Abstract

Ferrous shape memory alloys showing superelasticity have recently been obtained in two alloy systems in the 2010s. One is Fe–Mn–Al–Ni, which undergoes martensitic transformation (MT) between the α (bcc) parent and γ′ (fcc) martensite phases. This MT can be thermodynamically understood by considering the magnetic contribution to the Gibbs energy, and the β-NiAl (B2) nanoprecipitates play an important role in the thermoelastic MT. The temperature dependence of critical stress for the MT is very small (about 0.5 MPa/°C) due to the small entropy difference between the parent and martensite phases in the Fe–Mn–Al–Ni alloy, and consequently, superelasticity can be obtained in a wide temperature range from cryogenic temperature to about 200 °C. Microstructural control is of great importance for obtaining superelasticity, and the relative grain size is among the most crucial factors.

Similar content being viewed by others

Introduction

Over the last half-century, many alloy systems, including Ni–Ti-, Cu-, Fe-, Ni-, Co-, Ti-, and Mg-based systems, have shown a shape memory effect or superelasticity associated with reversible martensitic transformation (MT) [1,2,3,4,5]. Because of its good shape memory properties [6,7,8] and biocompatibility [9], Ni–Ti alloys have been most commercially used in such fields as medical, automotive, aerospace, and seismic, and for consumer products [10,11,12,13,14]. However, increasing demands on shape memory alloys (SMAs) have led researchers to focus on developing novel SMAs with new classes of functionality and properties, e.g., magnetic SMAs for actuators with a more rapid response, Ni-free Ti-based alloys with better biocompatibility, high-temperature SMAs, more ductile SMAs, and damping materials. Fe-based SMAs have attracted much attention for a long time due to their low cost. Although many attempts have been made to obtain superelasticity in Fe-based alloys since 1970s, they have shown no or poor superelasticity. However, in the early 2010s, authors in this study’s group achieved superelasticity in Fe–Ni–Co–Al–Ta–B and Fe–Mn–Al–Ni.

The conventional MT in Fe-based alloys has roughly been classified into two groups according to the crystal structure; transformations from the γ (fcc) parent to the α′ (bct, bcc or fct) martensite and from the γ parent to the ε (hcp) martensite. The most extensively studied Fe-based SMA is Fe–Mn–Si [15, 16], showing the γ/ε MT. Besides the shape memory effect, this alloy shows good fatigue lives and has been applied practically to a seismic damping component [17]. However, the transformation is non-thermoelastic and superelasticity cannot be obtained. The other is the Fe–Ni-based systems, showing the γ/α′ MT. It has been proposed that thermoelastic transformation can be achieved when a matrix is suitably strengthened and tetragonality (c/a) of the bct structure is suitably high [18, 19]. In the Fe–Ni–Co–Ti alloy, the transformation changes to thermoelastic by precipitation of the γ′ phase in coherency with the γ matrix [18]. However, it was previously difficult to obtain superelasticity at room temperature because of the brittleness caused by grain boundary precipitation. This problem was solved mainly by controlling the grain boundary character distribution. In 2010, superelasticity at room temperature was obtained in the Fe–Ni–Co–Al–Ta–B alloy [20] and later in its family of alloys, such as Fe–Ni–Co–Al–Nb–B and Fe–Ni–Co–Al–Ti–B [21,22,23], in which the grain boundary precipitation was effectively suppressed by lowering grain boundary energy with a strong recrystallization texture obtained by suitable cold-rolling and annealing. Consequently, a large superelastic strain up to 13.5% can be obtained in thin sheets, although wires remain brittle due to difficulty in obtaining the low-energy grain boundary. The MTs from the γ parent phase are responsible for shape memory properties in these alloy systems.

In 2011, a new ferrous SMA Fe–Mn–Al–Ni was reported [24]. This alloy has microstructural features similar to the Fe–Ni–Co-based SMAs. In addition, nanosized and coherent precipitates with an ordered structure formed in a disordered matrix play an important role in thermoelastic MT, although the α (bcc) “ferrite” parent phase martensitically transforms to the γ′ (fcc) “austenite” phase, unlike conventional Fe-based SMAs with the γ parent phase. A similar MT from the α (L21) to the γ′ (D022 or 2M) has been obtained in the Fe–Mn–Ga system [25, 26]. In addition to the advantages of the inexpensive constituents and the good cold workability, the Fe–Mn–Al–Ni alloy can overcome one drawback in superelastic alloys, which is a strong stress sensitivity to temperature for the MT and a resultant narrow temperature window for superelasticity. Until now, superelasticity has been obtained at temperatures from − 263 °C to 240 °C with small dependence of critical stress on temperature in the Fe–Mn–Al–Ni alloy; therefore, this SMA is a candidate material for practical applications. Since the first report of the superelasticity [24], the thermodynamics, microstructure, and superelasticity in Fe–Mn–Al–Al alloys have been investigated in both single-crystalline and polycrystalline samples. In this paper, the fundamental properties and recent progress in research on Fe–Mn–Al-based alloys are reviewed.

Thermodynamics of α/γ′ Martensitic Transformation in the Fe–Mn–Al System

The MT from the γ phase to the α′ phase is well known in Fe-based alloys. However, that from the α parent phase (bcc) has been reported almost exclusively in Fe–Mn–Al-based alloys [27,28,29,30]. Figure 1a shows the γ′ martensite phase in the α matrix in Fe–36at.%Mn–15at.%Al alloy quenched from 1200 °C (hereafter, the alloy composition is written as at.%). The amount of martensite increased by cooling, but the reverse transformation hardly occurred by heating to 500 °C [30]. This is a typical feature of the non-thermoelastic MT. Fe–40Mn–15Al shows much higher amount of martensite (Fig. 1b), meaning that an increase in the Mn content stabilizes the martensite.

Here, this unique martensitic phase transformation from the α phase to the γ′ phase in the Fe-based alloy will be discussed from a thermodynamic viewpoint. Figure 2 shows the vertical section diagram with the equilibrium temperature \(T_{0}^{\upalpha /\upgamma }\) line between the α and γ phases in the Fe–36Mn–Al alloy, calculated by the CALPHAD method [31]. The Fe–36Mn–15Al alloy has the \(T_{0}^{\upalpha /\upgamma }\) at about 800 °C, which suggests that the α/γ′ MT can occur when rapidly quenched from the α phase region. Figure 3 shows the isothermal section diagram at 1200 °C in the Fe–Mn–Al ternary system [32], where the alloys in the hatched region have been confirmed to show the MT. Note that this region is in the vicinity of the phase boundary and that the Curie temperature of the α phase, \(T_{\text{C}}^{\upalpha }\), is relatively low.

