathode materials.

摘要

本文提出了一种基于奥斯特瓦尔德熟化制备具有富钴表面的高镍正极材料的方法. 采用了商业化的Ni0.8Co0.1Mn0.1(OH)2和喷雾热解制备了多孔Co3O4作为前驱体. 在高温固相反应锂化过程中, 多孔的Co3O4会分解成颗粒. 根据奥斯特瓦尔德熟化过程, 这些颗粒与锂盐反应并自发地沉积于高镍材料的表面, 形成具有富钴表层的高镍正极材料. 作为锂离子电池正极材料时, 改性后的材料中阳离子的混排得到抑制, H2到H3的相变程度降低, 并减少了电解液和高镍正极材料之间的副反应. 因此, 具有富钴表层的高镍正极材料相比于原始材料循环和倍率性能得到很大提升. NCM-Co-1 (Ni0.8Co0.1Mn0.1(OH)2/Co3O4的摩尔比为 60:1)在1 C下循环200次放电容量仍有159.2 mA h g−1, 容量保持率为90.5%. 这一策略为制备梯度正极材料以及解决高镍正极材料的表面问题提供了一种通用而有效的方法.

Similar content being viewed by others

References

Deng Q, Lu C, Yu C. Characterizing ambient concentration of PM10 in urban environment of central south China. Indoor Built Environ, 2015, 24: 324–339

Liu G. Development of a general sustainability indicator for renewable energy systems: a review. Renew Sustain Energ Rev, 2014, 31: 611–621

Karden E, Ploumen S, Fricke B, et al. Energy storage devices for future hybrid electric vehicles. J Power Sources, 2007, 168: 2–11

Gong H, Wang MQ, Wang H. New energy vehicles in China: policies, demonstration, and progress. Mitig Adapt Strateg Glob Change, 2013, 18: 207–228

Braun PV, Cho J, Pikul JH, et al. High power rechargeable batteries. Curr Opin Solid State Mater Sci, 2012, 16: 186–198

Chen H, Hu Q, Huang Z, et al. Synthesis and electrochemical study of Zr-doped Li[Li0.2Mn0.54Ni0.13Co0.13]O2 as cathode material for Liion battery. Ceramics Int, 2016, 42: 263–269

He Z, Wang Z, Chen H, et al. Electrochemical performance of zirconium doped lithium rich layered Li1.2Mn0.54Ni0.13Co0.13O2 oxide with porous hollow structure. J Power Sources, 2015, 299: 334–341

Hu M, Pang X, Zhou Z. Recent progress in high-voltage lithium ion batteries. J Power Sources, 2013, 237: 229–242

Huang L, Wei Q, Sun R, et al. Nanowire electrodes for advanced lithium batteries. Front Energ Res, 2014, 2: 43–54

Leng J, Wang Z, Li X, et al. Accurate construction of a hierarchical nickel-cobalt oxide multishell yolk-shell structure with large and ultrafast lithium storage capability. J Mater Chem A, 2017, 5: 14996–15001

Li T, Li X, Wang Z, et al. A new design concept for preparing nickel-foam-supported metal oxide microspheres with superior electrochemical properties. J Mater Chem A, 2017, 5: 13469–13474

Liu H, Zhu G, Zhang L, et al. Controllable synthesis of spinel lithium nickel manganese oxide cathode material with enhanced electrochemical performances through a modified oxalate co-precipitation method. J Power Sources, 2015, 274: 1180–1187

Yan Z, Hu Q, Yan G, et al. Co3O4/Co nanoparticles enclosed graphitic carbon as anode material for high performance Li-ion batteries. Chem Eng J, 2017, 321: 495–501

Wang C, Wang J, Chen H, et al. An interlayer nanostructure of rGO/Sn2Fe-NRs array/rGO with high capacity for lithium ion battery anodes. Sci China Mater, 2016, 59: 927–937

Wei Q, Xiong F, Tan S, et al. Porous one-dimensional nanomaterials: design, fabrication and applications in electrochemical energy storage. Adv Mater, 2017, 29: 1602300

Yang DH, Yao ZQ, Wu D, et al. Structure-modulated crystalline covalent organic frameworks as high-rate cathodes for Li-ion batteries. J Mater Chem A, 2016, 4: 18621–18627

