Abstract

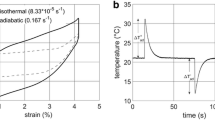

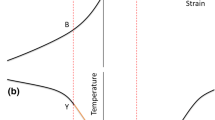

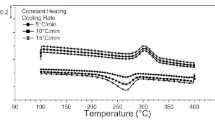

One of the most important parameters of superelastic shape memory alloys to be used in elastocaloric cooling and heating processes is their specific latent heat. Usually, the latent heat of a material is determined by differential scanning calorimetry (DSC) where the material phase transformation is induced thermally under zero stress. During elastocaloric processes however, the latent heat becomes accessible by stress-induced transformation under tensile or compression loading and unloading of the sample. In recent elastocaloric experiments, we observed drastic differences between latent heat values determined in DSC experiments and the ΔT values observed in nearly adiabatic elastocaloric cycles, which reflect the latent heat; in fact, the DSC experiments predicted rather pessimistic values and thus poor cooling performance. Based on these observations we developed and tested a novel experimental approach to determine the latent heat of superelastic materials directly during the elastocaloric process. By comparing or combining direct Joule heating with the strain based process we are able to accurately determine the latent heat for both tensile loading and unloading for any elastocaloric heating or cooling process. Furthermore, the influence of applied mechanical parameters as well as material conditioning on the latent heat can be observed in the elastocaloric experiment.

Similar content being viewed by others

Change history

21 January 2020

The original article listed the manuscript authors in the following order: Nicolas Michaelis, Andreas Schütze, Felix Welsch, Susanne-Marie Kirsch, Stefan Seelecke

References

El Dib M, Gorbet R, Kubica E, Gao X, Browne AL, Johnson NL (2011) Adaptive SMA actuator priming using resistance feedback. Smart Mater Struct 20:115018

Fasching A, Norwich D, Geiser T, Paul GW (2011) An evaluation of a NiTiCo alloy and its suitability for medical device applications. J Mater Eng Perform 20:641–645

Qian S, Geng Y, Wang Y, Ling J (2016) A review of elastocaloric cooling: materials, cycles and system integrations [Une synthèse du refroidissement élastocalorique : Matériaux, intégrations de cycles et de système]. Int J Refrig 64:1–19

Tušek J, Engelbrecht K, Eriksen D, Dall’Olio S, Tušek J, Pryds N (2016) A regenerative elastocaloric heat pump. Nat Energy 1:16134

Takeuchi I, Sandeman K (2015) Solid-state cooling with caloric materials. Phys Today 68:48–54

Fähler S, Rößler UK, Kastner O, Eckert J, Eggeler G, Emmerich H, Entel P, Müller S, Quandt E, Albe K (2012) Caloric effects in ferroic materials: new concepts for cooling. Adv Eng Mater 14:10–19

Schmidt M, Schütze A, Seelecke S (2013) The potential of NiTi-based solid state cooling processes. Deutsche Kälte- und Klimatagung, Hannover, pp 1–7

Wieczorek A, Frenzel J, Schmidt M, Maaß B, Seelecke S, Schütze A, Eggeler G (2017) Optimizing Ni–Ti-based shape memory alloys for ferroic cooling. Funct Mater Lett 10:1740001

Kirsch S-M, Welsch F, Michaelis N, Schmidt M, Wieczorek A, Frenzel J, Eggeler G, Schütze A, Seelecke S (2018) NiTi-based elastocaloric cooling on the macroscale - from basic concepts to realization. Energy Technol 6:1567–1587

Aprea C, Greco A, Angelo M, Masselli C (2018) Solid-state refrigeration: a comparison of the energy performances of caloric materials operating in an active caloric regenerator. Energy 165:439–455

Kitanovski A, Plaznik U, Tomc U, Poredoš A (2015) Present and future caloric refrigeration and heat-pump technologies. Int J Refrig 57:288–298

Moya X, Kar-Narayan S, Mathur ND (2014) Caloric materials near ferroic phase transitions. Nat Mater 13:439–450

Pieczyska EA, Gadaj SP, Nowacki WK, Tobushi H (2006) Phase-transformation fronts evolution for stress- and strain-controlled tension tests in TiNi shape memory alloy. Exp Mech 46:531–542

Ossmer H, Chluba C, Kauffmann-Weiss S, Quandt E, Kohl M (2016) TiNi-based films for elastocaloric microcooling—fatigue life and device performance. APL Mater 4:064102

Qian S, Geng Y, Wang Y, Muehlbauer J, Ling J, Hwang Y, Radermacher R, Takeuchi I (2016) Design of a hydraulically driven compressive elastocaloric cooling system. Sci Technol Built Environ 22:500–506

Kirsch S-M, Schmidt M, Welsch F, Michaelis N, Schütze A, Seelecke S (2017) Development of a shape memory based air conditioning system. In: 59th Ilmenau scientific colloquium, vol 59, pp 11–15

Welsch F, Kirsch S-M, Michaelis N, Schmidt M, Schütze A, Seelecke S (2018) Continuously operating elastocaloric cooling device based on shape memory alloys: modeling. In: 8th International conference on caloric cooling (Thermag VIII). Proceedings: Darmstadt, Germany, 16–20 September 2018, pp 244–249

Kirsch S-M, Welsch F, Michaelis N, Schmidt M, Schütze A, Seelecke S (2018) Continuously operating elastocaloric cooling device based on shape memory alloys: development and realization. . In: 8th International conference on caloric cooling (Thermag VIII). Proceedings: Darmstadt, Germany, 16–20 September 2018, pp 238–243

Michaelis N, Welsch F, Kirsch S-M, Schmidt M, Seelecke S, Schütze A (2019) Experimental parameter identification for elastocaloric air cooling. Int J Refrig 100:167–174

Shaw JA, Churchill CB, Iadicola MA (2008) Tips and tricks for characterizing shape memory alloy wire: Part 1—differential scanning calorimetry and basic phenomena. Exp Tech 32:55–62

Brown M (2003) Differential scanning calorimetry—an introduction for practitioners. Springer, Berlin

Webpage: FWM—Resource Library Fort Wayne Metals—nitinol wire. https://fwmetals.com/services/resource-library/nitinol-wire/

Michaelis N, Welsch F, Kirsch S-M, Seelecke S, Schütze A, Schuetze A (2019) Resistance monitoring of shape memory material stabilization during elastocaloric training. Smart Mater Struct 28(10):105046

Schmidt M, Schütze A, Seelecke S (2015) Scientific test setup for investigation of shape memory alloy based elastocaloric cooling processes. Int J Refrig 4:1–10

Schmidt M, Ullrich J, Wieczorek A, Frenzel J, Schütze A, Eggeler G, Seelecke S (2015) Thermal stabilization of NiTiCuV shape memory alloys: observations during elastocaloric training. Shape Mem Superelasticity 1:132–141

Acknowledgements

The authors would like to acknowledge the support of the German Research Foundation (DFG: Deutsche Forschungs-gemeinschaft) through priority Program No. 1599 “Caloric effects in ferroic materials: New concepts for cooling” (Project Nos. SCH2217/3-2, SE704/2-2). Moreover, the authors would like to thank Jan Frenzel and André Wieczorek from Ruhr University Bochum (cf. Fig. 1) as well as Lars Bumke from Christian-Albrecht-University Kiel for supporting us with DSC measurements of our SMA samples.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Michaelis, N., Schütze, A., Welsch, F. et al. Novel Experimental Approach to Determine Elastocaloric Latent Heat. Shap. Mem. Superelasticity 5, 352–361 (2019). https://doi.org/10.1007/s40830-019-00249-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40830-019-00249-y