Isothermal section diagram at 1200 °C in the Fe–Mn–Al ternary system, where the MT from α phase to γ′ phase occurs in Fe–Mn–Al alloys in the hatched region [32]. Iso-T C lines of the α phase were estimated from experimental data

The phase stability of Fe has been well investigated. The schematic diagrams of the entropy and Gibbs energy of Fe are shown in Fig. 4, and the entropy difference \(\Delta S_{i}^{\upalpha /\upgamma } = S_{i}^{\upgamma } - S_{i}^{\upalpha }\) and the Gibbs energy difference \(\Delta G_{i}^{\upalpha /\upgamma } = G_{i}^{\upgamma } - G_{i}^{\upalpha }\) between the α and γ phases calculated for Fe, Fe–20Mn–10Al, and Fe–36Mn–15Al by the CALPHAD method are shown in Fig. 5 [33]. In Fig. 4, the paramagnetic and ferromagnetic (\(T_{\text{C}}^{\upalpha }\) = 770 °C in Fe [34]) states are considered for the α phase, and the γ phase is antiferromagnetic at low temperatures (\(T_{\text{C}}^{\upgamma }\) = 67 K = − 206 °C in Fe [34]). The paramagnetic ground state at infinite temperature was set as a reference state and the magnetic contribution was considered as ordering here, as is often treated in CALPHAD. The larger vibrational entropy of the α phase with a more open structure makes it more stable at high temperatures than the γ phase due to the TS term in Gibbs energy G = H – TS, which is a common feature in many kinds of metals and causes the α(δ) (HT: high temperature)/γ (LT: low temperature) transformation at high temperatures in Fe and Fe alloys. The α (HT)/γ′ (LT) MT in Fe–36Mn–15Al can basically be understood by this explanation, whereas the \(T_{0}^{\upalpha /\upgamma }\) temperature is extremely low compared with that of pure Fe. However, entropy of the ferromagnetic phase is generally reduced by magnetic ordering. The lower entropy of the ferromagnetic α phase, compared with that of the γ phase, leads to the γ (HT)/α′ (LT) transformation at the low temperatures. In addition, the α phase becomes more stable than the γ phase at 0 K due to the ferromagnetism of the α phase in Fe [35]. The stabilization of the α phase by the magnetism at lower temperatures hinders the MT from the α to the γ′ phase in conventional Fe alloys. In contrast, in Fe–Mn–Al alloys the contribution of the magnetism is reduced by the large amount of alloying elements, which results in the appearance of the α/γ′ MT. It should also be noted that the antiferromagnetism in the γ phase also plays an important role for the α/γ transformation in Fe. This effect, however, may be less considerable because of the low Néel temperature, while being more visible in the Fe–Mn–Al-based alloys with a higher Néel temperature.

Calculated entropy difference \(\Delta S_{i}^{\upalpha /\upgamma } = S_{i}^{\upgamma } - S_{i}^{\upalpha }\) and Gibbs energy difference \(\Delta G_{i}^{\upalpha /\upgamma } = G_{i}^{\upgamma } - G_{i}^{\upalpha }\) between α and γ phases with and without magnetic contribution in a Fe, b Fe–20Mn–10Al, and c Fe–36Mn–15Al [33], where thermodynamic parameters in Ref. [31] were used

The subscripts “para” and “ferro” in the calculated \(\Delta S_{i}^{\upalpha /\upgamma } = S_{i}^{\upgamma } - S_{i}^{\upalpha }\) and \(\Delta G_{i}^{\upalpha /\upgamma } = G_{i}^{\upgamma } - G_{i}^{\upalpha }\) of Fig. 5 mean that the magnetic term is excluded and included in the calculation, respectively; therefore, the difference is the magnetic contribution to the entropy difference or Gibbs energy difference. Qualitatively, the ferromagnetic schematic of Fig. 4 can be applied to Fe and Fe–20Mn–10Al and the paramagnetic one is a case for Fe–36Mn–15Al. In Fe and Fe–20Mn–10Al, the magnetic contribution \(\Delta S_{\text{mag}}^{\upalpha /\upgamma }\) is large and the \(\Delta S_{\text{ferro}}^{\upalpha /\upgamma }\) is largely positive at around temperatures below \(T_{\text{C}}^{\upalpha }\). Hence, the α phase is stabilized at lower temperatures. However, the Fe–36Mn–15Al alloy has a much lower Curie temperature of the α phase, and the unusual stabilization of the α phase by the magnetism at low temperatures is not visible.

The vertical section diagram of Fe–Mn–Al with various Mn contents with the Curie temperature of the α phase are shown in Fig. 6. It can be seen that the γ loop is formed around the Curie temperature and that it expands to the high Al content and low temperature region with increasing Mn content and decreasing Curie temperature. Finally, in the 36Mn alloy, the loop disappears due to reduction of the magnetic effect. In this condition, the α phase of, e.g., the 15Al alloy crosses the \(T_{0}^{\upalpha /\upgamma }\) at relatively low temperature during cooling and the diffusionless α/γ′ MT can occur by rapid quenching.

Vertical section diagram of \(T_{0}^{\upalpha /\upgamma }\) and \(T_{C}^{\upalpha }\) in the Fe–Mn–Al system with various Mn contents [24]

Until now, unlike the Co-based Heusler alloys [36], the reentrant MT from the α phase to the γ phase by cooling has not been observed in the Fe–Mn–Al system. This is probably due to the antiferromagnetism of the γ phase, namely the magnetic contributions from the ferromagnetic α phase and antiferromagnetic γ phase are more or less balanced. It is difficult to predict the thermodynamic quantities at low temperatures in the current (second generation) CALPHAD method [37] as omitted in Figs. 5 and 6, but attempts are being made for thermodynamic analysis at low temperatures below room temperature based on experiments [38].

