Abstract

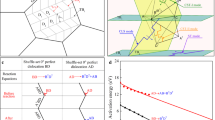

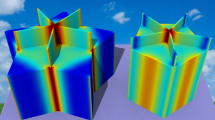

Nanotwinned diamond (nt-diamond), which demonstrates unprecedented hardness and stability, is synthesized through the martensitic transformation of onion carbons at high pressure and high temperature (HPHT). Its hardness and stability increase with decreasing twin thickness at the nanoscale. However, the formation mechanism of nanotwinning substructures within diamond nanograins is not well established. Here, we characterize the nanotwins in nt-diamonds synthesized under different HPHT conditions. Our observation shows that the nanotwin thickness reaches a minimum at ~ 20 GPa, below which phase-transformation twins and deformation twins coexist. Then, we use the density-functional-based tight-binding method and kinetic dislocation theory to investigate the subsequent plastic deformation mechanism in these pre-existing phase-transformation diamond twins. Our results suggest that pressure-dependent conversion of the plastic deformation mechanism occurs at a critical synthetic pressure for nt-diamond, which explains the existence of the minimum twin thickness. Our findings provide guidance on optimizing the synthetic conditions for fabricating nt-diamond with higher hardness and stability.

摘要

在高温高压条件下以洋葱碳为原料合成的纳米孪晶金刚石具有前所未有的硬度和稳定性, 且二者随纳米孪晶厚度的减小而提高. 目前为止, 在金刚石纳米晶中纳米孪晶的形成机制尚不明确. 本研究通过分析在不同条件下合成的纳米孪晶金刚石块材中的孪晶厚度, 发现在合成压力约为20 GPa时孪晶厚度达到一个极小值(~5 nm). TEM结果表明在合成压力低于20 GPa时, 纳米孪晶金刚石中同时存在因马氏体相变而形成的相变孪晶和塑性形变所导致的形变孪晶. 针对马氏体相变后形成的相变孪晶内部塑性变形, 基于密度泛函理论的紧束缚方法和位错运动学理论的分析表明: 纳米孪晶金刚石的塑性变形存在一个依赖于压力的机制转变, 而机制转变的临界压力能够解释孪晶厚度随压力变化时出现的极小值. 本研究对通过优化合成条件制备出更高硬度和稳定性的纳米孪晶金刚石具有指导意义.

Similar content being viewed by others

References

Yan C, Mao H, Li W, et al. Ultrahard diamond single crystals from chemical vapor deposition. Phys Status Solidi A, 2004, 201: R25–R27

Sumiya H, Harano K. Distinctive mechanical properties of nanopolycrystalline diamond synthesized by direct conversion sintering under HPHT. Diamond Related Mater, 2012, 24: 44–48

Irifune T, Kurio A, Sakamoto S, et al. Materials: ultrahard polycrystalline diamond from graphite. Nature, 2003, 421: 599–600

Sumiya H, Irifune T. Hardness and deformationmicrostructures of nano-polycrystalline diamonds synthesized from various carbons under high pressure and high temperature. J Mater Res, 2007, 22: 2345–2351

Hall EO. The deformation and ageing of mild steel: III discussion of results. Proc Phys Soc B, 1951, 64: 747–753

Petch NJ. The cleavage strength of polycrystals. J Iron Steel Ins, 1953, 174: 25–28

Veprek S. Recent search for new superhard materials: go nano! J Vacuum Sci Tech A-Vacuum Surfaces Films, 2013, 31: 050822

Lu L, Chen X, Huang X, et al. Revealing the maximum strength in nanotwinned copper. Science, 2009, 323: 607–610

Tian Y, Xu B, Yu D, et al. Ultrahard nanotwinned cubic boron nitride. Nature, 2013, 493: 385–388

Huang Q, Yu D, Xu B, et al. Nanotwinned diamond with unprecedented hardness and stability. Nature, 2014, 510: 250–253

Gao F, He J, Wu E, et al. Hardness of covalent crystals. Phys Rev Lett, 2003, 91: 015502

Guo X, Li L, Liu Z, et al. Hardness of covalent compounds: roles of metallic component and d valence electrons. J Appl Phys, 2008, 104: 023503