Zhang H, Yu X, Braun PV. Three-dimensional bicontinuous ultrafast-charge and -discharge bulk battery electrodes. Nat Nanotech, 2011, 6: 277–281

Zhang K, Hu Z, Tao Z, et al. Inorganic & organic materials for rechargeable Li batteries with multi-electron reaction. Sci China Mater, 2014, 57: 42–58

Zhou Y, Guo H, Yong Y, et al. Introducing reduced graphene oxide to improve the electrochemical performance of silicon-based materials encapsulated by carbonized polydopamine layer for lithium ion batteries. Mater Lett, 2017, 195: 164–167

Li T, Li X, Wang Z, et al. A short process for the efficient utilization of transition-metal chlorides in lithium-ion batteries: A case of Ni0.8Co0.1Mn0.1O1.1 and LiNi0.8Co0.1Mn0.1O2. J Power Sources, 2017, 342: 495–503

Liu L, Tian F, Wang X, et al. Electrochemical behavior of spherical LiNi1/3Co1/3Mn1/3O2 as cathode material for aqueous rechargeable lithium batteries. J Solid State Electrochem, 2012, 16: 491–497

Tang Z, Zheng H, Qian F, et al. Improvement of cycling and thermal stability of LiNi0.8Mn0.1Co0.1O2 cathode material by secondly treating process. Ionics, 2017, 451

Yang X, Wang X, Hu L, et al. Layered Li[Ni0.5Co0.2Mn0.3]O2-Li2 MnO3 core–shell structured cathode material with excellent stability. J Power Sources, 2013, 242: 589–596

Liu HS, Zhang ZR, Gong ZL, et al. Origin of deterioration for LiNiO2 cathode material during storage in air. Electrochem Solid-State Lett, 2004, 7: A190

Liu H, Yang Y, Zhang J. Investigation and improvement on the storage property of LiNi0.8Co0.2O2 as a cathode material for lithiumion batteries. J Power Sources, 2006, 162: 644–650

Wu F, Tian J, Su Y, et al. Effect of Ni2+ content on lithium/nickel disorder for Ni-rich cathode materials. ACS Appl Mater Interfaces, 2015, 7: 7702–7708

Zheng J, Kan WH, Manthiram A. Role of Mn content on the electrochemical properties of nickel-rich layered LiNi0.8–xCo0.1Mn0.1+xO2 (0.0 = x = 0.08) cathodes for lithium-ion batteries. ACS Appl Mater Interfaces, 2015, 7: 6926–6934

Sun HH, Choi W, Lee JK, et al. Control of electrochemical properties of nickel-rich layered cathode materials for lithium ion batteries by variation of the manganese to cobalt ratio. J Power Sources, 2015, 275: 877–883

Yoon WS, Chung KY, McBreen J, et al. A comparative study on structural changes of LiCo1/3Ni1/3Mn1/3O2 and LiNi0.8Co0.15Al0.05O2 during first charge using in situ XRD. Electrochem Commun, 2006, 8: 1257–1262

He P, Yu H, Li D, et al. Layered lithium transition metal oxide cathodes towards high energy lithium-ion batteries. J Mater Chem, 2012, 22: 3680–3695

Noh HJ, Youn S, Yoon CS, et al. Comparison of the structural and electrochemical properties of layered Li[NixCoyMnz]O2 (x = 1/3, 0.5, 0.6, 0.7, 0.8 and 0.85) cathode material for lithium-ion batteries. J Power Sources, 2013, 233: 121–130

Ohzuku T. Electrochemistry and structural chemistry of LiNiO2 (R3m) for 4 volt secondary lithium cells. J Electrochem Soc, 1993, 140: 1862–1870

Dahn J. Structure and electrochemistry of Li1±yNiO2 and a new Li2NiO2 phase with the Ni(OH)2 structure. Solid State Ion, 1990, 44: 87–97

Cho Y, Lee S, Lee Y, et al. Spinel-layered core-shell cathode materials for li-ion batteries. Adv Energ Mater, 2011, 1: 821–828

Hou P, Wang X, Song D, et al. Design, synthesis, and performances of double-shelled LiNi0.5Co0.2Mn0.3O2 as cathode for long-life and safe Li-ion battery. J Power Sources, 2014, 265: 174–181

Sun YK, Myung ST, Shin HS, et al. Novel core-shell-Structured Li [(Ni0.8Co0.2)0.8(Ni0.5Mn0.5)0.2]O2 via coprecipitation as positive electrode material for lithium secondary batteries. J Phys Chem B, 2006, 110: 6810–6815