Martensitic Transformation and Nanoprecipitates in the Fe–Mn–Al–Ni System

Superelasticity can be obtained by thermoelastic MT in most cases. While the α phase of Fe–Mn–Al ternary alloys with the disordered A2 structure show non-thermoelastic MT, the Fe–Mn–Al–Ni quaternary alloys with the β-NiAl nanoprecipitates with the B2 structure in the α matrix exhibit thermoelastic MT [24]. This is similar to the MT in Fe–Ni–Co–(Ti or Al)-based γ alloys with the L12 nanoprecipitates [18, 20,21,22,23]. The amount of Ni content has been optimized and addition of about 7.5 at.% Ni is the best, considering the reversibility of the MT and ductility [39], and the Fe–34Mn–15Al–7.5Ni alloy has been used in most reported studies.

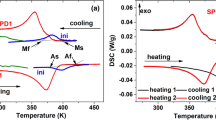

Although it is difficult to determine the MT temperature by electrical resistivity measurement [40] or differential scanning calorimetry, magnetization measurement is useful to detect the MT as shown in Fig. 7a [24] because the α parent and the γ′ martensite phases in the Fe–Mn–Al–Ni alloy are ferromagnetic and antiferromagnetic, respectively. The thermal hysteresis ΔT hys (defined by A f − M s with the transformation starting temperature M s and the reverse transformation finishing temperature A f) is normally smaller than 50 °C in thermoelastic MT, but that is about 150 °C in the Fe–Mn–Al–Ni alloy. However, the martensite plates reversibly grow and shrink during cooling and heating, respectively, (Fig. 7b) and such microstructural change is a typical feature of thermoelastic MT. The required driving force for the MT ΔG is given by ΔG ≈ ΔS·ΔT (ΔT: supercooling from T 0) and ΔG for Fe–Mn–Al–Ni is estimated to be 32 J mol−1 (ΔS = − 0.43 J mol−1 K−1, ΔT ≈ ΔT hys/2 = 75 K), which is much smaller than that of roughly 1000 J mol−1 in non-thermoelastic transformation in Fe-based alloys [41] and even smaller than that of about 80 J mol−1 in thermoelastic Ni–Ti alloys [42]. As discussed later, the ΔS is smaller in the Fe–Mn–Al–Ni alloy than that in other SMAs, and the large hysteresis is not due to the large driving force but caused by this thermodynamic property. Judging from these facts, the MT in the Fe–Mn–Al–Ni alloy is considered to be thermoelastic. The small ΔS also arrests the transformation by cooling and the relatively high magnetization in Fig. 7 is attributed to the residual parent phase.

a Thermomagnetization curve in the magnetic field of 0.5 kOe and b optical micrographs of martensitic forward and reverse transformation at (i) 20 °C, (ii) − 160 °C, (iii) − 30 °C, and (iv) 100 °C obtained by in situ observation in as-solution-treated Fe–34Mn–15Al–7.5Ni alloy [24]

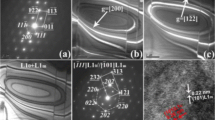

The β nanoprecipitate plays an important role in thermoelastic MT. The precipitate has been analyzed by atom probe tomography and is basically NiAl [43] with the B2 structure. This precipitation can be understood by a miscibility gap of the bcc phase in the Fe–Ni–Al system [44]. Figure 8 shows the high-angle annular dark-field scanning transmission electron microscopy (HAADF-STEM) image of the β precipitate with about 10 nm in diameter in the martensite matrix of the Fe–34Mn–15Al–7.5Ni alloy [45]. The crystal structure of the precipitate should be B2, but it is sheared to the [011] direction by about 5°. In the martensite phase, twins are introduced as indicated by the white lines. Although the stacking sequence is rather irregular, the average shear angle of the martensite is close to that of the β precipitate. Note that no misfit dislocations are observed at the parent/precipitate interface after reverse MT and that the coherency at the martensite/precipitate is considered high. These results suggest that the β precipitate is elastically distorted by the MT and that the martensite is finely and reversely sheared by the introduction of nano-twins due to internal elastic strain. Local strain generated by the MT is likely to be accommodated by the nano-twins in the martensite and the coherency at the parent/martensite habit plane becomes high. Therefore, the MT is thermoelastic in the Fe–Mn–Al–Ni alloy with the β nanoprecipitate. The elastic energy due to distortion of the β precipitates has been estimated by La Roca to range from about 10 to 500 J mol−1 (for aging conditions at 200 °C for up to 3 h) depending on the volume fraction of the precipitates, which decreases the MT temperatures [46]. The average stacking order observed in Ref. [45] is close to 8M with \((5\overline {3})\) in the Zhdanov notation. However, it is rather irregular, unlike the order stacking structure in Ni–Mn–Al [47] or Ni–Mn–Ga [48]. Therefore, the crystal structure of the martensite phase should probably be recognized as the fcc structure although nano-twins are densely introduced.

High-angle annular dark-field scanning transmission electron microscopy (HAADF-STEM) image of β precipitate in the martensite matrix in the Fe–34Mn–15Al–7.5Ni alloy aged at 200 °C for 15 min. Inset shows the HAADF-STEM image of the parent phase and β precipitate along [100] obtained in the region where the sample was transformed to the martensite phase by cooling using liquid nitrogen, and then reverse-transformed to the parent phase by heating before thinning for HAADF-STEM observation [45]

Superelasticity and Its Temperature Dependence in Fe–Mn–Al–Ni

The Fe–Mn–Al–Ni alloy exhibits superelasticity with temperature insensitivity in stress. The temperature dependence of the critical stress for inducing martensite σ c is related to the entropy difference ΔS (= S M − S P), transformation strain ε, and molar volume V m as written by the Clausius–Clapeyron relation [49]:

