Abstract

Confronted with the growing ecological awareness of the consumer market, the construction industry has been seeking strategies to promote a higher insertion of waste in the production chain while contributing to the technological improvement of processes and products, as well as mitigation of social and environmental impacts and, at the same time, conferring intangible value to the product. In this sense, the present work describes how iron ore tailings (IOT) can be used in the production of cement-based (hydraulic) tiles. The physical, chemical, and mineralogical characterizations carried out demonstrated that the IOT beneficiation (segregation) process resulted in a high-quality siliceous aggregate and a Fe-rich clay. The latter can be used as a pigment, whose pigmentation and cementing potentials improve with calcination and grinding. Compared to hydraulic tiles prepared with conventional materials, those obtained with the IOT-based materials displayed a pleasing appearance and the expected physical–mechanical performance.

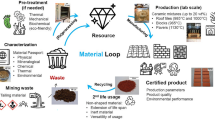

Graphical Abstract

Similar content being viewed by others

References

IPEA (2012) Diagnosis of solid waste from the mining activity of non-energy substances (technical report, in Portuguese). Instituto de Pesquisa Econômica Aplicada - IPEA, Brasília

FEAM (2016) Dam inventory of the State of Minas Gerais—2015 (technical report, in Portuguese). Fundação Estadual do Meio Ambiente de Minas Gerais - FEAM, Belo Horizonte

Marta-Almeida M, Mendes R, Amorim FN, Cirano M, Dias JM (2016) Fundão Dam collapse: oceanic dispersion of River Doce after the greatest Brazilian environmental accident. Mar Pollut Bull 112:359–364. https://doi.org/10.1016/j.marpolbul.2016.07.039

Flávio-F C, Kamino LHY, Tobias-Junior R, Campos IC, Felipe-F C, Silvino G, Castro KJSX, Mauro ML, Rodrigues NUA, Miranda MPS, Pinto CEF (2017) Fundão tailings dam failures: the environment tragedy of the largest technological disaster of Brazilian mining in global context. Perspect Ecol Conserv 15:145–151. https://doi.org/10.1016/j.pecon.2017.06.002

Cionek VM, Alves GHZ, Tófoli RM, Rodrigues-Filho JL, Dias RM (2019) Brazil in the mud again: lessons not learned from Mariana dam collapse. Biodivers Conserv 28:1935–1938. https://doi.org/10.1007/s10531-019-01762-3

Thompson F, Oliveira BC, Cordeiro MC, Masi BP, Rangel TP, Paz P, Freitas T, Lopes G, Silva BS, Cabral AS, Soares M, Lacerda D, Vergilio CS, Lopes-Ferreira M, Lima C, Thompson C, Rezende CE (2020) Severe impacts of the Brumadinho dam failure (Minas Gerais, Brazil) on the water quality of the Paraopeba River. Sci Total Environ 705:135914. https://doi.org/10.1016/j.scitotenv.2019.135914

Yellishetty M, Karpe V, Reddy EH, Subhash KN, Ranjith PG (2008) Reuse of iron ore mineral wastes in civil engineering constructions: a case study. Resour Conserv Recycl 52:1283–1289. https://doi.org/10.1016/j.resconrec.2008.07.007

Shettima AU, Hussin MW, Ahmad Y, Mirza J (2016) Evaluation of iron ore tailings as replacement for fine aggregate in concrete. Constr Build Mater 120:72–79. https://doi.org/10.1016/j.conbuildmat.2016.05.095

Oliveira JR, Barros JB, Peixoto RAF (2012) Separation process of iron ore contained in waste from the extraction and processing of iron ore. Patent BR 10 2012 008758 8 A2 (in Portuguese)

Andrade LCR (2014) Characterization of iron mining tailings, in natura and segregated, for application as civil construction material (Doctoral thesis, in Portuguese). Universidade Federal de Viçosa - UFV, Viçosa

Fontes WC, Franco de Carvalho JM, Andrade LCR, Segadães AM, Peixoto RAF (2019) Assessment of the use potential of iron ore tailings in the manufacture of ceramic tiles: from tailings-dams to “brown porcelain.” Constr Build Mater 206:111–121. https://doi.org/10.1016/j.conbuildmat.2019.02.052

ABNT (2013) NBR 9457: Hydraulic tiles for paving—specifications and test methods (technical standard, in Portuguese). Associação Brasileira de Normas Técnicas - ABNT, Rio de Janeiro

Baeck M (2006) Cement tiles: an exploration. J Tiles Archit Ceram Soc 12:20–30

Soufan A (2015) An overview of cement tile manufacturing and importation in Syria and Lebanon: Damascus-Beirut, 1880s–1940s. Archit Beyond Eur J. https://doi.org/10.4000/abe.2897

Kurup P, Gettu R (2019) Value addition to Athangudi tiles. In: Evangeline S, Rajkumar MR, Parambath SG (eds) Recent advances in materials, mechanics and management (Proc. IMMM 2017, Trivandrum, Kerala). Taylor and Francis, London, pp 372–378. https://doi.org/10.1201/9781351227544-62

Fontes WC, Fontes GG, Costa ECP, Mendes JC, Silva GJB, Peixoto RAF (2018) Iron ore tailings in the production of cement tiles: a value analysis on building sustainability. Ambient Construído 18:395–412. https://doi.org/10.1590/s1678-86212018000400312