Liu H. A comparative study of LiNi0.8Co0.2O2 cathode materials modified by lattice-doping and surface-coating. Solid State Ion, 2004, 166: 317–325

Wang D, Li X, Wang Z, et al. Role of zirconium dopant on the structure and high voltage electrochemical performances of LiNi0.5Co0.2Mn0.3O2 cathode materials for lithium ion batteries. Electrochim Acta, 2015, 188: 48–56

Chen H, Dawson JA, Harding JH. Effects of cationic substitution on structural defects in layered cathode materials LiNiO2. J Mater Chem A, 2014, 2: 7988–7996

Park MS, Lee JW, Choi W, et al. On the surface modifications of high-voltage oxide cathodes for lithium-ion batteries: new insight and significant safety improvement. J Mater Chem, 2010, 20: 7208–7213

Li L, Chen Z, Zhang Q, et al. A hydrolysis-hydrothermal route for the synthesis of ultrathin LiAlO2-inlaid LiNi0.5Co0.2Mn0.3O2 as a high-performance cathode material for lithium ion batteries. J Mater Chem A, 2015, 3: 894–904

Zhang B, Dong P, Tong H, et al. Enhanced electrochemical performance of LiNi0.8Co0.1Mn0.1O2 with lithium-reactive Li3VO4 coating. J Alloys Compd, 2017, 706: 198–204

Lin H, Zheng J, Yang Y. The effects of quenching treatment and AlF3 coating on LiNi0.5Mn0.5O2 cathode materials for lithium-ion battery. Mater Chem Phys, 2009, 119: 519–523

Wang J, Liu Z, Yan G, et al. Improving the electrochemical performance of lithium vanadium fluorophosphate cathode material: Focus on interfacial stability. J Power Sources, 2016, 329: 553–557

Yang J, Xia Y. Suppressing the phase transition of the layered Nirich oxide cathode during high-voltage cycling by introducing lowcontent Li2MnO3. ACS Appl Mater Interfaces, 2015, 8: 1297–1308

Liao JY, Manthiram A. Surface-modified concentration-gradient Ni-rich layered oxide cathodes for high-energy lithium-ion batteries. J Power Sources, 2015, 282: 429–436

Xiang J, Chang C, Yuan L, et al. A simple and effective strategy to synthesize Al2O3-coated LiNi0.8Co0.2O2 cathode materials for lithium ion battery. Electrochem Commun, 2008, 10: 1360–1363

Cho J, Kim TJ, Kim YJ, et al. High-performance ZrO2-coated Li-NiO2 cathode material. Electrochem Solid-State Lett, 2001, 4: A159

Kweon HJ, Kim SJ, Park DG. Modification of LixNi1-yCoyO2 by applying a surface coating of MgO. J Power Sources, 2000, 88: 255–261

Yoon S, Jung KN, Yeon SH, et al. Electrochemical properties of LiNi0.8Co0.15Al0.05O2-graphene composite as cathode materials for lithium-ion batteries. J Electroanal Chem, 2012, 683: 88–93

Ying J, Wan C, Jiang C. Surface treatment of LiNi0.8Co0.2O2 cathode material for lithium secondary batteries. J Power Sources, 2001, 102: 162–166

Song B, Li W, Oh SM, et al. Long-life nickel-rich layered oxide cathodes with a uniform Li2ZrO3 surface coating for lithium-ion batteries. ACS Appl Mater Interfaces, 2017, 9: 9718–9725

Wang D, Li X, Wang W, et al. Improvement of high voltage electrochemical performance of LiNi0.5Co0.2Mn0.3O2 cathode materials via Li2ZrO3 coating. Ceramics Int, 2015, 41: 6663–6667

Li L, Chen Z, Song L, et al. Characterization and electrochemical performance of lithium-active titanium dioxide inlaid LiNi0.5Co0.2Mn0.3O2 material prepared by lithium residue-assisted method. J Alloys Compd, 2015, 638: 77–82

Xiong X, Wang Z, Guo H, et al. Enhanced electrochemical properties of lithium-reactive V2O5 coated on the LiNi0.8Co0.1Mn0.1O2 cathode material for lithium ion batteries at 60°C. J Mater Chem A, 2013, 1: 1284–1288