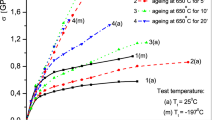

ΔS is normally negative, and therefore the critical stress increases with increasing temperature. As shown in the inset of Fig. 9a [24], the Ni–Ti alloy shows superelasticity at 20 °C but the critical stress is very high at 150 °C, leading to the introduction of slip and large residual strain. At − 50 °C, the martensite phase is stable under zero stress. The large temperature dependence (dσ c/dT = 5.7 MPa/°C in Ni–Ti) limits the superelastic temperature window. However, the Fe–Mn–Al–Ni alloy exhibits superelasticity at every temperature from − 50 °C to 150 °C in Fig. 9a, and the temperature dependence is smaller by one order of magnitude (dσ c/dT = 0.74 MPa/°C for 6-hour aging and dσ c/dT = 0.53 MPa/°C for 24-hour aging) than that of the Ni–Ti alloy. The small temperature dependence has been confirmed in the single crystals (0.60 MPa/°C for near 〈110〉 in tension [24], 0.54 MPa/°C for 〈100〉 in tension [50], and 0.41 MPa/°C in compression [50]). This unique property ensures a wide superelastic temperature window. Superelasticity has been observed at temperatures from − 196 °C to 240 °C (Fig. 9b) and recently cryogenic superelasticity at − 263 °C has been reported [38].

a Tensile stress–strain curves of the Fe–34Mn–15Al–7.5Ni alloy aged at 200 °C for 6 h with a bamboo structure at − 50, 20, and 150 °C. The inset shows stress–strain curves of the Ni–Ti alloy. b Temperature dependence of critical stress for inducing martensite in polycrystalline superelastic alloys. Two sets of data were obtained in the Fe–Mn–Al–Ni alloy aged at 200 °C for 6 or 24 h [24]

ΔS of the Fe–Mn–Al–Ni alloy is estimated to be − 0.43 J mol−1 K−1 using Eq. (1) [24]. The ε and V m of the Fe–Mn–Al–Ni alloy are similar to those in other alloys, while the ΔS (= − 0.43 J mol−1 K−1) is much smaller than that of other alloys (e.g., − 4.37 J mol−1 K−1 in the Ni–Ti alloy [24]). Therefore, it is concluded that the small temperature dependence of Fe–Mn–Al–Ni is caused by the small entropy difference.

Superelasticity in a Single Crystal

Tseng et al. have investigated the stress–strain response of a single-crystalline Fe–Mn–Al–Ni alloy oriented along 〈001〉 in tension and compression (Fig. 10) [50]. The tensile test shows only a limited superelastic strain, while the compressive test shows better superelasticity. The residual strain is caused by the retained martensite in both cases and a larger superelastic strain may be obtained in compression tests when the critical stress for inducing martensite is higher. They ascribe this difference between tension and compression to the variant selection of martensite. One martensite variant is induced in tension and the transformation strain is not well accommodated, resulting in the hairpin-shaped dislocation in the parent phase related to plastic deformation [51, 52] as well as parallel dislocations at parent/martensite interface. However, two variants are activated due to the equivalent Schmid factor in compression, which can more effectively accommodate strain, and the parent/martensite interface remains mobile. This finding provides important information on the role of variants and orientation selection for alloy development but does not mean that superelasticity of Fe–Mn–Al–Ni is always poor for tensile deformation. Indeed, a good superelastic response can be obtained even in tension in a Fe–Mn–Al–Ni single crystal with different orientations (Fig. 11) [24, 53].

Stress–strain curves of a Fe–34Mn–15Al–7.5 Ni 〈001〉 single crystal for a tension and b compression [50]

Tensile superelasticity with a superelastic strain of 9.7% in a Fe–34Mn–15Al–7.5 Ni single crystal aged at 200 °C for 3 h [24]. The crystal orientation for the tensile direction is shown in the inset

The transformation strain in the MT can be predicted by the shape strain using phenomenological [54, 55], lattice deformation [56], or energy minimization theory [57]. The transformation strain is larger in lattice deformation theory because the contribution of detwinning is included [58, 59]. The transformation strains in the α/γ′ MT calculated by energy minimization theory and lattice deformation theory are shown in Fig. 12 [53]. It is seen that the transformation strain in 〈001〉 is about 10.5% by energy minimization theory and about 26.5% by lattice deformation theory, while being reported to be about 12.5% by phenomenological theory [60]. Similar results on lattice deformation theory have been reported by other researchers [24, 61]. From a comparison between the calculations and experiments for a few orientations [24, 42, 49, 56], it seems that the suitable theory should be selected depending on the crystallographic tensile or compressive orientation, but further investigations are required for better prediction of the maximum superelastic strain.

Orientation dependence of transformation strains in tension calculated by a energy minimization and b lattice deformation theory [53]

Grain Size Dependence of Superelasticity

In a polycrystalline alloy, grain constraint from neighboring grains during deformation is a key factor in microstructural control. Figure 13 shows the results of strain incremental tensile test in 〈110〉 textured Fe–34Mn–15Al–7.5Ni wires with relative grain size d/D = 0.41 and d/D = 2.19 [60], where d and D are mean grain size (i.e., diameter in fine grains or grain length in a bamboo structure) and diameter of the wire, respectively. The texture was developed by wire-drawing at an area reduction ratio of 75% and subsequent solution treatment. The wire with d/D = 0.41 hardly shows a superelastic response, while that with d/D = 2.19 exhibits excellent superelasticity with the maximum superelastic strain of 5.5%. The maximum superelastic strain is evaluated in Fig. 14, which suggests that the grain size should be the same as or larger than the wire diameter (i.e., bamboo structure) to obtain good superelasticity. A similar result has been obtained in sheets [24, 62]. The stress is higher in wires with smaller d/D. This means that a larger grain constraint suppresses the stress-induced MT.

Stress–strain curves of 〈011〉 textured Fe–34Mn–15Al–7.5Ni alloy wires 1 mm in diameter with d/D = 0.41 and d/D = 2.19 aged at 200 °C for 3 h. Insets show inverse pole figure mapping for the drawing direction [60]

Maximum superelastic strain and critical stress for the MT in Fe–34Mn–15Al–7.5Ni alloy wires 1 mm in diameter [60]

Numerical analysis of superelastic behavior has been performed in Cu-based and Ni–Ti alloys [63,64,65,66,67,68] and also in the present Fe–Mn–Al–Ni alloy. The superelasticity of the Fe–Mn–Al–Ni wire can be explained by combination of the Sachs model [69], in which each grain deforms independently of its neighbors, and the Taylor model [70], in which strain compatibility at grain boundaries is maintained and each grain has the same internal strain. The critical stress lies between the lower bound of the Sachs model with unconstraint and the upper bound of the Taylor model with constraint, and seems to have a linear relation against the ratio of grains with free surface in a cross section. However, the superelastic strain shows a poor linear relation because of other microstructural factors [60]. The Taylor factor is large in Fe–Mn–Al–Ni alloys similar to Cu-based alloys and dissimilar to the Ti-Ni alloy [63], and thus the grain size is a crucial microstructural factor in superelasticity of Fe–Mn–Al–Ni SMA.