Tian Y, Xu B, Zhao Z. Microscopic theory of hardness and design of novel superhard crystals. Int J Refractory Met Hard Mater, 2012, 33: 93–106

Xu B, Tian Y. Ultrahardness: measurement and enhancement. J Phys Chem C, 2015, 119: 5633–5638

Xu B, Tian Y. Superhard materials: recent research progress and prospects. Sci China Mater, 2015, 58: 132–142

Zhao Z, Xu B, Tian Y. Recent advances in superhard materials. Annu Rev Mater Res, 2016, 46: 383–406

Brookes CA. Plastic deformation and anisotropy in the hardness of diamond. Nature, 1970, 228: 660–661

Humble P, Hannink RHJ. Plastic deformation of diamond at room temperature. Nature, 1978, 273: 37–39

Mao HK, Bell PM. High-pressure physics: sustained static generation of 1.36 to 1.72 megabars. Science, 1978, 200: 1145–1147

Weidner DJ, Wang Y, Vaughan MT. Strength of diamond. Science, 1994, 266: 419–422

Blumenau AT, Heggie MI, Fall CJ, et al. Dislocations in diamond: core structures and energies. Phys Rev B, 2002, 65: 205205

Mussi A, Eyidi D, Shiryaev A, et al. TEM observations of dislocations in plastically deformed diamond. Phys Status Solidi A, 2013, 210: 191–194

Pizzagalli L, Demenet JL, Rabier J. Theoretical study of pressure effect on the dislocation core properties in semiconductors. Phys Rev B, 2009, 79: 045203

Saka H, Yamamoto K, Arai S, et al. In-situ TEM observation of transformation of dislocations fromshuffle to glide sets in Si under supersaturation of interstitials. Philos Mag, 2006, 86: 4841–4850

Li Z, Picu RC. Shuffle-glide dislocation transformation in Si. J Appl Phys, 2013, 113: 083519–083519

Gaillou E, Post JE, Bassim ND, et al. Spectroscopic and microscopic characterizations of color lamellae in natural pink diamonds. Diamond Related Mater, 2010, 19: 1207–1220

Blumenau AT, Jones R, Frauenheim T, et al. Dislocations in diamond: dissociation into partials and their glide motion. Phys Rev B, 2003, 68: 014115

Duesbery MS. Dislocationmotion in silicon: the shuffle-glide controversy. Philos Mag Lett, 1996, 74: 253–258

Yacoot A, Moore M, Machado WG. Twinning in natural diamond. I. Contact twins. J Appl Crystallogr, 1998, 31: 767–776

Machado WG, Moore M, Yacoot A. Twinning in natural diamond. II. Interpenetrant cubes. J Appl Crystallogr, 1998, 31: 777–782

Hidetaka S, Hideki I. Atomic structure of fivefold twin center in diamond film. Diam Relat Mater, 2005, 14: 109–112

Delclos S, Dorignac D, Phillipp F, et al. Ultra-high resolution electron microscopy investigation of growth defects in CVD diamond films: twin interactions and fivefold twin centres. Diamond Related Mater, 2000, 9: 346–350

Tomlinson EL, Howell D, Jones AP, et al. Characteristics of HPHT diamond grown at sub-lithosphere conditions (10–20GPa). Diamond Related Mater, 2011, 20: 11–17

Kulnitskiy B, Perezhogin I, Dubitsky G, et al. Polytypes and twins in the diamond–lonsdaleite system formed by high-pressure and high-temperature treatment of graphite. Acta Crystallogr B Struct Sci Cryst Eng Mater, 2013, 69: 474–479

Tanigaki K, Ogi H, Sumiya H, et al. Observation of higher stiffness in nanopolycrystal diamond than monocrystal diamond. Nat Commun, 2013, 4: 2343

Britun VF, Oleynik GS, Semenenko NP. Deformation processes during high-pressure sintering of the diamond powders produced by catalytic synthesis. J Mater Sci, 1992, 27: 4472–4476

Walmsley JC, Lang AR. Transmission electron microscopic observations of deformation and microtwinning in a synthetic diamond compact. J Mater Sci Lett, 1983, 2: 785–788