Li L, Yao Q, Chen Z, et al. Effects of lithium-active manganese trioxide coating on the structural and electrochemical characteristics of LiNi0.5Co0.2Mn0.3O2 as cathode materials for lithium ion battery. J Alloys Compd, 2015, 650: 684–691

Song D, Hou P, Wang X, et al. Understanding the origin of enhanced performances in core–shell and concentration-gradient layered oxide cathode materials. ACS Appl Mater Interfaces, 2015, 7: 12864–12872

Sun YK, Kim DH, Yoon CS, et al. A novel cathode material with a concentration-gradient for high-energy and safe lithium-ion batteries. Adv Funct Mater, 2010, 20: 485–491

Sun YK, Myung ST, Park BC, et al. High-energy cathode material for long-life and safe lithium batteries. Nat Mater, 2009, 8: 320–324

Wen W, Chen S, Fu Y, et al. A core-shell structure spinel cathode material with a concentration-gradient shell for high performance lithium-ion batteries. J Power Sources, 2015, 274: 219–228

Giffard P V. Ostwald Ripening. 2011

Li T, Li X, Wang Z, et al. Robust synthesis of hierarchical mesoporous hybrid NiO-MnCo2O4 microspheres and their application in Lithium-ion batteries. Electrochim Acta, 2016, 191: 392–400

Li Y, Li X, Wang Z, et al. Distinct impact of cobalt salt type on the morphology, microstructure, and electrochemical properties of Co3O4 synthesized by ultrasonic spray pyrolysis. J Alloys Compd, 2017, 696: 836–843

Li T, Li X, Wang Z, et al. Synthesis of nanoparticles-assembled Co3O4 microspheres as anodes for Li-ion batteries by spray pyrolysis of CoCl2 solution. Electrochim Acta, 2016, 209: 456–463

Kong JZ, Zhou F, Wang CB, et al. Effects of Li source and calcination temperature on the electrochemical properties of LiNi0.5 Co0.2Mn0.3O2 lithium-ion cathode materials. J Alloys Compd, 2013, 554: 221–226

Thackeray MM, Kang SH, Johnson CS, et al. Comments on the structural complexity of lithium-rich Li1+xM1-xO2 electrodes (M=Mn, Ni, Co) for lithium batteries. Electrochem Commun, 2006, 8: 1531–1538

Lin F, Markus IM, Nordlund D, et al. Surface reconstruction and chemical evolution of stoichiometric layered cathode materials for lithium-ion batteries. Nat Commun, 2014, 5: 3529

Fu C, Li G, Luo D, et al. Nickel-rich layered microspheres cathodes: lithium/nickel disordering and electrochemical performance. ACS Appl Mater Interfaces, 2014, 6: 15822–15831

Acknowledgements

This work has been carried out with the financial support of the National Basic Research Program of China (2014CB643406), the National Natural Science Foundation of China (51674296, 51574287, 51704332), the National Postdoctoral Program for Innovative Talents (BX201700290), and the Fundamental Research Funds for the Central Universities of Central South University (2017zzts127).

Author information

Authors and Affiliations

Corresponding author

Additional information

Yan Li is now a Ph.D. student at School of Metallurgy and Environment, Central South University. She received her BSc degree (2012) and MSc degree (2015) in metallurgical engineering from Central South University (China). Her research interests include synthesis and modification of electrode materials for lithium ion battery, especially the Ni-rich cathode materials.

Jiexi Wang received his BSc degree (2010) in Metallurgical Engineering and PhD degree (2015) in Physical Chemistry of Metallurgy from Central South University (China). After working as a postdoctoral fellow at the Hong Kong University of Science & Technology and The University of Hong Kong, he started his independent research career as an Associate Professor at Central South University (China) in 2017. His research focuses on the green synthesis and application of nonferrous-based materials and composites for energy storage, such as high-power/high-energy lithium/sodium ion batteries, and supercapacitors. He has published about 80 SCI papers with ∼1600 citations (h-index=26).

Rights and permissions

About this article

Cite this article

Li, Y., Li, X., Wang, Z. et al. An Ostwald ripening route towards Ni-rich layered cathode material with cobalt-rich surface for lithium ion battery. Sci. China Mater. 61, 719–727 (2018). https://doi.org/10.1007/s40843-017-9162-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40843-017-9162-3