Abnormal Grain Growth

Abnormal grain growth (AGG) can be exploited to obtain a bamboo structure or even a single crystal. It has been reported that abnormal grain growth occurs by cyclic heat treatment between the single-phase region and two-phase region in Cu-Al–Mn SMAs [71] and this simple technique has been successfully applied to obtain a large single-crystal Cu-Al–Mn [72]. Fortunately, the Fe–Mn–Al–Ni alloy also shows the α single-phase at high temperatures and α + γ two-phase at low temperatures as shown in Fig. 2, and the AGG phenomenon by cyclic heat treatment is available for obtaining a coarse grain structure [24]. Figure 15 shows the AGG of the α phase in the Fe–Mn–Al–Ni alloy subjected to cyclic heat treatment between 1200 and 600 °C [73]. Two grains are abnormally growing, and smaller grains are seen inside the surrounding grains although they exist only in a part of the abnormal grains. The smaller grains are subgrains associated with precipitation of the γ phase and the sub-boundary energy is a dominant driving pressure in this AGG phenomenon [72, 73].

Abnormal grain growth of the Fe–34Mn–15Al–7.5Ni alloy subjected to cyclic heat treatment (1200 + 600 + 1200 °C) [73]

Effect of Aging

Aging treatment affects the MT and the superelastic performance through change of the size and the fraction of the β precipitates. The β particles actually precipitate during water quenching from 1200 °C. In addition, further precipitation and growth is proceeded by subsequent aging treatment at 200 °C, which increases the hardness and decreases the MT temperature [24]. Tseng et al. and Ozcan et al. have, respectively, investigated the effect of aging by compression tests in a 〈100〉 single-crystalline alloy [43] and by tensile tests in a 〈110〉 textured oligocrystalline alloy [74]. The critical stress for the MT remarkably increases with increasing aging time at 200 °C (about 100 MPa for 0 h, about 600 MPa for 24 h), while stress hysteresis slightly increases except for the lowest hysteresis aged for 3 h. In addition, the Δσ c/ΔT slope decreases with increasing aging time in a single crystal. The researchers concluded that the best aging condition for a larger superelastic strain is 200 °C for 3 h (Fig. 16), where the size and volume fraction of the β precipitates is 6–10 nm and 34%, respectively. These precipitates can strengthen the matrix and prevent it from slip deformation without coherency loss.

Maximum compressive superelastic strains for a Fe–Mn–Al–Ni single crystal along [100] aged at 200 °C for various periods [43]

Other Features and Problems

One major problem in the Fe–Mn–Al–Ni alloy is cracking during quenching after solution treatment. Fe–Mn–Al–Ni alloys are prone to crack formation by water quenching after solution treatment at 1200 or 1300 °C in the α single-phase region. The crack formation seems to be promoted by the high crystallographic anisotropy [75] and the β precipitation, but the reason is not clear yet. Vollmer et al. has shown that intergranular cracking can be suppressed by grain boundary decoration using the ductile γ phase formed during quenching with a slightly lower cooling rate from 1200 °C and that superelasticity does not largely deteriorate by the small amount of the γ phase [75]. It is important that a thin layer of the γ phase precipitates mainly at grain boundaries in a bamboo structure as reported in the Ni–Al [76], Co–Ni–Al [77, 78], and Co–Ni–Ga [79, 80] systems. Alloying elements can change the kinetics of precipitation and, especially, the addition of Ti is effective to obtain the favorable microstructure [81].

Another problem of the Fe–Mn–Al–Ni SMA is the cyclic degradation of superelasticity, which may be a common issue to be resolved in superelastic alloys. Rapid degradation of superelasticity has been reported in Fe–Mn–Al–Ni alloys [82] and should be addressed for practical applications for cyclic use. It has also been reported that the critical stress changes after long-time aging at room temperature [83]. The thermal shape memory effect has been less investigated probably because the output stress is not expected to be high. The reverse shape memory effect has recently been reported [84].

Owing to the large difference in magnetization between the ferromagnetic parent and antiferromagnetic martensite phases, magnetic-field-induced reverse transformation has been observed [45, 38], and the field-induced strain is probably possible. Magnetization and permeability change can be obtained by stress-inducing MT [24, 85], and a non-contact strain sensor is a potential application.

Many SMAs also possess high damping capacity [86], and a few studies on damping have been reported in Fe–Mn–Al–Ni alloys [87]. Figure 17 shows the tan δ-temperature curve during cooling and heating in an Fe–Mn–Al–Ni alloy [88]. The peaks correspond to the forward and reverse MT and the martensite phase has a relatively high damping capacity.

Tan δ versus temperature curve of an Fe–35.5Mn–15Al–7.5Ni alloy. Strain amplitude and frequency is 4.8 × 10−4 and 3 °C/min, respectively [88]

Concluding Remarks

Fe–Mn–Al and Fe–Mn–Al–Ni alloys undergo MT between the α parent and γ′ martensite phases, which appears to be caused by a reduced magnetic contribution to the Gibbs energy by alloying elements to Fe. The β nanoparticles precipitate in coherence with the α matrix by addition of Ni, which is responsible for the change of the transformation manner to thermoelastic. Owing to the disordered structure of the α phase and by use of the γ phase, the cold workability of Fe–Mn–Al–Ni is higher than that of Ni–Ti with an ordered structure. Among the most important characteristics of this alloy is the small entropy difference between the parent and martensite phases, which leads to almost temperature-invariant critical stress (about 0.5 MPa/°C), a wide temperature window for superelasticity from cryogenic temperature to high temperatures around 200 °C, and large thermal hysteresis. The Fe–Mn–Al–Ni alloy exhibits excellent superelasticity in a bamboo structure or single crystal, which can be obtained by abnormal grain growth induced by cyclic heat treatment. This alloy system with the inexpensive constituents has a potential to spread the range of applications of superelastic alloys to larger components.