Lee H-S, Lee J-Y, Yu M-Y (2003) Influence of iron oxide pigments on the properties of concrete interlocking blocks. Cement Concrete Res 33:1889–1896. https://doi.org/10.1016/S0008-8846(03)00209-6

Calbo J, Sorlí S, Llusar M, Tena MA, Monrós G (2004) Minimisation of toxicity in nickel ferrite black pigment. Br Ceram Trans 103:3–9. https://doi.org/10.1179/096797804225012729

Pereira OC, Bernardin AM (2012) Ceramic colorant from untreated iron ore residue. J Hazard Mater 233–234:103–111. https://doi.org/10.1016/j.jhazmat.2012.06.057

Cota FP, Melo CCD, Panzera TH, Araújo AG, Borges PHR, Scarpa F (2015) Mechanical properties and ASR evaluation of concrete tiles with waste glass aggregate. Sustain Cities Soc 16:49–56. https://doi.org/10.1016/j.scs.2015.02.005

Mármol I, Ballester P, Cerro S, Monrós G, Morales J, Sánchez L (2010) Use of granite sludge wastes for the production of coloured cement-based mortars. Cem Concr Compos 32:617–622. https://doi.org/10.1016/j.cemconcomp.2010.06.003

Marques JS (2012) Study of the production process of hydraulic tiles aiming at the incorporation of solid waste (Master’s dissertation, in Portuguese). Universidade Estadual de Londrina - UEL, Londrina

Dhawan R, Bisht BMS, Kumar R, Kumari S, Dhawan SK (2019) Recycling of plastic waste into tiles with reduced flammability and improved tensile strength. Process Saf Environ Prot 124:299–307. https://doi.org/10.1016/j.psep.2019.02.018

ABNT (2004) NBR 10007: sampling of solid waste (technical standard, in Portuguese). Associação Brasileira de Normas Técnicas - ABNT, Rio de Janeiro

ABNT (1991) NBR 5733: high early strength Portland cement—specification (technical standard, in Portuguese). Associação Brasileira de Normas Técnicas - ABNT, Rio de Janeiro

ABNT (2009) NBR NM 52: fine aggregates—determination of the bulk specific gravity and apparent specific gravity (technical standard, in Portuguese). Associação Brasileira de Normas Técnicas - ABNT, Rio de Janeiro

ABNT (2006) NBR NM 45: aggregates—determination of the unit weight and air-void content (technical standard, in Portuguese). Associação Brasileira de Normas Técnicas - ABNT, Rio de Janeiro

ABNT (2011) NBR 9939: coarse aggregate—determination of total moisture content—test method (technical standard, in Portuguese). Associação Brasileira de Normas Técnicas - ABNT, Rio de Janeiro

ABNT (2005) NBR 9778: hardened mortar and concrete—determination of absorption, voids and specific gravity (technical standard, in Portuguese). Associação Brasileira de Normas Técnicas - ABNT, Rio de Janeiro

ABNT (1997) NBR 13818: ceramic tiles—specification and test methods (technical standard, in Portuguese). Associação Brasileira de Normas Técnicas - ABNT, Rio de Janeiro

Galvão JLB, Andrade HD, Brigolini GJ, Peixoto RAF, Mendes JC (2018) Reuse of iron ore tailings from tailings dams as pigment for sustainable paints. J Clean Prod 200:412–422. https://doi.org/10.1016/j.jclepro.2018.07.313

Color Converter, ColorMine.org. http://colormine.org/color-converter. Accessed 3 Aug 2018

Vandenberghe RE, Barrero CA, da Costa GM, Van San E, De Grave E (2000) Mössbauer characterization of iron oxides and (oxy)hydroxides: the present state of the art. Hyperfine Interact 126:247–259. https://doi.org/10.1023/A:1012603603203

Cavalcante PMT, Dondi M, Guarini G, Raimondo M, Baldi G (2009) Colour performance of ceramic nano-pigments. Dyes Pigm 80:226–232. https://doi.org/10.1016/j.dyepig.2008.07.004

Silva AP, Segadães AM, Devezas TC (2006) Particle distribution design in a self-flow alumina refractory castable without cement. Adv Sci Technol 45:2260–2265. https://doi.org/10.4028/www.scientific.net/AST.45.2260

Acknowledgements

Authors gratefully acknowledge the general financial support provided by the Brazilian research funding agencies FAPEMIG, CNPq, CAPES, UFOP, UFV, and Fundação Gorceix. Authors are also grateful for the opportunity to use the infrastructure at the Research Group on Solid Wastes—RECICLOS—CNPq, the Nanolab Electron Microscopy Laboratory at the Redemat, UFOP, and the Department of Materials and Ceramic Engineering (CICECO) at the University of Aveiro, Portugal.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

The contributing editor for this article was João António Labrincha Batista.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Fontes, W.C., Franco de Carvalho, J.M., Defaveri, K. et al. Hydraulic Tiles Produced with Fine Aggregates and Pigments Reclaimed from Iron Ore Tailings. J. Sustain. Metall. 7, 151–165 (2021). https://doi.org/10.1007/s40831-020-00329-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40831-020-00329-9