Titkov SV, Krivovichev SV, Organova NI. Plastic deformation of natural diamonds by twinning: evidence from X-ray diffraction studies. Mineral Mag, 2012, 76: 143–149

Howell D, Piazolo S, Dobson DP, et al. Quantitative characterization of plastic deformation of single diamond crystals: a high pressure high temperature (HPHT) experimental deformation study combined with electron backscatter diffraction (EBSD). Diamond Related Mater, 2012, 30: 20–30

Churchman AT, Geach GA, Winton J. Deformation twinning in materials of the A4 (diamond) crystal structure. Proc R Soc Lond A, 1956, 238: 194–205

Dong H, Wen B, Melnik R. Relative importance of grain boundaries and size effects in thermal conductivity of nanocrystalline materials. Sci Rep, 2014, 4: 7037

Koike J, Parkin DM, Mitchell TE. Displacement threshold energy for type IIa diamond. Appl Phys Lett, 1992, 60: 1450–1452

Wang L, Zheng K, Zhang Z, et al. Direct atomic-scale imaging about the mechanisms of ultralarge bent straining in Si nanowires. Nano Lett, 2011, 11: 2382–2385

Shames AI, Mogilyansky D, Panich AM, et al. XRD, NMR, and EPR study of polycrystalline micro-and nano-diamonds prepared by a shock wave compression method. Phys Status Solidi A, 2015, 212: 2400–2409

Frondel C, Marvin UB. Lonsdaleite, a hexagonal polymorph of diamond. Nature, 1967, 214: 587–589

Nemeth P, Garvies LAJ, Aoki T, et al. Lonsdaleite is faulted and twinned cubic diamond and does not exist as a discrete material. Nat Commun, 2014, 5: 5447

Zhu YT, Liao XZ, Wu XL. Deformation twinning in nanocrystalline materials. Prog Mater Sci, 2012, 57: 1–62

Li X, Wei Y, Lu L, et al. Dislocation nucleation governed softening andmaximum strength in nano-twinnedmetals. Nature, 2010, 464: 877–880

Thomson RM, Balluffi RW. Kinetic theory of dislocation climb. I. Generalmodels for edge and screw dislocations. J Appl Phys, 1962, 33: 803–816

Porezag D, Frauenheim T, Köhler T, et al. Construction of tight-binding-like potentials on the basis of density-functional theory: application to carbon. Phys Rev B, 1995, 51: 12947–12957

Wheeler JM, Raghavan R, Wehrs J, et al. Approaching the limits of strength: measuring the uniaxial compressive strength of diamond at small scales. Nano Lett, 2016, 16: 812–816

Acknowledgments

This work was supported by the National Natural Science Foundation of China (51421091, 51332005, 51572225, 51272227, 51172197, 51525205 and 51672239) and the US National Science Foundation (EAR-1361276).

Author information

Authors and Affiliations

Corresponding author

Additional information

These authors contributed equally to this work.

Wentao Hu is a senior experimentalist at theCollege ofMaterials Science and Engineering, YanshanUniversity. He received his PhD degree fromYanshan University in 2013. His research interests include superhardmaterials and transmission electron microscopy.

Quan Huang works at HPSTAR as a postdoctoral fellow. He received his PhD degree fromYanshan University in 2015. His research interests include the design and synthesis of novelmetastablematerials under high pressure and high temperature.

Bin Wen is a professor at the College of Materials Science and Engineering, Yanshan University. He received his PhD degree from Dalian University of Technology in 2006. His research interests include theoretical calculation and molecular dynamics simulation.

Yongjun Tian is a professor at the College ofMaterials Science and Engineering, Yanshan University. He received his PhD degree from the Institute of Physics, Chinese Academy of Sciences, in 1994, and worked as a postdoctoral fellow at the Universität Jena supported by Humboldt Research Fellowships from1996 to 1998. His research interests include the design and synthesis of novel metastable materials.

Electronic supplementary material

Rights and permissions

About this article

Cite this article

Hu, W., Wen, B., Huang, Q. et al. Role of plastic deformation in tailoring ultrafine microstructure in nanotwinned diamond for enhanced hardness. Sci. China Mater. 60, 178–185 (2017). https://doi.org/10.1007/s40843-016-5161-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40843-016-5161-2