References

Miyazaki S, Otsuka K (1989) Development of shape memory alloys. ISIJ Int 29(5):353–377

Otsuka K, Wayman CM (eds) (1999) Shape memory materials. Cambridge University Press, Cambridge

Xu X, Omori T, Nagasako M, Okubo A, Umetsu RY, Kanomata T, Ishida K, Kainuma R (2013) Cooling-induced shape memory effect and inverse temperature dependence of superelastic stress in Co2Cr(Ga, Si) ferromagnetic Heusler alloys. Appl Phys Lett 103(16):164104

Miyazaki S, Kim HY, Hosoda H (2006) Development and characterization of Ni-free Ti-base shape memory and superelastic alloys. Mater Sci Eng A 438:18–24

Ogawa Y, Ando D, Sutou Y, Koike J (2016) A lightweight shape-memory magnesium alloy. Science 353(6297):368–370

Miyazaki S, Otsuka K, Suzuki Y (1981) Transformation pseudo-elasticity and deformation-behavior in a Ti-50.6at-percent Ni-alloy. Scr Metall 15(3):287–292

Miyazaki S, Ohmi Y, Otsuka K, Suzuki Y (1982) Characteristics of deformation and transformation pseudoelasticity in Ti-Ni alloys. Journal De Physique 43(Nc-4):255–260

Miyazaki S, Mizukoshi K, Ueki T, Sakuma T, Liu Y (1999) Fatigue life of Ti–50 at.% Ni and Ti–40Ni–10Cu (at.%) shape memory alloy wires. Mater Sci Eng A 273:658–663

Mantovani D (2000) Shape memory alloys: properties and biomedical applications. JOM J Miner Met Mater Soc 52(10):36–44

Van Humbeeck J (1999) Non-medical applications of shape memory alloys. Mater Sci Eng A 273:134–148

Morgan NB (2004) Medical shape memory alloy applications—the market and its products. Mater Sci Eng A 378(1–2):16–23

Jani JM, Leary M, Subic A, Gibson MA (2014) A review of shape memory alloy research, applications and opportunities. Mater Des 56:1078–1113

Desroches R, Smith B (2004) Shape memory alloys in seismic resistant design and retrofit: a critical review of their potential and limitations. J Earthq Eng 8(3):415–429

Janke L, Czaderski C, Motavalli M, Ruth J (2005) Applications of shape memory alloys in civil engineering structures—overview, limits and new ideas. Mater Struct 38(279):578–592

Sato A, Chishima E, Soma K, Mori T (1982) Shape memory effect in gamma reversible epsilon transformation in Fe-30mn-1si alloy single-crystals. Acta Metall 30(6):1177–1183

La Roca P, Baruj A, Sade M (2017) Shape-memory effect and pseudoelasticity in Fe–Mn-based alloys. Shape Mem Superelast 3(1):37–48

Sawaguchi T, Maruyama T, Otsuka H, Kushibe A, Inoue Y, Tsuzaki K (2016) Design concept and applications of Fe-Mn-Si-based alloys -from shape-memory to seismic response control. Mater Trans 57(3):283–293

Maki T, Kobayashi K, Minato M, Tamura I (1984) Thermoelastic martensite in an ausaged Fe-Ni-Ti-Co alloy. Scr Metall 18(10):1105–1109

Maki T (1999) Ferrous shape memory alloys. In: Otsuka K, Wayman CM (eds) Shape memory materials. Cambridge University Press, Cambridge, pp 117–132

Tanaka Y, Himuro Y, Kainuma R, Sutou Y, Omori T, Ishida K (2010) Ferrous polycrystalline shape-memory alloy showing huge superelasticity. Science 327(5972):1488–1490

Omori T, Abe S, Tanaka Y, Lee DY, Ishida K, Kainuma R (2013) Thermoelastic martensitic transformation and superelasticity in Fe-Ni-Co-Al-Nb-B polycrystalline alloy. Scr Mater 69(11–12):812–815

Chumlyakov YI, Kireeva IV, Kuts OA, Platonova YN, Poklonov VV, Kukshauzen IV, Kukshauzen DA, Panchenko MY, Reunova KA (2016) Thermoelastic martensitic transformations in single crystals of FeNiCoAlX(B) alloys. Russ Phys J 58(11):1549–1556

Lee D, Omori T, Kainuma R (2014) Ductility enhancement and superelasticity in Fe-Ni-Co-Al-Ti-B polycrystalline alloy. J Alloy Compd 617:120–123

Omori T, Ando K, Okano M, Xu X, Tanaka Y, Ohnuma I, Kainuma R, Ishida K (2011) Superelastic effect in polycrystalline ferrous alloys. Science 333(6038):68–71

Omori T, Watanabe K, Umetsu RY, Kainuma R, Ishida K (2009) Martensitic transformation and magnetic field-induced strain in Fe–Mn–Ga shape memory alloy. Appl Phys Lett 95(8):082508

Zhu W, Liu EK, Feng L, Tang XD, Chen JL, Wu GH, Liu HY, Meng FB, Luo HZ (2009) Magnetic-field-induced transformation in FeMnGa alloys. Appl Phys Lett 95(22):222512

Hwang KH, Yang WS, Wu TB, Wan CM, Byrne JG (1990) Evidence for Hcp needlelike martensite in a duplex Fe-Mn–Al-C Alloy. Metall Mater Trans A 21(10):2815–2817

Hwang KH, Wan CM, Byrne JG (1991) Phase transformation in a duplex Fe-Mn-Al-C alloy. Mater Sci Eng A 132:161–169

Lee WB, Chen FR, Chen SK, Olson GB, Wan CM (1995) Transmission electron-microscopy studies of the crystallography of Bcc/18r martensite in Fe-Mn-Al-C. Acta Metall Mater 43(1):21–30

Ando K, Omori T, Ohnuma I, Kainuma R, Ishida K (2009) Ferromagnetic to weak-magnetic transition accompanied by bcc to fcc transformation in Fe–Mn–Al alloy. Appl Phys Lett 95(21):212504

Umino R, Liu XJ, Sutou Y, Wang CP, Ohnuma I, Kainuma R, Ishida K (2006) Experimental determination and thermodynamic calculation of phase equilibria in the Fe–Mn–Al system. J Phase Equilibria Diffus 27(1):54–62

Ando K (2010) Martensitic transformation from BCC phase and shape memory effect in Fe-Mn-based alloys. Doctoral Thesis, Tohoku University

Omori T, Kainuma R (2015) BCC/FCC martensitic transformation and superelasticity in Fe-based alloys. Materia Japan 54(8):398–404 (in Japanese)

Dinsdale AT (1991) SGTE data for pure elements. Calphad 15(4):317–425

Weiss RJ, Tauer KJ (1956) Components of the thermodynamic functions of iron. Phys Rev 102(6):1490–1495

Xu X, Nagasako M, Kataoka M, Umetsu RY, Omori T, Kanomata T, Kainuma R (2015) Anomalous physical properties of Heusler-type ${\mathrm{Co}}_{2}\mathrm{Cr}$(Ga, Si) alloys and thermodynamic study on reentrant martensitic transformation. Phys Rev B 91(10):104434

Saunders N, Miodownik AP (1998) CALPHAD (calculation of phase diagrams): a comprehensive guide, Pergamon

Xia J, Xu X. Miyake A, Kimura Y, Omori T, Tokunaga M, Kainuma R (in press) Stress- and magnetic field-induced martensitic transformation at cryogenic temperatures in Fe-Mn-Al-Ni shape memory alloys. Shape Mem Superelast

Omori T, Ando K, Ohnuma I, Ishida K, Kainuma R (2012) Alloy design and superelasticity in Fe-Mn-Al-Ni alloy. In: CIMTEC 2012

La Roca P, Medina J, Sobrero CE, Avalos M, Malarria JA, Baruj A, Sade M (2015) Effects of B2 nanoprecipitates on the phase stability and pseudoelastic behavior of Fe-Mn-Al-Ni shape memory alloys. MATEC Web Conf 33:04005

Kaufman L, Cohen M (1958) Thermodynamics and kinetics of martensitic transformations. Prog Metal Phys 7:165–246

Niitsu K, Kimura Y, Xu X, Kainuma R (2015) Composition dependences of entropy change and transformation temperatures in Ni-rich Ti–Ni system. Shape Mem Superelast 1(2):124–131

Tseng LW, Ma J, Hornbuckle BC, Karaman I, Thompson GB, Luo ZP, Chumlyakov YI (2015) The effect of precipitates on the superelastic response of [100] oriented FeMnAlNi single crystals under compression. Acta Mater 97:234–244

Hao S, Takayama T, Ishida K, Nishizawa T (1984) Miscibility gap in Fe-Ni-Al and Fe-Ni-Al-Co systems. Metall Trans A 15(10):1819–1828

Omori T, Nagasako M, Okano M, Endo K, Kainuma R (2012) Microstructure and martensitic transformation in the Fe-Mn-Al-Ni shape memory alloy with B2-type coherent fine particles. Appl Phys Lett 101(23):231907

La Roca P, Baruj A, Sobrero CE, Malarría JA, Sade M (2017) Nanoprecipitation effects on phase stability of Fe-Mn-Al-Ni alloys. J Alloy Compd 708:422–427

Kainuma R, Gejima F, Sutou Y, Ohnuma I, Ishida K (2000) Ordering, martensitic and ferromagnetic transformations in Ni-Al-Mn Huesler shape memory alloys. Mater Trans JIM 41(8):943–949

Pons J, Chernenko VA, Santamarta R, Cesari E (2000) Crystal structure of martensitic phases in Ni–Mn–Ga shape memory alloys. Acta Mater 48(12):3027–3038

Wollants P, Debonte M, Roos JR (1979) Thermodynamic analysis of the stress-induced martensitic-transformation in a single-crystal. Zeitschrift Fur Metallkunde 70(2):113–117

Tseng LW, Ma J, Wang SJ, Karaman I, Kaya M, Luo ZP, Chumlyakov YI (2015) Superelastic response of a single crystalline FeMnAlNi shape memory alloy under tension and compression. Acta Mater 89:374–383

Kikuchi T, Kajiwara S (1993) Shape-memory effect and related transformation behavior in an unausaged Fe-Ni-Co-Ti alloy. Mater Trans JIM 34(10):907–918

Kajiwara S (1999) Characteristic features of shape memory effect and related transformation behavior in Fe-based alloys. Mater Sci Eng A 273:67–88

Tseng LW, Ma J, Wang SJ, Karaman I, Chumlyakov YI (2016) Effects of crystallographic orientation on the superelastic response of FeMnAlNi single crystals. Scr Mater 116:147–151

Wechsler MS, Lieberman DS, Read TA (1953) On the theory of the formation of martensite. Trans Am Inst Min Metall Eng 197(11):1503–1515

Bowles JS, Mackenzie JK (1954) The crystallography of martensite transformations I. Acta Metall 2(1):129–137

Saburi T, Nenno S (1982) The shape memory effect and related phenomena. In: Aaronson HI, Laughlin DE, Sekerka RE, Wayman CM (eds) International conference on solid-solid phase transformation. AIME, Pittsburgh, pp 1455–1479

Ball JM, James RD (1987) Fine phase mixtures as minimizers of energy. Arch Ration Mech Anal 100(1):13–52

Horikawa H, Ichinose S, Morii K, Miyazaki S, Otsuka K (1988) Orientation dependence of β1 → β1’ stress-induced martensitic transformation in a Cu-AI-Ni alloy. Metall Trans A 19(4):915–923

Miyazaki S, Kimura S, Otsuka K, Suzuki Y (1984) The habit plane and transformation strains associated with the martensitic-transformation in Ti-Ni single-crystals. Scr Metall 18(9):883–888

Omori T, Okano M, Kainuma R (2013) Effect of grain size on superelasticity in Fe-Mn-Al-Ni shape memory alloy wire. APL Mater 1(3):032103

Ojha A, Sehitoglu H (2016) Transformation stress modeling in new Fe-Mn-Al-Ni shape memory alloy. Int J Plast 86:93–111

Tseng LW, Ma J, Vollmer M, Krooß P, Niendorf T, Karaman I (2016) Effect of grain size on the superelastic response of a FeMnAlNi polycrystalline shape memory alloy. Scr Mater 125:68–72

Ono N, Satoh A, Ohta H (1989) A discussion on the mechanical-properties of shape memory alloys based on a polycrystal model. Mater Trans JIM 30(10):756–764

Ono N (1990) Pseudoelastic deformation in a polycrystalline Cu–Zn–Al shape memory alloy. Mater Trans JIM 31(5):381–385

Somerday M, Wert JA, Comstock RJ (1997) Effect of grain size on the observed pseudoelastic behavior of a Cu-Zn-Al shape memory alloy. Metall Mater Trans A 28(11):2335–2341

Shu YC, Bhattacharya K (1998) The influence of texture on the shape-memory effect in polycrystals. Acta Mater 46(15):5457–5473

Šittner P, Novák V (2000) Anisotropy of martensitic transformations in modeling of shape memory alloy polycrystals. Int J Plast 16(10):1243–1268

Sutou Y, Omori T, Yamauchi K, Ono N, Kainuma R, Ishida K (2005) Effect of grain size and texture on pseudoelasticity in Cu-Al-Mn-based shape memory wire. Acta Mater 53(15):4121–4133

Sachs G (1928) On the derivation of a condition of flowing. Zeitschrift Des Vereines Deutscher Ingenieure 72:734–736

Taylor GI (1938) Plastic strain in metals. J Inst. Metals 62:307–324

Omori T, Kusama T, Kawata S, Ohnuma I, Sutou Y, Araki Y, Ishida K, Kainuma R (2013) Abnormal grain growth induced by cyclic heat treatment. Science 341(6153):1500–1502

Kusama T, Omori T, Saito T, Kise S, Tanaka T, Araki Y, Kainuma R (2017) Ultra-large single crystals by abnormal grain growth. Nat Commun 8(1):354

Omori T, Iwaizako H, Kainuma R (2016) Abnormal grain growth induced by cyclic heat treatment in Fe-Mn-Al-Ni superelastic alloy. Mater Des 101:263–269

Ozcan H, Ma J, Wang SJ, Karaman I, Chumlyakov Y, Brown J, Noebe RD (2017) Effects of cyclic heat treatment and aging on superelasticity in oligocrystalline Fe-Mn-Al-Ni shape memory alloy wires. Scr Mater 134:66–70

Vollmer M, Segel C, Krooß P, Günther J, Tseng LW, Karaman I, Weidner A, Biermann H, Niendorf T (2015) On the effect of gamma phase formation on the pseudoelastic performance of polycrystalline Fe–Mn-Al-Ni shape memory alloys. Scr Mater 108:23–26

Ishida K, Kainuma R, Ueno N, Nishizawa T (1991) Ductility Enhancement in Nial (B2)-Base Alloys by Microstructural Control. Metall Trans A 22(2):441–446

Tanaka Y, Ohmori T, Oikawa K, Kainuma R, Ishida K (2004) Ferromagnetic Co-Ni-Al shape memory alloys with beta plus gamma two-phase structure. Mater Trans 45(2):427–430

Tanaka Y, Oikawa K, Sutou Y, Omori T, Kainuma R, Ishida K (2006) Martensitic transition and superelasticity of Co–Ni–Al ferromagnetic shape memory alloys with β + γ two-phase structure. Mater Sci Eng A 438–440:1054–1060

Dogan E, Karaman I, Chumlyakov YI, Luo ZP (2011) Microstructure and martensitic transformation characteristics of CoNiGa high temperature shape memory alloys. Acta Mater 59(3):1168–1183

Vollmer M, Krooss P, Segel C, Weidner A, Paulsen A, Frenzel J, Schaper M, Eggeler G, Maier HJ, Niendorf T (2015) Damage evolution in pseudoelastic polycrystalline Co-Ni-Ga high-temperature shape memory alloys. J Alloy Compd 633:288–295

Vollmer M, Krooss P, Karaman I, Niendorf T (2017) On the effect of titanium on quenching sensitivity and pseudoelastic response in Fe-Mn-Al-Ni-base shape memory alloy. Scr Mater 126:20–23

Vollmer M, Krooss P, Kriegel MJ, Klemm V, Somsen C, Ozcan H, Karaman I, Weidner A, Rafaja D, Biermann H, Niendorf T (2016) Cyclic degradation in bamboo-like Fe-Mn-Al-Ni shape memory alloys - The role of grain orientation. Scr Mater 114:156–160

Ozcan H, Ma J, Karaman I, Chumlyakov YI, Santamarta R, Brown J, Noebe RD (2018) Microstructural design considerations in Fe-Mn-Al-Ni shape memory alloy wires: Effects of natural aging. Scr Mater 142:153–157

Peng HB, Huang P, Zhou TN, Wang SL, Wen YH (2017) Reverse shape memory effect related to alpha → gamma transformation in a Fe-Mn-Al-Ni shape memory alloy. Metall Mater Trans A 48A(5):2132–2139

Mino J, Komanicky V, Durisin M, Saksl K, Kovac J, Varga R (2015) Structural and magnetic characterization of fe-Mn-Al-Ni Pseudo-Heusler alloy. IEEE Trans Magn 51(1):4000903

Van Humbeeck J (2003) Damping capacity of thermoelastic martensite in shape memory alloys. J Alloy Compd 355(1–2):58–64

Khovaylo VV, Golovin IS, Komissarov AA, Lyange MV, Omori T, Kainuma R (2016) Giant internal friction and impact toughness in superelastic FeMnAl(Ni) alloys. In: 5th international conference on ferromagnetic shape memory alloys

Mizui K (2015) Damping properties and microstructural control of Fe-Mn-Al-Ni alloy. Master Thesis, Tohoku University

Acknowledgements

The authors acknowledge the support from JSPS KAKENHI Grant Nos. JP15H05766 and JP26289226. We also thank our many colleagues for stimulating discussion, among whom K. Ando, M. Nagasako, I. Ohnuma, and K. Ishida deserve special mention.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Omori, T., Kainuma, R. Martensitic Transformation and Superelasticity in Fe–Mn–Al-Based Shape Memory Alloys. Shap. Mem. Superelasticity 3, 322–334 (2017). https://doi.org/10.1007/s40830-017-0129-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40830-017-0129-9